Welding Procedure Specification (WPS)

Welding Procedure Specification (WPS)

Uploaded by

คุณพ่อน้อง บิ๊กบอสCopyright:

Available Formats

Welding Procedure Specification (WPS)

Welding Procedure Specification (WPS)

Uploaded by

คุณพ่อน้อง บิ๊กบอสOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Welding Procedure Specification (WPS)

Welding Procedure Specification (WPS)

Uploaded by

คุณพ่อน้อง บิ๊กบอสCopyright:

Available Formats

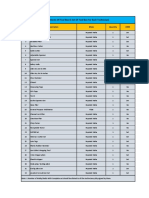

EP-CM-F-0004-003

CLIENT NAME : THAI PLASTIC AND CHEMICALS PUBLIC COMPANY LIMITED TOTAL: 6 SHEETS

PROJECT NAME : TPR Productivity improvement PG680,740 130 MTPD ( Including Cover )

PROJECT NO. : C-22-1092

LOCATION : RAYONG THAILAND

MECHANICAL DOCUMENT

WELDING PROCEDURE SPECIFICATION (WPS)

FOR BATCH RTRAINER H3001B

DISTRIBUTION

Master File

Client

Maintenance

Procurement

ENG. DESIGN

EM

PR

PIP

IE

MSE

MRE

EE

CVE

IC

] IA

CONSTRUCTION

PM

CM

CVE

ME

PIP

IE

EE

A IFR = Issue for Review Khanis Y. 12-Nov-22 Khanis Y. 12-Nov-22 Khanis Y. 12-Nov-22

REV. PURPOSE PRED. DATE CHKD. DATE APPD. DATE EM DATE PM DATE

PILIN PROJECT CO.,LTD.

Vendor / Fabricator / Contractor REPCO Doc. No. Client Doc. No. Issued Date

6518-PRO-00-A TPC-000-MSE-PRO-H3001B-00-A - 12-Nov-22

IFS = Issue for Squadcheck IFR = Issue for Review IFE = Issue for Enquiry IFD = Issue for Design IFC = Issue for Construction

IFI = Issue for Information IFP = Issue for Purchase IFF = Issue for Final

EP-CM-F-0004-003

PILIN PROJECT CO.,LTD.

REPCO Doc. No. Rev. Sheet No.

REVISION LIST

TPC-000-MSE-PRO-H3001B-00-A A 2 OF 6

REV. DATE ITEM No. REFERENCE DOCUMENT DESCRIPTION

A 12-Nov-22 - - IFR = Issue for Review

0 22-Jan-18 - - IFC = Issue for Construction

WELDING PROCEDURE SPECIFICATION (WPS)

For

Stainless steel 304 to Stainless steel 304

(RLlNJ PRE-WELDING PROCEDURE SPECIFICATION (WPS)

(QW-482 ; Section IX of ASME Boller and Pressure Vessel Code)

Company Name Pilln Project Comean}'. Limited. By Mr.Ramin Y.

WPS No. PLP-WPS-G-P8-P8-005 Date: 8 Sep 2016 Supporting PQR No.(S): PLP-PQR-G-P8-P8-005

Revision No. 0 Date: 8 Sep 2016

Welding Process GTAW Type(s): Manual

(Automatic, Manual, Machine. or Sem,-Automatic)

JOINT (QW-402)

Joint Design Single V (Butt weld) DETAILS

-

Backing (Yes) with or without (No) X

NIA -

0

Backing Material Size (Type) 61) -10•

(Refer to both Backing and Retainer)

□ □

j( I

Metal Nonfusing Metal

□ Nonmetallic □ Other

Tl ; 1•2mm

� - 2-3mm

Sketch, Production Drawing, Weld Symbols, or We!d Description

should show the general arrangement of the parts to be welded. ( See details attachment sheet joint sketch }

Where applicable, the root spacing and the detail of weld groove

may be speQfied.

(At the option of Mfgr.. sketCh may be attached to illustrate joint

design, weld layers and bea d sequence, eg., for notch toughness

procedures, for rrulliple process procedures, etc.)

