S300

S300

Uploaded by

Inkanata SacCopyright:

Available Formats

S300

S300

Uploaded by

Inkanata SacOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

S300

S300

Uploaded by

Inkanata SacCopyright:

Available Formats

Turbocharger S300

27/11/97 12:57 pm

Page 5

S300 TURBOCHARGER

SERVICE INSTRUCTIONS

S300

TURBOCHARGER

Introduction

These Service Instructions cover the

recommended procedures for overhauling

Schwitzer model S300 turbochargers.

These instructions should be used in conjunction

with the latest issue of the "Hundred Series

Turbocharger Service Limits and Torque Values"

Data Sheet.

Always use a Schwitzer Overhaul Kit when

servicing a Schwitzer turbocharger and ensure

that any replacement parts used are the correct

Original Schwitzer parts as specified in the

appropriate Turbocharger Parts List.

Please note that unless specialist dynamic

balancing equipment is available no attempt

should be made to service the cartridge

assembly of the turbocharger.

WORKSHOP EQUIPMENT

To service a Schwitzer S300 turbocharger it

is necessary to have the tools and equipment

listed below.

In addition you will need a clean work area

and the appropriate Schwitzer Overhaul Kit.

Securely mounted vice

Stiff natural or wire brush

Plastic scraper

A source of clean compressed air

Non-flammable solvent

Squirt can of clean engine oil

Internal circlip pliers (0 tip angle.)

Internal circlip pliers (90 tip angle.)

Snap-action torque spanner

Vee block

Vapour blasting equipment

Sand blasting equipment

Dynamic balancing equipment

Shaft stretch measurement equipment

2 x Box end spanner

13mm (1/2 ins) and 14mm ( 9/16 ins)

T-handle wrench

(prevents bending in the shaft during stretch)

14mm (9/16 ins)

Two standard, flat ended, screw drivers.

305mm length (12 ins)

Plastic tipped mallet

500gms (16oz)

2 x Dial indicator, range: 0 - 25mm (0 - 1 ins) and 0 - 2.5mm (0 - 0.1 ins)

12 point socket

17mm (11/16 ins)

Torque wrench

35Nm (0 - 300 lbs/ins)

SCHWITZER

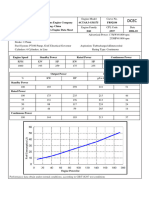

HUNDRED SERIES

TECHNICAL DATA SHEET

Turbocharger S300

27/11/97 12:57 pm

Page 2

S300 TURBOCHARGER

Parts List

1. Compressor cover

2. Compressor locknut

3. Compressor wheel

4. Circlip

5. Insert

6. Insert O ring

7. Piston ring (Compressor)

8.

9.

10.

11.

12.

13.

14.

15.

1

1

Flinger sleeve

Oil deflector

Thrust sleeve

Thrust bearing

Journal bearing circlip

Journal bearing

Bearing housing O ring (optional)

Bearing Housing

Parts listed in red are contained in a full S300 Overhaul Kit

10

11

12

Clamp plate

Screw and washer assembly

Piston ring (Turbine)

Turbine backplate

Shaft and Turbine wheel

Setscrew

Clamp plate

Turbine housing

16

12

1

1

4

2

1

16.

17.

18.

19.

20.

21.

22.

23.

13

12

14

4

8

1

6

3

17

15

13

18

19

21

20

22

23

Fig. 1

DISMANTLING.

IMPORTANT: Disassembly nullifies

Schwitzer warranty responsibility so

it is important to check that the

turbocharger is no longer under

warranty before dismantling.

l.

Mark the relative positions of the turbine

housing and compressor cover to the

bearing housing.

2.

Check the motion of the shaft for excessive

radial or axial play. Refer to the 'Service

Limits and Torque Values' Data Sheet.

3.

Rest the turbocharger on the bench and

unfasten the turbine housing clamp plates.

4.

Lift off the turbine housing.

5.

