IR Transmitter: Ir Led

IR Transmitter: Ir Led

Uploaded by

Pragna ThatipelliCopyright:

Available Formats

IR Transmitter: Ir Led

IR Transmitter: Ir Led

Uploaded by

Pragna ThatipelliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

IR Transmitter: Ir Led

IR Transmitter: Ir Led

Uploaded by

Pragna ThatipelliCopyright:

Available Formats

IR transmitter: IR LED:

Here the IR transmitter is nothing but the IR LED. It just looks like a normal LED but transmits the IR signals. Since the IR rays are out of the visible range we cannot observe the rays from the transmitter.

These are infrared LEDs; the light output is not visible by our eyes. They can be used as replacement LEDs for remote controls, night vision for camcorders, invisible beam sensors, etc.

Fig 30: IR LED Advantages:

Infrared LEDs are ideal light sources for use with night vision goggles, surveillance cameras, medical imaging, recognition and calibration systems.

Due to their resistance to ambient-light impediments and electromagnetic interference (EMI), Infrared LEDs enhance the performance of wireless computer-to-PDA links, collision avoidance systems, automation

equipment, equipment.

biomedical

instrumentation,

and

telecommunications

Solid-state design renders Infrared LEDs impervious to electrical and mechanical shock, vibration, frequent switching and environmental extremes. With an average life span of 100,000-plus hours (11 years), Infrared LEDs operate reliably year-after-year.

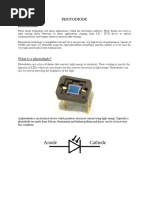

Photo diode: A photodiode is a type of photodetector capable of converting light into either current or voltage, depending upon the mode of operation. Photodiodes are similar to regular semiconductor diodes except that they may be either exposed (to detect vacuum UV or X-rays) or packaged with a window or optical fibre connection to allow light to reach the sensitive part of the device. Many diodes designed for use specifically as a photodiode will also use a PIN junction rather than the typical PN junction. Principle of operation A photodiode is a PN junction or PIN structure. When a photon of sufficient energy strikes the diode, it excites an electron thereby creating a mobile electron and a positively charged electron hole. If the absorption occurs in the junction's depletion region, or one diffusion length away from it, these carriers are swept from the junction by the built-in field of the depletion region. Thus holes move toward the anode, and electrons toward the cathode, and a photocurrent is produced. Photovoltaic mode When used in zero bias or photovoltaic mode, the flow of photocurrent out of the device is restricted and a voltage builds up. The diode becomes forward biased and "dark

current" begins to flow across the junction in the direction opposite to the photocurrent. This mode is responsible for the photovoltaic effect, which is the basis for solar cellsin fact, a solar cell is just an array of large photodiodes. Photoconductive mode In this mode the diode is often (but not always) reverse biased. This increases the width of the depletion layer, which decreases the junction's capacitance resulting in faster response times. The reverse bias induces only a small amount of current (known as saturation or back current) along its direction while the photocurrent remains virtually the same. Although this mode is faster, the photovoltaic mode tends to exhibit less electronic noise. (The leakage current of a good PIN diode is so low < 1nA that the JohnsonNyquist noise of the load resistance in a typical circuit often dominates.) Other modes of operation Avalanche photodiodes have a similar structure to regular photodiodes, but they are operated with much higher reverse bias. This allows each photo-generated carrier to be multiplied by avalanche breakdown, resulting in internal gain within the photodiode, which increases the effective responsivity of the device. Phototransistors also consist of a photodiode with internal gain. A phototransistor is in essence nothing more than a bipolar transistor that is encased in a transparent case so that light can reach the base-collector junction. The electrons that are generated by photons in the base-collector junction are injected into the base, and this current is amplified by the transistor operation. Note that although phototransistors have a higher responsivity for light they are unable to detect low levels of light any better than photodiodes. Phototransistors also have slower response times.

