Thread Inspection

Thread Inspection

Uploaded by

Ahmed MushtaqCopyright:

Available Formats

Thread Inspection

Thread Inspection

Uploaded by

Ahmed MushtaqOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Thread Inspection

Thread Inspection

Uploaded by

Ahmed MushtaqCopyright:

Available Formats

18-Jul-23 Threading Inspection 1

Thread Inspection

Casing:

•The terms Casing applies to pipe that is used to line the drilled hole to protect the

well from formation fluid flow or formation collapse.

Tubing:

•The term Tubing applies to the innermost pipe in a well. Well fluids are brought to

the surface through the tubing.

Threading

A machining process to form root and crest on the component to enable it to form

long gas tight string

Coupling

Component with Thread use to connect two part.

Thread inspection

Evaluation of Threading process to comply with API 5 B and API 5 B1

specification

18-Jul-23 Threading Inspection 2

Thread Inspection

Specifications and reference:

API 5 CT

Casing Size range 4½” to 20”

Tubing size range 1” to 4½”

Coupling for all product

API 5 B

•Specification for Threading, Gauging and Thread Inspection

of Casing, Tubing, and Line Pipe Threads.

API 5 B1

• Gauging and Inspection of Casing, Tubing, and Line Pipe Threads

18-Jul-23 Threading Inspection 3

Thread Inspection

Elements of Thread

Chamfer: The beveled surface, beginning at the end of the pipe or coupling, in

which the thread form starts

Crest: The top of the thread.

Root: The bottom of the thread.

Effective thread length: Designated as L2 for round thread This is the theoretical

point at which the vanish cone angle begins.

Full-crest thread length: The length measured parallel to the thread axis from the

end of the pipe to the first non full-crested thread.

Perfect thread length: The last perfect thread location on external threads.

Imperfect thread length: The buttress threads located beyond the L7 plane (away

from the pipe ends).

Standoff: A distance from coupling face to pipe thread vanish point

18-Jul-23 Threading Inspection 4

Thread Inspection

Elements of Thread

Height of thread: The distance between the root and crest of the thread measured

normal (perpendicular) to the thread axis.

Lead: The distance from a point on a thread to a corresponding point on the next

thread turn, measured parallel to the thread axis.

Pitch diameter: On a taper thread, the pitch diameter at a given position on the

thread axis is the diameter of the pitch cone at that position. On buttress threads, this

is midway between the major and minor diameter

Torque: A force that tends to produce rotation—the force causing a threaded

connection to makeup

18-Jul-23 Threading Inspection 5

Thread Inspection

Types of Threads

External Upset Tubing

Non Upset Tubing

Short Thread Casing

Long Thread Casing

Buttress Thread Casing

18-Jul-23 Threading Inspection 6

Thread Inspection

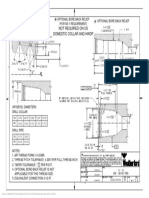

Elements of Thread - Round Tread Casing Tubing 8 RD LC

18-Jul-23 Threading Inspection 7

Thread Inspection

Elements of Thread - Round Tread Casing Tubing 8 RD LC

18-Jul-23 Threading Inspection 8

Thread Inspection

Elements of Thread – Buttress Tread Configuration up to 13 3/8 “ OD 5 TPI BC

18-Jul-23 Threading Inspection 9

Thread Inspection

Elements of Thread – Buttress Tread Configuration up to 13 3/8 “ OD 5 TPI BC

18-Jul-23 Threading Inspection 10

Thread Inspection

To Start With

•Request the product thread drawing or details of Threading parameter Production

order document is having all this information .

•Verify Required Measuring Gauges are available

•Verify inspection reports are available

•List all the gage serial numbers used to inspect the part

•Verify the ball contact sizes are correct

•Set the gages to a zero on a calibrated standard

•Clean thread with air remove any loose particle and burr on the thread profile

•Verify the thread form is correct

•Start the inspection

18-Jul-23 Threading Inspection 11

Thread Inspection

Ring and Plug Gauges to Measure Stand off

Deviation from Basic value is measured .