Repeat 3 for the compressor cover and

carefully lift the cartridge assembly from the

compressor cover.

6.

7.

8.

Remove the nut and slide off the compressor

wheel.

9.

Carefully remove the shaft from the bearing

housing assembly by gently tapping the shaft

with a small soft faced hammer.

10. Remove the turbine backplate and sit the

bearing housing on the turbine backplate.

12. Remove the oil deflector, thrust bearing and

thrust sleeve from the bearing housing.

13. Using circlip pliers, remove the outer circlip

from both ends of the bearing housing.

14. Remove the journal bearings.

Holding the cartridge in one hand release

the compressor locknut.

SCHWITZER

Fig. 3

TAKE CARE NOT TO BEND OR DAMAGE

THE SHAFT.

Clamp the 12 point socket wrench in the

vice and place the hub of the turbine wheel

into the socket so that the shaft is in a vertical

position. (Fig. 2)

NOTE: Left hand thread. Over tightening the nut

may cause yield in the shaft.

11. Remove the insert circlip using the circlip

pliers. Remove the insert assembly using two

levers and remove the flinger sleeve from the

insert. (Fig 3).

NOTE: New bearings should be fitted on reassembly.

Fig. 2

15. Remove inner circlips.

Turbocharger S300

27/11/97 12:57 pm

Page 3

PARTS CLEAN-UP PROCEDURE

Cleaning is generally done by soaking

the components in commercially

available

non-caustic

solvent,

wiping, brushing or scraping any

residue off and then blow drying

with

clean

compressed

air.

However, vapour blasting is a good

alternative if available, providing

the vapour blasting equipment

manufacturers

instructions

are

carefully followed and critical

surfaces are appropriately protected

(see details below).

If parts are to be stored for any length of

time after cleaning then they should

be stored in clean, dry plastic bags

and the surfaces of all potentially

rusting parts should be oiled prior to

storage.

2. Compressor Wheel

4. Compressor cover

a.

Immerse briefly in safety solvent to

remove any traces of oily residue.

a.

b.

Blow dry with compressed air.

Scrape, brush or wipe, as appropriate,

to remove accumulations of residue from

the exterior surfaces.

b.

Immerse briefly in safety solvent to

remove any oily residue.

c.

Blow dry with compressed air.

N.B. If vapour blasting then take care to mask

the bore with corks or rubber stoppers.

3. Shaft and Wheel

a.

b.

Scrape, brush or wipe as appropriate,

to remove accumulations of residue

from the exterior surfaces.

b.

Immerse briefly in safety solvent to

remove any oily residue.

c.

Blow dry with compressed air.

N.B. If vapour blasting is used mask the

bore with corks or rubber stoppers.

Blow dry with compressed air.

N.B. If vapour blasting then take care to

mask the entire shaft section with either

appropriately sized rubber hose or

adhesive backed cloth tape.

c.

1. Bearing Housing

a.

Immerse briefly in safety solvent to

remove any traces of oily residue.

After cleaning mount the shaft and

wheel between centres in a lathe and

lightly polish the journal section of the

shaft at 300 to 600 rpm with 400 grit

abrasive paper and clean oil.

NOTE: If the shaft and wheel shows any

evidence of imbalance (bearing

material smeared on only one side of

the shaft) - do not attempt to reuse.

d.

After polishing re-immerse briefly in safety

solvent and blow dry with compressed air.

N.B.No masking necessary if vapour blasting.

5. Turbine Housing and Backplate

a.

Blast with coarse sand or steel grit to obtain

total interior and exterior cleanliness.

b.

Immerse briefly in safety solvent to

remove residues.

c.

Blow dry with compressed air.

6. V Clamps

a.

Immerse in safety solvent agitating

moderately until foreign material deposits

have been softened or dissolved.

b.

Blow dry with compressed air.

7. Small Internal Parts

a.

Immerse briefly in clean safety solvent to

remove oily residues.

b.

Wipe dry with a clean cloth.

e.

