PG-GL Data Sheet

PG-GL Data Sheet

Uploaded by

azeem bilalCopyright:

Available Formats

PG-GL Data Sheet

PG-GL Data Sheet

Uploaded by

azeem bilalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

PG-GL Data Sheet

PG-GL Data Sheet

Uploaded by

azeem bilalCopyright:

Available Formats

Company Certified

ISO 9001:2008

TECHNICAL DATA SHEET - CST 01020/02 - 16/01/2018

PATRIOT PG-GL

BASIS

Glass fibers, NBR.

GENERAL PROPERTIES AND APPLICATION

Gasket material with excellent torque retention and good steam and

thermal resistance. Suitable for use with water, oil, gasses, fuels, organic

and inorganic acid.

PG-GL

Typical value thickness 2.0 mm

Compressibility ASTM F36 % 10

Recovery ASTM F36 % 55

Relaxation stress DIN 52913

16 hours, 300°C, 50 N/mm2 N/mm2 29

16 hours, 175°C, 50 N/mm2 34

Tensile strength DIN 52910 N/mm2 8

Thickness increase ASTM F146

1) Oil IRM 903, 5h, 150°C % 6

2) ASTM Fuel B, 5h, 23°C % 6

3) Distilled water, 5h, 100°C % 2

Max operating conditions

Peak Temperature °C / °F 400

Continuous Temperature °C / °F 340

Continuous Temperature with Steam °C / °F 250

Pressure Bar / psi 120

Available sizes : (mm) 1.500 x 1.500 and 1.500 x 3.000; (inch) 60” x 60” and 60” x 120”

Available thickness: (mm) 0,50 ÷ 0,80 ÷ 1,0 ÷ 1,5 ÷ 2,0 ÷ 2,5 ÷ 3,0 ÷ 4,00 ÷ 5,00;

(inch)1/64” ÷ 1/32” ÷ 3/64” ÷ 1/16” ÷ 3/32” ÷ 3/32” ÷ 1/8” ÷ 3/16” ÷ 7/32”;

other thickness available on demand.

Temperature and pressure represent maximum values and should not be used simultaneously. They are given only for guidance, since they depend not only on the

type of gasket material but also on the assembly conditions. Very important factors are: thickness of material, nature of service medium, type of flange, surface

stress. Steam application requires special consideration.

You might also like

- Rating and Design of Tubular Heat Exchangers Using HTRIDocument4 pagesRating and Design of Tubular Heat Exchangers Using HTRITejaswi AbburiNo ratings yet

- Atriot: Technical Data SheetDocument1 pageAtriot: Technical Data Sheetazeem bilalNo ratings yet

- PG 23Document1 pagePG 23azeem bilalNo ratings yet

- PG 20Document1 pagePG 20azeem bilalNo ratings yet

- TESNIT-BA-203 (1)Document2 pagesTESNIT-BA-203 (1)Hugo SegoviaNo ratings yet

- Hopelex Af 3100Document2 pagesHopelex Af 3100FarizNo ratings yet

- Donit TDS Ba102Document2 pagesDonit TDS Ba102thaniNo ratings yet

- SikaGrout-215 2011-11 - 1Document2 pagesSikaGrout-215 2011-11 - 1Fajar SodiqNo ratings yet

- Donit Tesnit Ba-203 NewDocument2 pagesDonit Tesnit Ba-203 NewPrem KumarNo ratings yet

- TDS Tesnit Ba-U 05-2015Document2 pagesTDS Tesnit Ba-U 05-2015thaniNo ratings yet

- Tesnit Ba 202 Donit1Document2 pagesTesnit Ba 202 Donit1steeluisNo ratings yet

- Gasket FASIT400 - SchedaDocument2 pagesGasket FASIT400 - SchedaStefano SalicchiNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- BA-CFDocument2 pagesBA-CFMIKEL ERMINANo ratings yet

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoNo ratings yet

- Fasit OmniaDocument1 pageFasit OmnianightmanirNo ratings yet

- Technical Data Sheet - MICALIT® FDocument1 pageTechnical Data Sheet - MICALIT® Fle chienNo ratings yet

- Hopelex Pc-1100uDocument2 pagesHopelex Pc-1100uChu ChuNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- TORZEN™ G3000HR BK34Document1 pageTORZEN™ G3000HR BK34Simone AnzaniNo ratings yet

