0 ratings0% found this document useful (0 votes)

46 viewsSikaflex®-11 FC

Sikaflex®-11 FC

Uploaded by

Abdulghani AsalaiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Sikaflex®-11 FC

Sikaflex®-11 FC

Uploaded by

Abdulghani Asalai0 ratings0% found this document useful (0 votes)

46 views4 pagesOriginal Title

Sikaflex®-11 FC (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

46 views4 pagesSikaflex®-11 FC

Sikaflex®-11 FC

Uploaded by

Abdulghani AsalaiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

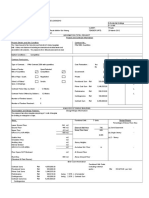

Product Data Sheet

Edition 2, 2015

Version no. 12.2014

Sikaflex ®-11 FC

One part advanced polyurethane, elastomeric sealant/adhesive

Product Sikaflex-11 FC is a one-component, gun-grade, adhesive and sealing compound of

Description permanent elasticity. This dual-purpose material is based on a special moisture-

cured polyurethane with an accelerated curing time.

Uses As an elastic adhesive for:

Cover plates, gaskets and coverings.

Construction

Acoustic ceiling tiles.

Floor moldings and door sills.

Wood or metal and door frames.

Roof tiles.

As an elastic joint sealer for:

Air ducts and high vacuum systems.

Gaskets in openings in walls or floors for ducts, piling, etc

Reservoirs or water retaining structures.

Aluminum fabrication.

Containers, tanks, and silos.

Bolted lap joints.

Characteristics / Excellent adhesion on all cement-based materials, brick, ceramics, glass,

Advantages metals, wood, epoxy,

Fast cure rate.

Good weathering and water resistance.

Non-corrosive.

Can be painted over with water, oil, and rubber-based paints. (Preliminary

tests recommended).

High durability.

Tests

Approvals / Standards Conforms to the requirements of ISEGA Certificate for foodstuff.

Sikaflex 11 FC has been tested as per US EPA Method 24.

Result: VOC Content is 28.5 g/L

Product Data

Form

Appearance / Colours Uniwhite, concrete grey, black

Packaging 300 ml cartridges, 12 cartridges per box

600 ml cartridges, 20 sausages per box

Sika flex ® -11FC 1/4

Storage Conditions / 12 months from date of production if stored in undamaged original sealed

Shelf-Life containers, in dry conditions and protected from direct sunlight at temperatures

between +10°C and +25°C.

Technical Data

Chemical Base 1-part polyurethane, moisture curing

Density ~ 1.3 kg/l (colour concrete grey) (DIN 53 4793)

Skinning Time ~ 60 minutes (+23°C / 50% r.h.)

Curing Rate ~ 3 mm/24h (+23°C / 50% r.h.)

Movement Capability 15%

Joint Dimensions Min. width = 10 mm / max. width = 30 mm

Sag Flow 0 mm, very good (DIN EN ISO 7390)

Service Temperature -40°C to +70°C

Mechanical / Physical

Properties

Tear Strength ~ 7 N/mm (+23°C / 50% r.h.) (DIN 53 515)

Shore A Hardness ~ 40 – 45 after 28 days (+23°C / 50% r.h.) (ASTM C-719)

2

E-Modulus ~ 0.7 N/mm at 100% elongation (23°C / 50% r.h.) (DIN EN ISO 8340)

Elongation at Break ~ 400% (+23°C / 50% r.h.) (DIN 53 504)

Elastic Recovery > 90% (+23°C / 50% r.h.) (ASTM C-719)

Resistance

Chemical Resistance Resistant to water, seawater, diluted alkalis, cement grout and water dispersed

detergents.

Not resistant to alcohols, organic acids, concentrated alkalis and concentrated

acids, chlorinated and aromatic (hydro-carbons) fuel.

System

Information

Application Details

Consumption / The joint width must be designed to suit the movement capability of the sealant. In

Joint Design general the joint width must be > 10 mm and < 35 mm. A width to depth ratio of

~ 1 : 0.8 (for floor joints) must be maintained.

All joints must be properly designed and dimensioned by the specifier and the main

contractor in accordance with the relevant standards, because changes are not

usually feasible after construction. The basis for calculation of the necessary joint

width are the technical values of the joint sealant and the adjacent building

materials, plus the exposure of the building, its method of construction and its

dimensions.

