Sic 639

Sic 639

Uploaded by

allradCopyright:

Available Formats

Sic 639

Sic 639

Uploaded by

allradOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Sic 639

Sic 639

Uploaded by

allradCopyright:

Available Formats

SiC639

www.vishay.com

Vishay Siliconix

50 A VRPower® Integrated Power Stage

DESCRIPTION FEATURES

The SiC639 are integrated power stage solutions optimized • Thermally enhanced PowerPAK® MLP55-31L

for synchronous buck applications to offer high current, high package

efficiency, and high power density performance. Packaged • Vishay’s Gen IV MOSFET technology and a low

in Vishay’s proprietary 5 mm x 5 mm MLP package, SiC639 side MOSFET with integrated Schottky diode

enables voltage regulator designs to deliver up to 50 A • Delivers up to 50 A continuous current

continuous current per phase.

• High efficiency performance

The internal power MOSFETs utilizes Vishay’s

• High frequency operation up to 1.5 MHz

state-of-the-art Gen IV TrenchFET technology that delivers

industry benchmark performance to significantly reduce • Power MOSFETs optimized for 19 V input stage

switching and conduction losses. • 3.3 V / 5 V PWM logic with tri-state and hold-off

The SiC639 incorporate an advanced MOSFET gate driver • Zero current detect control for light load efficiency

IC that features high current driving capability, adaptive improvement

dead-time control, an integrated bootstrap Schottky diode, • Low PWM propagation delay (< 20 ns)

a thermal warning (THWn) that alerts the system of

• Faster disable

excessive junction temperature, and zero current detection

to improve light load efficiency. The drivers are also • Thermal monitor flag

compatible with a wide range of PWM controllers and • Under voltage lockout for VCIN

supports tri-state PWM, 3.3 V / 5 V PWM logic. • Material categorization: for definitions of compliance

please see www.vishay.com/doc?99912

APPLICATIONS

• Multi-phase VRDs for computing, graphics card and

memory

• Intel IMVP-8/9 VRPower delivery

-VCORE, VGRAPHICS, VSYSTEM AGENT Skylake, Kabylake

platforms

-VCCGI for Apollo Lake platforms

• Up to 24 V rail input DC/DC VR modules

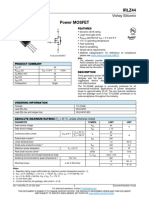

TYPICAL APPLICATION DIAGRAM

5V Input

VDRV

NC

V IN

BOOT

VCIN PHASE

ZCD_EN# Output

SW

DSBL# Gate

PWM

controller PWM driver

THWn

C GND

GL

PGND

Fig. 1 - SiC639 and SiC639A Typical Application Diagram

S18-0300-Rev. A, 19-Mar-18 1 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

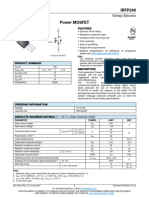

PINOUT CONFIGURATION

DSBL#

DSBL#

THWn

THWn

PGND

VDRV

PGND

VDRV

SW

SW

SW

SW

SW

SW

GL

GL

33

31 30 29 28 27 26 25 24 GL 24 25 26 27 28 29 30 31

PWM 1 23 VSWH VSWH 23 1 PWM

GL GL

ZCD_EN# 2 22 VSWH VSWH 22 2 ZCD_EN#

CGND 32

VCIN 3 21 VSWH VSWH 21 CGND 3 VCIN

CGND 4 20 VSWH VSWH 20 4 CGND

BOOT 5 PGND 19 VSWH VSWH 19 35 5 BOOT

PGND

N.C. 6 18 VSWH VSWH 18 6 N.C.

VIN 34

PHASE 7 17 VSWH VSWH 17 7 PHASE

VIN

VIN 8 16 VSWH VSWH 16 8 VIN

9 10 11 12 13 14 15 15 14 13 12 11 10 9

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

VIN

VIN

VIN

VIN

VIN

VIN

Top view Bottom view

Fig. 2 - SiC639 Pin Configuration

PIN CONFIGURATION

PIN NUMBER NAME FUNCTION

1 PWM PWM input logic

The ZCD_EN# pin enables or disables zero cross detection on inductor current when it detects

PWM = mid.

2 ZCD_EN#

When ZCD_EN# is LOW, GL stays on until ZCD detected when it detects PWM = mid.

When ZCD_EN# is HIGH, GL turns off when it detects PWM = mid.or PWM = 1

3 VCIN Supply voltage for internal logic circuitry

4, 32 CGND Signal ground

5 BOOT High side driver bootstrap voltage

6 N.C. Not connected internally, can be left floating or connected to ground

7 PHASE Return path of high side gate driver

8 to 11, 34 VIN Power stage input voltage. Drain of high side MOSFET

12 to 15, 28, 35 PGND Power ground

16 to 26 VSWH Phase node of the power stage

27, 33 GL Low side MOSFET gate signal

29 VDRV Supply voltage for internal gate driver

30 THWn Thermal warning open drain output

31 DSBL# Disable pin. Active low

ORDERING INFORMATION

PART NUMBER PACKAGE MARKING CODE OPTION

SiC639CD-T1-GE3 PowerPAK MLP55-31L SiC639 5 V PWM optimized

SiC639ACD-T1-GE3 PowerPAK MLP55-31L SiC639A 3.3 V PWM optimized

SiC639DB Reference board

S18-0300-Rev. A, 19-Mar-18 2 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

PART MARKING INFORMATION

= Pin 1 Indicator

P/N = Part Number Code

P/N = Siliconix Logo

= ESD Symbol

LL

F = Assembly Factory Code

Y = Year Code

FYWW

WW = Week Code

LL = Lot Code

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL PARAMETER CONDITIONS LIMIT UNIT

Input voltage VIN -0.3 to +30

Control logic supply voltage VCIN -0.3 to +7

Drive supply voltage VDRV -0.3 to +7

Switch node (DC voltage) -0.3 to +30

VSWH

Switch node (AC voltage) (1) -7 to +35

BOOT voltage (DC voltage) 35 V

VBOOT

BOOT voltage (AC voltage) (2) 40

BOOT to PHASE (DC voltage) -0.3 to +7

VBOOT-PHASE

BOOT to PHASE (AC voltage) (3) -0.3 to +8

All logic inputs and outputs

-0.3 to VCIN + 0.3

(PWM, DSBL#, and THWn)

Max. operating junction temperature TJ 150

Ambient temperature TA -40 to +125 °C

Storage temperature Tstg -65 to +150

Human body model, JESD22-A114 3000

Electrostatic discharge protection V

Charged device model, JESD22-C101 1000

Notes

• Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the

specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability

(1) The specification values indicated “AC” is V

SWH to PGND -8 V (< 20 ns, 10 μJ), min. and 35 V (< 50 ns), max.