- Technyl Star S 218 MT40 NCDocument3 pagesTechnyl Star S 218 MT40 NCmaria.goncalvesNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- NORYL GTX™ Resin - GTX820 - Americas - Technical - Data - SheetDocument2 pagesNORYL GTX™ Resin - GTX820 - Americas - Technical - Data - Sheetmaria.goncalvesNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- MOLYKOTE - HP-300 - Grease - 80-3103E-01Document2 pagesMOLYKOTE - HP-300 - Grease - 80-3103E-01jtelloNo ratings yet

- pp-1020-rtp-199-x-70815-isoDocument2 pagespp-1020-rtp-199-x-70815-isoQuang Quốc NguyễnNo ratings yet

- 30% Glass Fiber Reinforced PA66: Features ApplicationsDocument2 pages30% Glass Fiber Reinforced PA66: Features ApplicationssuhoanganNo ratings yet

- Pla Texture Wood ArceDocument4 pagesPla Texture Wood ArceRoberto Gonzalo PelazNo ratings yet

- TDS_ASTM_FR500(LGCYX)_Eng_240528Document2 pagesTDS_ASTM_FR500(LGCYX)_Eng_240528hassan.medicaldevicesNo ratings yet

- USA5892ps 10193Document5 pagesUSA5892ps 10193Mubashar HassanNo ratings yet

- Temasil NG: CSF Sheet JointingDocument3 pagesTemasil NG: CSF Sheet JointingTài TrầnNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- TDS Mafill CRHT6344Document1 pageTDS Mafill CRHT6344marcohang00No ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- ALTECH ABS A 2020/100 GF20: Technical Data SheetDocument1 pageALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- ABS-PC SABIC CYCOLAC™ Resin_DL200H_Asia_Technical_Data_Sheet-1Document2 pagesABS-PC SABIC CYCOLAC™ Resin_DL200H_Asia_Technical_Data_Sheet-1Mohamed NagibNo ratings yet

- ULTRADUR Sup ® Sup +B4300+G6+FC+AQUADocument3 pagesULTRADUR Sup ® Sup +B4300+G6+FC+AQUAPatricia Caldeira de AlmeidaNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- HT Cast: Product DescriptionDocument2 pagesHT Cast: Product DescriptionanassNo ratings yet

- Styrolution 3 G55Document3 pagesStyrolution 3 G55John EduardoNo ratings yet

- Santoprene 8211 55 B100 - MDS - ENDocument2 pagesSantoprene 8211 55 B100 - MDS - ENLITCoupie RAKVANNo ratings yet

- Ultramid® A3HG5 en SI - Product DatasheetDocument2 pagesUltramid® A3HG5 en SI - Product Datasheetshahin_723No ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Propriedades ABSDocument1 pagePropriedades ABSengmecanica07022013No ratings yet

- SAN - KUMHO - 350-HW - TDS FDocument4 pagesSAN - KUMHO - 350-HW - TDS FakshayNo ratings yet

- Seriola K 3120Document2 pagesSeriola K 3120WWTP SerafoodNo ratings yet

- Nylatron® 4.6 - BoedekerDocument6 pagesNylatron® 4.6 - BoedekerMas ZuhadNo ratings yet

- Hdpe p702bk DatasheetDocument1 pageHdpe p702bk Datasheetphanplastic299No ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- Globaltherm M Product Information SheetDocument4 pagesGlobaltherm M Product Information SheetMalek MahmoudNo ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsChristian SanhuezaNo ratings yet

- LNP™ THERMOCOMP™ Compound_9X11428J_Americas_Technical_Data_SheetDocument2 pagesLNP™ THERMOCOMP™ Compound_9X11428J_Americas_Technical_Data_SheetMohamed NagibNo ratings yet

- pp-1030-rtp-199-x-70815-astmDocument2 pagespp-1030-rtp-199-x-70815-astmQuang Quốc NguyễnNo ratings yet

- TDS Marlotherm LHDocument2 pagesTDS Marlotherm LHManu Fernandez AfonsoNo ratings yet

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- AF 220Document4 pagesAF 220azeem bilalNo ratings yet

- o ringDocument18 pageso ringazeem bilalNo ratings yet

- c4500Document1 pagec4500azeem bilalNo ratings yet

- Patriot Sealing Technologies CatalogueDocument27 pagesPatriot Sealing Technologies Catalogueazeem bilalNo ratings yet

