5113 en MiraDRAIN 6000 TDS

5113 en MiraDRAIN 6000 TDS

Uploaded by

JohnCopyright:

Available Formats

5113 en MiraDRAIN 6000 TDS

5113 en MiraDRAIN 6000 TDS

Uploaded by

JohnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

5113 en MiraDRAIN 6000 TDS

5113 en MiraDRAIN 6000 TDS

Uploaded by

JohnCopyright:

Available Formats

SCIENCE. SERVICE. SOLUTIONS.

WATERPROOFING ®

MiraDRAIN 6000

Description of the footing. MiraDRAIN eliminates the need for a protection course

over waterproofing systems. Native soils can be used over MiraDRAIN.

CCW MiraDRAIN 6000 is a high-strength drainage composite made up of a

(Contact your local CCW representative for specific guidelines).

nonwoven filter fabric that is bonded to the individual dimples of a molded

polypropylene core to minimize fabric intrusion into the flow channels For standard installation details, follow the MiraDRAIN detail drawings.

caused by backfill pressure. The filter fabric also prevents the passage of For non-standard installation instructions contact your local CCW

soil particles into the core, while allowing water to pass freely. representative.

MiraDRAIN 6000 is designed for use in high-flow, high-compressive- Foundation Walls / Vertical Applications

strength, vertical drainage applications where single-sided subsurface The MiraDRAIN panel can be installed in rows or columns with the fabric

drainage is needed. MiraDRAIN 6000 also serves as protection course over side toward the soil. Each method has its advantages depending on the

CCW waterproofing membranes. criteria of the project as to which method is best.

The flat side of MiraDRAIN 6000 fits snugly against wall surfaces, making When installing the CCW MiraDRAIN in rows:

this product ideal for foundation walls, retaining walls, bridge abutments,

1. Place the longitudinal edge of the core against the wall so that it is

and similar structures.

flush with the wall footing.

Features and Benefits 2. Attach subsequent panels in shingle fashion with fabric overlap at

bottom, placing the longitudinal edge of the upper panel over the

• Relieves hydrostatic pressure buildup against subterranean surfaces

flanged longitudinal edge of the lower panel and lap fabric from upper

• Consistent, multi-directional core configuration provides a uniform panel over lower panel.

flow path for water to escape

When installing the CCW MiraDRAIN in columns:

• High-flow drainage capacity - up to three times the flow capacity of

3. Start at the low point of the wall and attach the panel to the wall.

aggregate or sand

4. Adjacent panels should be joined together with the lateral edge of the

• No-clogging drainage performance

connectiong panel placed over the flanged edge of the previous panel.

• High-compressive-strength system withstands installation and in-

situ earth stresses The fabric from the adjacent panels should overlap the preceding panel.

The fabric can be adhered with CCW CAV-GRIP™, CCW Contact Adhesive,

• Enhances waterproofing system by channeling water away and CCW-704 Mastic, CCW LM-800XL, Aluma-Grip 701 or duct tape. The top

providing a secondarywater retention layer or terminal edge of the MiraDRAIN should be sealed by wrapping the extra

• Cost-saving, lightweight, easy-to-install panels eliminate the need filter fabric around to the back side of the panel, and if there is insufficient

for aggregate fabric, the core shall be cut out from the fabric by a depth of 3 dimples to

provide excess fabric for wrapping behind the core. This will prevent soil

Installation or other foreign construction materials from intruding into or behind the

panels. A “set back” or “ledge” condition may be encountered on some

MiraDRAIN prefabricated drainage panels maybe installed in a variety of

construction applications. Where this condition exists, MiraDRAIN panels

construction applications. They may be installed against retaining walls,

should be installed beginning at the bottom of the wall and ending at the

foundation walls (both waterproofed and non-waterproofed), lagging

ledge. Subsequent courses of MiraDRAIN should be installed flat against

systems and buttress/landfills. MiraDRAIN can be cut with a utility

the upper wall portion and placed so that 4 – 6" (10-15 cm) extend down

knife or scissors. Slurries, shotcrete or concrete may be placed directly

and over the lower edge. The overlapping MiraDRAIN sections will be

onto either side of the panels. The panels can terminate at the top of

pushed flush against the wall during backfilling.

the footing and are flexible enough to form right angles to cover the top

Carlisle Coatings & Waterproofing

900 Hensley Lane | Wylie, TX 75098 | 800.527.7092 | www.carlisleccw.com

SCIENCE. SERVICE. SOLUTIONS.