Ring gauge is used for External thread –

Casing and Tubing

Plug Gauge is used for Internal Threading -

Coupling

18-Jul-23 Threading Inspection 12

Thread Inspection

Thread Height Gauge

Align the gage base parallel to the

thread axis and tilt the base back and

Gauge setting ensure Zero on forth to obtain the lowest reading

master reference gauge by moving

backward and forward

•8 Round thread height = .072125”

•10 Round thread height = .05560”

•Buttress ¾”TPF thread height = .0620”

•Buttress 1”TPF thread height = .0620”

18-Jul-23 Threading Inspection 13

Thread Inspection

Thread Height Gauge

• Set Height Gauge using a setting Gauge Number TH-3002

standard

• Double check zero setting 1. Measure only within the perfect

• Start Measurement thread length. Perfect thread

length is labeled “L2” on the

product drawing.

2. Align the gage base parallel to

the thread axis and tilt the base

back and forth to obtain the

lowest reading.

8 Round thread height = .072125”

10 Round thread height = .05560”

Buttress ¾”TPF thread height = .0620”

Buttress 1”TPF thread height = .0620”

18-Jul-23 Threading Inspection 14

Thread Inspection

Thread Lead Gauge

Ensure Zero on master reference gauge by moving

gauge left/right in fixed distance 1inch or 2 inch

Place the fixed ball contact in the first full

depth thread. try to find out zero reading

record deviation

• Lead per inch +/-0.003”

•Cumulative Lead +/- 0.006”

18-Jul-23 Threading Inspection 15

Thread Inspection

Thread Lead Gauge

Measuring the part

Gauge Number LG-5002

Set using a Standard 1. Place the fixed ball contact in the first full depth

thread.

Double-check your zero setting

2. Move the fixed ball back one thread and check

Measure the part

again.

Compare the standard to the machined lead

3. Try to find out Zero or Deviation

18-Jul-23 Threading Inspection 16

Thread Inspection

Thread Taper Gauge

Set Zero reading at first thread Take

first reading at 5 or 8 TPI as per Thread

parameter by moving the dial pin in

thread root finding out gauge return

point repeat process two- three times

in same plan

There are two cone angles or tapers

Taper Per Foot -TPF

•All 8-round threads are ¾”

•Buttress sizes 4½”- 13⅜” are 1” TPF

•Buttress sizes 16”- 20” are 1” TPF

18-Jul-23 Threading Inspection 17

Thread Inspection

Thread Taper Gauge

Zero the dial on the first thread.

Do not lock the bezel clamp!

To inspect, move the gage up the taper 1”

(8-round = 8 threads, Buttress = 5 threads)

After moving back 1” up the taper, double-check

your radial position of the gage to the part or chuck

18-Jul-23 Threading Inspection 18

Thread Inspection

Thread MRP Gauge

Engage the fixed point in

starting thread try to find out

zero reading record deviation

18-Jul-23 Threading Inspection 19

Thread Inspection

Thread MRP Gauge

While holding

MRP-2001 the gage

is preset to sizeagainst the of

by the use part

“A”

face,

& “B”sweep left and right to find the

Rod Standards

largest indicator value. Then, rotate the “B”

gage 90° and repeat Standard

The MRP Shoe makes contact with the crest cone

“A” Standard

18-Jul-23 Threading Inspection 20

Thread Inspection

What we do with MRP Gauge

Largest and smallest indicator readings provide data for calculating Average Cone Diameter

(ACD) and Thread Ovality. They both use the same data but calculate the readings in

different ways.

Average Cone Diameter Ovality

The diameter of the part would be, How egg-shaped or out of round

if it were round LARGE

the pipe is

READING

(Largest Diameter - Smallest Diameter) = ACD Largest Diameter - Smallest Diameter = Ovality

2 SMALL

READING

Largest Smallest Averaged Largest Smallest

Ovality

Diameter Diameter Diameter Diameter Diameter

+.005 -.010 -.0025 +.005 -.010 .015

Largest Smallest Averaged Largest Smallest

Ovality

Diameter Diameter Diameter Diameter Diameter

-.005 -.010 -.0075 -.005 -.010 .005

Largest Smallest Averaged Largest Smallest

Ovality

Diameter Diameter Diameter Diameter Diameter

-.015 +.001 -.007 -.015 +.001 .016

18-Jul-23 Threading Inspection 21

Thread Inspection

Average Cone Diameter

Average Cone Diameter is the distance across the face of the pipe or coupling.

Determining the “round” diameter of a connector requires locating the largest and the smallest diameter

readings on the part and taking the average of these two readings.

