Engine Room Ventilation - Necesar Aer

Engine Room Ventilation - Necesar Aer

Uploaded by

BirshopulosCopyright:

Available Formats

Engine Room Ventilation - Necesar Aer

Engine Room Ventilation - Necesar Aer

Uploaded by

BirshopulosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Engine Room Ventilation - Necesar Aer

Engine Room Ventilation - Necesar Aer

Uploaded by

BirshopulosCopyright:

Available Formats

Consultant’s Corner:

Engine Room Ventilation

Engine room ventilation key to proper gen set operation

It's been estimated that up to 10 percent of the fuel consumed by the average internal combustion engine is dissipated to

the surrounding area as heat. This heat must be removed to maintain proper and safe gen set operation. This is usually

accomplished by induced draft or ventilation fans.

The most efficient method of removing this heat is with a system that pulls air past switchgear, then over the engine, from

back to front. If air curtains are used, the airflow should gather this radiant heat just above the gen set, which offers

greater efficiency and less exposure to high air velocities in other areas of the gen set room. Airflow should be upward

around each engine or in the case of engines with mounted radiators, across the back of the engine to the front. The ven-

tilation system should sufficiently move air to control temperature in all areas of the engine room.

Ventilation fan sizing

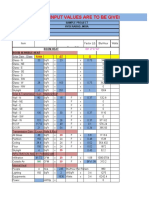

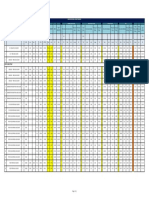

The following equations provide the proper airflow (cfm or m3/s velocity for a given gen set installation, assuming 100 F

(38C) ambient temperature:

Airflow (cfm or m3/s should increase 10 percent for every 2,500 feet (760m) above sea level.

V (cfm) = H + Engine combustion air

0.07 x 0.24 x delta T

V (m³/min) = H + Engine combustion air

1.099 x 0.017 x delta T

Where:

V = ventilating air

H = heat radiation

delta T = Permissible temperature rise in engine room (degrees F or C)

Density of air at 100°F = 0.07 lb/cu ft (1.099 kg/m³)

Specific heat of air = 0.24 Btu/°F (0.017 kW/°C).

Sound control

Minimizing engine noise while maintaining adequate cooling presents come design challenges. Insulated air ducts and

close attention to air inlet and outlet locations can greatly minimize noise problems. Unfortunately, air louvers are not ade-

quate to contain engine noise.

Engineers at Toromont Engine Power Systems have worked on several installations where ventilation noise was a key

design consideration. We can share the experience gained with you during your design phase.

Cold weather considerations

In colder climates, the desired temperature rise needed to maintain optimum engine operating temperature could be as

much ad 80 F (27C) instead of the usual 10 to 20 F (5.5 to 11C). In these cases, it is better to specify a number of smaller

fans than one large fan to supply ventilation air. This also allows you to adjust ventilation if the gen set operates at a lower

output. Movable louvers positioned to redirect engine heat back into the room until the jacket water temperatures reach

190 F (88 C) may be used. Then, these louvers close so ventilation air is exhausted.

Call us

Achieving correct ventilation levels is best accomplished during the design phase. We can help you at this juncture to

best plan for ventilation needs.

You might also like

- Sub-Zero BI Parts ManualDocument96 pagesSub-Zero BI Parts Manualp_rizz_30% (1)

- Camel Intro 2Document34 pagesCamel Intro 2Inventor SolidworksNo ratings yet

- Generator RoomDocument3 pagesGenerator Roomparthiv100% (1)

- Design of Ventilation SystemsDocument5 pagesDesign of Ventilation SystemsSimon LaurentNo ratings yet

- BDB SeriesDocument47 pagesBDB SeriesKedar Shethia100% (2)

- AHU Fresh AirDocument2 pagesAHU Fresh AirSvetla Nikolova100% (2)

- Caterpillar Proper-Engine-Room-Ventilation PDFDocument2 pagesCaterpillar Proper-Engine-Room-Ventilation PDFyadi_baeNo ratings yet

- Pumb RoomDocument2 pagesPumb RoomMohamed HamzaNo ratings yet

- Ventialtion Calculation SampleDocument21 pagesVentialtion Calculation SampleNico EchavarriaNo ratings yet

- Basic Load Calculation SheetDocument15 pagesBasic Load Calculation SheetZeeshan HasanNo ratings yet

