0 ratings0% found this document useful (0 votes)

486 viewsEEHA Inspection Sheet Template

EEHA Inspection Sheet Template

Uploaded by

david.bradley83This document is an inspection form for hazardous area equipment. It lists 60 items to check on the equipment and requires inspectors to mark each item as OK, N/A, or Reject. Any rejections require comments. The inspection can be detailed, close, or visual. Additional checks are required for certain explosion-proof techniques like Ex d, Ex e, and intrinsically safe equipment. Remediation actions are also identified by codes for any issues found.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

EEHA Inspection Sheet Template

EEHA Inspection Sheet Template

Uploaded by

david.bradley830 ratings0% found this document useful (0 votes)

486 views3 pagesThis document is an inspection form for hazardous area equipment. It lists 60 items to check on the equipment and requires inspectors to mark each item as OK, N/A, or Reject. Any rejections require comments. The inspection can be detailed, close, or visual. Additional checks are required for certain explosion-proof techniques like Ex d, Ex e, and intrinsically safe equipment. Remediation actions are also identified by codes for any issues found.

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document is an inspection form for hazardous area equipment. It lists 60 items to check on the equipment and requires inspectors to mark each item as OK, N/A, or Reject. Any rejections require comments. The inspection can be detailed, close, or visual. Additional checks are required for certain explosion-proof techniques like Ex d, Ex e, and intrinsically safe equipment. Remediation actions are also identified by codes for any issues found.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

486 views3 pagesEEHA Inspection Sheet Template

EEHA Inspection Sheet Template

Uploaded by

david.bradley83This document is an inspection form for hazardous area equipment. It lists 60 items to check on the equipment and requires inspectors to mark each item as OK, N/A, or Reject. Any rejections require comments. The inspection can be detailed, close, or visual. Additional checks are required for certain explosion-proof techniques like Ex d, Ex e, and intrinsically safe equipment. Remediation actions are also identified by codes for any issues found.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 3

Client:

Form No.

EEHA-Insp-01

HAZARDOUS AREA

Site: INSPECTION Project:

Tag No. Work Order No. Man Hrs.

Plant /Area/Module: Function / Location:

Cat. Serial

Manufacturer:

No. No.

Certifying Cert

Authority: No:

Temp

AREA CLASSIFICATION: Zone: Gas Group:

Class:

Temp

Equipment Classification Ex Technique: Ex - Gas Group:

Class:

IP Rating: Zone / Location DWG No.

GRADE OF INSPECTION PERFORMED (circle):

DETAILED CLOSE VISUAL

Notes: 1) Inspections shall only be performed by personnel deemed “skilled person” in accordance with IECEx / AS/NZ Standards.

2) All fields are to be completed. Any non-applicable fields shall state “NA”. Comments are required for ‘Reject’ columns ONLY.

3) An Inspection Sheet should be completed for EACH individual item of Equipment.