Dynamically balance the shaft and wheel

assembly, referring to the Service Limits

Tables. Do not attempt to straighten a

bent shaft.

INSPECTION OF PARTS FOR RE-USE

It is recommended that all visual and

dimensional checking of parts for re-use

be done after parts have been cleaned

as described above. Critical dimensions

mentioned below are given in the latest

issue of the Hundred Series Service

Limits and Torque Values' Data Sheet.

3. Shaft and Wheel

a.

1. Bearing Housing

a.

b.

c.

Inspect visually for evidence of cracks

and fractures, pitting of gasket and other

machined surfaces, or distortion of the

turbine end flange. Reject and replace

if any of the above conditions are

severe.

Closely inspect the bearing bore visually

for signs of damage or wear. The

condition of the removed bearings will

be a good indicator of the bore

condition. Refer to Service Limits Tables

for maximum bore diameters. Reject and

replace if bore condition is substandard.

b.

c.

Inspect visually for evidence of bent,

burred, nicked or eroded blades and for

evidence of scuffing on the back face.

Very minor damage is acceptable but

reject and replace if the damage

appears sufficient to affect wheel

balance. Do not attempt to straighten

bent blades.

Inspect hub visually for evidence of

smearing (as with high speed contact

with the bearing house bore) and for

deterioration of the original rectangular

configuration of the piston ring groove.

Reject and replace if the damage or

wear is excessive.

Inspect journal diameter for wear. If this

appears reusable the diameter should

be checked with a micrometer referring

to the Service Limits Tables.

Fig. 4

Examine the turbine end seal bore for

damage and replace bearing housing if

wear is excessive.

Inspect visually for evidence of contour damage

(as from high speed wheel contact). Reject

and replace if damage is excessive. It is

permissible to polish out minor surface

damage in the contour.

5. Turbine Housing and Backplate

Inspect visually for evidence of contour damage

(as from high speed wheel contact) and for

evidence of overtemperature damage such

as cracking, pitting, distortion or erosion.

Reject and replace if damage is excessive.

6. Insert

Inspect the insert bore for evidence of surface

damage. If there is evidence of contact

with rotating components or if the piston

ring wear has created a ridge the insert

should be rejected and replaced.

7. Flinger Sleeve

N.B. Do not mistake the machined step and

relief groove for a wear ridge.

Inspect visually for evidence of surface damage

from contact with stationary parts. If piston

ring wear has caused the ring groove to

deteriorate from its original rectangular

configuration reject and replace the flinger

sleeve.

2. Compressor Wheel

Inspect visually for evidence of bent,

burred, nicked or eroded blades and

for evidence of scuffing on the back

face.

Dynamically balance the

Compressor wheel and reject and

replace if any damage has affected

wheel balance. Do not attempt to

straighten bent blades.

4. Compressor Cover

d.

Measure eccentricity between the large

and small shaft diameters with a test dial

indicator and vee-block, referring to

Service Limits Tables. (Fig. 4).

8. V Clamps

Inspect visually for evidence of cracks or

distortion of the clamp and T-bolt threads.

Reject and replace if damage is excessive.

SCHWITZER

Turbocharger S300

27/11/97 12:57 pm

Page 4

S300 ASSEMBLY.

When reassembling the turbocharger a

Schwitzer Overhaul Kit should always be

used (see Parts List on the S300

Exploded View).

l.

Re-use only parts complying with the

"Inspection of Parts for re-use"

guidelines.

2.

Ensure all parts to be re-used have been

thoroughly cleaned as described in the

"Parts Clean-Up Procedure".

3.

Fit inner circlips to the bearing housing

with the chamfered edge towards the

bearing (Fig. 5).

4.

Lubricate the new journal bearings with

clean oil and fit into the bearing housing,

using the outer circlips with the chamfered

edge towards the bearing. (Fig. 5)

8.

Place the assembly into the turbine

housing with the shaft vertically up.

14. Fit the compressor wheel and new

locknut.