Joints < 10 mm are for crack control and therefore non movement joints. Relevant

is the joint width at the time of application of the sealant (guide value of +10°C.)

Approximate consumption

Joint Width 10 mm 15 mm 20 mm 25 mm 30 mm

Joint Depth 10 mm 12 - 15 mm 17 mm 20 mm 25 mm

Joint Length / 600 ml ~6m ~ 2.5 - 3.0 m ~ 1.8 m ~ 1.2 m ~ 0.8 m

Joint Length / 310 ml ~3m ~ 1.5 m ~ 0.9 m ~ 0.6 m ~ 0.4 m

Minimum joint width for perimeter joints around windows: 10 mm

Backing: Use only closed cell, polyethylene foam backing rods

Sika flex ® -11FC 2/4

Substrate Quality Clean and dry, homogeneous, free from oils and grease, dust and loose or friable

particles. Cement laitance must be removed.

Substrate Preparation / Priming is not usually necessary for anodized aluminum, steel, non-absorbent

Priming materials such as glass, ceramics, stoneware and tiles

Non porous substrates:

E.g. metals, powder coatings etc. have to be cleaned with a fine abrasive pad and

SikaCleaner 205 by using a clean towel / cloth.

After a flash off time of at least 15 min, apply SikaPrimer-3 N by using a brush.

Before sealing allow a flash off time of at least 15 min. (max. 8 hrs.).

For PVC use SikaPrimer 215.

Before sealing allow a flash off time of at least 15 min. (max. 8 hrs.).

Porous substrates:

E. g concrete, aerated concrete and cementitious renders, mortars, brick, etc. have

to be primed with SikaPrimer-3N by using a brush.

Before sealing allow a flash off time of at least 15 min. (max. 8 hrs.).

Important note: Primers are only adhesion promoters. They neither substitute for

the correct cleaning of the surface nor improve their strength significantly.

Primers improve long term performance of a sealed joint.

®

For further information refer to the Sika Primer table.

Application Conditions /

Limitations

Substrate Temperature +5°C min. / +40°C max.

Ambient Temperature +5°C min. / +40°C max.

Substrate Moisture Dry

Content

Application Instructions

®

Application Method / Sikaflex -11FC is supplied ready to use.

Tools After suitable joint and substrate preparation, insert backing rod to required depth

and apply primer if necessary. Insert cartridge into sealant gun and firmly extrude

Sikaflex 11FC into joint making sure that it is full contact with the side of the joint.

Fill the joint, avoiding air entrapment. Sikaflex-11 FC must be tooled firmly against

joint sides to ensure good adhesion.

Masking tape must be used where sharp exact joint lines or exceptionally neat lines

are required. Remove the tape whilst the sealant is still soft. Sleek joint with

smoothing liquid for a perfect sealant surface.

®

Cleaning of Tools Clean all tools and application equipment with Sika Remover-208 /

®

Sika TopClean-T immediately after use. Hardened / cured material can only be

removed mechanically.

Notes on Application / Elastic sealants may not be over painted.

Limitations Compatible coatings may cover the joint sides to max. 1 mm.

The compatibility must be tested according to DIN 52 452-2.

Colour deviations may occur due to exposure to chemicals, high temperatures, UV-

radiation (especially with colour shade white). However a change in colour will not

adversely influence the technical performance or the durability of the product.

Before using on natural stone contact our Technical Service.

®

Do not use Sikaflex -11 FC as a glass sealer, on bituminous substrates, natural

rubber, EPDM rubber or on building materials which might bleed oils, plastisicers or

solvents which could attack the sealant.

®

Do not use Sikaflex -11 FC to seal swimming pools.

Not suitable for joints with water pressure or permanent water immersion.

®

Do not mix with or expose uncured Sikaflex -11 FC to substances that may

react with isocyanates, especially alcohols which are often components

within e.g. thinners, solvents, cleaning agents and formwork releasing

compounds. Such contact could interfere or prevent the cross linking curing

reaction of the material.

Sika flex ® -11FC 3/4

Value Base All technical data stated in this Product Data Sheet are based on laboratory tests.

Actual measured data may vary due to circumstances beyond our control.

Local Restrictions Please note that as a result of specific local regulations the performance of this

product may vary from country to country. Please consult the local Product Data

Sheet for the exact description of the application fields.

Health and Safety For information and advice on the safe handling, storage and disposal of chemical

products, users should refer to the most recent Material Safety Data Sheet

Information containing physical, ecological, toxicological and other safety-related data.

