Wps 316L Gtaw R00

Wps 316L Gtaw R00

Uploaded by

Richard PeriyanayagamCopyright:

Available Formats

Wps 316L Gtaw R00

Wps 316L Gtaw R00

Uploaded by

Richard PeriyanayagamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Wps 316L Gtaw R00

Wps 316L Gtaw R00

Uploaded by

Richard PeriyanayagamCopyright:

Available Formats

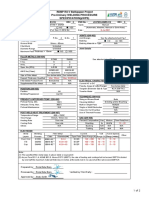

Page 1 of 2

AL JALHAMI CONT. & Trad. Co.

AL KHAFJI, K.S.A

Dat

e:

WELDING PROCEDURE SPECIFICATION (WPS)

QA/QC

Welding procedure specification no.

QC/WPS/07

Supporting PQR no.

Welding process

GTAW

CODE:

ASME IX

Revision no.

Revision no.

Type(s)

API 1104

BASE METALS (QW-403)

P. No.

8

Group no.

18/05/2014

Date

18/05/2014

Date

MANUAL

AWS D1.1

to

P. No.

Others

8

Group no.

Specification type and grade

A312, TP 316/316L or EQUIVALENT

To specification type and grade

A312, TP 316/316L or EQUIVALENT

Or

Chemical Analysis and Mech. Prop.

to Chemical Analysis and Mech. Prop.

Thickness Range:

Base Metal

Pipe Dia. Range

Other

Groove

Groove

JOINTS (QW-402)

Joint Design

Backing

1.5mm 12.04mm

All

Fillet

Fillet

Unlimited

Unlimited

Single bevel, v, J or u

Type

none

N/A

Details

A 1.2 mm

B 3.2 mm

FILLER METALS (QW-404)

F. No.

6

Other

None

A. No.

Spec No. (SFA)

AWS No. (Class)

Size of filler metals

Electrode flux (class)

Consumable insert

Other

none

5.9

ER316L

Dia. 2.4mm

N/A

N/A

TECHNICAL APPROVAL

Name

Al JALHAMI CONT. & TRAD. CO.

APPROVED BY KJO(AGOC/KGOC)

Name

Signature

Signature

Date

Date

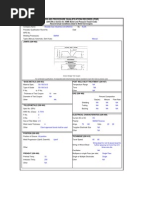

Page 2 of 2

AL JALHAMI CONT. & Trad. Co.

AL KHAFJI, K.S.A

Date

:

WELDING PROCEDURE SPECIFICATION (WPS)

QA/QC

POSITION (QW-405)

POSITION(S) or groove

All Positions (6G)

Up

Welding progression

position(s) of Fillet

Down

All Positions

PREHEAT (QW-406)

Preheat Temp. min.

Interpass Temp. max.

21C

140C

N/A

Preheat maintenamce

TECHNIQUE (QW-410)

String or Weaving Bead

POST WELD HEAT TREATMENT (QW-407)

Temperature range

None

Time range

N/A

Heating rate

N/A

cooling rate

N/A

GAS (QW-408)

Shielding gas(es)

Argon

% composition

99.9%

(mixtures)

Flow rate

10 15 lpm

Gas backing

10 15 lpm

Trailing shielding gas

N/A

composition

* Gas purging must be maintained until root is

completed

Root: String, Fill/Cap: Weave

Max. weave width

Orifice or Gas Cup Size

3 times electrode Dia.

12 19 mm

Initial And Interpass Cleaning

Brushing and/or Grinding

Method of Back Gouging

N/A

Oscillation

N/A

Contact Tube to Work Distance

N/A

Multiple or Single Pass (Per Side)

Multiple

Multiple or Single Electrodes

Single

Travel Speed (Range)

120 400 mm/min

Peening

N/A

Other

N/A

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC

DC

AMPS (range)

80 to 120 Amps

Polarity

Volt(range)

Tungsten electrode size and type

Mode of metal transfer for GMAW

N/A

Filler

metal

Process

Class

Straight / EN

8-20 Volts

2.4 mm, EWTH-2% Thoriated

N/A

Electrode wire feed speed range

Weld

Layer

18/05/2014

Dia. (mm)