LARGE

READING

SMALL

READING

Largest Smallest Averaged Largest Smallest Averaged

Diameter Diameter Diameter Diameter Diameter Diameter

+.005 -.010 -.0025 +.005 -.005 .000

18-Jul-23 Threading Inspection 22

Thread Inspection

Thread Ovality

Thread Ovality is the amount of out-of-roundness in a piece of pipe or a coupling. Determining

ovality requires locating the largest and the smallest diameter readings on the part and adding the

smallest reading to the largest reading. The ovality is the difference between these values. Ovality

readings are always positive (no sign attached).

LARGE

READING

SMALL

READING

Largest Smallest Total

Largest Smallest Total

Diameter Diameter Ovality

Diameter Diameter Ovality

+.005 -.010 .015 +.005 -.005 .010

18-Jul-23 Threading Inspection 23

Thread Inspection

Pin Length Inspection

Always keep the scale parallel to

the pipe axis.

L2=Perfect thread length. Crest of thread

L2 must have a full radius top.

L4

L4=Last scratch length.

18-Jul-23 Threading Inspection 24

Thread Inspection

Thread Form Inspection

TP-8R Profile inspecting pin and coupling thread. Always check the first starting thread.

Remember: When debarring the thread with a flapper wheel, burrs can be rolled into the thread groove. When the

connections are made up on the rig, burrs will cause galling Ensure

18-Jul-23 Threading Inspection 25

Thread Inspection

Coupling Thread Lead Inspection

Gauge number LG-5002

• Set Gauge to zero using a standard 1. Place the fixed ball contact in the first full

• Double check your zero setting depth thread.

2. Move the fixed ball back one thread and

check again.

3. Record measurement .

Remember: Each different taper requires a different lead setting standard

18-Jul-23 Threading Inspection 26

Thread Inspection

Coupling Thread Height Inspection

Set to zero using a standard

Double check your zero setting

Gauge number TH-3006

Thread Heights:

8-Round = .0721” 1. Align the gage parallel to the thread axis.

Buttress = .0620” 2. Lift up and down to obtain the lowest reading.

3. Record your measurement.

18-Jul-23 Threading Inspection 27

Thread Inspection

Coupling Taper Inspection

Gauge Number IT 6000

Zero the dial on the first thread.

Do not lock the bezel clamp!

Note the radial location of the gage to

the part or chuck.

(6 or 12 o’clock is best)

To inspect, move the gage down

the taper 1” or:

8 threads for 8-round

5 threads for Buttress

After moving 1” down the taper,

double check your radial position of

the gage to the part or chuck.

18-Jul-23 Threading Inspection 28

Thread Inspection

Coupling PD Inspection with an MRP-2002

(Crest Cone Diameter Inspection)

“B”

Standard

Gauge Number MRP-2002 is preset to size with the

use of “A” & “B” Rod Standards

While holding the gage against the part face,

sweep left & right to find the largest indicator

value

Rotate the gage 90° and repeat

“A”

Standard

18-Jul-23 Threading Inspection 29

Thread Inspection

Coupling Length Inspection

Q

“Q” is measured from the coupling face

to the start of the 35° chamfer.

Always keep the scale parallel to the

coupling axis.

NL/2 = ½ the coupling length.

NL/2

NL = Length of coupling.

Coupling Length (NL)

18-Jul-23 Threading Inspection 30

Thread Inspection

18-Jul-23 Threading Inspection 31

Thread Inspection

18-Jul-23 Threading Inspection 32

Thread Inspection

18-Jul-23 Threading Inspection 33

Thread Inspection

18-Jul-23 Threading Inspection 34

Thread Inspection

18-Jul-23 Threading Inspection 35

Thread Inspection

18-Jul-23 Threading Inspection 36

Thread Inspection

18-Jul-23 Threading Inspection 37

Thread Inspection

18-Jul-23 Threading Inspection 38

Thread Inspection

MRP Gauge Tolerance

18-Jul-23 Threading Inspection 39

Thread Inspection

MRP Gauge Tolerance

18-Jul-23 Threading Inspection 40

Thread Inspection

18-Jul-23 Threading Inspection 41

You might also like

- API Spec 7-2 Threading Ang Gauging of Rotary Shouldered Connections100% (1)API Spec 7-2 Threading Ang Gauging of Rotary Shouldered Connections124 pages

- Testing & Commissioning of Fan Coil Units FCU'sNo ratings yetTesting & Commissioning of Fan Coil Units FCU's3 pages

- Turbotorque™: Lightning Fast Torque On DemandNo ratings yetTurbotorque™: Lightning Fast Torque On Demand16 pages

- TenarisHydril Wedge 563 RunningGuidelinesNo ratings yetTenarisHydril Wedge 563 RunningGuidelines16 pages

