2015 Installation Guide

2015 Installation Guide

Uploaded by

alif suryantoCopyright:

Available Formats

2015 Installation Guide

2015 Installation Guide

Uploaded by

alif suryantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

2015 Installation Guide

2015 Installation Guide

Uploaded by

alif suryantoCopyright:

Available Formats

INSTALLATION GUIDE

Important: If these instructions are not followed while installing tank(s)

into your system, we are not responsible for damage that happens due

to negligence to these instructions and your warranty will be voided.

Installer is required to avoid continuous weight on flanges such as pipes, valves, and all

accessories. All weight needs to be supported by the ground and not supported by flanges

on tank.

All flanges need to have the full face of the flange gasketed (gasket no less than

3/16” thick) with 80 Duro or less.

Tank must be insulated from any vibration source using adapters like but not limited to

expansion joints.

Fittings should not be in direct contact with our plastic flange. Washer and lockwasher are

required.

All bolt connections to the tank must be torqued according to the guidelines provided

here in this document, set by Plastics Pipe Institute’s Technical Notes # 38 2011 which can

be found at this web address:

http://plasticpipe.org/pdf/tn-38_bolt_torque_flanged_joints.pdf

All instructions in following pages apply as a required action.

Please make as many copies of the “TORQUE AND INSTALLATION RECORD” as needed to

document the correct installation and torquing for each connection

Houston PolyTank Hopkins, MO 660-778-3393 houstonpolytank.com sales@houstonpolytank.com

Installation Guide Page 2

TORQUE AND INSTALLATION RECORD

Project: ____________________________ Flange Set Location: ____________________

Connecting HDPE Flange to _____________________________________Flange.

Bolt Dia. & Grade: ___________________ Nut Diameter & Grade: __________________

Lap-Joint Flange Dia. & Pressure Rating: _______________________________________

Lubricant Used: ______________________ Flange Temp: _________________________

Toque Wrench ID #: ___________________ Calibration Date: _____________________

If Specified: Full-face Gasket Info: Material: ____________ Thickness: _______________

Deep-Well Socket / Heavy-Hex Nut Wrench Size Used: ___________________________

Axis off-set:_____ Angular & Facial Gap: Top______ Bottom______L_____R______

“Initial” Each Step Upon Completion

1. Tank flange is being connected to a flexible connection.

2. Washers and lock washers are being used.

3. Connections’ weight is supported by ground and not causing continuous weight on tank flange.

4. Gasket used is no less than 1/8” Thick and 80 Duro or less

1. Visually examine and clean both flanges, bolts, nuts and washers. Replace damaged units.

2. Liberally lubricate bolt threads & nut threads & flange surface under nut.

3. Insert full-face gasket. Do not use wrinkled or damaged gaskets.

4. Number the bolt-holes in circumferential sequence starting at 12:00 position.

5. Check flange alignment, concentricity, angularity, and gap for acceptability.

6. To firm the flanges squarely together, hand tighten, then pre-tighten all bolts in proper

sequence to 10-20 foot-pounds torque. Do not exceed 20% of the TARGET TORQUE.

7. Re-check any flange-adapter face gap and LJF gap for uniformity. ****

8. Use the appropriate criss-cross pattern tightening in numerical sequence for Rounds 1,2,3, and

4 (tightening all bolts once in sequence constitutes a “round”).

****Note: Check LJF gap around the flange circumference between each of these rounds measured at

every other bolt. If any gap is not reasonably uniform around the circumference, make the apropriate

adjustments by selective bolt tightening before proceeding.

TARGET TORQUE (and 4 to 24-HOUR RE-TORQUE): _____________ foot-pounds.