Materials The material used to make a photodiode is critical to defining its properties, because only photons with sufficient energy to excite electrons across the material's bandgap will produce significant photocurrents. Materials commonly used to produce photodiodes include:

Material Silicon Germanium Indium gallium arsenide Lead sulfide

Wavelength range (nm) 1901100 4001700 8002600 <1000-3500

Because of their greater bandgap, silicon-based photodiodes generate less noise than germanium-based photodiodes, but germanium photodiodes must be used for wavelengths longer than approximately 1 m. Since transistors and ICs are made of semiconductors, and contain P-N junctions, almost every active component is potentially a photodiode. Many components, especially those sensitive to small currents, will not work correctly if illuminated, due to the induced photocurrents. In most components this is not desired, so they are placed in an opaque housing. Since housings are not completely opaque to X-rays or other high energy radiation, these can still cause many ICs to malfunction due to induced photo-currents. Features Critical performance parameters of a photodiode include: Responsivity:

The ratio of generated photocurrent to incident light power, typically expressed in A/W when used in photoconductive mode. The responsivity may also be expressed as a quantum efficiency, or the ratio of the number of photogenerated carriers to incident photons and thus a unitless quantity. Dark current: The current through the photodiode in the absence of light, when it is operated in photoconductive mode. The dark current includes photocurrent generated by background radiation and the saturation current of the semiconductor junction. Dark current must be accounted for by calibration if a photodiode is used to make an accurate optical power measurement, and it is also a source of noise when a photodiode is used in an optical communication system. Noise-equivalent power: (NEP) The minimum input optical power to generate photocurrent, equal to the rms noise current in a 1 hertz bandwidth. The related characteristic detectivity (D) is the inverse of NEP, 1/NEP; and the specific detectivity () is the detectivity normalized to the area (A) of the photodetector,. The NEP is roughly the minimum detectable input power of a photodiode. When a photodiode is used in an optical communication system, these parameters contribute to the sensitivity of the optical receiver, which is the minimum input power required for the receiver to achieve a specified bit error ratio.

Applications

Photodiode schematic symbol. P-N photodiodes are used in similar applications to other photodetectors, such as photoconductors, charge-coupled devices, and photomultiplier tubes.

Fig 31: Photo Diode Photodiodes are used in consumer electronics devices such as compact disc players, smoke detectors, and the receivers for remote controls in VCRs and televisions. In other consumer items such as camera light meters, clock radios (the ones that dim the display when it's dark) and street lights, photoconductors are often used rather than photodiodes, although in principle either could be used. Photodiodes are often used for accurate measurement of light intensity in science and industry. They generally have a better, more linear response than photoconductors. They are also widely used in various medical applications, such as detectors for computed tomography (coupled with scintillators) or instruments to analyze samples (immunoassay). They are also used in blood gas monitors. PIN diodes are much faster and more sensitive than ordinary p-n junction diodes, and hence are often used for optical communications and in lighting regulation. P-N photodiodes are not used to measure extremely low light intensities. Instead, if high sensitivity is needed, avalanche photodiodes, intensified charge-coupled devices or photomultiplier tubes are used for applications such as astronomy , spectroscopy, night vision equipment and laser range finding.

IR LED

DESCRIPTION: The QED233 / QED234 is a 940 nm GaAs/AlGaAs LED encapsulated in a clear untinted, plastic T-1 3/4 package.

FEATURES: Lambda= 940 nm Chip material =GaAs with AlGaAs window Package type: T-1 3/4 (5mm lens diameter) Matched Photo sensor: QSD122/123/124 Medium Emission Angle, 40 High Output Power Package material and color: Clear, untinted, plastic Ideal for remote control applications

LIGHT EMITING DIODES

It is a semiconductor diode having radioactive recombination. It requires a definite amount of energy to generate an electron-hole pair. The same energy is released when an electron recombines with a hole. This released energy may result in the emission of photon and such a recombination. Hear the amount of energy released when the electro reverts from the conduction band to the valence band appears in the form of radiation. Alternatively the released energy may result in a series of phonons causing lattice vibration. Finally the released energy may be transferred to another electron. The recombination radiation may be lie in the infra-red and visible light spectrum. In forward is peaked around the band gap energy and the phenomenon is called injection luminescence. I n a junction biased in the avalanche break down region , there results a spectrum of photons carrying much higher energies . Almost White light then gets emitted from micro-plasma breakdown region in silicon junction. Diodes having radioactive recombination are termed as Light Emitting Diode, abbreviated as LEDs.