Volt

range

Current

Type

Amp

Travel

speed

(mm/min)

Other

Root

GTAW

ER316L

2.4

DCEN

80-115

8-20

120-200

Hot

GTAW

ER316L

2.4

DCEN

95-120

8-20

150-400

Fill

GTAW

ER316L

2.4

DCEN

95-120

8-20

150-400

Cap

GTAW

ER316L

2.4

DCEN

95-120

8-20

150-400

You might also like

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla Reguii100% (1)

- Saudi Aramco Piping QC Inspector Sample Interview QuestionsDocument6 pagesSaudi Aramco Piping QC Inspector Sample Interview QuestionsRichard Periyanayagam90% (10)

- Wilhelm WPS - WH-WPS-012 - WH-WPS-055Document70 pagesWilhelm WPS - WH-WPS-012 - WH-WPS-055Elgen Igloria100% (3)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman67% (3)

- QW-482 201.1Document2 pagesQW-482 201.1Barwin Cruz100% (1)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki Hasya100% (1)

- WPS Sa 335 P91 PipeDocument3 pagesWPS Sa 335 P91 Pipecsankarananth67% (3)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingPutry NHy Saya0% (1)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Welder Qualification TemplateDocument1 pageWelder Qualification TemplatewentropremNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNo ratings yet

- WPQ FormatDocument1 pageWPQ FormatTridib Dey100% (1)

- Quality Control QuestionerDocument31 pagesQuality Control QuestionerKaukab Imam88% (42)

- Piping Inspector QuestionsDocument10 pagesPiping Inspector QuestionsRichard Periyanayagam100% (2)

- WPS-PQR Gmaw LtiDocument2 pagesWPS-PQR Gmaw Ltibgonzalez198150% (2)

- Wps A53 SMAW+GTAW R00Document3 pagesWps A53 SMAW+GTAW R00Richard Periyanayagam33% (3)

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (4)

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio Gomez100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad Daniel100% (2)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- WPQT CertificateDocument104 pagesWPQT CertificateMaged Lotfy Abdel-aal100% (3)

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (2)

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Alum 6xxx PwpsDocument1 pageAlum 6xxx PwpsAbu Zahid100% (1)

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- WPQ FormatDocument8 pagesWPQ FormatsanjaykumarmauryaNo ratings yet

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar78% (9)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Chem-Wps - PQR - WPQ-004 CS-SS 08-08 GtawDocument5 pagesChem-Wps - PQR - WPQ-004 CS-SS 08-08 Gtawvijay padaleNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- WPS PQR 12Document9 pagesWPS PQR 12Ranjan KumarNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (2)

- WPS Multi GMAW FCAW PDFDocument2 pagesWPS Multi GMAW FCAW PDFwentroprem75% (4)

- WPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWDocument1 pageWPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWRaja HoneNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- APSM WPS 008R Rev. 0Document3 pagesAPSM WPS 008R Rev. 0Amir NorNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- WPS - 020Document15 pagesWPS - 020MAT-LION100% (2)

- Wps PQR PDFDocument35 pagesWps PQR PDFquality unifab83% (6)

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- WPS GmawDocument2 pagesWPS Gmawasikur100% (7)

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Wps Magi Tig ExempleDocument6 pagesWps Magi Tig ExempleDanem HalasNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (2)

- Al Jalhami Cont. & Trad. Co.: Qa/QcDocument2 pagesAl Jalhami Cont. & Trad. Co.: Qa/QcRichard PeriyanayagamNo ratings yet

- QC-wps-06 Rev. 0 A283 GR.C Tank 130Document2 pagesQC-wps-06 Rev. 0 A283 GR.C Tank 130Richard PeriyanayagamNo ratings yet

- Request For Inspection: Saudi Aramco Project Inspection Division Inspection DepartmentDocument1 pageRequest For Inspection: Saudi Aramco Project Inspection Division Inspection DepartmentRichard Periyanayagam100% (2)