660-778-3393 houstonpolytank.com sales@houstonpolytank.com

Installation Guide Page 3

_____ Lubricate, Hand tighten, Pre-tighten

_____ Round 1 – Tighten to ____ ft.lbs. (30%)

_____ Round 2 – Tighten to ____ ft.lbs. (60%)

_____ Round 3 – Tighten to ____ ft.lbs. (100%)

_____ Rotational (clockwise) Round

_____ For Large Flanges ≥ 16 + Bolts

_____Lubricate, Hand tighten, Pre-tighten

_____ Round 1 – Tighten to ____ ft.lbs. (25%)

_____ Round 2 – Tighten to ____ ft.lbs. (50%)

_____ Round 3 – Tighten to ____ ft.lbs. (75%)

_____ Round 4 – Tighten to ____ ft.lbs. (100%)

_____ Rotational (clockwise) Round

_____ Rotational (clockwise) Round: 100% of Target Torque. Use rotational clockwise tightening

sequence, starting with bolt #1, for one complete round and continue until no further bolt or nut

rotation occurs at 100% of the target torque value for each nut.

_____ 4 – 24 Hour Re-Torque & Inspection:

Re-torque to target torque value using one or two sequence-rounds, followed by one Rotational

round at the target Torque value

Must be properly initialed, signed, and dated for warranty to be valid on flange repairs.

Documentation Recorded By: ________________________________________ Date: ______________

Joint Technicial/Mechanic: __________________________________________ Date: ______________

660-778-3393 houstonpolytank.com sales@houstonpolytank.com

Installation Guide Page 4

TIGHTENING SEQUENCE:

Number the bolts in rotation around the Lap-Joint Flange circumference in a clockwise order, beginning

with the first bolt at the top in the nominal 12:00 position, the second being the next bolt to the right,

the third being the next bolt to the right, etc until all bolts are numbered sequentially.

Following the table below, tighten the given bolt number to the desired torque value for the given

round of tightening as specified on the Torque Record Checklist.

TABLE 1 [refer to ASME Document PCC-1 for Bolt Sequences]

NUMBER

CRISS-CROSS PATTEREN TIGHTENING SEQUENCE

OF BOLTS

4 1-3-2-4

8 1-5-3-7 >> 2-6-4-8

12 1-7-4-10 >> 2-8-5-11 >> 3-9-6-12

16 1-9-5-13 >> 3-11-7-15 >> 2-10-6-14 >> 4-12-8-16

20 1-11-6-16 >> 3-13-8-18 >> 5-10-15-20 >> 2-12-7-17 >> 4-14-9-19

24 1-13-7-19 >> 4-16-10-22 >> 2-14-8-20 >> 5-17-11-23 >> 3-15-9-21 >> 6-18-12-24

1-15-8-22 >> 4-18-11-25 >> 6-20-13-27 >> 2-16-9-23 >> 5-19-12-26 >> 7-21-14-28 >>

28 3-17-10-24

1-17-9-25 >> 5-21-13-29 >> 3-19-11-27 >> 7-23-15-31 >> 2-18-10-26 >> 6-22-14-30 >>

32 4-20-12-28 >> 8-24-16-32

1-2-3 >> 19-20-21 >> 10-11-12 >> 28-29-30 >> 4-5-6 >> 22-23-24 >> 13-14-15 >> 31-32-

36 33 >> 7-8-9 >> 25-26-27 >> 16-17-18 >> 34-35-36

1-2-3-4 >> 21-22-23-24 >> 13-14-15-16 >> 33-34-35-36 >> 5-6-7-8 >> 25-26-27-28 >>

40 17-18-19-20 >> 37-38-39-40 >> 9-10-11-12 >> 29-30-31-32

1-2-3-4- >> 25-26-27-28 >> 13-14-15-16 >> 37-38-39-40 >> 5-6-7-8 >> 29-30-31-32 >>

44 17-18-19-20 >> 41-42-43-44 >> 9-10-11-12 >> 33-34-35-36 >> 21-22-23-24

1-2-3-4 >> 25-26-27-28 >> 13-14-15-16 >> 37-38-39-40 >> 5-6-7-8 >> 29-30-31-32 >>

48 17-18-19-20 >> 41-42-43-44 >> 9-10-11-12 >> 33-34-35-36 >> 21-22-23-24 >> 45-46-

47-48

1-2-3-4 >> 29-30-31-32 >> 13-14-15-16 >> 41-42-43-44 >> 5-6-7-8 >> 33-34-35-36 >>

52 17-18-19-20 >> 45-46-47-48 >> 21-22-23-24 >> 49-50-51-52 >> 25-26-27-28 >>

9-10-11-12 >> 37-38-39-40

The criss-cross bolt tightening sequence and multi-round tightening are necessary to counteract the

flange / bolt elastic interaction.