- Field Inspection Procedure For Used GPDS Connections Revision 03 PDF0% (1)Field Inspection Procedure For Used GPDS Connections Revision 03 PDF3 pages

- Tapered Thread Inspection - Tubing, Casing, &: Required EquipmentNo ratings yetTapered Thread Inspection - Tubing, Casing, &: Required Equipment1 page

- Pitch Diameter and Ovality Gages Tapered Threads MRP-1000 Series MRP-2000 Series MRP-3000 SeriesNo ratings yetPitch Diameter and Ovality Gages Tapered Threads MRP-1000 Series MRP-2000 Series MRP-3000 Series2 pages

- Running Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGNo ratings yetRunning Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KG16 pages

- BVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety Clamps100% (1)BVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety Clamps8 pages

- BDS VAM®+TOP+Casing Regular 7.000 29.00 RegularNo ratings yetBDS VAM®+TOP+Casing Regular 7.000 29.00 Regular1 page

- Tubing & Casing Thread Inspection-Thread LeadNo ratings yetTubing & Casing Thread Inspection-Thread Lead1 page

- ACS800 Single Drive Technical Catalogue REV E EN PDFNo ratings yetACS800 Single Drive Technical Catalogue REV E EN PDF56 pages

- Installation Guide: Directed Digital SolutionsNo ratings yetInstallation Guide: Directed Digital Solutions22 pages

- Starting Systems - Application & Installation Guide - Lebw4980No ratings yetStarting Systems - Application & Installation Guide - Lebw498032 pages

- Preventive Maintenance For The Max CR System Formerly The CR 975 System (PM1883-1)No ratings yetPreventive Maintenance For The Max CR System Formerly The CR 975 System (PM1883-1)30 pages

- Technical Information Sound Shell Installation Instructions For COPELAND SCROLL™ CompressorsNo ratings yetTechnical Information Sound Shell Installation Instructions For COPELAND SCROLL™ Compressors5 pages

- Study of Single Plate Clutch: Presented by:-PANKAJ SHARMANo ratings yetStudy of Single Plate Clutch: Presented by:-PANKAJ SHARMA16 pages

- SET-111. RFID Based Prepaid Card For Petrol StationNo ratings yetSET-111. RFID Based Prepaid Card For Petrol Station3 pages

- Operation Manual Plastic Extrusion WelderNo ratings yetOperation Manual Plastic Extrusion Welder20 pages

- Wolaita Sodo University School of Informatics: Department of Information TechnologyNo ratings yetWolaita Sodo University School of Informatics: Department of Information Technology4 pages

- API Spec 7-2 Threading Ang Gauging of Rotary Shouldered ConnectionsAPI Spec 7-2 Threading Ang Gauging of Rotary Shouldered Connections

- Field Inspection Procedure For Used GPDS Connections Revision 03 PDFField Inspection Procedure For Used GPDS Connections Revision 03 PDF

- Tapered Thread Inspection - Tubing, Casing, &: Required EquipmentTapered Thread Inspection - Tubing, Casing, &: Required Equipment

- Pitch Diameter and Ovality Gages Tapered Threads MRP-1000 Series MRP-2000 Series MRP-3000 SeriesPitch Diameter and Ovality Gages Tapered Threads MRP-1000 Series MRP-2000 Series MRP-3000 Series

- Running Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGRunning Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KG

- BVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety ClampsBVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety Clamps

- ACS800 Single Drive Technical Catalogue REV E EN PDFACS800 Single Drive Technical Catalogue REV E EN PDF

- Starting Systems - Application & Installation Guide - Lebw4980Starting Systems - Application & Installation Guide - Lebw4980

- Preventive Maintenance For The Max CR System Formerly The CR 975 System (PM1883-1)Preventive Maintenance For The Max CR System Formerly The CR 975 System (PM1883-1)

- Technical Information Sound Shell Installation Instructions For COPELAND SCROLL™ CompressorsTechnical Information Sound Shell Installation Instructions For COPELAND SCROLL™ Compressors

- Study of Single Plate Clutch: Presented by:-PANKAJ SHARMAStudy of Single Plate Clutch: Presented by:-PANKAJ SHARMA

- SET-111. RFID Based Prepaid Card For Petrol StationSET-111. RFID Based Prepaid Card For Petrol Station

- Wolaita Sodo University School of Informatics: Department of Information TechnologyWolaita Sodo University School of Informatics: Department of Information Technology