1 Solid Crank

1 Solid Crank

Uploaded by

Faiq ZulfiarCopyright:

Available Formats

1 Solid Crank

1 Solid Crank

Uploaded by

Faiq ZulfiarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1 Solid Crank

1 Solid Crank

Uploaded by

Faiq ZulfiarCopyright:

Available Formats

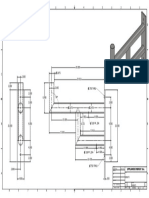

8 7 6 5 4 3 2 1

REVISIONS

ZONE REV. DESCRIPTION DATE APPROVED

A ORIGINAL RELEASE 6/17/2022

D D

6.750

.750

1.000 3.688

1.061 +.0000

.5000 - .0020

A 4X R.02 R.38

2X R.625

1.000

1.375

2X 18.44°

C C

.375 R.75

+.0000 .405 .125

2X .5000 - .0020

2.50

.625

R.13

2.219 2.844

2X .500

2X .031

45°

B .875 B

1.6875

A

.6250

R1.375

3.063

2.75

SECTION A-A

UNLESS OTHERWISE SPECIFIED: NAME DATE

DIMENSIONS ARE IN INCHES DRAWN DJH mm/dd/yy

TOLERANCES:

FRACTIONAL CHECKED TITLE:

A ANGULAR: MACH BEND A

CRANKSHAFT

ENG APPR.

TWO PLACE DECIMAL

THREE PLACE DECIMAL MFG APPR.

INTERPRET GEOMETRIC Q.A.

PROPRIETARY AND CONFIDENTIAL TOLERANCING PER:

COMMENTS:

THE INFORMATION CONTAINED IN THIS MATERIAL

SIZE DWG. NO. REV

AISI 4130 Steel, normalized at 870C

B Part1 A

DRAWING IS THE SOLE PROPERTY OF

ADVANCED CERTIFICATION & DESIGN, INC.

ANY REPRODUCTION IN PART OR AS A FINISH

WHOLE WITHOUT THE WRITTEN PERMISSION NEXT ASSY USED ON

OF ADVANCED CERTIFICATION & DESIGN

IS PROHIBITED. APPLICATION DO NOT SCALE DRAWING SCALE: 1:1 WEIGHT: 1.433 SHEET 1 OF 1

8 7 6 5 4 3 2 1

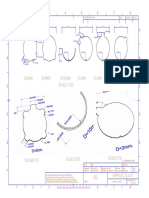

Stuart no. 1 Solid Crank with Counterweights

1. Cut 3” steel round stock to length ( 6 7/8” or 175mm) I used 4140

2. Face to length and center drill each end.

3. Turn the OD to 2.750”

4. Rough turn one end to 9/16” by 2.83” length using a 3 or 6 jaw chuck.

5. Rough turn second end to 9/16” by 2.20” length.

6. Measure distance between the inside of the main bearings.

7. Finish face to correct length 2.219”

8. Place finished face towards the 9/16 collect and finish face to the measured width of the inside

of the main bearings.

9. Finish turn both crank shafts to .500 or the size of your bearings.

10. Check fit to assembly.

11. Place the crack blank into the milling machine vise and find center line.

12. Using a 1/2” long 4 flute carbide endmill machine a groove along the center line of the crank

blank that is .875” deep.

13. Offset endmill from centerline until the slot is .625” exact.

14. Using a .625” x 1“ as a parallel, machine the same slot in the second side of the crank. (The .625

material will prevent the part from collapsing dur this operation.

15. Starting with one edge of the crank that is in the vise, check that the mill is on centerline and

plunge mill .030” at a time until only .875” offset pin remains. Take your time.

16. Now offset from centerline until the gap is .625 exact.

17. Using the 3” stock, build a turning fixture for the 1.00 offset pin. Make use you use index pin or a

¾ slot to drive the crank during the turning of the offset. I used a 1/2” boring bar placed

perpendicular to the lathe spindle facing and turning the inside nearest the fixture. Then

reversed the crank and finish the other face and pin. Take you time! Small Cuts.