"BASE METAL (QW-403)

P-No. 8 Group No. 1 to P-No. 8 Group No. 1

OR

Specification type and grade SA 2'40 Type 304&304l. Type 316&316l. SA 182 Type F30<&F304L.F3I6&f3151.. SA312 Type 304&3041.. Type 318&316LorE

to specification type and grade SA 240 Typo 304&3041.. Type 31e&.316L. SA 182 Type F30<&F304L.F316&F318L, SA312 Type 304&3041.. Type 318&316Lore

OR

Chem. Analysis and Mech. Properties .

-

to Chem. Analysis and Mech. Properties .

Thickness Range

Base Metal: Groove 1.5 - 14.22 mm Fillet Unlimited

Pipe Dia. Range All

Other NIA

•FILLER METAL (QW-404)

GTAW

Spec. No. (SFA) SFAS.9

AWS No. (Class) ER 308L

F-No. 6

A-No. 8

Size of Filler Metals 0 2.0, 2.4 mm

Weld Metal

Thickness Range :

Groove Max. 14.22 mm

Fillet Unlimited

Electrode Flux (Class) NIA

Flux Trade Name N/A

..... - - ---�

Consumable Insert N/A

Other KOBE or equivalent ( --♦-------

-.

1.Al,L;;t :; I

�i�-1

·-· •.J ;: I,•'·! •

I

·each base metal filler combination should be recorded Individually. If#' ,. _:,_ � '\.., J

You might also like

- Method Statement For Piping InstallationDocument9 pagesMethod Statement For Piping Installationคุณพ่อน้อง บิ๊กบอส100% (14)

- Method Statement For Rotating Equipment InstallationDocument10 pagesMethod Statement For Rotating Equipment Installationคุณพ่อน้อง บิ๊กบอส100% (4)

- HC-300 TaDocument56 pagesHC-300 TaOo Kenx OoNo ratings yet

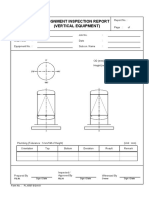

- Alignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / DateDocument6 pagesAlignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / Dateคุณพ่อน้อง บิ๊กบอส100% (2)

- Dpr1505 Assignment 02Document10 pagesDpr1505 Assignment 02ntombi100% (1)

- Method Statement For Static Equipment InstallationDocument20 pagesMethod Statement For Static Equipment Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Procedure Qualification Records (PQR)Document13 pagesProcedure Qualification Records (PQR)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Painting Procedure Rev.ADocument12 pagesPainting Procedure Rev.Aคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Welder Qualification Records (WQT)Document17 pagesWelder Qualification Records (WQT)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hydrostatic Test 3D-3711Document3 pagesHydrostatic Test 3D-3711คุณพ่อน้อง บิ๊กบอสNo ratings yet

- MKS 112 GEN AZ7 RQ 03 - A - Purchase Requisition For Painting MaterialsDocument21 pagesMKS 112 GEN AZ7 RQ 03 - A - Purchase Requisition For Painting MaterialsĐiệnBiênNhâm100% (1)

- Spec Report - 20150922Document1,507 pagesSpec Report - 20150922Midhun K Chandrabose100% (1)

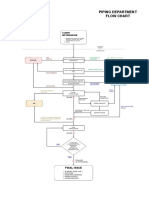

- Piping Department Flow Chart: Final IssueDocument2 pagesPiping Department Flow Chart: Final IssueFrancisco José Hernández Gómez100% (1)

- Pre Comm FormatDocument75 pagesPre Comm FormatHaleem Ur Rashid Bangash100% (1)

- PROJECT STANDARDS and SPECIFICATIONS Offshore Piping Fabrication and Installation Rev01Document8 pagesPROJECT STANDARDS and SPECIFICATIONS Offshore Piping Fabrication and Installation Rev01totongopNo ratings yet

- Bolt Torquing Tensioning Procedure PDFDocument29 pagesBolt Torquing Tensioning Procedure PDFric leonisoNo ratings yet

- Piping Fabrication 5Document4 pagesPiping Fabrication 5godennyNo ratings yet

- Flame Arrestor Procurement Spec.Document2 pagesFlame Arrestor Procurement Spec.hungNo ratings yet