(2) The specification value indicates “AC voltage” is V

BOOT to PGND, 40 V (< 50 ns) max.

(3) The specification value indicates “AC voltage” is V

BOOT to VPHASE, 8 V (< 20 ns) max.

RECOMMENDED OPERATING RANGE

ELECTRICAL PARAMETER MINIMUM TYPICAL MAXIMUM UNIT

Input voltage (VIN) 2.7 - 24

Drive supply voltage (VDRV) 4.5 5 5.5

V

Control logic supply voltage (VCIN) 4.5 5 5.5

BOOT to PHASE (VBOOT-PHASE, DC voltage) 4 4.5 5.5

Thermal resistance from junction to ambient - 10.6 -

°C/W

Thermal resistance from junction to case - 1.6 -

S18-0300-Rev. A, 19-Mar-18 3 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

ELECTRICAL SPECIFICATIONS

(DSBL# = ZCD_EN# = 5 V, VIN = 12 V, VDRV and VCIN = 5 V, TA = 25 °C)

LIMITS

PARAMETER SYMBOL TEST CONDITION UNIT

MIN. TYP. MAX.

POWER SUPPLY

VDSBL# = 0 V, no switching, VPWM = FLOAT - 5 -

Control logic supply current IVCIN VDSBL# = 5 V, no switching, VPWM = FLOAT - 300 - μA

VDSBL# = 5 V, fS = 300 kHz, D = 0.1 - 350 -

fS = 300 kHz, D = 0.1 - 9 14

mA

fS = 1 MHz, D = 0.1 - 30 -

Drive supply current IVDRV

VDSBL# = 0 V, no switching - 15 -

μA

VDSBL# = 5 V, no switching - 55 -

BOOTSTRAP SUPPLY

Bootstrap diode forward voltage VF IF = 2 mA 0.4 V

PWM CONTROL INPUT (SiC639)

Rising threshold VTH_PWM_R - - 4.2

Falling threshold VTH_PWM_F 0.72 - -

V

Tri-state voltage VTRI_FLOAT VPWM = FLOAT - 2.3 -

Tri-state window VTRI_WINDOW 1.38 - 3

Tri-state rising threshold hysteresis VHYS_TRI_R - 225 -

mV

Tri-state falling threshold hysteresis VHYS_TRI_F - 325 -

VPWM = 5 V, DSBL# = high - - 350

VPWM = 5 V, DSBL# = low - - 1

PWM input current IPWM μA

VPWM = 0 V, DSBL# = high - - -350

VPWM = 0 V, DSBL# = low - - -1

PWM CONTROL INPUT (SiC639A)

Rising threshold VTH_PWM_R - - 2.7

Falling threshold VTH_PWM_F 0.72 - -

V

Tri-state Voltage VTRI_FLOT VPWM = FLOAT - 1.8 -

Tri-state window VTRI_WINDOW 1.38 - 1.95

Tri-state rising threshold hysteresis VHYS_TRI_R - 250 -

mV

Tri-state falling threshold hysteresis VHYS_TRI_F - 300 -

VPWM = 3.3 V, DSBL# = high - - 225

VPWM = 3.3 V, DSBL# = low - - 1

PWM input current IPWM μA

VPWM = 0 V, DSBL# = high - - -225

VPWM = 0 V, DSBL# = low - - -1

TIMING SPECIFICATIONS

Tri-state to GH/GL rising

tPD_TRI_R - 30 -

propagation delay

Tri-state GH hold-off time tTSHO_GH - 35 -

Tri-state GL hold-off time tTSHO_GL - 130 -

GH - turn off propagation delay tPD_OFF_GH - 15 -

No load, see fig. 4

GH - turn on propagation delay

tPD_ON_GH - 10 -

(dead time rising) ns

GL - turn off propagation delay tPD_OFF_GL - 13 -

GL - turn on propagation delay

tPD_ON_GL - 10 -

(dead time falling)

DSBL# Lo to GH/GL falling

tPD_DSBL#_F Fig. 5 - 15 -

propagation delay

PWM minimum on-time tPWM_ON_MIN 30 - -

S18-0300-Rev. A, 19-Mar-18 4 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

ELECTRICAL SPECIFICATIONS

(DSBL# = ZCD_EN# = 5 V, VIN = 12 V, VDRV and VCIN = 5 V, TA = 25 °C)

LIMITS

PARAMETER SYMBOL TEST CONDITION UNIT

MIN. TYP. MAX.

DSBL# ZCD_EN# INPUT

VIH_DSBL# Input logic high 2 - -

DSBL# logic input voltage

VIL_DSBL# Input logic low - - 0.8

V

VIH_ZCD_EN# Input logic high 2 - -

ZCD_EN# logic input voltage

VIL_ZCD_EN# Input logic low - - 0.8

PROTECTION

VCIN rising, on threshold - 3.7 4.1

Under voltage lockout VUVLO V

VCIN falling, off threshold 2.7 3.1 -

Under voltage lockout hysteresis VUVLO_HYST - 575 - mV

THWn flag set (2) TTHWn_SET - 160 -

THWn flag clear (2) TTHWn_CLEAR - 135 - °C

THWn flag hysteresis (2) TTHWn_HYST - 25 -

THWn output low VOL_THWn ITHWn = 2 mA - 0.02 - V

Notes

(1) Typical limits are established by characterization and are not production tested

(2) Guaranteed by design

DETAILED OPERATIONAL DESCRIPTION

PWM Input with Tri-state Function Diode Emulation Mode (ZCD_EN#)