660-778-3393 houstonpolytank.com sales@houstonpolytank.com

Installation Guide Page 5

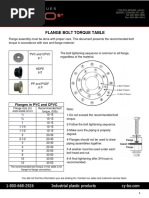

TABLE 2

EXAMPLES OF ESTIMATED BOLT TORQUE TO SEAL HDPE FLANGE FACES:

The engineer of record is usually responsible for establishing each flange joint criteria, and performing

the required calculations to determine the initial and residual torque values.

These estimated values are based on non-plated bolts and studs, using a nut factor of K =0.16 for lightly

greased bolts and nuts. The calculations uses a HDPE flange face seating stress of 1200-psi as a

minimum and 1800-psi as a maximum, and assumes the flanged joint is between two HDPE flange

adapters (in which the contact area is largest), without a rubber gasket.

NOTE: For bolting to ductile-iron pipe, steel flanges or butterfly valves, the flange face contact area is about half, so bolt torque

for that flange pair will be measurably less (refer to Table #3).

IPS Nominal LJF Bolt Number Minimum Lubed Maximum Lubed Flange

Initial Initial

Pipe Size Diameter of bolts Torque (Ft-Lbs) Torque (Ft-Lbs) OD/ID (in.)

2” 0.625 4 23 35 3.9/1.94

3” 0.625 4 33 50 5.0/2.86

4” 0.625 8 33 50 6.6/3.68

5” 0.75 8 44 66 7.5/4.40

6” 0.75 8 50 75 8.5/5.42

8” 0.75 8 80 120 10.63/6.76

10” 0.875 12 80 120 12.75/8.79

12” 0.875 12 105 160 15.00/10.43

14” 1 12 180 270 17.50/11.45

16” 1 16 180 270 20.00/13.09

18” 1.125 16 200 300 21.12/14.73

20” 1.125 20 200 300 23.50/16.36

22” 1.25 20 260 390 25.60/18.00

24” 1.25 20 290 435 28.00/19.64

26” 1.25 24 290 435 30.00/21.27

28” 1.25 28 290 435 32.30/22.91

30” 1.25 28 325 488 34.30/24.54

32” 1.5 28 425 640 36.50/26.18

34” 1.5 32 425 640 38.50/27.82

36” 1.5 32 460 690 40.80/29.45

40” 1.5 36 460 690 46.00/35.29

42” 1.5 36 460 690 47.50/37.06

48” 1.5 44 460 690 54.00/43.43

54” 1.75 44 560 840 60.00/48.86

NOTE: Uniform bolt pre-load (torque), without large “scatter”, is as useful as the target pre-load. Within the limits of the HDPE

flange adapter, gasket, or metal LJF, higher pre-load is desirable. The higher the pre-load is safely achievable, the more closely

the assembly will behave like the theoretical model and seal well. Higher pre-load means that a given internal pressure will

result in the least possible change in contact sealing pressure. Be consistent (avoid changes) with materials and tools when

following written assembly procedures.

Train and supervise the bolting personnel. Tell the crew what is to be accomplished, why, and explain that good results are not

automatically achieved. Skill and care are essential. Bolted Joint assembly is a technical skill that is not common in the

construction and maintenance profession, being considered more like a specialty. There is no universally accepted testing, nor

certification, of bolted-joint assembly mechanics. With no common training, certification, nor standards, it is no surprise there

is +/- 25% variability in assembly torque. Specifications and instructions by the engineer, followed by trained mechanics, help to

solve the dilemma.

