100%(1)100% found this document useful (1 vote)

228 viewsMOV Test Form

MOV Test Form

Uploaded by

Ali AkbarThis document provides a specification and test procedure for replacing seven drum screens and LCP's at a water utility company in Jubail and Yanbu. The test procedure involves verifying the installation, performing handwheel and local operation checks, conducting remote operation checks, and testing insulation resistance and for noise or vibration. Test results will be recorded as acceptable or not acceptable, and signed off by those performing and overseeing the quality control tests.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

MOV Test Form

MOV Test Form

Uploaded by

Ali Akbar100%(1)100% found this document useful (1 vote)

228 views1 pageThis document provides a specification and test procedure for replacing seven drum screens and LCP's at a water utility company in Jubail and Yanbu. The test procedure involves verifying the installation, performing handwheel and local operation checks, conducting remote operation checks, and testing insulation resistance and for noise or vibration. Test results will be recorded as acceptable or not acceptable, and signed off by those performing and overseeing the quality control tests.

Original Description:

MOV Testing procedure form

Original Title

MOV test form

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides a specification and test procedure for replacing seven drum screens and LCP's at a water utility company in Jubail and Yanbu. The test procedure involves verifying the installation, performing handwheel and local operation checks, conducting remote operation checks, and testing insulation resistance and for noise or vibration. Test results will be recorded as acceptable or not acceptable, and signed off by those performing and overseeing the quality control tests.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

228 views1 pageMOV Test Form

MOV Test Form

Uploaded by

Ali AkbarThis document provides a specification and test procedure for replacing seven drum screens and LCP's at a water utility company in Jubail and Yanbu. The test procedure involves verifying the installation, performing handwheel and local operation checks, conducting remote operation checks, and testing insulation resistance and for noise or vibration. Test results will be recorded as acceptable or not acceptable, and signed off by those performing and overseeing the quality control tests.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

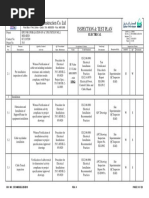

POWER & WATER UTILITY COMPANY FOR JUBAIL & YANBU

PROJECT CODE: GMD-MFQ-JUB-101

REPLACEMENT OF SEVEN DRUM SCREENS IN SWC-1 & LCP's IN SWP-2, JUBAIL

MOTOR OPERATED VALVE

SPECIFICATION

EQUIPMENT INSTRUMENT

TYPE RANGE

TAG NO. SERIAL NO.

MANUFACTURER ACCURACY

INPUT OUTPUT

S. NO. DESCRIPTION PASS FAIL N/A REMARKS

1 Installation Inspection

1.1 Verify and confirm that the physical location of the MOV.

1.2 All conduit connections are firm and intact.

1.3 Verify the continuity of all Fuses and their positions

1.4 Check MOV is correct in accordance with ISS / P&ID

1.5 Tag number correct

1.6 Electrical wiring connections are correct

1.6 Valve is upright and supported prior to carrying out test.

1.6 Ensure that no sand or foreign materials is in the body

2 Handwheel Operation Checks

2.1 Using the Hand wheel, fully close the valve

2.2 Check the Local display shows the valve is fully closed.

2.3 Using a Multi-meter check the "CLOSED" switch contact.

2.4 Using the Hand wheel, fully open the valve

2.5 Check the Local display shows the valve is fully open.

2.6 Using a Multi-meter check the "OPEN" switch contact.

3 Local Operation Checks

3.1 Ensure the motor is powered up and local display is ON

3.2 Verify the Hand-Off-Auto Switch function

3.3 In Local Control Mode, verify the Open / Close function

3.5 Verify th position indication lamps for correct operation

3.6 Opening and closing time will be noted and recorded.

3.7 Check the Limt switch functions during the operation

4 Remote Operation Checks

4.1 In Auto Mode, verify the Open / Close function from

Discrete contacts

4.2 Verify the position indication lamps for correct operation

4.3 Verify the limit switch functions during the operation

4.4 Manufacturer's Test variables if any to be highlited.

4.5 Perform Motor Insuation Resistance test (if applicable)

4.6 Check for any noise or vibration

TEST RESULTS: ACCEPTABLE NOT ACCEPTABLE

TEST PERFORMED BY : ____________________ SIGNATURE: _____________________

Q.C. ELECTRICAL ENGR: ___________________ SIGNATURE: _____________________

Q.C. MANAGER MARAFIQ / MASA ENGINEER

DATE TIME DATE TIME

INST-CAL-FORMS.xls\MOV 07/02/2023

You might also like

- Petra Split Unit Data SheetsDocument45 pagesPetra Split Unit Data SheetsAli AkbarNo ratings yet