The PWM input receives the PWM control signal from the VR When ZCD_EN# pin is driven below VIL_ZCD_EN# diode

controller IC. The PWM input is designed to be compatible emulation mode is enabled. If the PWM input is wi thin the

with standard controllers using two state logic (H and L) and tri-state window for longer than the tri-state hold off time,

advanced controllers that incorporate tri-state logic (H, L then the low side MOSFET is under control of the ZCD (zero

and tri-state) on the PWM output. For two state logic, the crossing detect) comparator. In this mode, the LS MOSFET

PWM input operates as follows. When PWM is driven above is turned off if the inductor current is < or = 0. Light load

VPWM_TH_R the low side is turned OFF and the high side is efficiency is improved by avoiding discharge of output

turned ON. When PWM input is driven below VPWM_TH_F the capacitors. If ZCD_EN# is high, diode emulation mode is

high side is turned OFF and the low side is turned ON. For disabled. In this mode if PWM enters tri-state, the device will

tri-state logic, the PWM input operates as previously stated go into tri-state mode after tri-state delay and both the high

for driving the MOSFETs when PWM is logic high and logic side and low side MOSFETs will be turned off.

low. However, there is a third state that is entered as the

Thermal Shutdown Warning (THWn)

PWM output of tri-state compatible controller enters its high

impedance state during shut-down. The high impedance The THWn pin is an open drain signal that flags the presence

state of the controller’s PWM output allows the SiC639 and of excessive junction temperature. Connect with a

SiC639A to pull the PWM input into the tri-state region (see maximum of 20 k, to VCIN. An internal temperature sensor

definition of PWM logic and Tri-State, fig. 4). If the PWM detects the junction temperature. The temperature

input stays in this region for the Tri-state Hold-Off Period, threshold is 160 °C. When this junction temperature is

tTSHO, both high side and low side MOSFETs are turned exceeded the THWn flag is set. When the junction

OFF. The function allows the VR phase to be disabled temperature drops below 135 °C the device will clear the

without negative output voltage swing caused by inductor THWn signal. The SiC639 and SiC639A do not stop

ringing and saves a Schottky diode clamp. The PWM and operation when the flag is set. The decision to shutdown

tri-state regions are separated by hysteresis to prevent false must be made by an external thermal control function.

triggering. Voltage Input (VIN)

Disable (DSBL#) This is the power input to the drain of the high side power

In the low state, the DSBL# pin shuts down the driver IC MOSFET. This pin is connected to the high power

and disables both high-side and low side MOSFETs. intermediate BUS rail.

WhenDSBL# is low, the PWM resistor divider is also

disconnected. In this state, standby current is minimized. If

DSBL# is left unconnected, an internal pull-down resistor

will pull the pin to CGND and shut down the IC.

S18-0300-Rev. A, 19-Mar-18 5 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

Switch Node (VSWH and PHASE) Bootstrap Circuit (BOOT)

The switch node, VSWH, is the circuit power stage output. The internal bootstrap diode and an external bootstrap

This is the output applied to the power inductor and output capacitor form a charge pump that supplies voltage to the

filter to deliver the output for the buck converter. The PHASE BOOT pin. An integrated bootstrap diode is incorporated so

pin is internally connected to the switch node VSWH. This pin that only an external capacitor is necessary to complete the

is to be used exclusively as the return pin for the BOOT bootstrap circuit. Connect a boot strap capacitor with one

capacitor. A 20 k resistor is connected between GH leg tied to BOOT pin and the other tied to PHASE pin.

(the high side gate) and PHASE to provide a discharge path

Shoot-Through Protection and Adaptive Dead Time

for the HS MOSFET in the event that VCIN goes to zero while

VIN is still applied. The SiC639 and SiC639A have an internal adaptive logic to

avoid shoot through and optimize dead time. The shoot

Ground Connections (CGND and PGND) through protection ensures that both high side and low side

PGND (power ground) should be externally connected MOSFETs are not turned ON at the same time. The adaptive

to CGND (signal ground). The layout of the printed circuit dead time control operates as follows. The high side and low

board should be such that the inductance separating CGND side gate voltages are monitored to prevent the MOSFET

and PGND is minimized. Transient differences due to turning ON from tuning ON until the other MOSFET's gate

inductance effects between these two pins should not voltage is sufficiently low (< 1 V). Built in delays also ensure

exceed 0.5 V that one power MOSFET is completely OFF, before the other

can be turned ON. This feature helps to adjust dead time as

Control and Drive Supply Voltage Input (VDRV, VCIN)

gate transitions change with respect to output current and

VCIN is the bias supply for the gate drive control IC. VDRV is temperature.

the bias supply for the gate drivers. It is recommended to

separate these pins through a resistor. This creates a low Under Voltage Lockout (UVLO)

pass filtering effect to avoid coupling of high frequency gate During the start up cycle, the UVLO disables the gate

drive noise into the IC. drive holding high side and low side MOSFET gates low

until the supply voltage rail has reached a point at which

the logic circuitry can be safely activated. The SiC639,

SiC639A also incorporates logic to clamp the gate drive

signals to zero when the UVLO falling edge triggers the

shutdown of the device. As an added precaution, a 20 k

resistor is connected between GH (the high side gate) and

PHASE to provide a discharge path for the HS MOSFET.