9.

Lubricate the new thrust bearing surfaces

and fit the new thrust sleeve.

15. Using the appropriate equipment tighten

the locknut in accordance with the

Fastener 'Torque Values' Table.

10. Fit the thrust bearing assembly into the

bearing housing engaging on the

locating pin, then fit the oil deflector with

the oil deflector tongue fitting into the

cutaway section of the thrust bearing

(Fig. 7).

16.

For turbochargers which have a

compressor end 'O' ring, (see

turbocharger Parts List to check), fit this to

the compressor end of the bearing housing

and lubricate with clean engine oil.

17. Place the bearing housing into the

compressor cover and fix the clamp plates,

using the set screw and washer assemblies

(Fig. 9).

Fig. 7

Fig. 9

Fig. 5

11. Fit the new 'O' ring onto the insert and

a new piston ring into the flinger sleeve.

12. Fit the flinger sleeve assembly into the

insert. TAKE CARE NOT TO DAMAGE

THE PISTON RING.

5.

Fit the new piston ring into the second

groove in the hub of the shaft.

6.

Place the bearing housing on the bench

turbine end uppermost and fit the

backplate.

7.

Lubricate both shaft and piston ring with

clean oil and fit the shaft and wheel

assembly into bearing housing (Fig. 6).

TAKE CARE NOT TO DAMAGE THE

PISTON RING.

13. Lubricate the insert 'O' ring and press the

insert into the bearing housing. Fit the circlip

with the gap at 90 degrees to the cutaway

section in the thrust bearing (Fig. 8).

ENSURE

THE

BEVELLED

EDGE

IS

UPPERMOST AND THE INSERT IS

PRESSED HOME FLAT.

Fig. 8

Fig. 6

Ensure circlip gap is

positioned at 90o to the

oil deflector tongue.

18. Orientate the turbine housing and

compressor cover to the desired position

and fit the clamp plates. Fasten in

accordance with the values given in the

'Fastener Torque' table.

Whilst every care has been taken to provide

accurate information in this Data Sheet

Schwitzer cannot accept any liability for any

inaccuracies. All rights reserved.

If you have any questions regarding service of Schwitzer turbochargers please contact your nearest Schwitzer location.

Schwitzer (Europe) Limited

Euroway Industrial Estate

Bradford

West Yorkshire BD4 6SE

ENGLAND

Schwitzer U.S. Inc.,

6040 West 62nd Street

Indianapolis

Indiana 46278

U.S.A.

Lacom-Schwitzer Equipamentos Ltda.

Estrada da Rhodia Km 15

CEP 13082 - Campinas

Sao Paulo

BRAZIL

Tel: + 44 (0)1274 684915

Fax: + 44 (0)1274 689671

Tel: +1 (317) 328 3100

Fax: +1 (317) 328 3292

Tel: +55 (0192) 574811

Fax: +55 (0192) 574989

Telex: 191238 Lacom Br

ISSUE SI S300 1/96 - E

You might also like

- Denso Common Rail Injector Test DataDocument28 pagesDenso Common Rail Injector Test DataInkanata Sac94% (18)

- ZF 4600 Family Operating InstructionsDocument10 pagesZF 4600 Family Operating Instructionsalan100% (60)

- Suzuki Satria 120Document19 pagesSuzuki Satria 120herrysugar50% (2)

- QuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualDocument21 pagesQuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service Manualshashiraj50% (2)

- 6BTA (330,2800,1975, HO, Nov 00, M-90208)Document2 pages6BTA (330,2800,1975, HO, Nov 00, M-90208)Erick Jonathan Nuñez BugueñoNo ratings yet

- Catalog GarrettDocument169 pagesCatalog GarrettGustavo Rozen100% (2)

- Pge and Pgev Locomotive Governor Installation: Product Manual 54053 (Revision C)Document14 pagesPge and Pgev Locomotive Governor Installation: Product Manual 54053 (Revision C)Ahmad RagabNo ratings yet