In gallium arsenide diode, recombination is predominantly a radiation recombination and the probability of this radio active recombination far exceeds that in either germanium or silicon . Hence Ga As LED has much higher efficiency in terms of Photons emitted per carrier. The internal efficiency of Ga As LED may be very close to 100% but because of high index of refraction, only a small fraction of the internal

radiation can usually come out of the device surface. In spite of this low efficiency of actually radiated light , these LEDs are efficiency used as light emitters in visual display units and in optically coupled circuits, The efficiency of light generation increases with the increase of injected current and with decreases in temperature. The light so generated is concentrated near the junction since most of the charge carriers are obtained within one diffusion length of the diode junction.

The following are the merits of LEDs over conventional incandescent and other types of lamps

1. Low working voltages and currents 2. Less power consumption 3. Very fast action 4. Emission of monochromatic light 5. small size and weight 6. No effect of mechanical vibrations 7. Extremely long life Typical LED uses a forward voltage of about 2V and current of 5 to 10mA. GaAs LED produces infra-red light while red, green and orange lights are produced by gallium arsenide phosphide (GaAs) and gallium phosphide(Gap) . Light Emitting Diodes (LEDs)

Example: Function

Circuit symbol:

LEDs emit light when an electric current passes through them.

Connecting and soldering LEDs must be connected the correct way round, the diagram may be labelled a or + for anode and k or - for cathode (yes, it really is k, not c, for cathode!). The cathode is the short lead and there may be a slight flat on the body of round LEDs. If you can see inside the LED the cathode is the larger electrode (but this is not official identification method). an

LEDs can be damaged by heat when soldering, but the risk is small unless you are very slow. No special precautions are needed for soldering most LEDs.

Testing an LED Never connect an LED directly to a battery or power supply! It will be destroyed almost instantly because too much current will pass through and burn it out. LEDs must have a resistor in series to limit the current to a safe value, for quick testing purposes a 1k resistor is suitable for most LEDs if your supply voltage is 12V or less. Remember to connect the LED the correct way round! Colors of LEDs

LEDs are available in red, orange, amber, yellow, green, blue and white. Blue and white LEDs are much more expensive than the other colours. The colour of an LED is determined by the semiconductor material, not by the colouring of the 'package' (the plastic body). LEDs of all colours are available in uncoloured packages which may be diffused (milky) or clear (often described

as 'water clear'). The coloured packages are also available as diffused (the standard(type)ortransparent.

Tri-colour LEDs The most popular type of tri-colour LED has a red and a green LED combined in one package with three leads. They are called tri-colour because mixed red and green light appears to be yellow and this is produced when both the red and green LEDs are on. The diagram shows the construction of a tri-colour LED. Note the different lengths of the three leads. The centre lead (k) is the common cathode for both LEDs, the outer leads (a1 and a2) are the anodes to the LEDs allowing each one to be lit separately, or both together to give the third colour.

Bi-color LEDs A bi- colour LED has two LEDs wired in 'inverse parallel' (one forwards, one backwards) combined in one package with two leads. Only one of the LEDs can be lit at one time and they are less useful than the tri-colour LEDs described above. Sizes, Shapes and Viewing angles of LEDs LEDs are available in a wide variety of sizes and shapes. The 'standard' LED has a round cross-section of 5mm diameter and this is probably the best type for general use, but 3mm round LEDs are also popular. Round cross-section LEDs are frequently used and they are very easy to install on boxes by drilling a hole of the LED diameter, adding a spot of glue will help to hold the LED if necessary. LED clips are also available to secure LEDs in holes. Other crosssection shapes include square, rectangular and triangular.