- UPSDocument63 pagesUPSgavinilaa100% (1)

- Compex Modules Ex01 - EX04Document3 pagesCompex Modules Ex01 - EX04Grid LockNo ratings yet

- Electrical Continuity TestDocument2 pagesElectrical Continuity TestMechanical EngineerNo ratings yet

- Alcad CellDocument32 pagesAlcad CellIsaac VoonNo ratings yet

- ABB HV MotorsDocument25 pagesABB HV MotorsSudhakar NNo ratings yet

- Electrical TestDocument3 pagesElectrical TestAce SpionNo ratings yet

- Cable Laying ProcedureDocument2 pagesCable Laying ProcedureZulfiqar AliNo ratings yet

- Axter General Solar PV Inspection and Routine Maintenance GuideDocument4 pagesAxter General Solar PV Inspection and Routine Maintenance GuideBAlaNo ratings yet

- BS 67-1987 PDFDocument26 pagesBS 67-1987 PDFJoel AlcantaraNo ratings yet

- LV Motors: Hazardous Area Applica On: Safety First, Always - Reliable - Long Las NGDocument44 pagesLV Motors: Hazardous Area Applica On: Safety First, Always - Reliable - Long Las NGGokul VenugopalNo ratings yet

- Unit: HT Motor Revision No: 0 Page 1 of 2: Title: Standard Operation ProceedureDocument2 pagesUnit: HT Motor Revision No: 0 Page 1 of 2: Title: Standard Operation ProceedureSarah FrazierNo ratings yet

- VCB ServiceDocument1 pageVCB ServiceimranNo ratings yet

- 5 1.itp ElectricalDocument1 page5 1.itp ElectricalmeeNo ratings yet

- Altivar 61 For Medium Voltage MotorsDocument34 pagesAltivar 61 For Medium Voltage MotorsEduard NurmetovNo ratings yet

- 8BK88PLUSDocument8 pages8BK88PLUSSwapnil PatilNo ratings yet

- Circuit Breaker MaintenanceDocument6 pagesCircuit Breaker MaintenanceTheresa WestNo ratings yet

- Ductor TestingDocument4 pagesDuctor Testingmgharrier100% (1)

- 7SR45 Argus Complete ManualDocument137 pages7SR45 Argus Complete ManualFrancisco PechNo ratings yet

- Certificate of Calibration and Conformance: OmicronDocument1 pageCertificate of Calibration and Conformance: OmicronNadiaNo ratings yet

- Ps8306 LV MCCB MaintenanceDocument5 pagesPs8306 LV MCCB MaintenancePhuc PhamNo ratings yet

- Breaker Rack Out and Rack in (PB QBook)Document3 pagesBreaker Rack Out and Rack in (PB QBook)Ehsan Pappu33% (3)

- All Electrical InterviewDocument20 pagesAll Electrical InterviewramprakashpatelNo ratings yet

- Motor Operated ValveDocument36 pagesMotor Operated ValveArie MuhardiNo ratings yet

- Interleaved Bus Bar Explanation PDFDocument4 pagesInterleaved Bus Bar Explanation PDFVikram Singh100% (3)

- PAT TestDocument28 pagesPAT Testmanzoor hassanNo ratings yet

- PEEC-A024 - Checklist - Hazardous Area Classification PDFDocument2 pagesPEEC-A024 - Checklist - Hazardous Area Classification PDFRisharto Yustitiardi100% (1)

- Caterpillar - Class of Insulation and Temprature Rise - Online CommunityDocument3 pagesCaterpillar - Class of Insulation and Temprature Rise - Online Communitylbk50No ratings yet

- Cable Gland-2 PDFDocument38 pagesCable Gland-2 PDFhkaruvathilNo ratings yet

- Explosionproof and Flameproof Enclosures - Part-2Document9 pagesExplosionproof and Flameproof Enclosures - Part-2HujiLokoNo ratings yet

- Motor Operated Valve RotorkDocument12 pagesMotor Operated Valve RotorkGeorge Asuncion100% (3)