- WP320L WP460LDocument59 pagesWP320L WP460Ljohn smithNo ratings yet

- Katalog 920 PDFDocument707 pagesKatalog 920 PDFbubulelaman100% (4)

- Powerunit Serie 50-60 6SE510Document102 pagesPowerunit Serie 50-60 6SE510Antony MorenoNo ratings yet

- TF-450 Power EndDocument2 pagesTF-450 Power EndppglNo ratings yet

- Chapter 3-Section 3.2-Cylinder BlockDocument46 pagesChapter 3-Section 3.2-Cylinder BlockNikkikumar MaisuriyaNo ratings yet

- Product Improvement Program For Removing Certain 7n-2405 Connecting Rod Bolts For 3500 and g3500 Engines From Dealer Parts StockDocument3 pagesProduct Improvement Program For Removing Certain 7n-2405 Connecting Rod Bolts For 3500 and g3500 Engines From Dealer Parts StockJorge Muñoz SilvaNo ratings yet

- Manual Serviço Volvo D49 A MTDocument216 pagesManual Serviço Volvo D49 A MTLucas Marques100% (1)

- Application Requirments For OFS TransmissionDocument13 pagesApplication Requirments For OFS TransmissionSonthi MooljindaNo ratings yet

- Bomba Inyeccion c4.4 RetroDocument4 pagesBomba Inyeccion c4.4 RetroAstrid RosasNo ratings yet

- Rebuilding The Cat 3208 Diesel PDFDocument12 pagesRebuilding The Cat 3208 Diesel PDFlymeng porNo ratings yet

- Inspection Procedures and Specifications For Pistons and Piston PinsDocument130 pagesInspection Procedures and Specifications For Pistons and Piston Pinsma.powersource100% (1)

- Heavyduty Kits Catalog 2017Document8 pagesHeavyduty Kits Catalog 2017panamapuro100% (1)

- 2000 Series 60 MasterDocument238 pages2000 Series 60 MasterFRANCO MAYANGANo ratings yet

- Caterpillar Engine Service Manual CT S Eng 3208Document9 pagesCaterpillar Engine Service Manual CT S Eng 3208Kyaw SoeNo ratings yet

- Mah Le ChartDocument6 pagesMah Le ChartFranklin CaizaNo ratings yet

- CAT 3208 Dieselengine Parts Manual Album Modeltrucks25 Completo 182 PaginasDocument178 pagesCAT 3208 Dieselengine Parts Manual Album Modeltrucks25 Completo 182 PaginasLuis Manuel100% (1)

- Jinma Tractor Fluid - Filter RecommendationsDocument3 pagesJinma Tractor Fluid - Filter RecommendationsChere ChannelNo ratings yet

- rqvwuxfwlrq, Qgxvwuldo Dqg3HwurohxppowerDocument19 pagesrqvwuxfwlrq, Qgxvwuldo Dqg3Hwurohxppower李春杰No ratings yet

- DDC SVC Bro 0002Document35 pagesDDC SVC Bro 0002SonthiMNo ratings yet

- Data Sheet-Cummins 6CTA8.3-GM175 Marine Generators EngineDocument4 pagesData Sheet-Cummins 6CTA8.3-GM175 Marine Generators EngineabdullahaljafarieNo ratings yet

- Turbocharger: Presented byDocument26 pagesTurbocharger: Presented byYasewn KALAWANTNo ratings yet

- Using Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Document20 pagesUsing Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Chrisdian FaraniNo ratings yet

- Application of Magneto Ignition (32-42)Document11 pagesApplication of Magneto Ignition (32-42)sureshkanna2100% (1)

- 12V Cummins Torque Specs PDFDocument8 pages12V Cummins Torque Specs PDF180976No ratings yet

- Catalog Journal BearingsDocument72 pagesCatalog Journal BearingsWaleed EzzatNo ratings yet