Inspection

INSPECTION RESULTS

ITEM EQUIPMENT – All Techniques Type

D C V OK NA Reject COMMENTS

1 Equipment is clearly marked with acceptable Ex compliance plate * * *

2 Equipment Gas Group and Temp Class is correct for the Area * *

3 Equipment and glands have IP rating appropriate to location (washers etc.) * *

4 Installation in accordance with documentation (incl. conditions on cert. - X) * * *

5 Equipment Ex Technique Appropriate for Area Classification * *

6 Equipment ID Label (structure) & Cable ID label is present & Correct * *

7 Sealing gaskets or compounds on glasses / windows are satisfactory *

8 Enclosure gaskets condition is satisfactory (clean, undamaged) *

9 Equipment NOT obviously damaged, No Visible Unauthorized Modifications * * *

10 Circuit ID conductor ferrules are installed & correct *

11 Equipment (bolts, covers) appear to be correct type, complete and tight * *

12 Unused entries have correct type plug for Ex technique (complete and tight) * *

13 Lamp rating and position are correct (check all are operating for visual) * * *

14 Cable glands have correct Ex rating identified (d or de) and installed correctly *

15 Cables / conduits not obviously damaged (immediate visible area only) * * *

16 Cable type is appropriate and Installed in accordance with Specification * *

17 All unused cores are terminated in spare terminals & earthed at one end *

18 Electrical connections are correct (Clearance, creepage, tightness) *

19 All cable cores are fitted with correct type Lugs, Spade, Crimp pin, etc. *

20 Equipotential Bonding satisfactory. Cable, Lug, Fixings, Grease (if required) * * *

21 Insulation resistance is as per requirements (sight test documents) *

22 Equip protected against corrosion / weather / vibration / etc * * *

23 No undue accumulation of dust and moisture * *

24 Electrical insulation is clean and dry (Internal equipment check) *

25 Motor fans and couplings are not rubbing on cowls/guards * *

26 All moving parts are free and have no obvious mechanical damage * *

27 Electrical Protection Devices set correctly and operate within permitted limits *

Extra Ex d checks

28 Ex d conduits seals are fitted to all conduits and satisfactorily sealed *

29 Cable glands are compound barrier type and correctly installed (where applic) * *

30 Adaptors, nipples, tees, glands etc. are all certified Ex d (where applicable) * *

31 No obstacles within permitted limits of flange joints (dependent on Gas Group) * * *

32 Flame paths are clean and undamaged *

33 Flange gap dimensions are within tolerances *

Extra Ex e checks

34 All Equipment is Ex e certified (including components within Enclosure) * * *

The No. of Components within Enclosure does not exceed permitted

35 *

maximum

Page 2 of 2

Inspection

INSPECTION RESULTS

ITEM Type

D C V OK NA Reject COMMENTS

36 Bridging links do not reduce creepage / clearance and are allowed *

37 Power conductors are not bunched together causing possible hot spots *

38 Unused Terminals are tightened down *

Extra Ex n checks

39 All Terminals are Ex n certified (if required on certificate) *

40 Bridging links do not reduce creepage / clearance and are allowed *

41 Hermetically sealed and Enclosed Break devices are undamaged *

Extra Ex nR (Restricted Breathing) checks

42 Gaskets and seals are in good condition *

43 Restricted breathing properties satisfactory (conduct vacumn test) *

Extra Ex p checks

44 Pressurisation Gas is correct type * *

45 Actual pressure is within maximum and minimum settings for Equipment * *

46 Timers set as per certification documentation *

47 Spark and/or flame arrestors are installed in accordance with specifications * *

48 Check intake & exhaust in NON – HAZARDOUS areas * * *

49 Alarms and Trip functions operate correctly as per certification Documentation *

Extra Ex i (Intrinsically Safe – IS) checks

50 Equipment has adequate Circuit Identification for ‘IS’ Installation * * *

51 Point-to-Point checks are OK (sight test Documentation). *

52 All cable cores are uniquely labeled (Check loop termination schedules) *

53 Cable screens are isolated at one end as per specification or as required *

54 All Cable Screens and associated equipment are earthed as per requirement *

55 Cable length for entire Loop is stated (and less than max allowable Length) *

56 Separation and segregation is maintained between IS and non-IS Circuits * * *

57 Earth Free test for IS installation (to prove IS earth) *

58 IS Barrier, energy limiting devices, fuses are Certified / approved * *

59 IS Calculation correct (view documentation) *

60 Make: Model:

BARRIER:

Authority: Cert No: Type:

REMEDIATION ACTIONS

FL FLAMEPATH IN INCORRECT INSTALLATION

EN ENCLOSURE ED EQUIPMENT DAMAGE

IP INGRESS TE TERMINATIONS

EB EARTH BOND GL/PL GLANDS/PLUGS

UM UNAUTHORISED MODIFICATION OT OTHER (please specify)

COMMENTS / DEFECTS (list item No.):

Item No.