- Method Statement For Paint Repair Procedure For Piping PDF FreeDocument16 pagesMethod Statement For Paint Repair Procedure For Piping PDF Freeumuhuza salomonNo ratings yet

- Material Inspection Report 6426-1Document5 pagesMaterial Inspection Report 6426-1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Bolted Flanged Joints New Methods Practices ProceedingsDocument2 pagesBolted Flanged Joints New Methods Practices ProceedingsMladen ČorokaloNo ratings yet

- E&I Tool Box ContentsDocument1 pageE&I Tool Box ContentsChandan RayNo ratings yet

- Progress Tracking Sheet-Piping Fabrication: Enter % Complete For Each Work StepDocument1 pageProgress Tracking Sheet-Piping Fabrication: Enter % Complete For Each Work StepRedouane MerabteneNo ratings yet

- QAPDocument6 pagesQAPRahul ChandanNo ratings yet

- KP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksDocument3 pagesKP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksUtku Can KılıçNo ratings yet

- NS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5Document46 pagesNS1 Work Plan Procedure For Circulating Water Piping Installation Rev.2 Part 1 of 5namdq-10% (1)

- Design Deliverable Documents ListDocument2 pagesDesign Deliverable Documents ListLai HuynhNo ratings yet

- ITP - (PIPING & Project Documents) PDFDocument5 pagesITP - (PIPING & Project Documents) PDFSUNNY BOSS100% (1)

- Project Status Report Sheet FormatDocument2 pagesProject Status Report Sheet FormatSkill IndiaNo ratings yet

- Inspection and Test PlanDocument3 pagesInspection and Test PlanGCRIADHNo ratings yet

- IOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Document6 pagesIOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Anonymous fLgaidVBhzNo ratings yet

- Itr-Pug (Ug Piping)Document12 pagesItr-Pug (Ug Piping)mahmoud100% (1)

- Sor CP17304Document18 pagesSor CP17304Neet NiteshNo ratings yet

- Polishing Procedure For PipesDocument4 pagesPolishing Procedure For Pipesคุณพ่อน้อง บิ๊กบอส0% (1)

- Tubing Leak TestDocument3 pagesTubing Leak TestOwais Malik100% (1)

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument1 pagePiping Daily Fit Up Quality Control and Inspection Report FormOnM deptNo ratings yet

- Certified QA QC Inspector PipingDocument5 pagesCertified QA QC Inspector Pipingamit84indNo ratings yet

- A3080 6040 Dat MC 142 eDocument11 pagesA3080 6040 Dat MC 142 erameshqcNo ratings yet

- Construction Method and Quality Control Planning For Concrete WorkDocument8 pagesConstruction Method and Quality Control Planning For Concrete Workibal_farhan67% (3)

- Method Statement Damaged Spool ReplacentDocument12 pagesMethod Statement Damaged Spool ReplacentMohsen KeramatiNo ratings yet

- FDAS PresentationDocument20 pagesFDAS PresentationRichmond Delos SantosNo ratings yet

- Inspection and Test Plan For Structure Steel Erection Works: Arabian Industrial Fibers Company (Ibn Rushd)Document11 pagesInspection and Test Plan For Structure Steel Erection Works: Arabian Industrial Fibers Company (Ibn Rushd)Yusup MulyanaNo ratings yet

- ITP TableDocument3 pagesITP Tablearunrad100% (1)

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khan100% (1)

- MS For Fabrication & Erection of PipingDocument24 pagesMS For Fabrication & Erection of PipingravikumarNo ratings yet

- 003 ITP UG PipingDocument4 pages003 ITP UG Pipingrvsingh70100% (1)

- TIMAS-PR-PI-001 - Hot Tapping ProcedureDocument11 pagesTIMAS-PR-PI-001 - Hot Tapping ProcedureMechanical Static WRKNo ratings yet

- Mechanical Package Design Quality ChecklistDocument1 pageMechanical Package Design Quality Checklistulfat100% (1)

- WBSDocument11 pagesWBSqasim7575No ratings yet

- List of Documents For Item Rate Contract For Consultants - CombinedDocument6 pagesList of Documents For Item Rate Contract For Consultants - CombinedSumantra ChattopadhyayNo ratings yet