- Engine Room AirflowDocument3 pagesEngine Room AirflowselisenNo ratings yet

- 1-Internal Heat GainDocument15 pages1-Internal Heat GainWunNa100% (1)

- Cooling Load Pasig GymnasiumDocument62 pagesCooling Load Pasig GymnasiumHenry San PedroNo ratings yet

- Flow Tech Louvers PDFDocument10 pagesFlow Tech Louvers PDFMoriyasuNguyenNo ratings yet

- Guide 1Document3 pagesGuide 1karimNo ratings yet

- Louver Calculation & ScheduleDocument2 pagesLouver Calculation & ScheduleAfsal JhNo ratings yet

- AUMR Series: Air Cooled Condensing UnitsDocument28 pagesAUMR Series: Air Cooled Condensing UnitsMohamed SamehNo ratings yet

- Summary Sheet of Heat Load Canculation and Equipment Selction Sheet - KIA MetroDocument10 pagesSummary Sheet of Heat Load Canculation and Equipment Selction Sheet - KIA Metrosiddharth gautamNo ratings yet

- Pressurization UnitDocument16 pagesPressurization UnitsheetalnathNo ratings yet

- Cooling Load Rule of Thumb PDFDocument36 pagesCooling Load Rule of Thumb PDFmaungNo ratings yet

- Calculo de CFM Pump Room Ventilation Calculation PDFDocument1 pageCalculo de CFM Pump Room Ventilation Calculation PDFsusansue50% (2)

- Ceiling DiffusersDocument25 pagesCeiling DiffusersrasheedillikkalNo ratings yet

- Sound AttenuatorDocument4 pagesSound AttenuatorFareethAbdullahNo ratings yet

- Stair Pressurization CalculationDocument2 pagesStair Pressurization Calculationnishad100% (1)

- Ahu 1Document1 pageAhu 1quynhanh2603No ratings yet

- VAV BrochureDocument28 pagesVAV BrochureMuralidharan SudhakarNo ratings yet

- Genetics Pharma Dehumidifying Load Input Sheet: 1 BlisteringDocument1 pageGenetics Pharma Dehumidifying Load Input Sheet: 1 Blisteringirfanbaig36No ratings yet

- Cooling and Heating Load Estimate SheetDocument1 pageCooling and Heating Load Estimate SheetJerome Russel PublìcòNo ratings yet

- HVAC FormulasDocument7 pagesHVAC Formulasisaiaspaula80No ratings yet

- Back Pressure ExhaustDocument12 pagesBack Pressure ExhaustmarjukiNo ratings yet

- Area ΔT U: Project Sample Project Location Hyderabad, India Client ConsultantDocument4 pagesArea ΔT U: Project Sample Project Location Hyderabad, India Client ConsultantUTKARSH GADVE100% (1)

- Pump Room Ventilation F21: IACS Req. 1987Document1 pagePump Room Ventilation F21: IACS Req. 1987NUm SaiChon RT100% (1)

- AUMR Series: Air Cooled Condensing UnitsDocument27 pagesAUMR Series: Air Cooled Condensing UnitsOmair FarooqNo ratings yet

- Sound Formulae SheetDocument2 pagesSound Formulae SheetSohJiaJie100% (1)

- Heat Load Format Sample WITH ADPDocument21 pagesHeat Load Format Sample WITH ADPShreegunali AmmuluNo ratings yet

- Smoke Calculation Based On ACPHDocument8 pagesSmoke Calculation Based On ACPHabuwaquaseNo ratings yet

- Sea Level: Ashrae Psychrometric Chart No.1Document1 pageSea Level: Ashrae Psychrometric Chart No.1mdalt9180No ratings yet

- World Highest Building (Burj Kalifa) Air DisruptionDocument40 pagesWorld Highest Building (Burj Kalifa) Air DisruptionPrabu RajaNo ratings yet

- A Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsDocument3 pagesA Theoretical and Practical Guide To The Basics of Designing Air Flow Systemsmarcoo8No ratings yet

- HVAC Heater Calculation SheetDocument1 pageHVAC Heater Calculation SheetselisenNo ratings yet

- Cooling Load Casa AzulDocument40 pagesCooling Load Casa AzulHenry San PedroNo ratings yet

- Systemair CatalogueDocument21 pagesSystemair CataloguePARVEZ AMEENNo ratings yet