Legal Notes The information, and, in particular, the recommendations relating to the application and end-use of Sika

products, are given in good faith based on Sika's current knowledge and experience of the products when

properly stored, handled and applied under normal conditions in accordance with Sika’s recommendations.

In practice, the differences in materials, substrates and actual site conditions are such that no warranty in

respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal

relationship whatsoever, can be inferred either from this information, or from any written recommendations,

or from any other advice offered. The user of the product must test the product’s suitability for the intended

application and purpose. Sika reserves the right to change the properties of its products. The proprietary

rights of third parties must be observed. All orders are accepted subject to our current terms of sale and

delivery. Users must always refer to the most recent issue of the local Product Data Sheet for the product

Construction

concerned, copies of which will be supplied on request.

Sika Egypt for Construction Chemicals

El Abour City Tel :+202- 4481 0580

st

1 industrial zone (A) Fax :+202- 4481 0459

Section # 10 Block 13035, Mob :+2012- 2390 8822/55

Egypt www.sika.com.eg

Sika flex ® -11FC 4/4

You might also like

- Sikacem®-711 Elastic: Provisional Product Data SheetDocument4 pagesSikacem®-711 Elastic: Provisional Product Data SheetDavid V. BaltazarNo ratings yet

- Sikaflex 1ADocument4 pagesSikaflex 1Athe pilotNo ratings yet

- Eca Rumah Banglo 2012Document9 pagesEca Rumah Banglo 2012Nor Hazwani SharifNo ratings yet

- Glenn Murcutt PDFDocument25 pagesGlenn Murcutt PDFArunagiri Senthil Kumar100% (1)

- Sikaflex - 11 FC: 1-Part Moisture Curing, Polyurethane Adhesive SealantDocument4 pagesSikaflex - 11 FC: 1-Part Moisture Curing, Polyurethane Adhesive SealantGi GoNo ratings yet

- Sika Construction Data SheetDocument4 pagesSika Construction Data SheetsathiyanNo ratings yet

- Sikaflex - 11 FCDocument4 pagesSikaflex - 11 FCSahanNo ratings yet

- Sikaflex Pro 3 I CureDocument5 pagesSikaflex Pro 3 I Curemuhammad aliNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Sikaflex 11FCDocument3 pagesSikaflex 11FCthe pilot100% (1)

- Flex - 11fc+ - Icure 0211Document5 pagesFlex - 11fc+ - Icure 0211Gabz WilliamsNo ratings yet

- Sikaflex 11FC - PDS PDFDocument4 pagesSikaflex 11FC - PDS PDFrajeevNo ratings yet

- PDS - Sikaflex®-11 FC+ PDFDocument5 pagesPDS - Sikaflex®-11 FC+ PDFblancogonzalosNo ratings yet

- Sikaflex 11FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureDocument6 pagesSikaflex 11FC Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureMonraj BIKOONo ratings yet

- SikaflexPRO TdsDocument6 pagesSikaflexPRO TdsidontlikeebooksNo ratings yet

- PDS - Sikaflex®-11 FC+Document4 pagesPDS - Sikaflex®-11 FC+Mahmoud MohamedNo ratings yet

- Shaliseal Ps GG: DescriptionDocument3 pagesShaliseal Ps GG: DescriptionVikas Singh ChandelNo ratings yet

- Sikaflex 11fc+ en Pds Swiss (03 2016)Document4 pagesSikaflex 11fc+ en Pds Swiss (03 2016)MutaalekNo ratings yet

- Sikaflex PRO 3 WFDocument4 pagesSikaflex PRO 3 WFfrahliaNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data Sheetislam mohamedNo ratings yet

- Ikote CM X30 TDSDocument2 pagesIkote CM X30 TDScarlosmendozaiiiNo ratings yet

- Ottocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingDocument3 pagesOttocoll® M 590: The Hybrid-Adhesive For Full-Surface BondingJoeNo ratings yet

- Sikaflex - 11 FC+Document5 pagesSikaflex - 11 FC+emmanuel nwankwoNo ratings yet

- Sikaflex 11 FC PDSDocument4 pagesSikaflex 11 FC PDSEran MeiriNo ratings yet

- Sikaflex® 1aDocument5 pagesSikaflex® 1aMohamed AlamirNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data SheetArrow LazarusNo ratings yet