- PGS SSWG Data-SheetDocument5 pagesPGS SSWG Data-Sheetazeem bilalNo ratings yet

- PGS DFR Data-SheetDocument3 pagesPGS DFR Data-Sheetazeem bilalNo ratings yet

- Din 2393-2 PDFDocument5 pagesDin 2393-2 PDFKarthikeyan NNo ratings yet

- Henikwon BrochureDocument10 pagesHenikwon BrochureTariq NaukhezNo ratings yet

- Henry's LawDocument6 pagesHenry's LawEn Csak0% (1)

- ECG553 Tutorial Vertical Stress DistributionDocument13 pagesECG553 Tutorial Vertical Stress DistributionieyaaaNo ratings yet

- MasterFiber 154 - 155Document2 pagesMasterFiber 154 - 155aruncg2No ratings yet

- Bu 2508 AfDocument7 pagesBu 2508 AfMarcos MadrizNo ratings yet

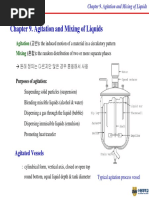

- Ch9 - Unit Operations of Chemical Engineering - Slide PDFDocument16 pagesCh9 - Unit Operations of Chemical Engineering - Slide PDFWillbrynner Marques0% (1)

- Column NotesDocument62 pagesColumn NotesAnno AlNo ratings yet

- Webinar Buehler 2021 - Fundamentals of EtchingDocument64 pagesWebinar Buehler 2021 - Fundamentals of EtchingSeverino NetoNo ratings yet

- Design of Journal BearingDocument8 pagesDesign of Journal BearingjhpandiNo ratings yet

- Test D'adhesion en MetauxDocument2 pagesTest D'adhesion en MetauxBESNo ratings yet

- Unit VDocument70 pagesUnit VVani SenthilNo ratings yet

- Waste Heat BoilerDocument16 pagesWaste Heat Boilerdevilturn70No ratings yet

- When Temper Is Not Specified, Plate, Bar, Sheet, and Strip Will Be Furnished in The Half-Hard TemperDocument10 pagesWhen Temper Is Not Specified, Plate, Bar, Sheet, and Strip Will Be Furnished in The Half-Hard TempersatyendraNo ratings yet

- GM Institute of Technology, Davangere Department of Mechanical EngineeringDocument5 pagesGM Institute of Technology, Davangere Department of Mechanical EngineeringSyed Shueab.sNo ratings yet

- Fatigue Assessment Methods For Reinforced Concrete Bridges in EurocodeDocument167 pagesFatigue Assessment Methods For Reinforced Concrete Bridges in EurocodeSimonas Purneckas100% (1)

- Group # 05 Complex Engineering ProblemDocument6 pagesGroup # 05 Complex Engineering ProblemHASSAN WASEEMNo ratings yet

- Studying The Electrical Conductivity of Different Carbon Fillers Reinforced Polyvinyl Chloride Composite MaterialsDocument10 pagesStudying The Electrical Conductivity of Different Carbon Fillers Reinforced Polyvinyl Chloride Composite MaterialsyasameenNo ratings yet

- selfstudys_com_file (2)Document18 pagesselfstudys_com_file (2)adehcm2021tsiNo ratings yet

- Enclustra Connection Rev8 25-Jul-22Document9 pagesEnclustra Connection Rev8 25-Jul-22gunrjsNo ratings yet

- Elastic Recovery CRMBDocument4 pagesElastic Recovery CRMBaalignup arc & const. pvt ltdNo ratings yet

- Rapport 15000Document10 pagesRapport 15000Said AnejareNo ratings yet

- Bolts-Types of FastenersDocument8 pagesBolts-Types of FastenersChandaKundaNo ratings yet

- Capacitance new moduleDocument16 pagesCapacitance new modulep78shrx5gbNo ratings yet

- 04 Purlins, Sag Rods, Tie RodsDocument3 pages04 Purlins, Sag Rods, Tie RodsAnna TanoNo ratings yet

- The Morphology, Crystallography, and Chemistry of Phases in As-Cast Nickel-Aluminum BronzeDocument9 pagesThe Morphology, Crystallography, and Chemistry of Phases in As-Cast Nickel-Aluminum BronzeKay WhiteNo ratings yet

- Seatwork 1 Mathematics: Specific WeightDocument5 pagesSeatwork 1 Mathematics: Specific WeightRenz PagcaliwaganNo ratings yet

- Experiment 2. Vapor Pressure.Document4 pagesExperiment 2. Vapor Pressure.Esmeralda A OcampoNo ratings yet

- Week9 Metal FormingDocument29 pagesWeek9 Metal Formingebuka onwunyirigboNo ratings yet