FUNCTIONAL BLOCK DIAGRAM

THWn BOOT V IN

VDRV

Thermal monitor

& warning

VCIN UVLO

DISB#

VCIN

- 20K

+ PHASE

DISB PWM logic Anti-cross Vref = 1 V

control & conduction GL

state control SW

machine logic -

+

PWM Vref = 1 V

VDRV

DISB

CGND

SW

PGND

ZCD_EN# GL PGND

Fig. 3 - SiC639 Functional Block Diagram

S18-0300-Rev. A, 19-Mar-18 6 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

DEVICE TRUTH TABLE

DSBL# ZCD_EN# PWM GH GL

H L H H L

H, IL > 0 A

H L H to mid L

L, IL < 0 A

H L L to mid L L

H L L L H

L X X L L

H H L L H

H H H H L

H H mid L L

PWM TIMING DIAGRAM

Fig. 4 - Timing Diagram

DSBL# PROPAGATION DELAY

PWM PWM

DSBL# Disable DSBL#

GH GH

GL GL

t t

DSBL#Low to GH Falling Propagation Delay DSBL# Low to GL Falling Propagation Delay

Fig. 5 - DSBL# Falling Propagation Delay

S18-0300-Rev. A, 19-Mar-18 7 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

ELECTRICAL CHARACTERISTICS

Test condition: VIN = 13 V, DSBL# = VDRV = VCIN = 5 V, ZCD_EN# = 5 V, VOUT = 1 V, LOUT = 250 nH (DCR = 0.32 m), TA = 25 °C,

natural convection cooling (All power loss and normalized power loss curves show SiC639 and SiC639A losses only unless otherwise stated)

94 55

90 50

86 45

500 kHz

500 kHz

Output Current, IOUT (A)

750 kHz

82 40

Efficiency (%)

1 MHz

1 MHz

78 35

74 30

70 25

Complete converter efficiency

66 PIN = [(VIN x IIN) + 5 V x (IVDRV + IVCIN)] 20

POUT = VOUT x IOUT, measured at output capacitor

62 15

0 5 10 15 20 25 30 35 40 45 50 0 15 30 45 60 75 90 105 120 135 150

Output Current, IOUT (A) PCB Temperature, TPCB (°C)

Fig. 6 - Efficiency vs. Output Current (VIN = 12.6 V) Fig. 9 - Safe Operating Area

5.0 16.0

IOUT = 25A

4.5 14.0

Power Loss, PL (W)

4.0 12.0

Power Loss, PL (W)

3.5 10.0

1 MHz

3.0 8.0

2.5 6.0 750 kHz

2.0 4.0

1.5 2.0 500 kHz

1.0 0.0

200 300 400 500 600 700 800 900 1000 1100 0 5 10 15 20 25 30 35 40 45

Switching Frequency, fs (KHz) Output Current, IOUT (A)

Fig. 7 - Power Loss vs. Switching Frequency (VIN = 12.6 V) Fig. 10 - Power Loss vs. Output Current (VIN = 12.6 V)

98 94

500 kHz

500 kHz

94 90

90

86

Efficiency (%)

86

82

Efficiency (%)

82 750 kHz 750 kHz

1 MHz 78 1 MHz

78

74

74

70

70

Complete converter efficiency Complete converter efficiency

PIN = [(VIN x IIN) + 5 V x (IVDRV + IVCIN)] 66 PIN = [(VIN x IIN) + 5 V x (IVDRV + IVCIN)]

66

POUT = VOUT x IOUT, measured at output capacitor POUT = VOUT x IOUT, measured at output capacitor

62 62

0 5 10 15 20 25 30 35 40 45 50 0 5 10 15 20 25 30 35 40 45 50

Output Current, IOUT (A) Output Current, IOUT (A)

Fig. 8 - Efficiency vs. Output Current (VIN = 9 V) Fig. 11 - Efficiency vs. Output Current (VIN = 19 V)

S18-0300-Rev. A, 19-Mar-18 8 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

ELECTRICAL CHARACTERISTICS

Test condition: VIN = 13 V, DSBL# = VDRV = VCIN = 5 V, ZCD_EN# = 5 V, VOUT = 1 V, LOUT = 250 nH (DCR = 0.32 m), TA = 25 °C,

natural convection cooling (All power loss and normalized power loss curves show SiC639 and SiC639A losses only unless otherwise stated)

4.2 0.40

4.0 0.35

IF = 2 mA

BOOT Diode Forward Voltage, VF (V)

Control Logic Supply Voltage, VCIN (V)

3.8 VUVLO_RISING 0.30

3.6 0.25

3.4 0.20

3.2 0.15

3.0 VUVLO_FALLING 0.10

2.8 0.05

2.6 0.00

-60 -40 -20 0 20 40 60 80 100 120 140 -60 -40 -20 0 20 40 60 80 100 120 140

Temperature (°C) Temperature (°C)

Fig. 12 - UVLO Threshold vs. Temperature Fig. 15 - Boot Diode Forward Voltage vs. Temperature

3.20 3.20

2.85 2.85

Control Logic Supply Voltage, VPWM (V)

PWM Threshold Voltage, VPWM (V)

VTH_PWM_R

VTH_PWM_R

2.50 2.50

VTRI_TH_F

VTRI_TH_F

2.15 2.15

1.80 1.80

VTRI VTRI

1.45 VTRI_TH_R 1.45

VTRI_TH_R

1.10 1.10

0.75 VTH_PWM_F 0.75

VTH_PWM_F

0.40 0.40

-60 -40 -20 0 20 40 60 80 100 120 140 4.5 4.6 4.7 4.8 4.9 5.0 5.1 5.2 5.3 5.4 5.5

Temperature (°C) Driver Supply Voltage, VCIN (V)

Fig. 13 - PWM Threshold vs. Temperature (SiC639A) Fig. 16 - PWM Threshold vs. Driver Supply Voltage (SiC639A)

5.0 5.00

4.5 4.50 VTH_PWM_R

PWM Threshold Voltage, VPWM (V)

VTH_PWM_R

4.0 4.00

Control Logic Supply Voltage, VPWM (V)

3.5 3.50

VTRI_TH_F

3.0 VTRI_TH_F 3.00

VTRI VTRI

2.5 2.50

2.0 2.00

1.5 VTRI_TH_R 1.50 VTRI_TH_R

1.0 1.00

VTH_PWM_F VTH_PWM_F

0.5 0.50

0.0 0

-60 -40 -20 0 20 40 60 80 100 120 140 4.5 4.6 4.7 4.8 4.9 5.0 5.1 5.2 5.3 5.4 5.5

Temperature (°C) Driver Supply Voltage, VCIN (V)

Fig. 14 - PWM Threshold vs. Temperature (SiC639) Fig. 17 - PWM Threshold vs. Driver Supply Voltage (SiC639)

S18-0300-Rev. A, 19-Mar-18 9 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