WATERPROOFING

MiraDRAIN 6000

Attachment Method – No Waterproofing Membrane Packaging

The MiraDRAIN should be attached to non-waterproofed walls with CCW Rolls of 4' x 50' (1.22 m x 15.24 m)

CAV-GRIP, CCW Contact Adhesive, SecurTAPE™ tape or or fasteners

compatible with substrate and 1" washers. The MiraDRAIN will be MiraDRAIN is made in the USA and is sold through a highly qualified sales

permanently secured upon completion of backfilling. Backfill should be representative network.

placed as soon as possible. Backfill to at least 6" (15 cm) above the tape

edge of the MiraDRAIN. Typical Properties

Attachment Method – CCW Waterproofing Membranes

Property Method Unit Typical Value

The CCW MiraDRAIN should be attached with CCW CAV-GRIP, CCW

Contact Adhesive, or SecurTAPE. Apply CAV-GRIP over entire surface CORE

of waterproofing membrane and mate the two surfaces together. The Thickness ASTM D1777 in (mm) 0.40 (10.16)

MiraDRAIN will be permanently secured upon completion of backfill. Compressive Strength ASTM D1621 psf (kPa) 15,000 (719)

Backfill should be placed as soon as possible. Backfill to at least 6" (15

Maximum Flow Rate ASTM D4716 gpm/ft (I/min/m) 21 gpm/ft

cm) above the top edge of the MiraDRAIN.

FABRIC

Attachment Method – CCW MiraCLAY® Waterproofing Membrane

Apparent Opening Size ASTM D4751 US Std Sieve (mm) 40 (0.425)

The MiraDRAIN should be attached over the CCW MiraCLAY membrane

Water Flow Rate ASTM D4491 gpm/ft 2 (I/min/m) 110 gpm/ft 2

using fasteners compatible with substrate and 1" washers.

Grab Tensile Strength ASTM D4632 lbs (kN) 100 (0.45)

Attachment Method – Soldier Pile Supported Excavations

Grab Elongation ASTM D4632 % 60

The MiraDRAIN should be secured with the appropriate fasteners for the

CBR Puncture

substrate, i.e. concrete, masonry, wood or soil. Prevent concrete from ASTM D6241 lbs (N) 250 (1113)

Strength

flowing behind the MiraDRAIN core by sealing the backside of the panel

with a strip of CCW-705, CCW-701 or duct tape. Sealing the backside of

the panel is not necessary if CCW waterproofing membrane is applied

Limited Warranty

over the MiraDRAIN prior to pouring concrete or shotcrete. Carlisle Coatings & Waterproofing Incorporated (Carlisle) warrants this product

to be free of defects in workmanship and materials only at the time of shipment

Drainage Collector/Discharge System from our factory. If any Carlisle materials prove to contain manufacturing defects

that substantially affect their performance, Carlisle will, at its option, replace the

Collector Pipe: Place collector pipe as required in design details. For materials or refund its purchase price. This limited warranty is the only warranty

installations where a collector pipe is specified, encapsulate the collector extended by Carlisle with respect to its materials. There are no other warranties,

pipe in a gravel bed with a supplemental section of filter fabric as a including the implied warranties of merchantability and fi tness for a particular

purpose. Carlisle specifi cally disclaims liability for any incidental, consequential, or

separator/filter. other damages, including but not limited to, loss of profi ts or damages to a structure

or its contents, arising under any theory of law whatsoever. The dollar value of

Limitations Carlisle’s liability and buyer’s remedy under this limited warranty shall not exceed

the purchase price of the Carlisle material in question.

Limit ultraviolet exposure by backfilling within 30 days of installation. Any

panels damaged during installation should be replaced by the installer.

MiraDRAIN is resistant to chemicals in normal soil environments.

However some reagants may affect its performance. CCW

representatives should be consulted concerning the suitability of

MiraDRAIN in unusual soil environments.

Carlisle Coatings & Waterproofing

900 Hensley Lane | Wylie, TX 75098 | 800.527.7092 | www.carlisleccw.com

02.21.20 © 2020 Carlisle. Carlisle, MiraCLAY, CAV-GRIP, MiraDRAIN and SecurTAPE are trademarks of Carlisle.