(NOTE: Consult ASME Document PCC-1, Appendix A for training and certification of bolted joint assemblers)

660-778-3393 houstonpolytank.com sales@houstonpolytank.com

Installation Guide Page 6

TABLE 3

Examples of Estimated Bolt Torque to Seal the HDPE Flange Face To a Butterfly-

Valve, Steel Pipe Flange, or Ductile Iron Flange

The engineer of record is usually responsible for establishing each flange joint criteria, and performing the required

calculations to determine the initial and residual torque values.

These estimated liberally lubricated torque values assume the flanged joint connects one HDPE flange-adapter to a

Butterfly-Valve or Steel Pipe flange of Schedule 40 ID, or a Ductile-Iron flange. For bolting to steel flanges or

butterfly valves, the flange face contact area is just over half that of HDPE to HDPE flanges, so calculated bolt

torque for this flange pair will be measurably less than the values listed in Table #2.

Dimensional flange data should be obtained for each case from the pipe flange suppliers, so as to be able to

calculate the face contact area.

These estimated values are based on non-plated bolts and studs, using a K=0.16 for lightly greased bolts and nuts.

These calculations use an HDPE material minimum and maximum compressive seating stress of 1200-psi to 1800-

psi.

IPS Nominal LJF Bolt Number Minimum Lubed Maximum Lubed Flange OD

Initial Initial

Pipe Size Diameter of bolts Torque (Ft-Lbs) Torque (Ft-Lbs) Steep Pipe ID (in.)

2” 0.625 4 22 32 3.90/2.067

3” 0.625 4 30 45 5.00/3.068

4” 0.625 8 30 45 6.60/4.026

5” 0.75 8 44 66 7.50/4.40

6” 0.75 8 44 66 8.50/6.06

8” 0.75 8 58 88 10.63/7.98

10” 0.875 12 58 88 12.75/10.02

12” 0.875 12 75 114 15.00/11.94

14” 1 12 140 210 17.50/13.13

16” 1 16 140 210 20.00/15.00

18” 1.125 16 140 210 21.12/16.88

20” 1.125 20 140 210 23.50/18.81

22” 1.25 20 160 240 25.60/21.25

24” 1.25 20 180 270 28.00/23.25

26” 1.25 24 180 270 30.00/25.25

28” 1.25 28 180 270 32.30/27.25

30” 1.25 28 180 270 34.30/29.25

32” 1.5 28 240 360 36.50/31.00

34” 1.5 32 240 360 38.50/33.00

36” 1.5 32 260 390 40.80/35.00

40” 1.5 36 310 465 46.00/39.00

42” 1.5 36 310 465 47.50/41.00

48” 1.5 44 310 465 54.00/47.00

54” 1.75 44 365 550 60.00/53.00

Train and supervise the bolting personnel. Tell the crew what is to be accomplished, why, and explain that good results are not

automatically achieved. Skill and care are essential. Bolted Joint assembly is a technical skill that is not common in the

construction and maintenance profession, being considered more like a specialty. There is no universally accepted testing, nor

certification, of bolted-joint assembly mechanics. With no common training, certification, nor standards, it is no surprise there

is +/- 25% variability in assembly torque. Specifications and instructions by the engineer, followed by trained mechanics, help to

solve the dilemma.

(NOTE: Consult ASME Document PCC-1, Appendix A for training and certification of bolted joint assemblers)

660-778-3393 houstonpolytank.com sales@houstonpolytank.com

You might also like

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Hydratight PDFDocument40 pagesHydratight PDFTamer Farahat100% (1)

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 pagesCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71589% (27)

- Serie 60 Informacion AdicionalDocument51 pagesSerie 60 Informacion AdicionalMauricio Campos Quiros100% (1)

- Calibracion QSK23Document7 pagesCalibracion QSK23Kionss Kions67% (3)

- 608 Study Guide (New2018) PDFDocument28 pages608 Study Guide (New2018) PDFxripper86100% (1)

- Guide For Cast-in-Place Low-Density Cellular Concrete: ACI 523.1R-06Document25 pagesGuide For Cast-in-Place Low-Density Cellular Concrete: ACI 523.1R-06Gasoline L’orroreNo ratings yet