As well as a variety of colors, sizes and shapes, LEDs also vary in their viewing angle. This tells you how much the beam of light spreads out. Standard LEDs have a viewing angle of 60 but others have a narrow beam of 30 or less. Rapid Electronics stock a wide selection of LEDs and their catalogue is a good guide to the range available.

Calculating an LED resistor value An LED must have a resistor connected in series to limit the current through the LED, otherwise it will burn out almost instantly.

The resistor value, R is given by R = (VS - VL) / I VS = supply voltage VL = LED voltage (usually 2V, but 4V for blue and white LEDs) I = LED current (e.g. 20mA), this must be less than the maximum permitted If the calculated value is not available choose the nearest standard resistor value which is greater, so that the current will be a little less than you chose. In fact you may wish to choose a greater resistor value to reduce the current (to increase battery life for example) but this will make the LED less bright. Working out the LED resistor formula using Ohm's law

Ohm's law says that the resistance of the resistor, R = V/I,

where: V = voltage across the resistor (= VS - VL in this case) I = the current through the resistor So R = (VS - VL) / I Connecting LEDs in series If you wish to have several LEDs on at the same time it may be possible to connect them in series. This prolongs battery life by lighting several LEDs with the same current as just one LED. All the LEDs connected in series pass the same current so it is best if they are all the same type. The power supply must have sufficient voltage to provide about 2V for each LED (4V for blue and white) plus at least another 2V for the resistor. To work out a value for the resistor you must add up all the LED voltages and use this for VL. Avoid connecting LEDs in parallel Connecting several LEDs in parallel with just one resistor shared between them is generally not a good idea. If the LEDs require slightly different voltages only the lowest voltage LED will light and it may be destroyed by the larger current flowing through it. Although identical LEDs can be successfully connected in parallel with one resistor this rarely offers any useful benefit because resistors are very cheap and the current used is the same as connecting the LEDs individually.

CIRCUIT DESCRIPTION: Main aim of our project is to control the room light based on visitors, by this we can save the power by controlling the devices status i.e., on or off depending upon number of visitors. We provide IR transmitter and the receivers to count the number of visitors; this transmitter and the receivers are places at both sides of the path, one transmitter, and receiver at the entering path and other at the exiting path. When the visitor enters, IR transmitter signal to the receiver will be interrupted and the one count will be incremented. In the same way at the exiting path. Whenever logic low signal comes to microcontroller, it will increment count by one and depending upon the program, when the number of visitors increase, controller will automatically on the devices. And as the count gets decremented at the exiting path, it automatically offs the devices. Relays are used to perform on and off operations. This will save the power in shopping malls

You might also like

- Theory of Light and LightingDocument59 pagesTheory of Light and LightingbbbmxNo ratings yet

- Led 0704Document40 pagesLed 0704Chris RogersNo ratings yet

- From Wikipedia, The Free EncyclopediaDocument7 pagesFrom Wikipedia, The Free EncyclopediaratannsNo ratings yet

- A Photo Diode Is A Type of Photo Detector Capable of Converting Light Into Either Current or Voltage Repaired)Document14 pagesA Photo Diode Is A Type of Photo Detector Capable of Converting Light Into Either Current or Voltage Repaired)vikassist1024No ratings yet

- Photodiode: From Wikipedia, The Free EncyclopediaDocument10 pagesPhotodiode: From Wikipedia, The Free EncyclopediamanuaaNo ratings yet

- Photo DiodeDocument5 pagesPhoto DiodeNoble SharmaNo ratings yet

- Photodiode - WikipediaDocument15 pagesPhotodiode - WikipediaIKENNANo ratings yet