ELECTRICAL CHARACTERISTICS

Test condition: VIN = 13 V, DSBL# = VDRV = VCIN = 5 V, ZCD_EN# = 5 V, VOUT = 1 V, LOUT = 250 nH (DCR = 0.32 m), TA = 25 °C,

natural convection cooling (All power loss and normalized power loss curves show SiC639 and SiC639A losses only unless otherwise stated)

1.7 2.20

1.6 VIH_DSBL# 2.00

DSBL# Threshold Voltage, VDSBL# (V)

ZCD_EN# Threshold Voltage, VZCD_EN# (V)

1.5 1.80

VIH_ZCD_EN#_R

1.4 1.60

1.3 1.40

1.2 1.20

1.1 1.00 VIL_ZCD_EN#_F

1.0 VIL_DSBL# 0.80

0.9 0.60

-60 -40 -20 0 20 40 60 80 100 120 140 4.5 4.6 4.7 4.8 4.9 5.0 5.1 5.2 5.3 5.4 5.5

Temperature (°C) Driver Supply Voltage, VCIN (V)

Fig. 18 - DSBL# Threshold vs. Temperature Fig. 21 - ZCD_EN# Threshold vs. Driver Supply Voltage

1.7 8

VDSBL# = 0 V

1.6 VIH_DSBL# 7

Driver Supply Current, IVDVR & IVCIN (V)

DSBL# Threshold Voltage, VDSBL# (V)

1.5 6

1.4 5

1.3 4

1.2 3

1.1 2

VIL_DSBL#

1.0 1

0.9 0

4.5 4.6 4.7 4.8 4.9 5.0 5.1 5.2 5.3 5.4 5.5 -60 -40 -20 0 20 40 60 80 100 120 140

Driver Supply Voltage, VCIN (V) Temperature (°C)

Fig. 19 - DSBL# vs. Driver Input Voltage Fig. 22 - Driver Shutdown Current vs. Temperature

10.8 340

Driver Supply Current, IVDVR & IVCIN (V)

10.7 330

DSBL# Pull-Down Current, IDSBL# (uA)

VPWM = FLOAT

10.6 320

10.5 310

10.4 300

10.3 290

10.2 280

10.1 270

10.0 260

-60 -40 -20 0 20 40 60 80 100 120 140 -60 -40 -20 0 20 40 60 80 100 120 140

Temperature (°C) Temperature (°C)

Fig. 20 - DSBL# Pull-Down Current vs. Temperature Fig. 23 - Driver Supply Current vs. Temperature

S18-0300-Rev. A, 19-Mar-18 10 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

PCB LAYOUT RECOMMENDATIONS

Step 1: VIN/GND Planes and Decoupling Step 3: VCIN/VDRV Input Filter

VSWH

CVDRV

P

G

N

D

PGND

VIN CVCIN

CGND

VIN plane

PGND plane

1. Layout VIN and PGND planes as shown above 1. The VCIN/VDRV input filter ceramic cap should be placed

2. Ceramic capacitors should be placed right between VIN very close to IC. It is recommended to connect two caps

and PGND, and very close to the device for best separately.

decoupling effect 2. CVCIN cap should be placed between pin 3 and pin 4

3. Difference values / packages of ceramic capacitors (CGND of driver IC) to achieve best noise filtering.

should be used to cover entire decoupling spectrum e.g. 3. CVDRV cap should be placed between pin 28 (PGND of

1210, 0805, 0603 and 0402 driver IC) and pin 29 to provide maximum instantaneous

4. Smaller capacitance value, closer to device VIN pin(s) driver current for low side MOSFET during switching

- better high frequency noise absorbing cycle

Step 2: VSWH Plane 4. For connecting CVCIN analog ground, it is recommended

to use large plane to reduce parasitic inductance.

Step 4: BOOT Resistor and Capacitor Placement

VVSWH

SWH

Snubber

Cboot

Rboot

PPGND

GND plane

Plane

1. Connect output inductor to DrMOS with large plane to

lower the resistance 1. These components need to be placed very close to IC,

2. If any snubber network is required, place the right between PHASE (pin 7) and BOOT (pin 5).

components as shown above and the network can be 2. To reduce parasitic inductance, chip size 0402 can be

placed at bottom used.

S18-0300-Rev. A, 19-Mar-18 11 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

Step 5: Signal Routing

1. Thermal relief vias can be added on the VIN and PGND

CGND pads to utilize inner layers for high current and thermal

dissipation.

CGND 2. To achieve better thermal performance, additional vias

can be put on VIN plane and PGND plane.

3. VSWH pad is a noise source and not recommended to put

vias on this plane.

4. 8 mil drill for pads and 10 mils drill for plane can be the

optional via size. Vias on pad may drain solder during

assembly and cause assembly issue. Please consult

with the assembly house for guideline.

Step 7: Ground Connection

PGND CGND

VSWH

1. Route the PWM / ZCD_EN# / DSBL# / THWn signal

traces out of the top left corner next DrMOS pin 1.

2. PWM signal is very important signal, both signal and PGND

return traces need to pay special attention of not letting

this trace cross any power nodes on any layer.

3. It is best to “shield” traces form power switching nodes,

e.g. VSWH, to improve signal integrity.

4. GL (pin 27) has been connected with GL pad internally

and does not need to connect externally.

Step 6: Adding Thermal Relief Vias 1. It is recommended to make single connection between

CGND and PGND and this connection can be done on top

layer.

2. It is recommended to make the whole inner 1 layer (next

to top layer) ground plane and separate them into CGND

and PGND plane.

VSWH 3. These ground planes provide shielding between noise

source on top layer and signal trace on bottom layer.

CGND

PGND

VIN

PGND

plane

VIN plane

S18-0300-Rev. A, 19-Mar-18 12 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

SiC639

www.vishay.com

Vishay Siliconix

Multi-Phases VRPower PCB Layout

Following is an example for 6 phase layout. As can be seen, all the VRPower stages are lined in X-direction compactly with

decoupling caps next to them. The inductors are placed as close as possible to the SiC639 and SiC639A to minimize the PCB

copper loss. Vias are applied on all PADs (VIN, PGND, CGND) of the SiC639 and SiC639A to ensure that both electrical and thermal

performance are excellent. Large copper planes are used for all the high current loops, such as VIN, VSWH, VOUT and PGND. These

copper planes are duplicated in other layers to minimize the inductance and resistance. All the control signals are routed from

the SiC639 and SiC639A to a controller placed to the north of the power stage through inner layers to avoid the overlap of high

current loops. This achieves a compact design with the output from the inductors feeding a load located to the south of the

design as shown in the figure.