- Phison Flash IdDocument2 pagesPhison Flash Idclaudi bran0% (1)

- Tighting Torque MethodDocument6 pagesTighting Torque Methodibrahim hegazyNo ratings yet

- Fluid Tech-Info enDocument17 pagesFluid Tech-Info enadhityaNo ratings yet

- GIW Technical Series: Pipe Flange BoltsDocument4 pagesGIW Technical Series: Pipe Flange BoltsTravis SkinnerNo ratings yet

- Catalog HRC Jaw CouplingsDocument8 pagesCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Manual Coning Tool-BrochureDocument4 pagesManual Coning Tool-BrochuresreekumarNo ratings yet

- Method Statement of Gasket, Flange, Fittings and Valves Tightening SequenceDocument6 pagesMethod Statement of Gasket, Flange, Fittings and Valves Tightening SequenceRuel CabonceNo ratings yet

- Air Hydrilic PumpDocument6 pagesAir Hydrilic Pumpcampa150No ratings yet

- Technical Data 37 FlaredDocument13 pagesTechnical Data 37 FlaredhernychtNo ratings yet

- Quick Couplers Mechanical Hydraulic 068700 PDFDocument26 pagesQuick Couplers Mechanical Hydraulic 068700 PDFSTEVHEN MARTHINNo ratings yet

- Bolting Procedures: The Following Is A Sample Bolting Procedure Using A Manual or Hydraulic Torque WrenchDocument4 pagesBolting Procedures: The Following Is A Sample Bolting Procedure Using A Manual or Hydraulic Torque WrenchKyaw Kyaw AungNo ratings yet

- Installation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt HolesDocument4 pagesInstallation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt Holesquiron2010No ratings yet

- Torque Value PDFDocument8 pagesTorque Value PDF7761430No ratings yet

- VDO Gauge InstallationDocument4 pagesVDO Gauge Installationurule2kNo ratings yet

- Geith - Acople Ec460bDocument25 pagesGeith - Acople Ec460bjrincon26No ratings yet

- Hydraulic Cylinder Parker 3lDocument48 pagesHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- High Strength Bolts InstallationDocument7 pagesHigh Strength Bolts InstallationChristian ApfelmannNo ratings yet

- MANUAL016Document8 pagesMANUAL016kim johnNo ratings yet

- Operation Manual: Q250 Pneumatic Spinning WrenchDocument12 pagesOperation Manual: Q250 Pneumatic Spinning Wrenchmehdi HKNo ratings yet

- Air CylinderDocument4 pagesAir Cylindersimbua720% (1)

- PowerCutter Assembly and Arming ProceduresDocument7 pagesPowerCutter Assembly and Arming ProceduresmortizNo ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsmahesh_eilNo ratings yet

- Steel SAE O-Rings AdaptersDocument3 pagesSteel SAE O-Rings Adaptersgeav25653855No ratings yet

- 3 - 05 Biela Motor L7044Document13 pages3 - 05 Biela Motor L7044Javier LeonidasNo ratings yet

- Vision Mechanical Coupling Installation DataDocument7 pagesVision Mechanical Coupling Installation DataSyazwan KhairulNo ratings yet

- Manual Mantenimiento Mission 40Document8 pagesManual Mantenimiento Mission 40Daygor Martinez SabucoNo ratings yet

- CBTTT Sales Leaflet PDFDocument2 pagesCBTTT Sales Leaflet PDFElmer RaulNo ratings yet

- Manual Balancing Valves CIM 747H: Technical InformationDocument10 pagesManual Balancing Valves CIM 747H: Technical InformationblindjaxxNo ratings yet

- SOP Reach Stacker01Document7 pagesSOP Reach Stacker01vozefjadav100% (2)

- SD Slip ManualDocument9 pagesSD Slip ManualGregory StewartNo ratings yet

- SENR3130 - Torque General InformationDocument5 pagesSENR3130 - Torque General InformationAdolfo MarínNo ratings yet