CCW-3438 - “MiraDRAIN 6000 Technical Data Sheet”

You might also like

- Cherry TV - Sex For WomenDocument1 pageCherry TV - Sex For Womencherrytv100% (3)

- Dr. Fixit Prebond: Hdpe Pre Applied Fully Bonded MembraneDocument3 pagesDr. Fixit Prebond: Hdpe Pre Applied Fully Bonded Membranevelmurug_balaNo ratings yet

- Technal Submittal For Ug Tank Water ProofingDocument43 pagesTechnal Submittal For Ug Tank Water ProofingArunashish Mazumdar100% (3)

- Product Submittal - MasterSeal 730 UVSDocument66 pagesProduct Submittal - MasterSeal 730 UVSTrầnDuyNo ratings yet

- ActiMat Installation Guide SmallDocument3 pagesActiMat Installation Guide Smallgerardo manuel canto barreraNo ratings yet

- CCW MiraDRAIN 6200 DataDocument2 pagesCCW MiraDRAIN 6200 DataDariel Cedeño CastilloNo ratings yet

- 4806 en MiraDRAIN 9800 TDSDocument2 pages4806 en MiraDRAIN 9800 TDSabdalla el-saadaneyNo ratings yet

- CCW Miradrain: Installation GuideDocument16 pagesCCW Miradrain: Installation GuideHookway FisherNo ratings yet

- Waterproofing: Miradrain Installation GuideDocument12 pagesWaterproofing: Miradrain Installation GuideRami TarrafNo ratings yet

- CCW-1037 MiraDRI 860-861 TDS 03-18-14Document2 pagesCCW-1037 MiraDRI 860-861 TDS 03-18-14meetvinayak2007No ratings yet

- AquaArm Power Prufe 900 (W)Document4 pagesAquaArm Power Prufe 900 (W)Ketaki HallurNo ratings yet

- WaterproofingDocument20 pagesWaterproofingmorhaf100% (1)

- Geocomposite DrainsDocument6 pagesGeocomposite DrainssanjeevgupNo ratings yet

- Waterproofing: CCW-525 Liquid Applied Waterproofing MembraneDocument4 pagesWaterproofing: CCW-525 Liquid Applied Waterproofing Membraneジャ ネットNo ratings yet

- Architectural Laminate Shingles Installation Guide MalarkeyDocument11 pagesArchitectural Laminate Shingles Installation Guide MalarkeyHoeNo ratings yet

- BT Final ReviewerDocument245 pagesBT Final ReviewerKenneth GrospeNo ratings yet

- MasterSeal 726 - TDSDocument2 pagesMasterSeal 726 - TDSKhin Sandi KoNo ratings yet

- Below-Grade Waterproofing of Back-Filled WallsDocument2 pagesBelow-Grade Waterproofing of Back-Filled WallsOmar LiraNo ratings yet

- 1.AquaArm Power Prufe 800 Ver 5Document4 pages1.AquaArm Power Prufe 800 Ver 5Bijaya Raula100% (1)

- LP Smartside Strand Substrate Lap Siding Application Instructions EnglishDocument5 pagesLP Smartside Strand Substrate Lap Siding Application Instructions EnglishzachNo ratings yet

- GP-05 TDS-Proofex-12-IndiaDocument2 pagesGP-05 TDS-Proofex-12-IndiaEddy NgNo ratings yet

- General: 38 and 76 Series Strand Substrate Smooth Finish or Cedar Texture Primed Lap SidingDocument5 pagesGeneral: 38 and 76 Series Strand Substrate Smooth Finish or Cedar Texture Primed Lap SidingmamexteriorsNo ratings yet

- AquaArm PowerPrufe 900Document4 pagesAquaArm PowerPrufe 900Ketaki HallurNo ratings yet

- WPM 3000 BG TDSDocument2 pagesWPM 3000 BG TDSshivmangal2008No ratings yet

- Heavy Duty: Waterproofing MembraneDocument4 pagesHeavy Duty: Waterproofing MembranekoliNo ratings yet

- Terramesh Install Guide PDFDocument2 pagesTerramesh Install Guide PDFJorge RosalNo ratings yet

- Waterstop RX Product Data 1693262Document4 pagesWaterstop RX Product Data 1693262Gonzalo OviedoNo ratings yet

- Glo Sikaplan WP WT TapesDocument8 pagesGlo Sikaplan WP WT Tapesahmedmido14No ratings yet

- Masterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Document2 pagesMasterpren Masterpren Masterpren Masterpren 1000 1000 1000 1000Lemark R.No ratings yet