- Bezares PTO Application Catalog PDFDocument457 pagesBezares PTO Application Catalog PDFfiat127sportNo ratings yet

- Cam Timing DDEC S50Document4 pagesCam Timing DDEC S50Hamilton mirandaNo ratings yet

- QuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualDocument20 pagesQuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualArief FadillaNo ratings yet

- Catalogo SiouxDocument13 pagesCatalogo Siouxdef2009100% (1)

- Supercharging and TurbochargingDocument8 pagesSupercharging and TurbochargingMudassir Hussain100% (1)

- Cramkshaft Main Bearimg InstallDocument5 pagesCramkshaft Main Bearimg InstallNimNo ratings yet

- ABB Turbocharging VTC PDFDocument8 pagesABB Turbocharging VTC PDFhanifNo ratings yet

- MR 14002-Extended Light Load Specific TurbochargerDocument16 pagesMR 14002-Extended Light Load Specific TurbochargerVictor Noschang100% (1)

- Psitons IzumiDocument5 pagesPsitons Izumiabdullah kozanNo ratings yet

- Cat 3406C 380HP D RatingDocument4 pagesCat 3406C 380HP D RatingDian Aprilia II100% (1)

- Sebf 8269 Привод 3408Document16 pagesSebf 8269 Привод 3408mohamed hamedNo ratings yet

- 3SA438 DDC Series 60 Specification - Coach SpecDocument2 pages3SA438 DDC Series 60 Specification - Coach SpecMOHD NAJMAN BIN MUDA100% (1)

- DATA BOOSTER 3412C Marine Engine High Performance 3JK00146-UP (SEBP2969 - 54) - Sistemas y ComponentesDocument8 pagesDATA BOOSTER 3412C Marine Engine High Performance 3JK00146-UP (SEBP2969 - 54) - Sistemas y ComponentesmanuelNo ratings yet

- Install Oil PumpDocument4 pagesInstall Oil PumpbagoesNo ratings yet

- Tractor Parts and Attachments - Front Wheel Bearing and Spindles PDFDocument4 pagesTractor Parts and Attachments - Front Wheel Bearing and Spindles PDFgovindkaniNo ratings yet

- Re - 8n Manual - Part Three, Chapter III, Engine and ClutchDocument10 pagesRe - 8n Manual - Part Three, Chapter III, Engine and ClutchsouthaustinroadkingNo ratings yet

- Otc Detroit Diesel Flyer 5 PDFDocument2 pagesOtc Detroit Diesel Flyer 5 PDFIsmael TrejoNo ratings yet

- Engine Valve Lash - Inspect AdjustDocument3 pagesEngine Valve Lash - Inspect AdjustRay CapriNo ratings yet

- 001-016 Crankshaft: Preparatory StepsDocument28 pages001-016 Crankshaft: Preparatory StepsWaad HarbNo ratings yet

- NPR (Nippon Piston Ring) Piston RingsDocument11 pagesNPR (Nippon Piston Ring) Piston RingsjoralbbargarNo ratings yet

- Catálogo de Productos MurphyDocument28 pagesCatálogo de Productos MurphyRené GPNo ratings yet

- Media Search - SENR2824 - 3304 & 3306 VEHICULAR ENGINE PDFDocument7 pagesMedia Search - SENR2824 - 3304 & 3306 VEHICULAR ENGINE PDFMichael DavenportNo ratings yet

- 15LD 440 K4B6610 T BombaDocument32 pages15LD 440 K4B6610 T BombaJean MartesNo ratings yet

- Caterpillar Cat 236B SKID STEER LOADER (Prefix HEN) Service Repair Manual (HEN06750 and Up)Document24 pagesCaterpillar Cat 236B SKID STEER LOADER (Prefix HEN) Service Repair Manual (HEN06750 and Up)rpoy9396615No ratings yet

- Understanding Model Name of Turbo Garret G Series - WWW - Magyarturbo.huDocument12 pagesUnderstanding Model Name of Turbo Garret G Series - WWW - Magyarturbo.huAnprtmk072100% (1)