- Detailed Design and Engineering Deliverable List (Sample)Document9 pagesDetailed Design and Engineering Deliverable List (Sample)mohan babuNo ratings yet

- Third Party Inspection For Power CableDocument6 pagesThird Party Inspection For Power CableBeareaterNo ratings yet

- QCF307 Post Weld Heat TreamentDocument1 pageQCF307 Post Weld Heat TreamentminhnnNo ratings yet

- Scope of Supply T60Document25 pagesScope of Supply T60cmaduroheNo ratings yet

- Gail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFDocument612 pagesGail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFChirag ShahNo ratings yet

- Check List For MDB InstallationDocument2 pagesCheck List For MDB InstallationNaing Win TunNo ratings yet

- NCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestDocument1 pageNCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestCharles KingNo ratings yet

- Request For NDT Test FormDocument1 pageRequest For NDT Test FormJohn OliverNo ratings yet

- Commissioning Procedure of CB 150 KV - ENDIRADocument10 pagesCommissioning Procedure of CB 150 KV - ENDIRAYoga SamNo ratings yet

- MAS FormatDocument2 pagesMAS FormatDebesh ChaudharyNo ratings yet

- Punch List 01Document147 pagesPunch List 01MITHUNNo ratings yet

- Hydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkDocument8 pagesHydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkCipta Adikarya100% (1)

- Common Reference Guide To Piping EngineeringDocument32 pagesCommon Reference Guide To Piping EngineeringSteve WanNo ratings yet

- Fabrication and Control ProcedureDocument19 pagesFabrication and Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hydrostatic Test ProcedureDocument11 pagesHydrostatic Test Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- PL-6220-1-ITP-001 Inspection and Test Plan (A)Document5 pagesPL-6220-1-ITP-001 Inspection and Test Plan (A)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- CC F 01102557Document1 pageCC F 01102557คุณพ่อน้อง บิ๊กบอสNo ratings yet

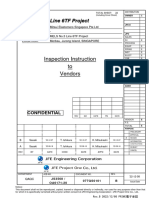

- Att-6 - 077QS0101 - B - INSPECTION INSTRUCTION TO VENDORSDocument22 pagesAtt-6 - 077QS0101 - B - INSPECTION INSTRUCTION TO VENDORSคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Weld Location MapDocument1 pageWeld Location Mapคุณพ่อน้อง บิ๊กบอสNo ratings yet

- ITP Equipment1Document9 pagesITP Equipment1คุณพ่อน้อง บิ๊กบอส100% (1)

- MDR lNDEXDocument35 pagesMDR lNDEXคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Inspection Report TK3200Document100 pagesInspection Report TK3200คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Cleaning Inspection ReportDocument2 pagesCleaning Inspection Reportคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Shell DimensionDocument1 pageShell Dimensionคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Slope CheckDocument2 pagesSlope Checkคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Inspection & Test PlansDocument3 pagesInspection & Test Plansคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hydrostatic Test ProcedureDocument11 pagesHydrostatic Test Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- CAST - WP0 - Deliverable 0.3Document34 pagesCAST - WP0 - Deliverable 0.3คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Fabrication and Control ProcedureDocument19 pagesFabrication and Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- 7) - Procedure FRP Tank InstallationDocument34 pages7) - Procedure FRP Tank Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 pageWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- Field Schedule Control ProcedureDocument37 pagesField Schedule Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Material Inspection Report 6426-1Document5 pagesMaterial Inspection Report 6426-1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- PL 6507 Pul 01Document1 pagePL 6507 Pul 01คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Polishing Procedure For PipesDocument4 pagesPolishing Procedure For Pipesคุณพ่อน้อง บิ๊กบอส0% (1)

- S-A3-125f-01 - Specification For Painting Work - Rev.b - CDocument35 pagesS-A3-125f-01 - Specification For Painting Work - Rev.b - Cคุณพ่อน้อง บิ๊กบอสNo ratings yet

- MANPOWER STATUS (Shop) 30-07-16Document1 pageMANPOWER STATUS (Shop) 30-07-16คุณพ่อน้อง บิ๊กบอสNo ratings yet

