Pessing Libya INC: SA 312 TP 316 TO SA 312 TP

Uploaded by

Mahmoud HaggagPessing Libya INC: SA 312 TP 316 TO SA 312 TP

Uploaded by

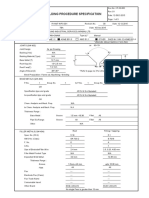

Mahmoud HaggagPESSING LIBYA INC WELDING PROCEDURE

CONSTRUCTION & ENGINEERING SERVICES SPECIFICATION

Client: WABAG WPS No.: PL03/2021 Date: 21. 12. 2021

PQR No.: PL/PQR-101 Project No.: GDCOL TOBRUK - 11P89

Weld Type: BW, Single Side Welding Process: GTAW

Base Metal Details

Base Material: SA 312 TP 316 TO SA 312 TP P No. 8 Gr No.1 TO P No.8 Gr No.1

Thickness (mm): 1.5 TO 18 mm Diameter: 25 mm & above

Welding Position: All Root: GTAW Fill: GTAW Technique: stringer/weave

Filler Metal Details

AWS No. Classification: ER-316 L SFA. No.: A5.9 F No.: 6 A No.: 8

Designation and Manufacturer: ESAB or Equivalent Preheat Temperature: Ambient

Size of electrode: 2.0 & 3.2 mm Post Weld heat treatment: N/A

Flux: N/A Method of prepare edges: Grinding

Shielding gas/ Backing gas: Ar Flow Rate : 15-20 Lpm Fit-Up method: Spacer

JOINT DETAIL

PREPARATION METHOD WELD DETAIL

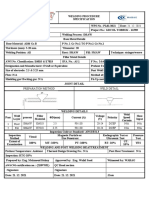

WELDING DETAILS

Weld

Weld Filler Voltage Heat

Pass process ΦD Current (A) Polarity Speed

Layer Material (V) Input

Cm/min

1 Root GTAW ER-316 L mm 2 80-100 18-25 straight N/A N/A

2 Fill GTAW mm 3.2

ER-316 L 110-130 18-25 straight N/A N/A

Inspection Code or Standard: ANSI B31.3

Inspection Magnetic Particle or Radiographic Test or Pressure

Visual

Method Dye Penetrant Ultrasonic Test Test

Extent of UT:

100% MT: 100% PT: 100% RT: 10% YES

Examination 10%

WELDING AND POST WELDING HEATTREATMENT

Preheat Temperature: Ambient Thermal Design Drawing No.: N/A Post Heat Treatment: N/A

Inspection: RTG-10%

Prepared by: Eng. Mahmoud Helmy Approved by: Eng. Walid Saad Witnessed by: WABAG

AWS/CWI certification no.: (21097031) QC Head section

:Signature :Signature

Date: 21. 12. 2021 Date: 21. 12. 2021 :Date

You might also like

- Project Report On Coconut Shell Charcoal/activated Carbon100% (1)Project Report On Coconut Shell Charcoal/activated Carbon7 pages

- For Fillet Weld Joint Project:Production Manifold50% (2)For Fillet Weld Joint Project:Production Manifold1 page

- Welding Procedure Specification (WPS) : Joint Design PositionNo ratings yetWelding Procedure Specification (WPS) : Joint Design Position9 pages

- Pessing Libya INC: Weld Detail Preparation MethodNo ratings yetPessing Libya INC: Weld Detail Preparation Method1 page

- Pessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/ANo ratings yetPessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/A1 page

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CNo ratings yetPessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg C1 page

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CNo ratings yetPessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg C1 page

- Pessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/ANo ratings yetPessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/A1 page

- Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4No ratings yetPessing Libya INC: As Per P No.3,4 To As Per P No.3,41 page

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment:680-720 Deg CNo ratings yetPessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment:680-720 Deg C1 page

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CNo ratings yetPessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg C1 page

- Pessing Libya INC: Weld Detail Preparation MethodNo ratings yetPessing Libya INC: Weld Detail Preparation Method1 page

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKNo ratings yetWelding Procedure Specification: PQR 2" Dia-5.54mm THK2 pages

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)No ratings yetTecnicas Reunidas S.A: Welding Procedure Specification (WPS)2 pages

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)No ratings yetTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)2 pages

- Welding Procedure Specification: JOINTS (QW-402)No ratings yetWelding Procedure Specification: JOINTS (QW-402)3 pages

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1No ratings yetWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph12 pages

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelNo ratings yetWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - Steel3 pages

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)No ratings yetWelding Procedure Specification (WPS) : (Asme Sec. Ix)2 pages

- Welding Procedure Specification: Backing MaterialNo ratings yetWelding Procedure Specification: Backing Material2 pages

- Heterojunction Bipolar Transistors for Circuit Design: Microwave Modeling and Parameter ExtractionFrom EverandHeterojunction Bipolar Transistors for Circuit Design: Microwave Modeling and Parameter ExtractionNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- 2012, Patras, J Esthet Restor Dent, Management of Provisional Restorations' Deficiencies - A Literature ReviewNo ratings yet2012, Patras, J Esthet Restor Dent, Management of Provisional Restorations' Deficiencies - A Literature Review13 pages

- Failure Analysis of API 5L (Grade B) Oil Field Separator Flowline PipeNo ratings yetFailure Analysis of API 5L (Grade B) Oil Field Separator Flowline Pipe6 pages

- Electrical Material Take Off (MTO) For Lighting Fixtures & AccessoriesNo ratings yetElectrical Material Take Off (MTO) For Lighting Fixtures & Accessories7 pages

- Low Cost Eco Friendly Building Material A Case Study in EthiopiaNo ratings yetLow Cost Eco Friendly Building Material A Case Study in Ethiopia6 pages

- Observations of Chemical Changes: Lab Report For Experiment #2 25 PointsNo ratings yetObservations of Chemical Changes: Lab Report For Experiment #2 25 Points9 pages

- Zinc Oxide: Central Drugs and Pharmaceuticals No.3 Multi Industrial Nagar, Gerugambakkam, Chennai 600128No ratings yetZinc Oxide: Central Drugs and Pharmaceuticals No.3 Multi Industrial Nagar, Gerugambakkam, Chennai 6001282 pages

- Davies Paints Philippines, Inc.: Anti-Formaldehyde Anti-Bacterial Paint100% (1)Davies Paints Philippines, Inc.: Anti-Formaldehyde Anti-Bacterial Paint2 pages

- Studies On Environment Friendly Dyes Obtained From Waste FlowersNo ratings yetStudies On Environment Friendly Dyes Obtained From Waste Flowers5 pages