- Photo DiodeDocument3 pagesPhoto DiodeAngga Wijaya KusumaNo ratings yet

- Optical SC Photo DiodeDocument3 pagesOptical SC Photo DiodeAnonymous mlYYLRe7HNo ratings yet

- Photodiode: Principle of OperationDocument6 pagesPhotodiode: Principle of OperationRahul SharmaNo ratings yet

- Photodiode THERMISTOR UM66Document16 pagesPhotodiode THERMISTOR UM66Shashank KesasrwaniNo ratings yet

- A Semiconductor Device Is An Electronic Component That Exploits The Electronic Properties of Semiconductor MaterialDocument10 pagesA Semiconductor Device Is An Electronic Component That Exploits The Electronic Properties of Semiconductor MaterialPrakhar Pratap SinghNo ratings yet

- Swagata Deb BurmanDocument9 pagesSwagata Deb Burmanvincent GamingNo ratings yet

- Sensors - FinalDocument13 pagesSensors - Finalbob123No ratings yet

- Optical Detectors in Fiber Optic ReceiversDocument83 pagesOptical Detectors in Fiber Optic Receiversali ghalibNo ratings yet

- Detectors and Storage DevicesDocument32 pagesDetectors and Storage Devices7t854s6wd2No ratings yet

- KVS Physics ProjectDocument10 pagesKVS Physics ProjectLokesh MaliNo ratings yet

- PhotoconductivityDocument12 pagesPhotoconductivitySarathy Kannan100% (1)

- Photodiode DetectorDocument7 pagesPhotodiode DetectorEyuel AregaNo ratings yet

- PhotodiodeDocument4 pagesPhotodiodeGargeya ChatiNo ratings yet

- Unit 5 REVISED 3.4.20 (1)Document32 pagesUnit 5 REVISED 3.4.20 (1)srishtika1620No ratings yet

- Presentation 4Document21 pagesPresentation 4xoranek474No ratings yet

- Presentation 4Document17 pagesPresentation 4xoranek474No ratings yet

- LED or Light Emitting Diode What Is Light Emitting Diode?Document8 pagesLED or Light Emitting Diode What Is Light Emitting Diode?ihsanNo ratings yet

- Presentation 4Document21 pagesPresentation 4xoranek474No ratings yet

- Physics Investigatory Project: Submitted By: Gunjan XIIDocument15 pagesPhysics Investigatory Project: Submitted By: Gunjan XIIblack in universeNo ratings yet

- Unit-2 - L-12 - Characteristics of LED, Photodiode, and LDRDocument9 pagesUnit-2 - L-12 - Characteristics of LED, Photodiode, and LDRwebip33713No ratings yet

- Photodiode - FinalDocument16 pagesPhotodiode - Finaldankymemey96No ratings yet

- Unit-Iv Optoelectronic Devices: 1. Describe The Working of Photo DiodeDocument7 pagesUnit-Iv Optoelectronic Devices: 1. Describe The Working of Photo DiodeVijay GNo ratings yet

- Presentation 4Document21 pagesPresentation 4xoranek474No ratings yet

- KVS Physics ProjectDocument11 pagesKVS Physics ProjectLokesh MaliNo ratings yet

- Presentation 4Document21 pagesPresentation 4xoranek474No ratings yet

- Presentation 4Document17 pagesPresentation 4xoranek474No ratings yet

- More On TransducersDocument18 pagesMore On TransducersRand Ahmed BushnaqNo ratings yet

- Automatic Room Light Controller: Bharat Institute of Technology SonipatDocument53 pagesAutomatic Room Light Controller: Bharat Institute of Technology SonipatParveen DahiyaNo ratings yet

- AU-222-Automobile Instrumentation: Lecture No:15 DR - Saqib Jamshed RindDocument19 pagesAU-222-Automobile Instrumentation: Lecture No:15 DR - Saqib Jamshed RindAkber AnwarNo ratings yet

- Introduction To Optoelectronics: Ronette S. Garcia Bsee-IvDocument37 pagesIntroduction To Optoelectronics: Ronette S. Garcia Bsee-IvRv Abejo AngaganNo ratings yet