- Piping Engineer 2019Document8 pagesPiping Engineer 2019Richard Periyanayagam0% (1)

- Twi India Cswip Fee 2017Document4 pagesTwi India Cswip Fee 2017kamal100% (1)

- Some Imp NotesDocument5 pagesSome Imp NotesRichard PeriyanayagamNo ratings yet

- What Is QualityDocument3 pagesWhat Is Qualitysubhash kumar1958100% (2)

- Safco Welding SummryDocument148 pagesSafco Welding SummryRichard PeriyanayagamNo ratings yet

- Aramco Questions. Coating & WeldingDocument1 pageAramco Questions. Coating & WeldingRichard Periyanayagam100% (1)

- Yearly Prayer TimesDocument2 pagesYearly Prayer TimesRichard PeriyanayagamNo ratings yet

- PT Request28janDocument3 pagesPT Request28janRichard PeriyanayagamNo ratings yet

- Pmirequest 11febDocument8 pagesPmirequest 11febRichard PeriyanayagamNo ratings yet

- Request For Inspection: Rfi No: Abis-Mech-Yr/72Document7 pagesRequest For Inspection: Rfi No: Abis-Mech-Yr/72Richard PeriyanayagamNo ratings yet

- (If Applicable) : NON Conformance Report/ Corrective Preventive Action RequestDocument1 page(If Applicable) : NON Conformance Report/ Corrective Preventive Action RequestRichard Periyanayagam100% (1)

- Cleartrip Flight E-TicketDocument1 pageCleartrip Flight E-TicketRichard PeriyanayagamNo ratings yet

- Daily Fit-Up/Welding Inspection ReportDocument7 pagesDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNo ratings yet

- Abdullah A. Al Barrak & Sons Co.: Inspection Work Sheet (IWS) For Monomer and Polymer AreaDocument1 pageAbdullah A. Al Barrak & Sons Co.: Inspection Work Sheet (IWS) For Monomer and Polymer AreaRichard PeriyanayagamNo ratings yet

- Ch2 Fluid Statics: - Fluid Either at Rest or Moving in ADocument24 pagesCh2 Fluid Statics: - Fluid Either at Rest or Moving in ARichard Periyanayagam100% (1)

- Bill of Quantity For LP Separator Walkway and StaircaseDocument1 pageBill of Quantity For LP Separator Walkway and StaircaseRichard PeriyanayagamNo ratings yet

- Daily Fit-Up/Welding Inspection ReportDocument7 pagesDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNo ratings yet

- ITP For LpseperatorDocument2 pagesITP For LpseperatorRichard PeriyanayagamNo ratings yet

- 6.5exit Letter PDFDocument1 page6.5exit Letter PDFRichard PeriyanayagamNo ratings yet

- Installation of Interconnecting Walkway With Stairs Between Inlet Separators V-0701 A/B/C at Fdp-1Document1 pageInstallation of Interconnecting Walkway With Stairs Between Inlet Separators V-0701 A/B/C at Fdp-1Richard PeriyanayagamNo ratings yet

- Qa/Qc Dossier Qa/Qc Dossier: VOL: 1 - 5 VOL: 2 - 5Document3 pagesQa/Qc Dossier Qa/Qc Dossier: VOL: 1 - 5 VOL: 2 - 5Richard PeriyanayagamNo ratings yet

- Attachment A - Coatings Applicator Qualification Report: Blasting Test Application TestDocument3 pagesAttachment A - Coatings Applicator Qualification Report: Blasting Test Application TestRichard PeriyanayagamNo ratings yet

- Exit LetterDocument1 pageExit LetterRichard PeriyanayagamNo ratings yet

- SL - NO. Joint No. Joint Description Joint Preparation 10RTR-BW-001 10RTR-BW-002 10RTR-TA-003Document2 pagesSL - NO. Joint No. Joint Description Joint Preparation 10RTR-BW-001 10RTR-BW-002 10RTR-TA-003Richard PeriyanayagamNo ratings yet

- Request For Inspection: Kgoc AgocDocument2 pagesRequest For Inspection: Kgoc AgocRichard PeriyanayagamNo ratings yet