VIN

PGND

VOUT

Fig. 24 - Multi - Phase VRPower Layout Top View

VIN

PGND

VOUT

Fig. 25 - Multi - Phase VRPower Layout Bottom View

Vishay Siliconix maintains worldwide manufacturing capability. Products may be manufactured at one of several qualified locations. Reliability data for Silicon

Technology and Package Reliability represent a composite of all qualified locations. For related documents such as package / tape drawings, part marking, and

reliability data, see www.vishay.com/ppg?76585.

S18-0300-Rev. A, 19-Mar-18 13 Document Number: 76585

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Package Information

www.vishay.com

Vishay Siliconix

PowerPAK® MLP55-31L Case Outline

5 6 0.08 C D2-5 K12

Pin 1 dot 2x A K7

by marking K1 D2- 1

A 0.10 C A A1

D K4

F2

2x D2-4

F1

A2

K8

0.10 C B 24 31

E2-4

K11

23 1

K5 E2- 1

0.10 m C A B

K6

K3

K10

(Nd-1) xe

MLP55-31L

ref.

(5 mm x 5 mm)

E

E2- 3

E2- 2

e

4

16 8

b

B

L

15 K2 9

C D2- 3 D2- 2

K9

(Nd-1) x e

ref.

Top view Side view Bottom view

MILLIMETERS INCHES

DIM.

MIN. NOM. MAX. MIN. NOM. MAX.

A (8) 0.70 0.75 0.80 0.027 0.029 0.031

A1 0.00 - 0.05 0.000 - 0.002

A2 0.20 ref. 0.008 ref.

b (4) 0.20 0.25 0.30 0.008 0.010 0.012

D 4.90 5.00 5.10 0.193 0.196 0.200

e 0.50 BSC 0.019 BSC

E 4.90 5.00 5.10 0.193 0.196 0.200

L 0.35 0.40 0.45 0.013 0.015 0.017

N (3) 32 32

Nd (3) 8 8

Ne (3) 8 8

D2-1 0.98 1.03 1.08 0.039 0.041 0.043

D2-2 0.98 1.03 1.08 0.039 0.041 0.043

D2-3 1.87 1.92 1.97 0.074 0.076 0.078

D2-4 0.30 BSC 0.012 BSC

D2-5 1.00 1.05 1.10 0.039 0.041 0.043

E2-1 1.27 1.32 1.37 0.050 0.052 0.054

E2-2 1.93 1.98 2.03 0.076 0.078 0.080

E2-3 3.75 3.80 3.82 0.148 0.150 0.152

E2-4 0.45 BSC 0.018 BSC

F1 0.20 BSC 0.008 BSC

F2 0.20 BSC 0.008 BSC

K1 0.67 BSC 0.026 BSC

K2 0.22 BSC 0.008 BSC

K3 1.25 BSC 0.049 BSC

K4 0.05 BSC 0.002 BSC

K5 0.38 BSC 0.015 BSC

K6 0.12 BSC 0.005 BSC

Revision: 24-Oct-16 1 Document Number: 64909

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Package Information

www.vishay.com

Vishay Siliconix

MILLIMETERS INCHES

DIM.

MIN. NOM. MAX. MIN. NOM. MAX.

K7 0.40 BSC 0.016 BSC

K8 0.40 BSC 0.016 BSC

K9 0.40 BSC 0.016 BSC

K10 0.85 BSC 0.033 BSC

K11 0.40 BSC 0.016 BSC

K12 0.40 BSC 0.016 BSC

ECN: T16-0644-Rev. E, 24-Oct-16

DWG: 6025

Notes

1. Use millimeters as the primary measurement

2. Dimensioning and tolerances conform to ASME Y14.5M. - 1994

3. N is the number of terminals,

Nd is the number of terminals in X-direction, and

Ne is the number of terminals in Y-direction

4. Dimension b applies to plated terminal and is measured between 0.20 mm and 0.25 mm from terminal tip

5. The pin #1 identifier must be existed on the top surface of the package by using indentation mark or other feature of package body

6. Exact shape and size of this feature is optional

7. Package warpage max. 0.08 mm

8. Applied only for terminals

Revision: 24-Oct-16 2 Document Number: 64909

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

PAD Pattern

www.vishay.com

Vishay Siliconix

Recommended Land Pattern

PowerPAK® MLP55-31L for SiC620, SiC620A

Top side transparent view

(not bottom view) Land pattern for MLP55-31L

(D2-4) 5

0.75

1.35 0.57

0.3

0.33

3.4

(D2-1) (D2-5) 31 0.5 1 24

31 1.03 1.05 24

0.75

1 (D3) 0.3

23 1.13

1 23

1.6

0.45

(E3)

0.85

0.3

0.5 (e)

0.35

(E2-2)

1.15

1.42

1.32

0.15

0.33

(K2) 0.22 2.02

1.75 0.3

(E2-1)

0.4

4.2

(K1) 0.67

3.5

5

3.05

0.07

0.25

2.15

(E2-3)

(b)

2.08

1.98

0.5

8 16 8 0.35 0.18 16

0.58

0.65

(L) 9 15 (L) 0.3

0.4 (D2-2) (D2-3) 0.4 9 15

0.35

0.3

1.03 1.92 0.35 0.5 0.75

0.5 0.65

All dimensions in millimeters

31 24

1 23

33

Component for MLP55-31L

32

35 Land pattern for MLP55-31L

33

8 16

9 15

Revision: 24-Jul-17 1 Document Number: 66944

For technical questions, contact: powerictechsupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of

typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding

statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular application.

Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over

time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk.

Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for

such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document

or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2017 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 08-Feb-17 1 Document Number: 91000

You might also like

- Cs301 Assignment SolutionDocument8 pagesCs301 Assignment Solutioncs619finalproject.com100% (1)

- Spare Parts CatalogueDocument419 pagesSpare Parts CatalogueClaudio Rafael Deola SadaNo ratings yet

- Movie Project PlanDocument14 pagesMovie Project PlanEris Perfect100% (1)

- Steam Trace Specification PDFDocument55 pagesSteam Trace Specification PDFPaulo CostaNo ratings yet

- Sic632, Sic632A: Vishay SiliconixDocument18 pagesSic632, Sic632A: Vishay SiliconixŁukasz SrogaNo ratings yet

- Sic 632Document19 pagesSic 632techgamebr85No ratings yet

- Sic 789 ADocument19 pagesSic 789 AFlorinMacoveiNo ratings yet

- Sic 634Document17 pagesSic 634Tri Nguyen Real EstateNo ratings yet

- Sic 631Document19 pagesSic 631djavus123 djNo ratings yet

- Sic 533Document16 pagesSic 533Tri Nguyen Real EstateNo ratings yet

- Sic780, Sic780A: Vishay SiliconixDocument14 pagesSic780, Sic780A: Vishay SiliconixBoris ȚepeșNo ratings yet

- Datasheet NCP81109Document28 pagesDatasheet NCP81109zigmund zigmundNo ratings yet

- Sllsec 4Document29 pagesSllsec 4solihinNo ratings yet

- Sic417-Buck ConverterDocument22 pagesSic417-Buck ConverterengenheirodiasNo ratings yet

- LM 5574Document31 pagesLM 5574KholilNo ratings yet

- 5-V Can Transceiver With I/O Level Shifting and Low-Power Mode Supply OptimizationDocument22 pages5-V Can Transceiver With I/O Level Shifting and Low-Power Mode Supply OptimizationMurilo MarquesNo ratings yet

- NCP81251 Single-Phase Voltage Regulator With SVID Interface For Computing ApplicationsDocument18 pagesNCP81251 Single-Phase Voltage Regulator With SVID Interface For Computing Applicationsankur rathiNo ratings yet

- Irlz 44Document8 pagesIrlz 44entNo ratings yet

- Irf 9640Document8 pagesIrf 9640Saeid AbraziNo ratings yet

- Irfp 360Document10 pagesIrfp 360movick.25No ratings yet

- MosfetsDocument22 pagesMosfetsWillie TanyuNo ratings yet

- Irfp 250Document10 pagesIrfp 250bando janson purbaNo ratings yet

- IRFPG50Document11 pagesIRFPG50RuslanNo ratings yet

- NCV59749 D-2317605Document12 pagesNCV59749 D-2317605Adrian WongNo ratings yet

- Aoz5311nqi PDFDocument17 pagesAoz5311nqi PDFJohn InfinityNo ratings yet

- Irfp 240Document10 pagesIrfp 240Junior JuniorNo ratings yet

- NCV7357 CAN FD Transceiver, High Speed: DescriptionDocument16 pagesNCV7357 CAN FD Transceiver, High Speed: DescriptionJose Otilio Chavez CantuNo ratings yet

- 2-4 Cell Li+ Battery Smbus Charge Controller With N-Channel Power Mosfet Selector and Advanced Circuit ProtectionDocument41 pages2-4 Cell Li+ Battery Smbus Charge Controller With N-Channel Power Mosfet Selector and Advanced Circuit Protectionarranguezjr5991No ratings yet

- BQ 24725Document43 pagesBQ 24725Diyan Budi SNo ratings yet

- Synchronous Buck Nexfet Power Block: Features DescriptionDocument22 pagesSynchronous Buck Nexfet Power Block: Features DescriptionRawi MontillaNo ratings yet

- Vishay Siliconix: FeaturesDocument7 pagesVishay Siliconix: Featuresمركز القدسNo ratings yet

- Tidue 54 BDocument71 pagesTidue 54 BCương PhạmNo ratings yet

- Irfp 9240Document11 pagesIrfp 9240NaderNo ratings yet

- 1700v Scale-Idriver Family DatasheetDocument24 pages1700v Scale-Idriver Family DatasheetpotykaNo ratings yet

- AOZ5311NQIDocument18 pagesAOZ5311NQIShareduwan SannosiNo ratings yet

- Irfp460B, Sihg460B: Vishay SiliconixDocument9 pagesIrfp460B, Sihg460B: Vishay SiliconixNguyễn ThứcNo ratings yet

- AOZ5312NQIDocument17 pagesAOZ5312NQISamuel tuñonNo ratings yet

- Tsop 752 WDocument13 pagesTsop 752 WMatias RendonNo ratings yet

- DSASFU60008070Document21 pagesDSASFU60008070Orlando MendiolarNo ratings yet

- ISL6455 RenesasDocument13 pagesISL6455 RenesasArief MandolloNo ratings yet

- Green Mode Power Switch For Valley Switching Converter - Low EMI and High Efficiency FSQ0365, FSQ0265, FSQ0165, FSQ321Document22 pagesGreen Mode Power Switch For Valley Switching Converter - Low EMI and High Efficiency FSQ0365, FSQ0265, FSQ0165, FSQ321Mekkati MekkatiNo ratings yet

- Data Sheet: TDA6111QDocument16 pagesData Sheet: TDA6111QNestor TorresNo ratings yet

- High Voltage Bootstrap High Side Driver Features: FN9087.2 Data Sheet July 25, 2005Document6 pagesHigh Voltage Bootstrap High Side Driver Features: FN9087.2 Data Sheet July 25, 2005Elves MattosNo ratings yet

- IRFR9310 VishaySiliconixDocument11 pagesIRFR9310 VishaySiliconixDimas AprlioNo ratings yet

- Irfz 48Document9 pagesIrfz 48Alexis GueraNo ratings yet

- LAB2Document21 pagesLAB2ORK BUNSOKRAKMUNYNo ratings yet

- Irfz 44Document9 pagesIrfz 44Harlan 123No ratings yet

- Isl95870ahruz TDocument28 pagesIsl95870ahruz TDede GunawanNo ratings yet

- SN65HVD1050Document19 pagesSN65HVD1050ZaegorNo ratings yet

- SC 2595Document12 pagesSC 2595Stelian DobreNo ratings yet

- An 4103Document16 pagesAn 4103taninavcoNo ratings yet

- SIP41109 VishaySiliconixDocument7 pagesSIP41109 VishaySiliconixEric Lenin Marin MoncadaNo ratings yet