- Date: Prepared By: Checked & Approved By: Client Name: Project No.: Location: Document No.: Project Name: RevisionDocument3 pagesDate: Prepared By: Checked & Approved By: Client Name: Project No.: Location: Document No.: Project Name: RevisionMohsin ShaikhNo ratings yet

- Fresh Air Louver Selection - 11-10-2015Document1 pageFresh Air Louver Selection - 11-10-2015organicspolybondNo ratings yet

- Acoustic Calculation of Ventilation SystemsDocument49 pagesAcoustic Calculation of Ventilation SystemsHari Babu DharmavarapuNo ratings yet

- Heat Load CalculationDocument13 pagesHeat Load CalculationshriramNo ratings yet

- AHRI Guideline T 2002Document16 pagesAHRI Guideline T 2002trangweicoNo ratings yet

- Air Duct CalculatorDocument1 pageAir Duct CalculatortrungvuNo ratings yet

- Trosten Ahu CatalogueDocument88 pagesTrosten Ahu Cataloguehanimamoo7No ratings yet

- APMRG1 Series: Packaged Air ConditionersDocument32 pagesAPMRG1 Series: Packaged Air Conditionerszaid jamaluNo ratings yet

- Pressure Relief Damper: Type ARK2Document14 pagesPressure Relief Damper: Type ARK2vvlad34No ratings yet

- EXHAUST FAN Static Pressure CalculationDocument15 pagesEXHAUST FAN Static Pressure CalculationCarlo Santi Bayabay0% (1)

- 01-Fire Pump & Generator Room CalculationDocument3 pages01-Fire Pump & Generator Room Calculationbilal almelegyNo ratings yet

- Ducted - 42CCDDocument2 pagesDucted - 42CCDsalaheddine seddaouiNo ratings yet

- Condensate Drain Calculation - Development Block - Igate PuneDocument1 pageCondensate Drain Calculation - Development Block - Igate PuneJitheesh SahadevanNo ratings yet

- Generator Set VentilationDocument2 pagesGenerator Set VentilationGia BảoNo ratings yet

- Proper Engine Room VentilationDocument2 pagesProper Engine Room VentilationAsok AyyappanNo ratings yet

- Calculate Required Air Ventilation and Heat Generation of DG SetDocument2 pagesCalculate Required Air Ventilation and Heat Generation of DG SetJesus RodriguezNo ratings yet

- Radiator CoolingDocument4 pagesRadiator Coolingvishal.nithamNo ratings yet

- Cooling System Design Specification NotesDocument3 pagesCooling System Design Specification Notesdanena88No ratings yet

- Cooling System Design Specification NotesDocument3 pagesCooling System Design Specification NotesAshutosh PattalwarNo ratings yet

- Panou Solar FV Ledvance - Declaratie EUDocument5 pagesPanou Solar FV Ledvance - Declaratie EUBirshopulosNo ratings yet

- Technical Data For Configuration - ElectromotorDocument19 pagesTechnical Data For Configuration - ElectromotorBirshopulosNo ratings yet

- Panou Solar FV Trina Solar 475 - 505 - Fisa Tehnica - Site TrinaDocument2 pagesPanou Solar FV Trina Solar 475 - 505 - Fisa Tehnica - Site TrinaBirshopulosNo ratings yet

- Panou Solar FV Risen Energy 390 - 405 - Fisa TehnicaDocument2 pagesPanou Solar FV Risen Energy 390 - 405 - Fisa TehnicaBirshopulosNo ratings yet

- Panou Solar FV Ledvance PERC - Bifacial - 650-670 W - Fisa TehnicaDocument2 pagesPanou Solar FV Ledvance PERC - Bifacial - 650-670 W - Fisa TehnicaBirshopulosNo ratings yet

- Nivoflip CatalogDocument2 pagesNivoflip CatalogBirshopulosNo ratings yet

- Plumbing Plan 1Document1 pagePlumbing Plan 1Dialyn San Jose MangcoyNo ratings yet

- Selection Guide-TCV 2019 Rev2Document3 pagesSelection Guide-TCV 2019 Rev2Вадим НуруллинNo ratings yet

- Equipment R Equipment S Equipment T Equipment UDocument2 pagesEquipment R Equipment S Equipment T Equipment UMiriam JonesNo ratings yet

