Nozzle Check 211039C

Nozzle Check 211039C

Uploaded by

Gaurav BedseCopyright:

Available Formats

Nozzle Check 211039C

Nozzle Check 211039C

Uploaded by

Gaurav BedseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Nozzle Check 211039C

Nozzle Check 211039C

Uploaded by

Gaurav BedseCopyright:

Available Formats

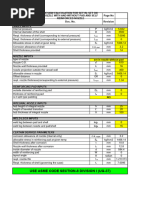

ENPRO INDUSTRIES PVT. LTD.

Rev.1

MIN. REQUIRED THICKNESS FOR NOZZLE

Chapter No:-7.1 Page 1 of 1

PIPES N1 & N2

REFERENCE CLAUSE :UG-45

Nozzle N1,N2-Oil Inlet & Outlet-(DN 40)-Sch 40S Location : Header Pipe

Sr. No. Description Symbol Unit Value

1 Design Pressure( Internal) Pi MPag 0.971

2 Design Pressure(External) Pe MPag 0.000

3 Design Temperature °C 100

4 Material SA-106

5 Max. Allowable stress at design temperature S MPa 118.00

6 Joint Efficiency of Nozzle pipe E 0.85

7 Out side diameter of nozzle D mm 48.3

8 Out side radius of nozzle Ro mm 24.15

9 Corrosion Allowance CA mm 3

Min. Required thickness of nozzle for internal as per Appendix 1.1

ta(Internal) mm 3.233

10 ta = Pi Ro/(SE+0.4Pi) + CA

Min. Required thickness of nozzle for external as per Appendix 1.1

ta(External) mm 3.000

11 ta = Pe Ro/(SE+0.4Pe) + CA

12 ta = Max (ta (Internal) , ta (External)) ta mm 3.233

Calculated Min.thickness of Bonnet for Internal Pressure

mm 3.899

13 assuming E = 1 plus Corrosion Allowance at nozzle location.

Calculated Min.thickness of Bonnet for external pressure

mm 3.000

14 assuming E = 1 plus Corrosion Allowance at nozzle location.

Min. Thickness specified as per

15 mm 5.50

UG-16(b)=1.5 + CA

16 Greater of (13) and (15) tb1 mm 5.50

17 Greater of (14) and (15) tb2 mm NA

Nozzle minimum thickness requirement mm

18 3.22

( Thickness given in table UG-45 )

Min. Thickness specified as per Table UG -45 + CA

19 tb3 mm 6.22

= 3.22 + 0

20 Min (tb3, max( tb1,tb2 ) ) tb mm 5.50

21 Required Nozzle Thickness :Max ( ta, tb ) tUG-45 mm 5.50

22 Nominal Nozzle thickness provided (Sch 40S) mm 7.14

Provided Minimum nozzle thickness with

23 allowable 12.5 % under tolerance mm 6.25

= 3.38 x 0.875

Provided nozzle thickness as per sr no.23 (3.68 mm) is more than required

thickness given by sr no.21 (1.5 mm) and hence adequate.

ENPRO INDUSTRIES PVT. LTD.

Rev.1

MIN. REQUIRED THICKNESS FOR NOZZLE

Chapter No:-7.1 Page 1 of 1

PIPES N1 & N2

REFERENCE CLAUSE :UG-45

Nozzle N1,N2-Oil Inlet & Outlet-(DN 40)-Sch 40S Location : Header Pipe

Sr. No. Description Symbol Unit Value

1 Design Pressure( Internal) Pi MPag 0.834

2 Design Pressure(External) Pe MPag 0.000

3 Design Temperature °C 100

4 Material SA-106

5 Max. Allowable stress at design temperature S MPa 118.00

6 Joint Efficiency of Nozzle pipe E 0.85

7 Out side diameter of nozzle D mm 48.3

8 Out side radius of nozzle Ro mm 24.15

9 Corrosion Allowance CA mm 3

Min. Required thickness of nozzle for internal as per Appendix 1.1

ta(Internal) mm 3.200

10 ta = Pi Ro/(SE+0.4Pi) + CA

Min. Required thickness of nozzle for external as per Appendix 1.1

ta(External) mm 3.000

11 ta = Pe Ro/(SE+0.4Pe) + CA

12 ta = Max (ta (Internal) , ta (External)) ta mm 3.200

Calculated Min.thickness of Bonnet for Internal Pressure

mm 3.772

13 assuming E = 1 plus Corrosion Allowance at nozzle location.