18. Use the spacer block as you finish the mill work.

You might also like

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- NYU School of Professional Studies RecommendationDocument3 pagesNYU School of Professional Studies RecommendationcollinsNo ratings yet

- A111wan03105060eDocument158 pagesA111wan03105060edugi100% (3)

- Ship TypesDocument20 pagesShip TypesCatalin Apetre100% (6)

- STFC Pay Grading System 3Document9 pagesSTFC Pay Grading System 3nishantNo ratings yet

- C Stile, Latch WG-1010: Double E Creations LLCDocument1 pageC Stile, Latch WG-1010: Double E Creations LLCGPNo ratings yet

- Ag Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUDocument1 pageAg Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUAnonymous ONsqg3No ratings yet

- Notes:: ThermxDocument1 pageNotes:: ThermxTruong CaoNo ratings yet

- Bobby Marino - HW 02 Part 1Document1 pageBobby Marino - HW 02 Part 1bmarinoNo ratings yet

- Hill Acme: Detail B Scale 1: 1Document1 pageHill Acme: Detail B Scale 1: 1agussaliim345No ratings yet

- Hill Acme: Cutter Quill For 3-5/8 StockDocument1 pageHill Acme: Cutter Quill For 3-5/8 Stockagussaliim345No ratings yet

- Accustream Support BracketDocument1 pageAccustream Support BracketKeith PetersonNo ratings yet

- View A-A: Weight (LBS) Inductance Loss (Watts) 25 0.2 MH 82Document1 pageView A-A: Weight (LBS) Inductance Loss (Watts) 25 0.2 MH 82physicudoNo ratings yet

- Custom Ball Valve TITAN-810: Proprietary and ConfidentialDocument1 pageCustom Ball Valve TITAN-810: Proprietary and ConfidentialGundhi AsmoroNo ratings yet

- Ag Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUDocument1 pageAg Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUAnonymous ONsqg3No ratings yet

- 24f Cam8515-030 MT HandoutDocument3 pages24f Cam8515-030 MT Handoutdurfishan37No ratings yet

- Ag Group: .438 C'BORE X .25 DEEP 4 Places .257 THRUDocument1 pageAg Group: .438 C'BORE X .25 DEEP 4 Places .257 THRUAnonymous IQD4PqB876No ratings yet

- CV 12000 22 OnDocument1 pageCV 12000 22 OnmhanyprotecNo ratings yet

- ICG WebsterDocument32 pagesICG WebsterHugo AlmeidaNo ratings yet

- Ag Group: .438 C'BORE X .25 DEEP 4 Places .257 THRU 7.600 .400Document1 pageAg Group: .438 C'BORE X .25 DEEP 4 Places .257 THRU 7.600 .400Anonymous IQD4PqB876No ratings yet

- Bumper Mount DrawingDocument1 pageBumper Mount Drawingrfarnold204No ratings yet

- Eje 2.idwDocument1 pageEje 2.idwNhoj AicragNo ratings yet

- XR60W 20 700001Document1 pageXR60W 20 700001keanjimlauNo ratings yet

- B Slide, Lock WG-1012: Double E Creations LLCDocument1 pageB Slide, Lock WG-1012: Double E Creations LLCGPNo ratings yet

- Blade+1Document1 pageBlade+1MJ DuNo ratings yet

- ShopDocument1 pageShopRaul VerberNo ratings yet

- 20008-001-1703 01-12-005-13-A Palanca para Sin FinDocument1 page20008-001-1703 01-12-005-13-A Palanca para Sin FinKarlosdcd WikiNo ratings yet

- Ag GroupDocument1 pageAg GroupTonyTzuNo ratings yet

- Index Feed Final - Jake FalbeDocument1 pageIndex Feed Final - Jake Falbeapi-537722646No ratings yet

- Lab 2Document2 pagesLab 2macsen.malacaiNo ratings yet

- Section A-A Scale 1 / 2: Pete Lenz 8/21/2010Document8 pagesSection A-A Scale 1 / 2: Pete Lenz 8/21/2010Manish PatilNo ratings yet

- AR-15 Bolt Schematic Part 1Document1 pageAR-15 Bolt Schematic Part 1pberkay422No ratings yet

- AR-15 Bolt Schematic Part 1Document1 pageAR-15 Bolt Schematic Part 1S KlarsNo ratings yet

- TF 000105Document1 pageTF 000105api-299556237No ratings yet

- B9-3004 Knee HingeDocument1 pageB9-3004 Knee HingeneovondorfmamNo ratings yet

- Musbc111xx 1395729Document3 pagesMusbc111xx 1395729xavi serranoNo ratings yet

- Fa2318 002 01Document1 pageFa2318 002 01hoangluyen1201No ratings yet

- Ag Group: B Ring Mold - Inner AG-0005-BDocument1 pageAg Group: B Ring Mold - Inner AG-0005-BAnonymous IQD4PqB876No ratings yet