- ISBL ISO Joint DB 14-9-16Document35 pagesISBL ISO Joint DB 14-9-16คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Go ballistic (bơ lít tịc)Document21 pagesGo ballistic (bơ lít tịc)Lê LợiNo ratings yet

- 5: Spoon FeedingDocument2 pages5: Spoon FeedingM.SHOURYA VARDHANNo ratings yet

- Manufacturing Step in Ginger Oil ProcessingDocument3 pagesManufacturing Step in Ginger Oil ProcessingmilindNo ratings yet

- Chapter 3 Costing Methods The Costing of Resource Output 2015Document21 pagesChapter 3 Costing Methods The Costing of Resource Output 2015Amha SeyoumNo ratings yet

- Types of Accounts & DiscountDocument10 pagesTypes of Accounts & Discountsarvesh kumarNo ratings yet

- PPC Semiotic TheoryDocument17 pagesPPC Semiotic TheoryBEATphNo ratings yet

- Buku Siswa 1Document6 pagesBuku Siswa 1srikhairunnisaNo ratings yet

- Ptolemy's CentiloquiumDocument22 pagesPtolemy's CentiloquiumZubyre Khalid100% (1)

- EJMCM - Volume 9 - Issue 7 - Pages 8448-8453 PDFDocument6 pagesEJMCM - Volume 9 - Issue 7 - Pages 8448-8453 PDFVijayakumarNo ratings yet

- SriMathaIsUniversalMother DescrptionDocument3 pagesSriMathaIsUniversalMother DescrptionAnonymous VdXFPOvGxNo ratings yet

- Concorde HistoryDocument5 pagesConcorde HistoryMonosyndromeNo ratings yet

- VD ReportDocument18 pagesVD Reportviraj21mechNo ratings yet

- Unit 7. Revision and ConclusionDocument5 pagesUnit 7. Revision and ConclusionAryla AdhiraNo ratings yet

- Pain Gate TheoryDocument28 pagesPain Gate Theorysahinuri348No ratings yet

- Compendium Food Additives Regulations (3) 09.11.2017Document558 pagesCompendium Food Additives Regulations (3) 09.11.2017Abhishek BanerjeeNo ratings yet

- Atoms and MoleculesDocument5 pagesAtoms and MoleculesDilip Kumar KumawatNo ratings yet

- Digital Twin Technology in Railway IndustryDocument20 pagesDigital Twin Technology in Railway Industryatheena paulsonNo ratings yet

- Gofamint 3rd & 4th Quarters ManualsDocument115 pagesGofamint 3rd & 4th Quarters ManualsVictor AndyNo ratings yet

- 456895431585387343213$5 1refnoapplied MechanicsDocument1 page456895431585387343213$5 1refnoapplied MechanicsKumar SaurabhNo ratings yet

- GQ Usa - March 2019Document146 pagesGQ Usa - March 2019YuenNo ratings yet

- Siddarth Patwa Bio-Data Single PageDocument1 pageSiddarth Patwa Bio-Data Single PageKashish JainNo ratings yet

- Strawberry DNA LabDocument2 pagesStrawberry DNA LabChelsey PavaoNo ratings yet

- Chapter One Introduction To Operations ManagementDocument10 pagesChapter One Introduction To Operations ManagementWiz SantaNo ratings yet

- GK TODAY Aug ObjectiveadcfeDocument78 pagesGK TODAY Aug ObjectiveadcfeArush SharmaNo ratings yet

- Public International Law ProjectDocument13 pagesPublic International Law ProjectSukrit GandhiNo ratings yet

- Chapter 1 2 Ito Yung PinassDocument47 pagesChapter 1 2 Ito Yung PinassJohn aries SOLANONo ratings yet

- Sample 10277Document23 pagesSample 10277lousieNo ratings yet

- "Research Is A Process of Steps Used To Collect Information To Increase Our Understanding of A Topic or An Issue." - John W. CreswellDocument2 pages"Research Is A Process of Steps Used To Collect Information To Increase Our Understanding of A Topic or An Issue." - John W. CreswellFrancees TambasenNo ratings yet