Draft Wps Astm A 743 GR - Ca6nm

Uploaded by

Ilham PaneCopyright:

Available Formats

Draft Wps Astm A 743 GR - Ca6nm

Uploaded by

Ilham PaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Draft Wps Astm A 743 GR - Ca6nm

Uploaded by

Ilham PaneCopyright:

Available Formats

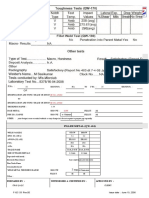

PT.

STAINLESS STEEL PRIMAVALVE MAJUBERSAMA

Page 1 of 2

WELDING PROCEDURE SPECIFICATION (WPS)

ASME Section IX - 2021

Company Name : PT STAINLESS STEEL PRIMAVALVE MAJUBERSAMA

Welding Procedure Specification No. : WPS-SPV-017 Project Name : - Date : July 07, 2023

Supporting PQR No.(S) : PQR-SPV-019 Revision No. : 0

Welding Process(es) : GTAW Type(s) : Manual

(Automatic, Manual, Machine, or Semi-Automatic)

*JOINTS DETAILS (QW-402)

Joint Design : V-GROOVE (BUTT JOINT)

Root Spacing : 1-2 mm θ (Groove Angels: 60 ̊

Backing : N/A r (Root Gap) : 1-2 mm

Backing Material (Type) : N/A f (Root Face) : 1-2 mm

(Refer to both backing and retairners) T : 5-200 mm

*BASE METALS (QW-403)

P No : 6 Group No : 1 To P No. : 6 Group No : 1

Or

Specification and type/grade or UNS number : SA-240 Gr.410 / S41000

To Specification and type/grade or UNS number : SA-240 Gr.410 / S41000

Or

Chemical Analysis and Mechanical Properties : -

to Chemical Analysis and Mechanical Properties : -

Thickness Range

Base Metal : Groove ALL Fillet Metal ALL

Maximum Pass Thickness ≤ 1/2 in. (13 mm) : YES

*FILLER METALS (QW-404)

Welding Process GTAW

Specification SFA No. SFA-5.9

AWS No. (Class) ER 410NiMo

F No. 6

A No. 8

Size of Filler Metals Dia 2.4 mm

Filler Metal Product Form Solid

Supplemental Filler Metal N/A

Weld Metal -

Deposited Thickness Range -

Groove ALL

Fillet ALL

Electrode-flux (Class) N/A

Flux Type N/A

Flux Trade Name N/A

Consumable Insert N/A

Other -

*Each base metal-filler metal combination should be recorded individually

POSITION (QW-405) POST WELD HEAT TREATMENT (QW-407)

Position(s) of Groove 1G (Flat) Solution Treatment

Welding Progression N/A Down N/A Heating Rate Temperature 200 ̊C/h

Position(s) of Fillet ALL Holding Temperature 1000 ̊C - 1050 ̊C

Holding Time 25 Minute

PREHEAT (QW-406) Cooling Method Air

Preheat Temparature, Minimum min 150 ̊C

Interpass Temparatur, Maximum 300 ̊C Tempering 1

Preheat Maintenance Continuous Welding Heating Rate Temperature 200 ̊C/h

Other Holding Temperature 600 ̊C - 630 ̊C

Holding Time 6 Hours

GAS (QW-408 Cooling Method Air in the furnace

Percent Composition

Gas(es) (Mixture) Flow Rate Tempering 2

Shielding Argon 99.99% 10-20 lt/min Heating Rate Temperature 200 ̊C/h

Trailing N/A N/A N/A Holding Temperature 600 ̊C - 630 ̊C

Backing Gas N/A N/A N/A Holding Time 6 Hours

Cooling Method Air in the furnace

PT. STAINLESS STEEL PRIMAVALVE MAJUBERSAMA

Page 2 of 2

WELDING PROCEDURE SPECIFICATION (WPS)

ASME Section IX - 2021

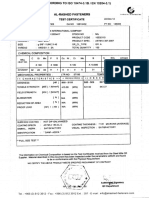

WPS No. WPS-SPV-017 Rev. 0

Electrical Characteristic (QW-409)