- Ag Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUDocument1 pageAg Group: .44 C'BORE X .25 DEEP 5 Places .257 THRUAnonymous IQD4PqB876No ratings yet

- SMBADocument1 pageSMBAjrameshNo ratings yet

- Drawing 1Document1 pageDrawing 1Monse HernándezNo ratings yet

- Test Fixture Optical MountDocument1 pageTest Fixture Optical Mounti50229No ratings yet

- 68 107426 02 - SLDDRWDocument3 pages68 107426 02 - SLDDRWHugo Cesar Ramirez VazquezNo ratings yet

- Ag Group: Item No. Part Number Description Qty. 1 AG-0002-B Ring Assembly 1 2 AG-0003-B Roller 29Document1 pageAg Group: Item No. Part Number Description Qty. 1 AG-0002-B Ring Assembly 1 2 AG-0003-B Roller 29Anonymous IQD4PqB876No ratings yet

- Sigma: Revisions Zone Rev. Description Date Approved M16 Clearance Hole Added 14.7.2024Document1 pageSigma: Revisions Zone Rev. Description Date Approved M16 Clearance Hole Added 14.7.2024pokharkarsunil00No ratings yet

- A Bar, Horz, M WG-1052: Double E Creations LLCDocument1 pageA Bar, Horz, M WG-1052: Double E Creations LLCGPNo ratings yet

- Lowering BlockDocument1 pageLowering Blockalex_christiebNo ratings yet

- Titan 69MDocument1 pageTitan 69MMustafa AtmNo ratings yet

- Master Frame of HPPDocument1 pageMaster Frame of HPPYadi KusmayadiNo ratings yet

- Paul Smith 15 August 2013: Metal + Plastic COM-11992 Through COM-11997Document1 pagePaul Smith 15 August 2013: Metal + Plastic COM-11992 Through COM-11997Alejandro González asuntoNo ratings yet

- AJ Sai Clock Ver2-Layout1SketchyDocument1 pageAJ Sai Clock Ver2-Layout1Sketchynoonot126No ratings yet

- Ag Group: C Ring Mold - Inner AG-0005-CDocument1 pageAg Group: C Ring Mold - Inner AG-0005-CAnonymous IQD4PqB876No ratings yet

- B. Jack: Chapter ExercisesDocument11 pagesB. Jack: Chapter ExercisesMaxCuevaNo ratings yet

- A.04 AtapDocument1 pageA.04 AtapintanNo ratings yet

- Modular CNC 3-Axis RouterDocument4 pagesModular CNC 3-Axis RouterModularCNC80% (5)

- 2 32001565-DrawingDocument2 pages2 32001565-Drawing李秀No ratings yet

- 2UPX210B-T2-L Line DrawingDocument1 page2UPX210B-T2-L Line DrawingsamithajkNo ratings yet

- Sigma: Industrial SolutionDocument1 pageSigma: Industrial Solutionpokharkarsunil00No ratings yet

- Fa2311 005 02Document1 pageFa2311 005 02hoangluyen1201No ratings yet

- Drawn Checked QA MFG Approved DWG No TitleDocument1 pageDrawn Checked QA MFG Approved DWG No TitleSEBASTIAN PAZ CORREANo ratings yet

- FLECHADocument1 pageFLECHAnerproci2023No ratings yet

- 2125N36 - High-Pressure Steel PipDocument1 page2125N36 - High-Pressure Steel Pippavanijakka2No ratings yet

- MANOPLADocument1 pageMANOPLAJuan José HernándezNo ratings yet

- Fa2319 001 01Document1 pageFa2319 001 01hoangluyen1201No ratings yet

- Simple 1 Cylinder OscillatingDocument2 pagesSimple 1 Cylinder OscillatingFaiq ZulfiarNo ratings yet

- 5-Yli Naz EngineeringDocument1 page5-Yli Naz EngineeringFaiq ZulfiarNo ratings yet

- Data Print 221219 JombangDocument9 pagesData Print 221219 JombangFaiq ZulfiarNo ratings yet

- No - Kontrak Agrmnt - Id App - No Nomor - Po Costumer - No Customer - IdDocument21 pagesNo - Kontrak Agrmnt - Id App - No Nomor - Po Costumer - No Customer - IdFaiq ZulfiarNo ratings yet

- Naz Engineering Utama: Revision Date BY QTY Note 1 UnitDocument1 pageNaz Engineering Utama: Revision Date BY QTY Note 1 UnitFaiq ZulfiarNo ratings yet