- Spec Sheets - Cat 3054 GensetDocument8 pagesSpec Sheets - Cat 3054 Gensetjuan_34fierro0% (1)

- Instruction Book: TWD610G/P, TWD710G/P TAD730G/PDocument32 pagesInstruction Book: TWD610G/P, TWD710G/P TAD730G/PSigit WahyudiNo ratings yet

- Caterpillar C15 ACERT Tier 4Document4 pagesCaterpillar C15 ACERT Tier 4Alfred Hernandez MendozaNo ratings yet

- Engine Performance Data at 1500 RPM: Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: Cummins IncMd ShNo ratings yet

- Service Repair Manual: TurbochargersDocument31 pagesService Repair Manual: TurbochargersCoC Dummy100% (1)

- R1A4016R B12A1H1A A: Q Series PumpsDocument40 pagesR1A4016R B12A1H1A A: Q Series Pumpseaglego00No ratings yet

- Ford Tractor Conversions: The Story of County, DOE, Chaseside, Northrop, Muir-Hill, Matbro & BrayFrom EverandFord Tractor Conversions: The Story of County, DOE, Chaseside, Northrop, Muir-Hill, Matbro & BrayNo ratings yet

- School Bus ClassificationsDocument6 pagesSchool Bus ClassificationsInkanata SacNo ratings yet

- Perkins 1103 Valve InstallDocument10 pagesPerkins 1103 Valve InstallInkanata SacNo ratings yet

- 2000W Metal Halide Ballast Data SheetDocument1 page2000W Metal Halide Ballast Data SheetInkanata SacNo ratings yet

- SPM 4210 Wetkret Concrete Spraying Machine SpecificationsDocument6 pagesSPM 4210 Wetkret Concrete Spraying Machine SpecificationsInkanata SacNo ratings yet

- HYW-35 T5: Generating RatesDocument6 pagesHYW-35 T5: Generating RatesInkanata SacNo ratings yet

- Baldwin Filters Product CatalogDocument1,307 pagesBaldwin Filters Product CatalogInkanata Sac100% (1)

- Mitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4S-Z3DT65SPDocument1 pageMitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4S-Z3DT65SPInkanata SacNo ratings yet

- FIG 101 Cylinder Head: Year / MonthDocument24 pagesFIG 101 Cylinder Head: Year / MonthInkanata Sac100% (1)

- Winnovative PDF Tools Demo: Global Stage Literacy Book 1Document4 pagesWinnovative PDF Tools Demo: Global Stage Literacy Book 1Inkanata SacNo ratings yet

- Underground ProductsDocument6 pagesUnderground ProductsInkanata SacNo ratings yet

- BOSCHDocument3 pagesBOSCHDiego Pacheco VelaNo ratings yet

- HX80 PDFDocument2 pagesHX80 PDFInkanata SacNo ratings yet

- ITM Drilling Machines WebDocument6 pagesITM Drilling Machines WebInkanata SacNo ratings yet

- The Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramDocument1 pageThe Tolerance Unless Classified 0.3mm: Outline Dimension & Block DiagramInkanata SacNo ratings yet

- Rev. Change Details by DateDocument1 pageRev. Change Details by DateInkanata SacNo ratings yet

- Valve Assembly, Main Relief (lp22v00001f1 & Lp22v00001f2)Document2 pagesValve Assembly, Main Relief (lp22v00001f1 & Lp22v00001f2)Inkanata SacNo ratings yet

- QNTC Dellsvr01 Inetpub - D PartsLiterature F 720 033 Rev. B Metal Face SealsDocument2 pagesQNTC Dellsvr01 Inetpub - D PartsLiterature F 720 033 Rev. B Metal Face SealsInkanata Sac100% (1)

- TEMA/ Theme: Likes and Dislikes PrimaryDocument3 pagesTEMA/ Theme: Likes and Dislikes PrimaryInkanata SacNo ratings yet