- Manual Compresor 3707VDocument100 pagesManual Compresor 3707Vjose miguel quinteroNo ratings yet

- Modular L Product Profile ECPEN18-416 EnglishDocument8 pagesModular L Product Profile ECPEN18-416 EnglishIorgu CristacheNo ratings yet

- Numerical Heat Transfer and Fluid Flow PDFDocument107 pagesNumerical Heat Transfer and Fluid Flow PDFNeelkanth NirmalkarNo ratings yet

- ASHRAE ResdLoadCalculationDocument5 pagesASHRAE ResdLoadCalculationSamuel JacobsNo ratings yet

- 821g - Wheel Loader - Tier 4b (Na) (10/16 - ) 10 - Engine 10.400.010 (01) - Var - 482585 - 482931 - Cooling System Line InstallationDocument3 pages821g - Wheel Loader - Tier 4b (Na) (10/16 - ) 10 - Engine 10.400.010 (01) - Var - 482585 - 482931 - Cooling System Line InstallationVladimirCarrilloNo ratings yet

- Hot Gas Defrost Systems For Large Evaporators PDFDocument18 pagesHot Gas Defrost Systems For Large Evaporators PDFBehnam Ashouri100% (1)

- Generator Room Ventilation (DAR) Only (1) Free PasswordDocument2 pagesGenerator Room Ventilation (DAR) Only (1) Free PasswordamrNo ratings yet

- 01-rmh Setingkat-Model 6Document1 page01-rmh Setingkat-Model 6Amirul AdamNo ratings yet

- Safety Data Sheet Lexsol 542: Trade Name Synonyms Use Company Address TelephoneDocument8 pagesSafety Data Sheet Lexsol 542: Trade Name Synonyms Use Company Address TelephonedanielNo ratings yet

- MHI Brochure (2019) PDFDocument132 pagesMHI Brochure (2019) PDFlechepinitoNo ratings yet

- SSCDW-1112 R134a Water Cooled Screw Chiller SSCX (55-300RT) (Rev2 230413)Document12 pagesSSCDW-1112 R134a Water Cooled Screw Chiller SSCX (55-300RT) (Rev2 230413)Naing Oo KyawNo ratings yet

- Toto Sanitary Catalogue 2015Document15 pagesToto Sanitary Catalogue 2015Doni FirezaNo ratings yet

- Commercial Catalogue en 2020Document60 pagesCommercial Catalogue en 2020Al Jamaheer Gen TrdNo ratings yet

- BITZER Company Presentation 2011 - EN - FINxDocument30 pagesBITZER Company Presentation 2011 - EN - FINxAndr_Guerra_3324No ratings yet

- Kiyora Catlog SeiresDocument6 pagesKiyora Catlog SeiresMd SazadNo ratings yet

- Psa012b733d EnglishDocument40 pagesPsa012b733d EnglishDirt FilterNo ratings yet

- Soalar Air HeaterDocument6 pagesSoalar Air Heaternidhul07No ratings yet

- Portable Air Conditioner Climatiseur Portatif Acondicionador de Aire PortatilDocument13 pagesPortable Air Conditioner Climatiseur Portatif Acondicionador de Aire PortatilChuck Pickard100% (1)

- Index ChillDocument95 pagesIndex Chillreezqee100% (1)

- Things in The KitchenDocument4 pagesThings in The KitchenElin EdginaNo ratings yet

- Enerpac Fittings CatalogDocument1 pageEnerpac Fittings CatalogTitanplyNo ratings yet

- Glaunach SilencersDocument10 pagesGlaunach Silencersjrri16No ratings yet

- Product - Documentation - Emerson - HPC-M, - 273546eng Chiller PDFDocument72 pagesProduct - Documentation - Emerson - HPC-M, - 273546eng Chiller PDFEmson PortilloNo ratings yet

- Error Codes Display AC: PCB Idea (Lama) : TSD 75 - 150D PCB Idea (Lama) : TSD 200 - 300 Masalah Error ErrorDocument1 pageError Codes Display AC: PCB Idea (Lama) : TSD 75 - 150D PCB Idea (Lama) : TSD 200 - 300 Masalah Error Errorkaito kidNo ratings yet

- Valve ScheduleDocument70 pagesValve SchedulekarparabhusawalNo ratings yet

- Desc Multi EngDocument7 pagesDesc Multi EngAleksander CanjugaNo ratings yet