ACCESS (List any special access restrictions or requirements):

Extension

Ground Steps Ladder Scaffold Harness Other:

Ladder

INSPECTION SURVEY COMPLETED BY:

NAME & EW LICENCE NUMBER (print):

COMPANY / POSITION TITLE:

SIGNATURE:

DATE:

You might also like

- CompEx 01-04 Course HandoutDocument110 pagesCompEx 01-04 Course Handoutco2maker88100% (1)

- Compex Ex01 To Ex04Document3 pagesCompex Ex01 To Ex04Muhammad Ali100% (1)

- CompEX01-04 Practice QuestionDocument28 pagesCompEX01-04 Practice QuestionJhondava NailesNo ratings yet

- Soal CompEx Test (Blank)Document30 pagesSoal CompEx Test (Blank)Jhondava NailesNo ratings yet

- CompEx Ex01 - Ex04Document2 pagesCompEx Ex01 - Ex04Sidhartha Mallick67% (3)

- Ajay Kumar Consolidated MarksheetDocument1 pageAjay Kumar Consolidated MarksheetKeshav GGSU100% (1)

- CompEx Ex11 CD PDFDocument1 pageCompEx Ex11 CD PDFVignesh Madhavan100% (2)

- Product Manual For HDPE PipesDocument23 pagesProduct Manual For HDPE PipesKashyap PathakNo ratings yet

- 2392 Inspection Test Short Paper 1 PDFDocument5 pages2392 Inspection Test Short Paper 1 PDFBaris DasNo ratings yet

- IHA AssessmentDocument4 pagesIHA Assessmentbmanojkumar16No ratings yet

- IECEx CoPC 001,003, 004, 006, 007 & 008Document1 pageIECEx CoPC 001,003, 004, 006, 007 & 008saravanan100% (1)

- Compex Q & A'sDocument5 pagesCompex Q & A'sCal GrassieNo ratings yet

- CompEx GuideDocument22 pagesCompEx GuideFederico MaggiNo ratings yet

- Comp EX 1Document120 pagesComp EX 1Vignesh Madhavan100% (3)

- 01-E2aaf-1 Ic 10Document12 pages01-E2aaf-1 Ic 10Blaze123xNo ratings yet

- Mechanical Seals and ATEXDocument23 pagesMechanical Seals and ATEXMihai CiorbaruNo ratings yet

- ATEX Ex-EDocument10 pagesATEX Ex-EBrajan's B.No ratings yet

- Lnterte Course Gas Vapou: MultiDocument21 pagesLnterte Course Gas Vapou: MultiAdel FawziNo ratings yet

- Unit 11 - Inspection and Maintenance (2013)Document13 pagesUnit 11 - Inspection and Maintenance (2013)carlosNo ratings yet

- Handbook For Use and Maintenance and Directive ATEX: Elvem S.R.LDocument18 pagesHandbook For Use and Maintenance and Directive ATEX: Elvem S.R.LE.ANANDAN100% (1)

- Ha Elec InspectDocument16 pagesHa Elec InspectDebajit BurhagohainNo ratings yet

- CompEx Exam1Document8 pagesCompEx Exam1a.f.nakshaNo ratings yet

- CP 5001 Hazardous 5 Days CompEx Competence Based CourseDocument1 pageCP 5001 Hazardous 5 Days CompEx Competence Based CourseHan LesyNo ratings yet

- Compex Training: Energy & Industry DivisionDocument3 pagesCompex Training: Energy & Industry DivisionGistek MarcoNo ratings yet

- Test Your Knowledge-DeepexDocument23 pagesTest Your Knowledge-Deepexvishnudas100% (1)

- Awareness Compex EX01-01-03&04 Courses OutlineDocument6 pagesAwareness Compex EX01-01-03&04 Courses OutlinemoumenengNo ratings yet

- Section 2 Area Classification 10-2018 Rev 5Document16 pagesSection 2 Area Classification 10-2018 Rev 5kingmltNo ratings yet

- Explosionproof and Flameproof Enclosures - Part-2Document9 pagesExplosionproof and Flameproof Enclosures - Part-2HujiLokoNo ratings yet

- TR CD 04e - Compex Ex01 04Document1 pageTR CD 04e - Compex Ex01 04Ullas Krishnan100% (1)

- IECEx Vs CompEx - UnitsDocument1 pageIECEx Vs CompEx - UnitsJaaffer Ali100% (1)