- TDS Waterstop-Rx 103 Emea en 202001 V1Document4 pagesTDS Waterstop-Rx 103 Emea en 202001 V1Angelo Carlo MalabananNo ratings yet

- 1.deepseal PVC WaterstopsDocument4 pages1.deepseal PVC WaterstopsTimothy HughesNo ratings yet

- Maccaferri Gabion Mat BrochureDocument4 pagesMaccaferri Gabion Mat BrochurePedroLouisNo ratings yet

- Enviroseal RW Installation GuideDocument2 pagesEnviroseal RW Installation GuideLEONARDONo ratings yet

- Waterproofing SyntechDocument32 pagesWaterproofing SyntechAnastasia ErlitaNo ratings yet

- Install WOOD 2021Document8 pagesInstall WOOD 2021Javier LópezNo ratings yet

- Fiber Cement Board Installation InstructionsDocument24 pagesFiber Cement Board Installation InstructionsAnu dasNo ratings yet

- Buildex BrochureDocument14 pagesBuildex BrochurejtayNo ratings yet

- Proofex 12Document2 pagesProofex 12vinoth kumar SanthanamNo ratings yet

- CCW 703 Liquiseal Liquid Applied Waterproofing Membrane Product Data 951767Document2 pagesCCW 703 Liquiseal Liquid Applied Waterproofing Membrane Product Data 951767rangarajan1989No ratings yet

- MS-Precon + Drainage Board-R3 26.3.2020)Document4 pagesMS-Precon + Drainage Board-R3 26.3.2020)sammyNo ratings yet

- TagoProof StrongDocument2 pagesTagoProof StrongShaikh Nadim Akhtar0% (1)

- SIKA SARNAFIL Waterproofing-Installation-Instructions-04-12Document25 pagesSIKA SARNAFIL Waterproofing-Installation-Instructions-04-12Teuku FurqanNo ratings yet

- Install ALUM 2021Document8 pagesInstall ALUM 2021Javier LópezNo ratings yet

- PREPRUFE® 300R - 160R Membranes - GCP Applied TechnologiesDocument8 pagesPREPRUFE® 300R - 160R Membranes - GCP Applied TechnologiesthowchinNo ratings yet

- Matliner: Extruded Monofilaments Geodrain Composite With GeomembraneDocument12 pagesMatliner: Extruded Monofilaments Geodrain Composite With GeomembraneAnonymous CQ4rbzLVENo ratings yet

- 2.AquaArm SBS 3000XDocument3 pages2.AquaArm SBS 3000XBijaya RaulaNo ratings yet

- Maccaferri Gabion Mat BrochureDocument4 pagesMaccaferri Gabion Mat BrochureBogdan ChioreanNo ratings yet

- Atlas Summit 60 Data Sheet-2Document2 pagesAtlas Summit 60 Data Sheet-2jeanbedollaNo ratings yet

- GCPAT Procor Composite Waterproofing System Us 1676Document7 pagesGCPAT Procor Composite Waterproofing System Us 1676Saurav Negi EtherealNo ratings yet

- MasterSeal 730 UVS v4Document2 pagesMasterSeal 730 UVS v4Chaitanya MehtaNo ratings yet

- Cavitrol® III Trim With Improved Sealing TechnologiesDocument2 pagesCavitrol® III Trim With Improved Sealing TechnologiesAhmed KhairyNo ratings yet

- Wykamol Damp Treatment CM8HD-CDM-DataSheetDocument4 pagesWykamol Damp Treatment CM8HD-CDM-DataSheetIan MitchellNo ratings yet

- Visqueen Self Adhesive Damp Proof Membrane: Description Typical PropertiesDocument2 pagesVisqueen Self Adhesive Damp Proof Membrane: Description Typical PropertiesJNo ratings yet

- Blindside Waterproofing: Complex and Grueling Demands Require The Right Materials and Know-HowDocument2 pagesBlindside Waterproofing: Complex and Grueling Demands Require The Right Materials and Know-HowKris NauthNo ratings yet

- Treeguard Conductor CoverDocument2 pagesTreeguard Conductor CoverAdrian PramantaNo ratings yet

- Radcon Formula 7 - BrochyrDocument6 pagesRadcon Formula 7 - BrochyrAsep PirmanSyahNo ratings yet