- Drmos BLN01G52 Aoz5311 RTX3070Document18 pagesDrmos BLN01G52 Aoz5311 RTX3070techgamebr85No ratings yet

- High Voltage Bootstrap High Side Driver Features: FN9087.1 Data Sheet October 2002Document7 pagesHigh Voltage Bootstrap High Side Driver Features: FN9087.1 Data Sheet October 2002Joil AlvesNo ratings yet

- 1K 2.5V Dual Mode I C Serial EEPROM: Features Package TypesDocument12 pages1K 2.5V Dual Mode I C Serial EEPROM: Features Package TypesVictor TruccoNo ratings yet

- 24V, High Current Synchronous Buck Converter With +/-1.5A LDO and Buffed ReferenceDocument21 pages24V, High Current Synchronous Buck Converter With +/-1.5A LDO and Buffed Reference8ctanoNo ratings yet

- MCSG TA Biz Proposal PDFDocument24 pagesMCSG TA Biz Proposal PDFMartono Abu HanifNo ratings yet

- ncv7718b DDocument28 pagesncv7718b DanalgayNo ratings yet

- MP2212 r1.01Document14 pagesMP2212 r1.01Joseni FigueiredoNo ratings yet

- TSOP752.., TSOP754..: Vishay SemiconductorsDocument13 pagesTSOP752.., TSOP754..: Vishay SemiconductorsMaktum KamatNo ratings yet

- Irf 840 BDocument8 pagesIrf 840 BDerkis MarcanoNo ratings yet

- BQ 24725Document41 pagesBQ 24725Papanya Rovie N TsanyNo ratings yet

- Irfp054, Sihfp054: Vishay SiliconixDocument10 pagesIrfp054, Sihfp054: Vishay SiliconixEmanuelLanNo ratings yet

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- What Is Critical Infrastructure in The PhilippinesDocument3 pagesWhat Is Critical Infrastructure in The PhilippinesJuan Pablo JavarezNo ratings yet

- Assignment 2Document3 pagesAssignment 2Farah ThabitNo ratings yet

- Cryptography and Network SecurityDocument37 pagesCryptography and Network SecuritygnanalakshmiNo ratings yet

- Unit 5 Multiple Access TechniqueDocument57 pagesUnit 5 Multiple Access TechniqueVinamra KumarNo ratings yet

- UGRP Guidelines Students-2023Document6 pagesUGRP Guidelines Students-2023Rojan ShresthaNo ratings yet

- Impact of Social Media Marketing On Consumer Buying Behaviour: An Empirical StudyDocument10 pagesImpact of Social Media Marketing On Consumer Buying Behaviour: An Empirical StudyDivineNo ratings yet

- Wepik Securing The Digital Frontier Unleashing The Power of Cyber Security 20231218073242tAWzDocument14 pagesWepik Securing The Digital Frontier Unleashing The Power of Cyber Security 20231218073242tAWzpriyansh9462No ratings yet

- Module 3 - Basic Weblogic AdministrationDocument63 pagesModule 3 - Basic Weblogic AdministrationavinjoyNo ratings yet

- 256 Hibernate Interview Questions Answers GuideDocument12 pages256 Hibernate Interview Questions Answers GuidePrasant KumarNo ratings yet

- Image SegmentationDocument9 pagesImage SegmentationGURUDUTTA PALNo ratings yet

- CO4 - AUOPE Handouts - Risk AssessmentDocument6 pagesCO4 - AUOPE Handouts - Risk AssessmentTin CorderoNo ratings yet

- DP5 Practice Activities - AnswersDocument3 pagesDP5 Practice Activities - Answersgery sumual100% (1)

- Wireless Integrated Network Sensors (WINS) : CH - Srujana 17VE1A04K2Document16 pagesWireless Integrated Network Sensors (WINS) : CH - Srujana 17VE1A04K2soujanya soujNo ratings yet

- Dbms RecordDocument94 pagesDbms RecordChris Sosa JacobNo ratings yet

- Learngit AnswerhintDocument39 pagesLearngit AnswerhintBeket AmirkhanovNo ratings yet

- EhP 4, Support Packages Stacks, Etc...Document59 pagesEhP 4, Support Packages Stacks, Etc...jorsancoNo ratings yet

- Brosur Altec Lansing MX 6021Document2 pagesBrosur Altec Lansing MX 6021Adi AjaNo ratings yet

- Algorithms and Correctness Past PaperDocument7 pagesAlgorithms and Correctness Past PaperBilly GeneNo ratings yet

- Dr. HENG, Chun Huat Teaching Assistant Dr. BA MyintDocument7 pagesDr. HENG, Chun Huat Teaching Assistant Dr. BA MyintNixNo ratings yet

- Commented - GS Control Offer of LT PANELSDocument16 pagesCommented - GS Control Offer of LT PANELSGautam MishraNo ratings yet

- Toshiba Tecra A11 FHNSY1 A5A002688010 PDFDocument131 pagesToshiba Tecra A11 FHNSY1 A5A002688010 PDFvinuNo ratings yet

- A To Z About UpworkDocument20 pagesA To Z About UpworkA to ZNo ratings yet

- TST 20pa 2001 20cmsx 20workshopDocument17 pagesTST 20pa 2001 20cmsx 20workshopIsaias MartinezNo ratings yet

- Er 96 2 6 PDFDocument6 pagesEr 96 2 6 PDFCamilo Andres Cardozo FajardoNo ratings yet

- Why ISO 20000? Awareness Presentation: Subtitle or PresenterDocument14 pagesWhy ISO 20000? Awareness Presentation: Subtitle or PresenterRoberto Fabiano FernandesNo ratings yet

- An Intuitive Guide To Linear Algebra - BetterExplainedDocument25 pagesAn Intuitive Guide To Linear Algebra - BetterExplainedvkk intensiveNo ratings yet