Filler Metal Current

Weld Layer Process Volt Range (V) Travel Speed (mm/min) Heat Input

Size (mm) Class Type of Polarity Amperage Range (A)

Root Pass GTAW 2.4 ER410NiMo DCEN 70-100 11-14 60-100 1,42 Kj/mm

Hot Pass GTAW 2.4 ER410NiMo DCEN 100-130 14-17 90-120 1,42 Kj/mm

Fill Pass GTAW 2.4 ER410NiMo DCEN 100-130 14-17 90-120 1,42 Kj/mm

Cap Pass GTAW 2.4 ER410NiMo DCEN 130-175 17-19 110-140 1,42 Kj/mm

Note : Above parameter are only recommendation, actual may be different

Pulsing current N/A

Tungsten Electrode Size Ø 2.4

Tungsten Electrode Type EWTh-2

(Pure Tungsten, 2% Thoriated, etc)

Mode of Metal tranfer for GMAW (FCAW) N/A

(Spray arc, Short Circuitng arc, etc)

Techniques (QW-410)

String or Weave Bead String and Weaving

Orifice, Nozzle, or Gas Cup Size 6-10

Initial and Interpass Cleaning (Brushing, Grinding, Etc) Brushing and Grinding

Method of Back Gouging Arc air Gouging and / or Grinding if required

Oscilation N/A

Contact Tube to Work Distance N/A

Multiple or Single Pass (Per Side) Multipass

Multiple or Single Electrodes Single Electrode

Electrodes Spacing N/A

Peening N/A

Closed to Out Chamber None

Use of Thermal Process None

WELDING INSTRUCTION

Before Welding

1. LPT shall be perform after thorough cleaning

2. The defects that can be repaired must be in a non-penetrating or non-through condition 5. Prepare the welding area by cleaning the surface from dirt, oil, paint, or other coatings

and still fall within the qualification that allows for repair. 6. Perform preheat treatment.

3. Defect shall be marked from tip to tip

4. Traces of all penetrant shall be removed after completion

During Welding

1. Monitor the heat input during welding to prevent overheating and distortion of the workpiece.

2. Monitor the interpass temperature to avoid excessive heat buildup and maintain proper weld properties

After Welding

1. Perform a visual inspection of the weld to check for any visible defects.

2. Conduct non-destructive testing methods using LPT (Liquid Penetrant Testing) to detect any internal defects that may not be visible during visual inspection

3. Perform heat treatment according to the established procedure.

4. Grind or finish the weld to achieve the desired surface smoothness or contour.

Prepared by, Reviewed and Approved by,

Welding Engineer PT Stainless Steel Primavalve MajuBersama

M Ilham Fauzi Pane Kukuh Anggoro

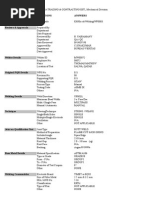

You might also like

- PT. FAB: Proposed Welding Procedure Specification (PWPS)No ratings yetPT. FAB: Proposed Welding Procedure Specification (PWPS)12 pages

- Welding of Dissimilar Ferritic Joints For New Power Plant SteelsNo ratings yetWelding of Dissimilar Ferritic Joints For New Power Plant Steels21 pages

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeNo ratings yetQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel Code2 pages

- Material Specification Sheet Saarstahl - 30Mnvs6 (27mnsivs6) - Saarform 900100% (1)Material Specification Sheet Saarstahl - 30Mnvs6 (27mnsivs6) - Saarform 9001 page

- STD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXNo ratings yetSTD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEX2 pages

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQNo ratings yet177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQ4 pages

- Welder Qualification Test Record (Email)No ratings yetWelder Qualification Test Record (Email)1 page

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFNo ratings yet253 MA Austenitic - High - Temperature - Grades - Datasheet PDF12 pages

- Blank Sample PQR Form (GMAW & FCAW - Page 1) Procedure Qualification Record (PQR)No ratings yetBlank Sample PQR Form (GMAW & FCAW - Page 1) Procedure Qualification Record (PQR)2 pages