- Ex Equipment Repair Requirement (Ex Err)Document13 pagesEx Equipment Repair Requirement (Ex Err)jk.jackycheokNo ratings yet

- Installation Instructions For CMP Cable Gland Types T3Cds & T3CdspbDocument2 pagesInstallation Instructions For CMP Cable Gland Types T3Cds & T3CdspbLailyMLNo ratings yet

- Quiz Answers: Hazardous Area Classifications and Equipment QuizDocument5 pagesQuiz Answers: Hazardous Area Classifications and Equipment QuizJaadi 786No ratings yet

- CompEx NA Course DescriptionsDocument2 pagesCompEx NA Course DescriptionsDwi Mulyanti DwimulyantishopNo ratings yet

- Poster Ex Marking 1706333062Document4 pagesPoster Ex Marking 1706333062Efari BahcevanNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFMMNo ratings yet

- Hazardous Area SH CourseDocument22 pagesHazardous Area SH Courseafnaksh100% (1)

- Glanding: Glands Must Maintain Integrity of EnclosureDocument11 pagesGlanding: Glands Must Maintain Integrity of EnclosureMohamed HamedNo ratings yet

- EEMUA Publications Catalogue May 2016Document5 pagesEEMUA Publications Catalogue May 2016malkaniravinderNo ratings yet

- Z2 A-M - CompEX Modules EX01 EX04Document1 pageZ2 A-M - CompEX Modules EX01 EX04Muruga DossNo ratings yet

- Hazardous Area Classification - Dust AtmospheresDocument23 pagesHazardous Area Classification - Dust AtmospheresMohd Lutfi MahaliNo ratings yet

- IECEx TCD 02 Scheme Ed 8.1Document110 pagesIECEx TCD 02 Scheme Ed 8.1Luís Felipe SchrirNo ratings yet

- CMP IECEx ATEX 01Document10 pagesCMP IECEx ATEX 01rocket-vtNo ratings yet

- Compex Uk CentresDocument2 pagesCompex Uk CentresDevadasSmijaNo ratings yet

- Compex Brochure V1Document12 pagesCompex Brochure V1AhmedSaidNo ratings yet

- 2017 ATEC Singapore CompEx 01-04Document1 page2017 ATEC Singapore CompEx 01-04murugan1620No ratings yet

- Classification of Hazardous AreasDocument1 pageClassification of Hazardous Areasadhi2001No ratings yet

- 01 CompEx Summary of Keypoints (VT)Document26 pages01 CompEx Summary of Keypoints (VT)Jhondava NailesNo ratings yet

- PEEC-A024 - Checklist - Hazardous Area Classification PDFDocument2 pagesPEEC-A024 - Checklist - Hazardous Area Classification PDFRisharto Yustitiardi100% (1)

- BOS Ex Presentation Jorgen AkessonDocument57 pagesBOS Ex Presentation Jorgen AkessonsourcNo ratings yet

- BS 5345-4 1977 PDFDocument18 pagesBS 5345-4 1977 PDFArt JamesNo ratings yet

- CompEx Course SyllabusDocument14 pagesCompEx Course SyllabusJoshuaNo ratings yet

- Hazardous Area ClassificationDocument2 pagesHazardous Area ClassificationMahdi100% (1)

- (TC31) IEC 60079-0 Edition 6.0 (2011-06-22)Document9 pages(TC31) IEC 60079-0 Edition 6.0 (2011-06-22)Shirish100% (1)

- Guide To ATEX 137Document128 pagesGuide To ATEX 137E.ANANDANNo ratings yet

- Iec TS 60079-44 2020Document26 pagesIec TS 60079-44 2020Nicolas150956100% (1)

- Battery Rooms and Transformer Quality Control and Inspection Report FormDocument1 pageBattery Rooms and Transformer Quality Control and Inspection Report FormMOST PASON100% (1)

- ITR INL (Insulation)Document2 pagesITR INL (Insulation)mahmoudNo ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