- GCPAT Grace Ice Water Shield Us 5226Document5 pagesGCPAT Grace Ice Water Shield Us 5226vinoth kumar SanthanamNo ratings yet

- Metode Ugradnje Tunelske FolijeDocument7 pagesMetode Ugradnje Tunelske FolijeIzetNo ratings yet

- Supercast PVC Waterstops: Technical Data SheetDocument4 pagesSupercast PVC Waterstops: Technical Data Sheetmystrophan100% (1)

- Drainage PanelDocument4 pagesDrainage Panelconstruct404No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

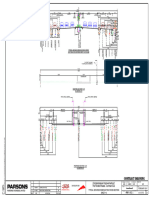

- RT Tunnel - BA Anchors-ModelDocument1 pageRT Tunnel - BA Anchors-ModelJohnNo ratings yet

- An Atheist in Heaven (F3thinker)Document547 pagesAn Atheist in Heaven (F3thinker)JohnNo ratings yet

- Information and Document Design Varieties On Recent Research (Document Design Companion Series) (Information Design Conference, Saul Carliner Etc.)Document266 pagesInformation and Document Design Varieties On Recent Research (Document Design Companion Series) (Information Design Conference, Saul Carliner Etc.)JohnNo ratings yet

- As Q Luko Risk Management Part 1Document8 pagesAs Q Luko Risk Management Part 1JohnNo ratings yet

- Raisebore Stability Assessment of An Upcast Ventilation ShaftDocument11 pagesRaisebore Stability Assessment of An Upcast Ventilation ShaftJohnNo ratings yet

- U 1 01 02Document1 pageU 1 01 02JohnNo ratings yet

- U 1 01 15Document1 pageU 1 01 15JohnNo ratings yet

- Is 12918 1990Document11 pagesIs 12918 1990JohnNo ratings yet

- Megaflo General Brochure M010 07-15-1Document4 pagesMegaflo General Brochure M010 07-15-1JohnNo ratings yet

- TC 0120211127001523 1Document2 pagesTC 0120211127001523 1John100% (1)

- Ijciet 07 03 019Document9 pagesIjciet 07 03 019JohnNo ratings yet

- Fence Opt-2Document1 pageFence Opt-2JohnNo ratings yet

- 54593+89+BIF BAF+Chemical+Free+Iron+Filter+ManualDocument40 pages54593+89+BIF BAF+Chemical+Free+Iron+Filter+ManualJohnNo ratings yet

- Mvu l95 Data Sheet Eng 395238Document8 pagesMvu l95 Data Sheet Eng 395238JohnNo ratings yet

- Dyuthi T0355 PDFDocument253 pagesDyuthi T0355 PDFJohnNo ratings yet

- NKBA Kitchen and Bath WorkbookDocument20 pagesNKBA Kitchen and Bath WorkbookJohnNo ratings yet

- Processes 10 01376Document18 pagesProcesses 10 01376JohnNo ratings yet

- Self Healing ConcreteDocument15 pagesSelf Healing ConcreteJohnNo ratings yet

- VR 20220425 Geostructural Industrial PDFDocument6 pagesVR 20220425 Geostructural Industrial PDFJohnNo ratings yet

- FCS JV Office PDFDocument356 pagesFCS JV Office PDFJohnNo ratings yet

- 10005VSA Otc11bDocument46 pages10005VSA Otc11bJohnNo ratings yet

- Bridge DesignDocument265 pagesBridge DesignJohnNo ratings yet

- Dokumen - Tips - Bsi Standards Publication 2019 12 13 Bs 59752019 A Tracked Changes ComparesDocument21 pagesDokumen - Tips - Bsi Standards Publication 2019 12 13 Bs 59752019 A Tracked Changes ComparesJohnNo ratings yet

- 2.15. Risk ScheduleDocument33 pages2.15. Risk ScheduleJohnNo ratings yet

- KENT Iron Removal Filter ManualDocument9 pagesKENT Iron Removal Filter ManualJohnNo ratings yet

- Fire Safety Solutions For Tunnels - Siemens Building TechnologiesDocument2 pagesFire Safety Solutions For Tunnels - Siemens Building TechnologiesJohnNo ratings yet

- Project Job Number Engineer: Error: Section Overstressed Warning: KL/R 200 (AISC E2)Document2 pagesProject Job Number Engineer: Error: Section Overstressed Warning: KL/R 200 (AISC E2)JohnNo ratings yet