- Sikaflex-1a-Purform Es enDocument5 pagesSikaflex-1a-Purform Es enArturo Aguilar SantesNo ratings yet

- Sikafloor-ColourSeal W 0307Document4 pagesSikafloor-ColourSeal W 0307Chris AdaminovicNo ratings yet

- SikaflexEBTColours-V1 1 PDFDocument3 pagesSikaflexEBTColours-V1 1 PDFKhin Sandi KoNo ratings yet

- Product Data Sheet: Sikaflex® ConstructionDocument6 pagesProduct Data Sheet: Sikaflex® ConstructionRaheel AhmedNo ratings yet

- Sika PDS - E - Sikaflex Construction (NWE)Document4 pagesSika PDS - E - Sikaflex Construction (NWE)Pisut LeelalumlertNo ratings yet

- Eucolastic 1NS: S - C, P H SDocument2 pagesEucolastic 1NS: S - C, P H Svasanth rNo ratings yet

- Sikaflex Construction (AP)Document4 pagesSikaflex Construction (AP)Benpetro ChaichuaNo ratings yet

- Sikahyflex 140 Construction - Pds enDocument4 pagesSikahyflex 140 Construction - Pds enPutra AfriadeNo ratings yet

- Sikaflex®-Construction (AP) : One-Part Polyurethane Elastic Adhesive /sealantDocument4 pagesSikaflex®-Construction (AP) : One-Part Polyurethane Elastic Adhesive /sealantJoeNo ratings yet

- Ottocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionDocument4 pagesOttocoll® Hitack: The Hybrid Adhesive With High Initial AdhesionJoeNo ratings yet

- Sikacryl®-150: Product Data SheetDocument3 pagesSikacryl®-150: Product Data SheetMoatz HamedNo ratings yet

- Sikasil PoolDocument4 pagesSikasil PoolRockweed InternationalNo ratings yet

- Specification GlassFiberDocument6 pagesSpecification GlassFiberMukesh MaharjanNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- CIKOjoint Plyflex 1200 SealantDocument3 pagesCIKOjoint Plyflex 1200 SealantRamez Bou-RizkNo ratings yet

- Anti-Crak: Solutions For Concrete ReinforcementDocument8 pagesAnti-Crak: Solutions For Concrete ReinforcementCopyingCatNo ratings yet

- Sika Multiseal: Self-Adhesive Bituminous Sealing TapeDocument2 pagesSika Multiseal: Self-Adhesive Bituminous Sealing TapeTitis W. PratiwiNo ratings yet

- Aac Block Adhesive: Product DescriptionDocument2 pagesAac Block Adhesive: Product DescriptionmaznahNo ratings yet

- Tds OTTOCOLL M 500 42 - 28gb PDFDocument4 pagesTds OTTOCOLL M 500 42 - 28gb PDFJoeNo ratings yet

- Asmaco PU SealantDocument3 pagesAsmaco PU SealantJoseph EzekielNo ratings yet

- Sikaflex®-11 FC+: Product Data SheetDocument5 pagesSikaflex®-11 FC+: Product Data SheetYousef HalasehNo ratings yet

- 01 - Sikaflex - T68WDocument2 pages01 - Sikaflex - T68WAyman AldeebNo ratings yet

- Ottocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantDocument4 pagesOttocoll® M 500: The Water-Resistant Premium Hybrid Adhesive/sealantJoeNo ratings yet

- (Sika) Sikacem 133 Gunite Safety Data SheetDocument5 pages(Sika) Sikacem 133 Gunite Safety Data Sheet_at_to_No ratings yet

- Sikasil UniversalDocument3 pagesSikasil UniversalahmadbardawilkamalNo ratings yet

- TDS Pattex BondsealfillDocument5 pagesTDS Pattex BondsealfilldknisNo ratings yet

- Aftek Fyreflex Jun14 Tds - Fire SealantDocument4 pagesAftek Fyreflex Jun14 Tds - Fire SealantYndia SorianoNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Ikote CM X 30 PRODUCT SUBMITAL (19-May-2022)Document34 pagesIkote CM X 30 PRODUCT SUBMITAL (19-May-2022)Jisan DasNo ratings yet

- Sikaflex® PRO-3: Product Data SheetDocument4 pagesSikaflex® PRO-3: Product Data SheetLovely BoutikNo ratings yet

- Ikote Ac X30 TDS (4-22) 2Document2 pagesIkote Ac X30 TDS (4-22) 2Jisan DasNo ratings yet