- Inspeksi AlatDocument33 pagesInspeksi AlatAngga HSE dbn05100% (1)

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- Offshore Helicopter Landing Areas - Guidance On Standards Annex 1 - CAP 437 6 Edition Comparison TableDocument9 pagesOffshore Helicopter Landing Areas - Guidance On Standards Annex 1 - CAP 437 6 Edition Comparison TableΑγγελος ΠιλατηςNo ratings yet

- Typical Wiring Diagram: Deep Sea ElectronicsDocument2 pagesTypical Wiring Diagram: Deep Sea ElectronicsBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- Troubleshoot AD FS Issues in Azure Active Directory and Office 365Document16 pagesTroubleshoot AD FS Issues in Azure Active Directory and Office 365awslab8100% (1)

- Group 11Document33 pagesGroup 11api-666595981No ratings yet

- Panasonic Fax MachineDocument3 pagesPanasonic Fax MachineAnu ThakurNo ratings yet

- Re-Evaluation of BoQ RatesDocument3 pagesRe-Evaluation of BoQ RatesMartinNo ratings yet

- ELITE Turno EnglishDocument5 pagesELITE Turno EnglishmiguelrdezNo ratings yet

- Resume RF Engineer LTE 4g Jobs LTE India South Central Asia PDFDocument3 pagesResume RF Engineer LTE 4g Jobs LTE India South Central Asia PDFsebaNo ratings yet

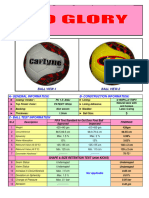

- 4 C10 GloryDocument1 page4 C10 GloryAmer ZeeshanNo ratings yet

- AWS D14.1 - Puentes GruasDocument141 pagesAWS D14.1 - Puentes GruasAlejandro Dionisio OlivasNo ratings yet

- Sample 19544Document16 pagesSample 19544Sharad KumarNo ratings yet

- Pipe Schedules PDFDocument2 pagesPipe Schedules PDFpongpitsanu k.No ratings yet

- FMEA-Revised Veera Oct11e PDFDocument64 pagesFMEA-Revised Veera Oct11e PDFaman_ranhotraNo ratings yet

- Dual Diode BAV70Document3 pagesDual Diode BAV70shounakroyNo ratings yet

- 8aluminuim WeldingDocument131 pages8aluminuim WeldingjyothilalNo ratings yet

- Galva PulseDocument4 pagesGalva PulseAlex CrispimNo ratings yet

- Heat Exchanger Shell Id CalculationsDocument7 pagesHeat Exchanger Shell Id CalculationsmanojNo ratings yet

- Acoustical MaterialDocument31 pagesAcoustical MaterialVISHAL SHARMANo ratings yet

- SMD Package PosterDocument1 pageSMD Package PosterMantasPuskoriusNo ratings yet

- Usa 10my Ud1800cs BBBDocument90 pagesUsa 10my Ud1800cs BBBSahaya Grinspan100% (5)

- Legalinst Vol III (Part1)Document223 pagesLegalinst Vol III (Part1)saradhi26No ratings yet

- Research Design: Unit-IIIDocument34 pagesResearch Design: Unit-IIIAshok Kumar UppariNo ratings yet

- Effective Utilization of Solar Energy in Air Dryer: M. Joseph Stalin & P. BarathDocument10 pagesEffective Utilization of Solar Energy in Air Dryer: M. Joseph Stalin & P. BarathTJPRC PublicationsNo ratings yet

- Training Material For OperatorsDocument360 pagesTraining Material For OperatorsBui Vanluong100% (1)

- Spare Parts Proposal Kit: Boyles C5CDocument6 pagesSpare Parts Proposal Kit: Boyles C5CRafael Castillo LimachiNo ratings yet

- HVAC LayoutDocument1 pageHVAC LayoutSushil ChauhanNo ratings yet

- Daily News: Pubudu Engineering Recives SL IEC 61439 For 'Powerlink' PanelsDocument1 pageDaily News: Pubudu Engineering Recives SL IEC 61439 For 'Powerlink' PanelsWalter MenesesNo ratings yet