- PHOTO SENSORSDocument41 pagesPHOTO SENSORSSrinithi BabuNo ratings yet

- Photo Detectors: Joseph S. BraleyDocument5 pagesPhoto Detectors: Joseph S. Braleyhenryjack1No ratings yet

- Photo DiodeDocument40 pagesPhoto DiodeMadhu46d0% (1)

- Unit3 EDC 2020Document20 pagesUnit3 EDC 2020Arun RamNo ratings yet

- Ldr/Photo Diode/Photo Transistor Characteristics Trainer Model No. ITB - 27Document20 pagesLdr/Photo Diode/Photo Transistor Characteristics Trainer Model No. ITB - 27Arindam SenNo ratings yet

- Aim: To Study Optical Detectors Theory: IntoductionDocument5 pagesAim: To Study Optical Detectors Theory: IntoductionHrushikesh JoshiNo ratings yet

- Module 1 - AdeDocument62 pagesModule 1 - AdeCharita NNo ratings yet

- FTTH OFC Unit II PART B Optical ReceiversDocument29 pagesFTTH OFC Unit II PART B Optical Receiversmowolef973No ratings yet

- Light DetectionDocument42 pagesLight Detectionanitangabire017No ratings yet

- Basic ElectronicsDocument17 pagesBasic ElectronicsDevikaNo ratings yet

- Optical Fiber Transmission: Institute of Technical Education and ResearchDocument24 pagesOptical Fiber Transmission: Institute of Technical Education and ResearchTanvi TanayaNo ratings yet

- All About PhotodiodesDocument4 pagesAll About PhotodiodesCan IlicaNo ratings yet

- IR Sensor ReportDocument14 pagesIR Sensor ReportAbhijeet chaudhary100% (1)

- Principles of Infrared AlarmDocument12 pagesPrinciples of Infrared AlarmvijufbNo ratings yet

- Photodiode Are Semiconductor Light Sensor That Generate A Current or Voltage When The P-NDocument4 pagesPhotodiode Are Semiconductor Light Sensor That Generate A Current or Voltage When The P-NMohamed A SbaihNo ratings yet

- 1Document4 pages1Giezel RevisNo ratings yet

- 17 - Mini Project ReportDocument16 pages17 - Mini Project ReportPriyadarshi M67% (3)

- Sensors & Transducers (Unit 4)Document59 pagesSensors & Transducers (Unit 4)sarangpsivanNo ratings yet

- Analog Electronics - Study Material Author Sarat Kumar Muduli, Mahesweta PattanaikDocument70 pagesAnalog Electronics - Study Material Author Sarat Kumar Muduli, Mahesweta PattanaikvhanzchaprotzNo ratings yet

- Unit 4 S&TDocument41 pagesUnit 4 S&TCharan VelavanNo ratings yet

- Ir Trans and ReceiverDocument13 pagesIr Trans and ReceiverAnil KumarNo ratings yet

- Photodiode Phototranistor PMTDocument9 pagesPhotodiode Phototranistor PMTNazreen AshrafNo ratings yet

- Unit 6: 1. With Schematic Representation Explain The Working Principle of Pin Photo Diode. AnsDocument11 pagesUnit 6: 1. With Schematic Representation Explain The Working Principle of Pin Photo Diode. AnskksundariNo ratings yet

- Photodetectors and Optical ReceiversDocument30 pagesPhotodetectors and Optical ReceiversjohnsNo ratings yet

- Amateur Radio Electronics on Your MobileFrom EverandAmateur Radio Electronics on Your MobileRating: 5 out of 5 stars5/5 (1)

- EN RaychemE100AE100LA DS H56829 - tcm432 26264 PDFDocument4 pagesEN RaychemE100AE100LA DS H56829 - tcm432 26264 PDFshareyhouNo ratings yet