- 001 Removal - of - Iron - From - Industrial - Ground - WaterDocument5 pages001 Removal - of - Iron - From - Industrial - Ground - WaterJohnNo ratings yet

- ITBADocument8 pagesITBAAalok AwasthiNo ratings yet

- Skimming in ReadingDocument2 pagesSkimming in ReadingAvalina EnevieveNo ratings yet

- Conditionals-4 - BPP PythonDocument14 pagesConditionals-4 - BPP Pythondorian451No ratings yet

- ValueCutRegistratonGuide SAiDocument5 pagesValueCutRegistratonGuide SAisanmaru77No ratings yet

- Vehicular Ad-Hoc Network VanetDocument4 pagesVehicular Ad-Hoc Network VanetAgusurio AzmiNo ratings yet

- V8 - Chapter 3 - Methods of Analysis - Delta Wye - TE 58 A - B and CDocument74 pagesV8 - Chapter 3 - Methods of Analysis - Delta Wye - TE 58 A - B and CMubashir KhanNo ratings yet

- 3BHS814749 ZAB E01 RevA GF D563 A Technical-DescriptionDocument56 pages3BHS814749 ZAB E01 RevA GF D563 A Technical-DescriptionMauricioNo ratings yet

- Wireless Communi of UAVDocument295 pagesWireless Communi of UAVmdab2529No ratings yet

- 2541 Oop 0 OpDocument3 pages2541 Oop 0 OpNhlanhla HlátzNo ratings yet

- Tacnet Tactical Radio (TTR)Document17 pagesTacnet Tactical Radio (TTR)coralonsoNo ratings yet

- 2x BREW750-eMotion UL Pall Brazil (18377) Separator 1Document189 pages2x BREW750-eMotion UL Pall Brazil (18377) Separator 1oscar alfredoNo ratings yet

- Gardner's Multiple IntelligenceDocument26 pagesGardner's Multiple IntelligenceDela Cruz Marlon100% (5)

- Ent300 4 Business OpportunityDocument16 pagesEnt300 4 Business OpportunityIrfan NazhanNo ratings yet

- Section V - AODB-invertDocument31 pagesSection V - AODB-invertSarup SubgNo ratings yet

- Resume Seth PlattDocument1 pageResume Seth Plattapi-571406636No ratings yet

- Importance of Mathematical LogicDocument11 pagesImportance of Mathematical LogicBaby Joy Jovita-BasubasNo ratings yet

- Requirements Gathering QuestionsDocument2 pagesRequirements Gathering QuestionsMerouane AmraouiNo ratings yet

- 492 856ML C44CL MPS 492 021 Installation Guide V01 NewDocument10 pages492 856ML C44CL MPS 492 021 Installation Guide V01 Newbosborn76No ratings yet

- Transaction Codes Human Resources SAPDocument7 pagesTransaction Codes Human Resources SAPKarolina ReyNo ratings yet

- Oppo F5 - 4Gb - Gold: Apa Yang Ada Di Dalam KotakDocument1 pageOppo F5 - 4Gb - Gold: Apa Yang Ada Di Dalam KotakTry Lestari Kusuma PutriNo ratings yet

- SlimPulse PDFDocument2 pagesSlimPulse PDFYaqoob IbrahimNo ratings yet

- The Popular Culture and MediaDocument17 pagesThe Popular Culture and MediaURS-John Emmer JoseNo ratings yet

- Cut Order PlanningDocument12 pagesCut Order PlanningShirisha Bala100% (3)

- Timing Paths: Timing Analysis Is Performed by Splitting The Design Into Different Paths Based OnDocument3 pagesTiming Paths: Timing Analysis Is Performed by Splitting The Design Into Different Paths Based OnNandaNo ratings yet

- Cen TR 17223 (2018) (E)Document7 pagesCen TR 17223 (2018) (E)jjyotiNo ratings yet

- ADC Section 4 - 2013 PDFDocument216 pagesADC Section 4 - 2013 PDFjohnNo ratings yet

- Session - 8 - PLA PALDocument14 pagesSession - 8 - PLA PALmohammedsaniyaamrinNo ratings yet

- Internet Censorship Thesis StatementDocument7 pagesInternet Censorship Thesis Statementfjjf1zqp100% (2)

- Fire Risk Situation Analysis in The Nimtoli Area of Old DhakaDocument13 pagesFire Risk Situation Analysis in The Nimtoli Area of Old DhakaAsmee JahanNo ratings yet