- FA15 CEE Brief - 5feb FinalDocument114 pagesFA15 CEE Brief - 5feb FinalRusu RăzvanNo ratings yet

- PTP1 - Reading Test 5Document17 pagesPTP1 - Reading Test 5Anh DucNo ratings yet

- Psychic Intuitive Management For Our Modern AgeDocument20 pagesPsychic Intuitive Management For Our Modern AgeCommercial ScoutsNo ratings yet

- Dipal Ashok Thokale ResumeDocument1 pageDipal Ashok Thokale Resumedipalthokale2000No ratings yet

- Annex C2103536810 05122023Document12 pagesAnnex C2103536810 05122023ashishshetty1991No ratings yet

- Microstructure and Wear Resistance of Electrodeposited Ni-Sio Nano-Composite Coatings On Az91Hp Magnesium Alloy SubstrateDocument6 pagesMicrostructure and Wear Resistance of Electrodeposited Ni-Sio Nano-Composite Coatings On Az91Hp Magnesium Alloy SubstrateDhananjay ShimpiNo ratings yet

- Subaru Forester: First Generation (SF 1997)Document25 pagesSubaru Forester: First Generation (SF 1997)roberto0% (1)

- Case Study of Electrical AccidentDocument5 pagesCase Study of Electrical AccidentSr. DEENo ratings yet

- PRIME Diagnostic Test 4 MDSP Problem SolvingDocument5 pagesPRIME Diagnostic Test 4 MDSP Problem SolvingFrankie NovelaNo ratings yet

- VJIM Proceedings 5th Intl. Conf April-2023 FinalPublicaitonFile v2FDocument306 pagesVJIM Proceedings 5th Intl. Conf April-2023 FinalPublicaitonFile v2Fsanalasravanthi123No ratings yet

- Suz-Ka25-71va2 Service Manual (Och472a)Document74 pagesSuz-Ka25-71va2 Service Manual (Och472a)Chi Phạm HồngNo ratings yet

- Learning Chinese in The Digital Age Celin Brief Edu enDocument15 pagesLearning Chinese in The Digital Age Celin Brief Edu enXerxes BreakNo ratings yet

- HST TrainingDocument11 pagesHST TrainingRamesh BabuNo ratings yet

- Yale YK Series Electric WR Operation Manual 2018 April A11867501 Rev AADocument102 pagesYale YK Series Electric WR Operation Manual 2018 April A11867501 Rev AALiam LuntunganNo ratings yet

- Yusuffdm, Department of Management Studies, Indian Institute of Technology RoorkeeDocument5 pagesYusuffdm, Department of Management Studies, Indian Institute of Technology Roorkeeडॉ. सुधांशु जोशीNo ratings yet

- American Style Resume GuidelinesDocument3 pagesAmerican Style Resume GuidelinesJames GordonNo ratings yet

- Manufacturing Engineer - North TexasDocument3 pagesManufacturing Engineer - North TexasNaznin Nuria AfrinNo ratings yet

- JNTU Old Question Papers 2007Document8 pagesJNTU Old Question Papers 2007Srinivasa Rao GNo ratings yet

- 3 PDFDocument1 page3 PDFDenver Esyaben Sin-otNo ratings yet

- BestPower 610 Family 7 To10 kVA (Specs)Document2 pagesBestPower 610 Family 7 To10 kVA (Specs)Kostas TsoumanisNo ratings yet

- 08.phil. Long Distance Telephone Co. vs. NLRCDocument13 pages08.phil. Long Distance Telephone Co. vs. NLRCCharisseCastilloNo ratings yet

- EVERDIGM Concrete Pump RSP List: 1. Drive UnitDocument6 pagesEVERDIGM Concrete Pump RSP List: 1. Drive Unitbasem elhosanyNo ratings yet

- Agraph TutorialDocument22 pagesAgraph TutorialJose Perez GarciaNo ratings yet

- 332 Annex 1 2022 FAQDocument13 pages332 Annex 1 2022 FAQJoyce MaraNo ratings yet

- "If" and "Whether" Practice: Part 1. Underline All The Noun Clauses in The Following SentencesDocument2 pages"If" and "Whether" Practice: Part 1. Underline All The Noun Clauses in The Following Sentencesangel2019No ratings yet

- Scientists Prove Abiotic Oil Is Real!Document4 pagesScientists Prove Abiotic Oil Is Real!Eddie WinklerNo ratings yet