- Basic Kit For Arduino PDFDocument52 pagesBasic Kit For Arduino PDFsombatNo ratings yet

- SwitchFamily 116Document1 pageSwitchFamily 116Dwi PutrantoNo ratings yet

- BachmannDocument84 pagesBachmannGeorge IstrateNo ratings yet

- Lighting DesignDocument34 pagesLighting DesignHindu HaridassNo ratings yet

- SensorsDocument15 pagesSensorsMuhammad Fasih KhanNo ratings yet

- ELTR100 Sec2Document112 pagesELTR100 Sec2ifeniyiNo ratings yet

- Unit 3 Lesson 5 Combining Semiconductors Into Phosphors 2017 Teacher'sDocument34 pagesUnit 3 Lesson 5 Combining Semiconductors Into Phosphors 2017 Teacher'sThomas Cancino LastraNo ratings yet

- Water Level IndicatorDocument7 pagesWater Level IndicatorPonnampet Grama PanchayatNo ratings yet

- Street LightingDocument44 pagesStreet Lightingmohammedviqhas3541100% (1)

- Jecet.v3i3c 7Document11 pagesJecet.v3i3c 7Jose LunaNo ratings yet

- Pilot DevicesDocument24 pagesPilot DevicesmariusrotaruNo ratings yet

- Fluke 15B 17B 18B (+) Meter User's ManualDocument28 pagesFluke 15B 17B 18B (+) Meter User's ManualmrzorbatronNo ratings yet

- Visvesvaraya Technological University: "Jnana Sangama", Belagavi-590018, KarnatakaDocument21 pagesVisvesvaraya Technological University: "Jnana Sangama", Belagavi-590018, KarnatakaPrajwal GowdaNo ratings yet

- Traxoil Electronic Oil Level ControlDocument4 pagesTraxoil Electronic Oil Level Controlsreekanth reddyNo ratings yet

- Hawkeye HK: Nonincendive and Intrinsically Safe For Point SensingDocument2 pagesHawkeye HK: Nonincendive and Intrinsically Safe For Point SensingErick Moreira ValdezNo ratings yet

- VBElectronics PDFDocument24 pagesVBElectronics PDFGhuggu vhghkkhNo ratings yet

- Improved Light Extraction of Wafer-Bonded Algainp Leds by Surface RougheningDocument3 pagesImproved Light Extraction of Wafer-Bonded Algainp Leds by Surface RougheningNASER012No ratings yet

- EN Catalogue GL OPTICAM SYSTEMSDocument20 pagesEN Catalogue GL OPTICAM SYSTEMSrandom randomNo ratings yet

- Seabeacon 2Document27 pagesSeabeacon 2josecamposx24No ratings yet

- Light Source Characteristics: (Part 1: LED Properties)Document3 pagesLight Source Characteristics: (Part 1: LED Properties)RMK BrothersNo ratings yet

- Automatic Street Light Control Proposal by Muzammil ZahoorDocument11 pagesAutomatic Street Light Control Proposal by Muzammil ZahoorKaleemNo ratings yet

- User ManualDocument198 pagesUser ManualdodyNo ratings yet

- Fair Use Building and Research Labs Presents: Introduction To Electronics and Breadboarding CircuitsDocument33 pagesFair Use Building and Research Labs Presents: Introduction To Electronics and Breadboarding CircuitslornfateNo ratings yet

- MEGAMAN-2012 New ProductsDocument8 pagesMEGAMAN-2012 New Productshassan153679No ratings yet

- Shadows Stories of LightDocument27 pagesShadows Stories of Lightvaidehi shirsathNo ratings yet

- Densitybasedtrafficsignalcontrolusingmicrocontroller 160508184856Document17 pagesDensitybasedtrafficsignalcontrolusingmicrocontroller 160508184856Venkata SainadhNo ratings yet

- Crouse Hinds Dlla Led BrochureDocument12 pagesCrouse Hinds Dlla Led Brochurebala murugan100% (1)