Calculated Min.thickness of Bonnet for external pressure

mm 3.000

14 assuming E = 1 plus Corrosion Allowance at nozzle location.

Min. Thickness specified as per

15 mm 5.50

UG-16(b)=2.5 + CA

16 Greater of (13) and (15) tb1 mm 5.50

17 Greater of (14) and (15) tb2 mm NA

Nozzle minimum thickness requirement mm

18 3.22

( Thickness given in table UG-45 )

Min. Thickness specified as per Table UG -45 + CA

19 tb3 mm 6.22

= 3.22 + 0

20 Min (tb3, max( tb1,tb2 ) ) tb mm 5.50

21 Required Nozzle Thickness :Max ( ta, tb ) tUG-45 mm 5.50

22 Nominal Nozzle thickness provided (Sch 40S) mm 7.14

Provided Minimum nozzle thickness with

23 allowable 12.5 % under tolerance mm 6.25

= 3.38 x 0.875

Provided nozzle thickness as per sr no.23 (3.68 mm) is more than required

thickness given by sr no.21 (1.5 mm) and hence adequate.

ENPRO INDUSTRIES PVT. LTD.

Rev.1

MIN. REQUIRED THICKNESS FOR NOZZLE

Chapter No:-7.1 Page 1 of 1

PIPES N1 & N2

REFERENCE CLAUSE :UG-45

Nozzle N1,N2-Oil Inlet & Outlet-(DN 40)-Sch 40S Location : Header Pipe

Sr. No. Description Symbol Unit Value

1 Design Pressure( Internal) Pi MPag 1.000

2 Design Pressure(External) Pe MPag 0.000

3 Design Temperature °C 100

4 Material SA-312 TP316L

5 Max. Allowable stress at design temperature S MPa 118.00

6 Joint Efficiency of Nozzle pipe E 1

7 Out side diameter of nozzle D mm 168.3

8 Out side radius of nozzle Ro mm 84.15

9 Corrosion Allowance CA mm 3

Min. Required thickness of nozzle for internal as per Appendix 1.1

ta(Internal) mm 3.711

10 ta = Pi Ro/(SE+0.4Pi) + CA

Min. Required thickness of nozzle for external as per Appendix 1.1

ta(External) mm 3.000

11 ta = Pe Ro/(SE+0.4Pe) + CA

12 ta = Max (ta (Internal) , ta (External)) ta mm 3.711

Calculated Min.thickness of Bonnet for Internal Pressure

mm 4.716

13 assuming E = 1 plus Corrosion Allowance at nozzle location.

Calculated Min.thickness of Bonnet for external pressure

mm 3.000

14 assuming E = 1 plus Corrosion Allowance at nozzle location.

Min. Thickness specified as per

15 mm 5.50

UG-16(b)=1.5 + CA

16 Greater of (13) and (15) tb1 mm 5.50

17 Greater of (14) and (15) tb2 mm NA

Nozzle minimum thickness requirement mm

18 6.22

( Thickness given in table UG-45 )

Min. Thickness specified as per Table UG -45 + CA

19 tb3 mm 9.22

= 3.22 + 0

20 Min (tb3, max( tb1,tb2 ) ) tb mm 5.50

21 Required Nozzle Thickness :Max ( ta, tb ) tUG-45 mm 5.50

22 Nominal Nozzle thickness provided (Sch 40S) mm 7.11

Provided Minimum nozzle thickness with

23 allowable 12.5 % under tolerance mm 6.22

= 3.38 x 0.875

Provided nozzle thickness as per sr no.23 (3.68 mm) is more than required

thickness given by sr no.21 (1.5 mm) and hence adequate.