- Toyota Truck Tacoma 2002Document17 pagesToyota Truck Tacoma 2002FlorentinoChoquehuancaNo ratings yet

- 0620000008Document6 pages0620000008mahsaNo ratings yet

- TDS 012 Turn-Of-Nut InstallationDocument2 pagesTDS 012 Turn-Of-Nut InstallationGuillermo Arnulfo Villa GarayNo ratings yet

- TDS012 Turn of Nut InstallationsDocument2 pagesTDS012 Turn of Nut InstallationsAris Bulaong100% (1)

- 3 WayDocument18 pages3 WayLeonardNo ratings yet

- Clock Spring Installation ManualDocument8 pagesClock Spring Installation ManualacornejomNo ratings yet

- Appendices V2Document76 pagesAppendices V2Nikola AngjelkovskiNo ratings yet

- Valve Lash G3408Document9 pagesValve Lash G3408Djebali MouradNo ratings yet

- AppendicesDocument69 pagesAppendicesIvan CanoNo ratings yet

- GPT Installation Instructions - LoresDocument7 pagesGPT Installation Instructions - LoresEWheelerFKNo ratings yet

- TraducirDocument59 pagesTraducirKasuki KasamaNo ratings yet

- Installation and Maintenance Instructions Figure C67 Fabri-Valve Bi-Directional Knife Gate ValveDocument6 pagesInstallation and Maintenance Instructions Figure C67 Fabri-Valve Bi-Directional Knife Gate Valveعبدالرحمن عمرNo ratings yet

- DAKE Press Model 75 H - 907003Document6 pagesDAKE Press Model 75 H - 907003mark_dayNo ratings yet

- Gen00001-00 (PC400-7 Field Assembly Instruction)Document17 pagesGen00001-00 (PC400-7 Field Assembly Instruction)Ebrahim SabouriNo ratings yet

- SAEP-351 Bolted Flange Joint AssemblyDocument12 pagesSAEP-351 Bolted Flange Joint AssemblyBebin Mathew75% (8)

- DSQ4 10M SidedoorDocument15 pagesDSQ4 10M SidedoorДудла СтаніславNo ratings yet

- FS4-3 - Installation Instructions (MM-601J)Document8 pagesFS4-3 - Installation Instructions (MM-601J)mendozaNo ratings yet

- Grid Coupling Installation InstructionsDocument2 pagesGrid Coupling Installation Instructionsakashwsl92No ratings yet

- Installation and Maintenance Guidelines For Nibco Butterfly Valves With Rubber SeatsDocument16 pagesInstallation and Maintenance Guidelines For Nibco Butterfly Valves With Rubber SeatsJosé marinNo ratings yet

- TM 5-4000 Pneumatic Chain Saw, Timberhog 24-Inch, Reed-Prentice Corp 1942Document31 pagesTM 5-4000 Pneumatic Chain Saw, Timberhog 24-Inch, Reed-Prentice Corp 1942Sheri Canham100% (1)

- Flange ChecklistDocument9 pagesFlange ChecklistxaviNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- PM-401 Vinyl Mechanical Joining Rev 005 11-01-16Document25 pagesPM-401 Vinyl Mechanical Joining Rev 005 11-01-16alif suryantoNo ratings yet

- Flange Bolt Torque TableDocument3 pagesFlange Bolt Torque Tablealif suryantoNo ratings yet

- 2017 Datasheet Ecom DDocument1 page2017 Datasheet Ecom Dalif suryantoNo ratings yet

- sch80c July12019Document12 pagessch80c July12019alif suryantoNo ratings yet

- 2017 Datasheet Ecom EN2FDocument1 page2017 Datasheet Ecom EN2Falif suryantoNo ratings yet

- 2017 Datasheet Ecom ProEasyDocument1 page2017 Datasheet Ecom ProEasyalif suryantoNo ratings yet

- CAT 323 DL 2013 LeafletDocument20 pagesCAT 323 DL 2013 LeafletLuka BornaNo ratings yet

- Probability V3 Sep9Document34 pagesProbability V3 Sep9angelimc100% (1)