- Cable Bending Radius GuideDocument4 pagesCable Bending Radius GuideOctober EchoNo ratings yet

- Integrated Safety Device Comem RIS2: Instruction ManualDocument12 pagesIntegrated Safety Device Comem RIS2: Instruction ManualMichel BrunoNo ratings yet

- SRL-High Mast O&M ManualDocument7 pagesSRL-High Mast O&M ManualmaninderpreetNo ratings yet

- DGS Test Transformer OilDocument18 pagesDGS Test Transformer OilIkhsan LyNo ratings yet

- 132 Testing - CTDocument1 page132 Testing - CTSantosh GairheNo ratings yet

- Auma MovDocument52 pagesAuma MovPrudhvi Raj100% (1)

- Acb Fault ReasonsDocument14 pagesAcb Fault ReasonsDakshinaMoorthyNo ratings yet

- Low Voltage Electrical Switchboard Testing ProceduresDocument1 pageLow Voltage Electrical Switchboard Testing Proceduresrozi54No ratings yet

- Manual Instruciton NGRDocument4 pagesManual Instruciton NGRAhmad Ikhsan KurniantoNo ratings yet

- Method For Static and Dynamic Resistance Measurement of HV Circuit BreakerDocument5 pagesMethod For Static and Dynamic Resistance Measurement of HV Circuit BreakerAislanGaldino100% (1)

- Manual AUMA MOVDocument60 pagesManual AUMA MOVBonzo DigolodogNo ratings yet

- 2017 ATEC Singapore CompEx 01-04Document1 page2017 ATEC Singapore CompEx 01-04murugan1620No ratings yet

- Awareness Compex EX01-01-03&04 Courses OutlineDocument6 pagesAwareness Compex EX01-01-03&04 Courses OutlinemoumenengNo ratings yet

- The Value of Electrical InspectionDocument6 pagesThe Value of Electrical InspectionASAPASAPASAPNo ratings yet

- Very Low Frequency VLF Testing of HV Cables Manual HP 3651308 211216Document45 pagesVery Low Frequency VLF Testing of HV Cables Manual HP 3651308 211216Anonymous 1AAjd0No ratings yet

- Federal Cable Catalogue-MinDocument17 pagesFederal Cable Catalogue-MinAhmadBintangNegoroNo ratings yet

- Testing & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981Document14 pagesTesting & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981PKNo ratings yet

- Buchholz RelayDocument2 pagesBuchholz RelayjitheshsvNo ratings yet

- LOTO SystemDocument4 pagesLOTO SystemHitesh NavlaniNo ratings yet

- GS112 3 PDFDocument19 pagesGS112 3 PDFadamNo ratings yet

- 12.es-10 Capcitor BankDocument5 pages12.es-10 Capcitor BankDEADMANNo ratings yet

- Oil Sampling Process For Qualitrol DGA 150/250/400: Step 1: Step 2Document3 pagesOil Sampling Process For Qualitrol DGA 150/250/400: Step 1: Step 2mirelamanteamirelaNo ratings yet

- Instrument Installation ChecklistDocument1 pageInstrument Installation ChecklistAli AkbarNo ratings yet

- 802848-D Optistar LE Service ChecklistDocument6 pages802848-D Optistar LE Service ChecklistDanilo MirandaNo ratings yet

- Construction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederDocument2 pagesConstruction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederhrimklimNo ratings yet

- 1 AcdbDocument9 pages1 AcdbmaheshknmNo ratings yet

- Auxiliary Relay Test Report: Sheet 1 of 1Document1 pageAuxiliary Relay Test Report: Sheet 1 of 1TariqMalikNo ratings yet

- Work - Instruction 66-33KV TRANSFORMERDocument5 pagesWork - Instruction 66-33KV TRANSFORMERTAHIR HUSAINNo ratings yet

- 802870-D Optistar LE PM ChecklistDocument4 pages802870-D Optistar LE PM ChecklistDanilo MirandaNo ratings yet

- Calibration ProcedureDocument5 pagesCalibration ProcedureManu SharmaNo ratings yet

- Fuse Junction Box-400a Rev-01Document2 pagesFuse Junction Box-400a Rev-01Ali AkbarNo ratings yet

- Pressure Switch Calibration FormDocument1 pagePressure Switch Calibration FormAli AkbarNo ratings yet

- Cable Continuity FormDocument1 pageCable Continuity FormAli AkbarNo ratings yet