- 5800 2 Ecomax t4 93kw Ipu LRDocument4 pages5800 2 Ecomax t4 93kw Ipu LRInkanata SacNo ratings yet

- E5924 ws08w01Document2 pagesE5924 ws08w01Inkanata SacNo ratings yet

- Winkie Parts 1Document9 pagesWinkie Parts 1Inkanata SacNo ratings yet

- Shaft SinkingDocument10 pagesShaft SinkingAnonymous 340A7vnwV1No ratings yet

- Road ShineDocument28 pagesRoad ShineindosiataNo ratings yet

- Gear IntroductionDocument17 pagesGear Introductionpatel ketan100% (1)

- 1998 Sec 7-Manual TransmissionDocument25 pages1998 Sec 7-Manual TransmissionLuis TomboNo ratings yet

- Conectores de Sensores y Actuadores de Spark 2008 1.0Document13 pagesConectores de Sensores y Actuadores de Spark 2008 1.0Victor SanchezNo ratings yet

- Popular WoodWorkingDocument224 pagesPopular WoodWorkingAnonymous 6lgg4xOYG100% (8)

- 1.1 Transmission:: Design and Fabrication of A Two-Wheel Drive in A BikeDocument37 pages1.1 Transmission:: Design and Fabrication of A Two-Wheel Drive in A BikeKARUNKO Covid ProductsNo ratings yet

- Suspension DelanteraDocument22 pagesSuspension DelanteraJavier DíazNo ratings yet

- Dy23 2, Dy27 2, Ep5754aDocument30 pagesDy23 2, Dy27 2, Ep5754anijosoNo ratings yet

- FLOWCHARTDocument2 pagesFLOWCHARTFareed MindalanoNo ratings yet

- Mike Holt's Illustrated Guide Onal Electrical Code, 2020 NEC 355Document1 pageMike Holt's Illustrated Guide Onal Electrical Code, 2020 NEC 355Tito BustamanteNo ratings yet

- Theory of Machine LabDocument2 pagesTheory of Machine LabJaishree ChauhanNo ratings yet

- Hope Headsets 2011Document5 pagesHope Headsets 2011Krakovchi LorandNo ratings yet

- Assembling and Testing Manual TransmissionDocument65 pagesAssembling and Testing Manual TransmissionNaive EilevorNo ratings yet

- Q-Io 2201aaa Santiago Ceballos PotenciaDocument2 pagesQ-Io 2201aaa Santiago Ceballos PotenciayaguaramayNo ratings yet

- Superbolt Dimension-List Torque-Guidelines MT UncDocument1 pageSuperbolt Dimension-List Torque-Guidelines MT UncaputraNo ratings yet

- Mechatronics and The Motor Car: Kon-41.5151 Seminar Jan Akmal, Prabilson & Param JollyDocument24 pagesMechatronics and The Motor Car: Kon-41.5151 Seminar Jan Akmal, Prabilson & Param JollyTeo T. ConstantinNo ratings yet

- Act1 S004 1Document1 pageAct1 S004 1Joe MattieNo ratings yet

- STPL110 PDFDocument66 pagesSTPL110 PDFStefanoNo ratings yet

- Compression: InspectionDocument2 pagesCompression: InspectionMoh DeBrNo ratings yet

- GTC 200 Mazda RX 8 New InstallDocument2 pagesGTC 200 Mazda RX 8 New InstallwebNo ratings yet

- Model-16 TX 2440 TO - 1370.002.019Document78 pagesModel-16 TX 2440 TO - 1370.002.019Cute little mochiNo ratings yet

- BCS 948 Parts CatalogDocument13 pagesBCS 948 Parts CatalogPaweł SorokaNo ratings yet

- Tow Master PDF BrohureDocument84 pagesTow Master PDF BrohureClarence SiebertNo ratings yet

- Gear Box ReportDocument39 pagesGear Box ReportNisar HussainNo ratings yet