- Professional Summary: DC Generators in RailwaysDocument28 pagesProfessional Summary: DC Generators in RailwaysDharini KrishnanNo ratings yet

- Mandate Vision Mission DostDocument11 pagesMandate Vision Mission DostsarahbansilNo ratings yet

- Me010 605 Mechatronics and Control SystemsDocument3 pagesMe010 605 Mechatronics and Control SystemsSreehari VpNo ratings yet

- Exp# 5d Shared Memory Aim: CS2257 Operating System LabDocument4 pagesExp# 5d Shared Memory Aim: CS2257 Operating System LabVasantha KumariNo ratings yet

- LQP03TN - 02 Series 0603 (MM) 0201 (Inch)Document4 pagesLQP03TN - 02 Series 0603 (MM) 0201 (Inch)BLUEE009No ratings yet

- KORADO KonvektoriDocument100 pagesKORADO KonvektoriRaske89No ratings yet

- ShaftDocument1 pageShaftgmNo ratings yet

- Hydrometallurgy: Richard G. Haverkamp, Desiderius Kruger, Ranjeeth RajashekarDocument6 pagesHydrometallurgy: Richard G. Haverkamp, Desiderius Kruger, Ranjeeth Rajashekarfauzi_alcupuNo ratings yet

- BOHEMIAN RhAPSODY (Mama) Cresc Rev. Im - DriDocument2 pagesBOHEMIAN RhAPSODY (Mama) Cresc Rev. Im - DriElena ARTEaga PuenteNo ratings yet

- Kinematics Problems With SolutionDocument17 pagesKinematics Problems With SolutionApril ClaireNo ratings yet

- αξεσουαρ SKODA CITIGO SPORTDocument7 pagesαξεσουαρ SKODA CITIGO SPORTSkoda Club PeloponnhsouNo ratings yet

- PDF 87Document1 pagePDF 87Nova CastyNo ratings yet

- Division of Responsibility (DOR) For Fabriction of Tank at BPCL Barghar, OdishaDocument4 pagesDivision of Responsibility (DOR) For Fabriction of Tank at BPCL Barghar, OdishaRAYAN FERRAONo ratings yet

- RS W446 PUMP OperationManualDocument29 pagesRS W446 PUMP OperationManualADM MTCNo ratings yet

- Design of Highway Vertical Alignment: Dr. Taleb M. Al-RousanDocument30 pagesDesign of Highway Vertical Alignment: Dr. Taleb M. Al-RousanPenelope MalilweNo ratings yet

- NA To Bs en 1992-1-2-2004 PDFDocument6 pagesNA To Bs en 1992-1-2-2004 PDFIsaac WabbiNo ratings yet

- Sterner Infranor Capella-5d Series Brochure 2010Document8 pagesSterner Infranor Capella-5d Series Brochure 2010Alan MastersNo ratings yet

- Import Export Confusion in MeteringDocument1 pageImport Export Confusion in Meteringjagadeesh_kumar_20No ratings yet

- IMSE EU BrochureDocument14 pagesIMSE EU BrochureDanny TaylorNo ratings yet

- A Truck Mounted Drilling RigDocument2 pagesA Truck Mounted Drilling Rigมนต์ชัย บุญธนลาภNo ratings yet

- The Temperature of Water Is Kept Constant During SwimmingDocument2 pagesThe Temperature of Water Is Kept Constant During SwimmingBizay MarikhuNo ratings yet

- World TBA - InertiaPM5Document8 pagesWorld TBA - InertiaPM5Aswar AwaNo ratings yet

- Chemical Coil Clean - MSDS PDFDocument3 pagesChemical Coil Clean - MSDS PDFKhairul MuzamilNo ratings yet

- AFL Fiber Optic Hardware OPGWDocument43 pagesAFL Fiber Optic Hardware OPGWRohit DeraNo ratings yet

- Energy Savings Calculator - Pump and Fan VFDDocument37 pagesEnergy Savings Calculator - Pump and Fan VFDASHUTOSH RANJANNo ratings yet