- 131.4.1-1 Temperaturas de PreaquecimentoNo ratings yet131.4.1-1 Temperaturas de Preaquecimento1 page

- Duplex and Superduplex Stainless SteelsNo ratings yetDuplex and Superduplex Stainless Steels11 pages

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2100% (2)(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 22 pages

- Fillet Weid Break and Macroetch Test PlateNo ratings yetFillet Weid Break and Macroetch Test Plate1 page

- IS Materail Specification For General Application100% (1)IS Materail Specification For General Application1 page

- Wps Imco Is-101801-17 Saw Twin Arc - Aws d1.1 Rev 01No ratings yetWps Imco Is-101801-17 Saw Twin Arc - Aws d1.1 Rev 0114 pages

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4No ratings yetProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 44 pages

- Covered Electrodes For Stainless Steel: Avesta Electrodes Product ProgrammeNo ratings yetCovered Electrodes For Stainless Steel: Avesta Electrodes Product Programme4 pages

- Welding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmNo ratings yetWelding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mm1 page

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel Without PWHT (SMAW)No ratings yetWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel Without PWHT (SMAW)1 page

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat Treatment100% (1)SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat Treatment2 pages

- Pt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)No ratings yetPt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)1 page

- Tugas Membuat WPS Pengelasan Standar ASME_Guntur Ahmad Affendi_TM2924No ratings yetTugas Membuat WPS Pengelasan Standar ASME_Guntur Ahmad Affendi_TM29242 pages

- QW - 482 Welding Procedure Specification (WPS)No ratings yetQW - 482 Welding Procedure Specification (WPS)5 pages

- Design and Economic Analysis of High-Pressure Proton Exchange Membrane Electrolysis For Renewable Energy StorageNo ratings yetDesign and Economic Analysis of High-Pressure Proton Exchange Membrane Electrolysis For Renewable Energy Storage17 pages

- Lecture Planner Inorganic Chemistry Yakeen NEET 3.0 2025No ratings yetLecture Planner Inorganic Chemistry Yakeen NEET 3.0 20252 pages

- Polymers and Composite Materials: Review Questions100% (2)Polymers and Composite Materials: Review Questions8 pages

- CFD Design and Simulation of Ethylene Dichloride (EDC) Thermal Cracking ReactorNo ratings yetCFD Design and Simulation of Ethylene Dichloride (EDC) Thermal Cracking Reactor17 pages

- Topic:-Structuree of Atom Made By: - Nikunj Agarwal 1XDNo ratings yetTopic:-Structuree of Atom Made By: - Nikunj Agarwal 1XD16 pages

- Abbasi Et Al, 2010, A Scheme For The Classification of Explosions in The Chemical Process IndustryNo ratings yetAbbasi Et Al, 2010, A Scheme For The Classification of Explosions in The Chemical Process Industry11 pages

- What'S New in HSC Chemistry 5.0: A. Roine June 28, 2002 02103-ORC-TNo ratings yetWhat'S New in HSC Chemistry 5.0: A. Roine June 28, 2002 02103-ORC-T19 pages

- Katarzyna Chojnacka - Biosorption and Bioaccumulation in Practice (2008, Nova Science Publishers) PDFNo ratings yetKatarzyna Chojnacka - Biosorption and Bioaccumulation in Practice (2008, Nova Science Publishers) PDF149 pages

- Report Organic Chemistry II Fabrizzio RodríguezNo ratings yetReport Organic Chemistry II Fabrizzio Rodríguez5 pages

- Formulation and Evaluation of Skin Invigorating Caffeine Face MaskNo ratings yetFormulation and Evaluation of Skin Invigorating Caffeine Face Mask4 pages

- Pre - Board Examination in Power and Industrial Plant Engineering100% (1)Pre - Board Examination in Power and Industrial Plant Engineering5 pages

- Analisis de Estructuras Bajo Acciones Dinámicas - Arturo M. CassanoNo ratings yetAnalisis de Estructuras Bajo Acciones Dinámicas - Arturo M. Cassano22 pages