You might also like

- Ligament Efficiency and Thickness of The Support PlateNo ratings yetLigament Efficiency and Thickness of The Support Plate10 pages

- Design Calculations For Pressure VesselsNo ratings yetDesign Calculations For Pressure Vessels43 pages

- Experiment No-5 AIM Theory: Use Case Actor DescriptionNo ratings yetExperiment No-5 AIM Theory: Use Case Actor Description2 pages

- E.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45No ratings yetE.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-452 pages

- 7-12-0013 Rev. 6 Nozzle Reinforcement & Projection100% (1)7-12-0013 Rev. 6 Nozzle Reinforcement & Projection2 pages

- BS-VI Projects For Panipat Refineriy of IOCL: Column/ Tower Carbon Stee L, CladNo ratings yetBS-VI Projects For Panipat Refineriy of IOCL: Column/ Tower Carbon Stee L, Clad301 pages

- Application For The Static Equipment Design EngineerNo ratings yetApplication For The Static Equipment Design Engineer3 pages

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionNo ratings yet"Lifting - Lug" - Lifting Lug Analysis: Program Description3 pages

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWNo ratings yetBalaji S - Static Equipment Design - 7 Years - Resume - NEW5 pages

- 18 (A) - Thread Length Verfication Calculation For Header Plug 1-1/8" (Design Pressure)No ratings yet18 (A) - Thread Length Verfication Calculation For Header Plug 1-1/8" (Design Pressure)2 pages

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2No ratings yet15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.24 pages

- Branch Reinforcement Per Asme B31.4 PipelineNo ratings yetBranch Reinforcement Per Asme B31.4 Pipeline1 page

- External Pressure-Dish Head and Shell-Taiwan TankNo ratings yetExternal Pressure-Dish Head and Shell-Taiwan Tank1 page

- Design of Nozzle Thickness As Per Ug-45 of Asme Sec. Viii Div. 1 Nozzle MarkNo ratings yetDesign of Nozzle Thickness As Per Ug-45 of Asme Sec. Viii Div. 1 Nozzle Mark1 page

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414No ratings yetSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-4147 pages

- Thickness Calculations For - 406.4 MM Dia of Pipe For Pressure MainNo ratings yetThickness Calculations For - 406.4 MM Dia of Pipe For Pressure Main1 page

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018No ratings yetPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,201832 pages

- t821201001pf - Civil and Structural Design CriteriaNo ratings yett821201001pf - Civil and Structural Design Criteria137 pages

- SAES-D-109 - Design of Small Metallic Atmospheric StorageNo ratings yetSAES-D-109 - Design of Small Metallic Atmospheric Storage24 pages

- T821950001PF - Basic Engineering Design Data (Bedd)No ratings yetT821950001PF - Basic Engineering Design Data (Bedd)28 pages

- Hypro Engineers Pvt. Ltd. Mechanical Design Engineering (MDE) BOM - Detailed Project Code: 18441-36 Project Name: UB OrrisaNo ratings yetHypro Engineers Pvt. Ltd. Mechanical Design Engineering (MDE) BOM - Detailed Project Code: 18441-36 Project Name: UB Orrisa3 pages

- Channel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of ConstructionNo ratings yetChannel Thickness Calculation: 1 Design Data: CO2 Condenser / Liquefier Design Code of Construction6 pages

- 3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''No ratings yet3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''22 pages

- Analysis of Stress in Nozzle/Shell of Cylindrical Pressure Vessel Under Internal Pressure and External Loads in NozzleNo ratings yetAnalysis of Stress in Nozzle/Shell of Cylindrical Pressure Vessel Under Internal Pressure and External Loads in Nozzle8 pages

- List of Files: SR Name File Number Date From/ToNo ratings yetList of Files: SR Name File Number Date From/To1 page

- Oil and Natural Gas Corporation Limited: Project No. Unit Doc - Type Mat Code Serial No. RevNo ratings yetOil and Natural Gas Corporation Limited: Project No. Unit Doc - Type Mat Code Serial No. Rev6 pages

- Application Acknowledgment For Curfew Pass For Goods VehicleNo ratings yetApplication Acknowledgment For Curfew Pass For Goods Vehicle1 page

- Setup and User Manual RetroPay (Enhanced)No ratings yetSetup and User Manual RetroPay (Enhanced)23 pages

- Red Hat OpenStack Platform-8-Director Installation and Usage-En-USNo ratings yetRed Hat OpenStack Platform-8-Director Installation and Usage-En-US165 pages

- Jayshree Periwal International School: Sub.: Physics Topic: KinematicsNo ratings yetJayshree Periwal International School: Sub.: Physics Topic: Kinematics33 pages

- GENERATOR LOAD SHARING PRINCIPLE - Power System StudiesNo ratings yetGENERATOR LOAD SHARING PRINCIPLE - Power System Studies12 pages

- SH RH QH RH : 2.642 M/s Critical Velocity (V)No ratings yetSH RH QH RH : 2.642 M/s Critical Velocity (V)4 pages