- Sikacrete - 114: Free Flowing Microconcrete For Grouting and RepairDocument3 pagesSikacrete - 114: Free Flowing Microconcrete For Grouting and RepairQazinadeemNo ratings yet

- Wood Cement BoardDocument15 pagesWood Cement BoardpiangphetNo ratings yet

- 1.ACI 318 Code Comparison With IS456-2000Document14 pages1.ACI 318 Code Comparison With IS456-2000dhamal4mastiNo ratings yet

- Fan & Motor SpecsDocument15 pagesFan & Motor SpecsMahmoud GwailyNo ratings yet

- STADIUMDocument8 pagesSTADIUMAkshai Anand GuruNo ratings yet

- Wide Width Tensile StrengthDocument4 pagesWide Width Tensile StrengthMohit SharmaNo ratings yet

- Technical Data Handbook of Carbon Steel FittingsDocument244 pagesTechnical Data Handbook of Carbon Steel FittingsKrishna KumarNo ratings yet

- Composite MaterialsDocument4 pagesComposite Materialsbharath2bkrNo ratings yet

- Gastite Sizing Tables Natural GasDocument6 pagesGastite Sizing Tables Natural Gasghazanfar.aliNo ratings yet

- Active Transducers - ThermocoupleDocument29 pagesActive Transducers - ThermocoupleKritika GuptaNo ratings yet

- Desain Dinding PenahanDocument32 pagesDesain Dinding Penahanghina hidayatullahNo ratings yet

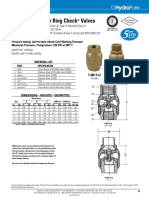

- Valvula Check de Una y MediaDocument1 pageValvula Check de Una y MediaRobertoNo ratings yet

- Design of Thrust Block 2Document7 pagesDesign of Thrust Block 2Pratul Choudhury100% (1)

- HF Series Oil Boiler - Start Up, Service and CleaningDocument28 pagesHF Series Oil Boiler - Start Up, Service and CleaningCurtler PaquibotNo ratings yet

- Installation GuideDocument60 pagesInstallation GuidebatataNo ratings yet

- Viscous Fluid Flow: Second EditionDocument4 pagesViscous Fluid Flow: Second EditionAnonymous ObsY3S7Otq100% (2)

- Mbma 2010Document73 pagesMbma 2010BIM STRATEGYNo ratings yet

- Marine Air Condition System 1Document10 pagesMarine Air Condition System 1Argie CayabyabNo ratings yet

- Code Design and Evaluation For Cyclic Loading - Section III and VIIIDocument34 pagesCode Design and Evaluation For Cyclic Loading - Section III and VIIIMatthieu100% (1)

- Safid Dampers1Document125 pagesSafid Dampers1Mohammed Tausif AhmedNo ratings yet

- TECS-W3252L-E (Aryaduta Bandung)Document5 pagesTECS-W3252L-E (Aryaduta Bandung)Made PutraNo ratings yet

- MDP Module 3Document51 pagesMDP Module 3ADITYA RAJ CHOUDHARYNo ratings yet

- '8.6 Optimization of The Insulation in The Rotary KilnDocument3 pages'8.6 Optimization of The Insulation in The Rotary KilnDEMI PADILLANo ratings yet

- Led Par Lamps: Par20, Par30, Par38 SeriesDocument3 pagesLed Par Lamps: Par20, Par30, Par38 SeriesJorge GomezNo ratings yet

- Failures of Concrete Structures - Jacob Feld ACI 1957Document22 pagesFailures of Concrete Structures - Jacob Feld ACI 1957lflorest2005100% (1)

- N2Xfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesN2Xfgby 2 X (1.5-300) MM 0.6/1 KVRince OktavianaNo ratings yet

- Cet401 Design of Steel Structures, December 2023Document3 pagesCet401 Design of Steel Structures, December 2023neds74099No ratings yet

- High-Type Bituminous Pavements: Dr. Taleb M. Al-RousanDocument67 pagesHigh-Type Bituminous Pavements: Dr. Taleb M. Al-RousanSaurav BhattacharjeeNo ratings yet

- Sample BQ TNB Double ChamberDocument14 pagesSample BQ TNB Double ChamberrokiahhassanNo ratings yet

- Assignment 1 2Document2 pagesAssignment 1 2Jeevan GNo ratings yet