- JSADocument19 pagesJSAAli AkbarNo ratings yet

- Instrument Installation ChecklistDocument1 pageInstrument Installation ChecklistAli AkbarNo ratings yet

- 2/2 Direct Acting, High Orifice Solenoid Valve Normally ClosedDocument2 pages2/2 Direct Acting, High Orifice Solenoid Valve Normally ClosedAli AkbarNo ratings yet

- CINCO - Safety PlanDocument113 pagesCINCO - Safety PlanAli Akbar100% (1)

- Curriculum Management SystemDocument81 pagesCurriculum Management SystemLynyakat TañonNo ratings yet

- Mechanical SpliceDocument14 pagesMechanical SpliceErwin SiagianNo ratings yet

- State of The Art Power Electronics Systems For Solar To Grid IntegrationDocument39 pagesState of The Art Power Electronics Systems For Solar To Grid IntegrationKanaga GnanaNo ratings yet

- Chapter 2 - Mec132Document23 pagesChapter 2 - Mec132Hakimi MohdNo ratings yet

- Chapter: 8 The D and F Block Elements: Points To Be RememberedDocument8 pagesChapter: 8 The D and F Block Elements: Points To Be RememberedsrideviNo ratings yet

- DefuzzificationDocument4 pagesDefuzzificationjayadurgaNo ratings yet

- ASADocument115 pagesASAVidhu Ranjan GopalNo ratings yet

- Swiss Cam 2012Document10 pagesSwiss Cam 2012Jonas MarçaloNo ratings yet

- Davisa Data Assignment Description Sec 1 and 2Document6 pagesDavisa Data Assignment Description Sec 1 and 2api-739527028No ratings yet

- Computer Methods and Experimental Measurements For Surface Effects and Contact MechanicsDocument353 pagesComputer Methods and Experimental Measurements For Surface Effects and Contact MechanicsRuben CallisayaNo ratings yet

- Reporte Khan Academy - 9C - SEM2Document21 pagesReporte Khan Academy - 9C - SEM2Elias Velarde SalcedoNo ratings yet

- 1.2 Units of Measurement From Hands-On Chemistry All Rights ReservedDocument17 pages1.2 Units of Measurement From Hands-On Chemistry All Rights ReservedShizraNo ratings yet

- 2017 NASCC Intro 15ed ManualDocument25 pages2017 NASCC Intro 15ed Manualhrol31060No ratings yet

- Ua 4FXDocument1 pageUa 4FXinamistNo ratings yet

- Chapter Two C++Document64 pagesChapter Two C++mift ademNo ratings yet

- BM14G4 DatasheetDocument4 pagesBM14G4 Datasheetl1f3b00kNo ratings yet

- Database Chapter 3Document34 pagesDatabase Chapter 3seiyfuNo ratings yet

- Use of Sulphur Dioxide in Food PreservationsDocument1 pageUse of Sulphur Dioxide in Food PreservationsJoel YeongNo ratings yet

- Autocad Plummer Block Base 1Document5 pagesAutocad Plummer Block Base 1Murali Siddarth0% (2)

- Learning ActivitiesDocument7 pagesLearning Activitiescarren salen100% (1)

- GPP CompilerDocument2 pagesGPP CompilerNishant KeswaniNo ratings yet

- HGI7000 Manual AGO21-ENDocument58 pagesHGI7000 Manual AGO21-ENdlauerNo ratings yet

- ConduitDocument2 pagesConduitRabah AmidiNo ratings yet

- 2007 Schmidt2007 PanamaDocument17 pages2007 Schmidt2007 PanamaEDWIN URREA ZULUAGANo ratings yet

- Direct Utilization of Solar EnergyDocument9 pagesDirect Utilization of Solar EnergySushmitha BadukondaNo ratings yet

- Ferro CementDocument17 pagesFerro CementAlemayehu DargeNo ratings yet

- Retrograde Condensation PDFDocument11 pagesRetrograde Condensation PDFJosiane Bezerra100% (1)

- Drilling Rig ComponentsDocument27 pagesDrilling Rig ComponentsBasit Khan0% (1)

- ECEN 454: Digital Integrated Circuit DesignDocument36 pagesECEN 454: Digital Integrated Circuit DesignJoe KingNo ratings yet

- Tone DecoderDocument7 pagesTone DecodermastelecentroNo ratings yet