Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement Grout

Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement Grout

Uploaded by

mickyfelixCopyright:

Available Formats

Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement Grout

Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement Grout

Uploaded by

mickyfelixOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement Grout

Measuring Changes in Height of Cylindrical Specimens of Hydraulic-Cement Grout

Uploaded by

mickyfelixCopyright:

Available Formats

Designation: C1090 − 10

Standard Test Method for

Measuring Changes in Height of Cylindrical Specimens of

Hydraulic-Cement Grout1

This standard is issued under the fixed designation C1090; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C670 Practice for Preparing Precision and Bias Statements

1.1 This test method covers measurement of the changes in for Test Methods for Construction Materials

height of hydraulic-cement grout by the use of 75 by 150-mm C827 Test Method for Change in Height at Early Ages of

(3 by 6-in.) cylinders, when the cylinders are protected so that Cylindrical Specimens of Cementitious Mixtures

the tendency to change in height does not include evaporation C939 Test Method for Flow of Grout for Preplaced-

so as to cause drying, uptake of moisture, carbonation, or Aggregate Concrete (Flow Cone Method)

exposure to temperatures outside the range 23 6 2.0 °C (73 6

3 °F) or, optionally, to another specified temperature controlled 3. Terminology

within 6 2.0 °C (6 3 °F). 3.1 Definitions:

1.2 If desired, this test method can be adapted to studies of 3.1.1 For definitions of terms used in this test method, refer

changes in height involving either schedules or environmental to Terminologies C125 and C219.

treatment different from the standard procedures prescribed by

3.2 Definitions of Terms Specific to This Standard:

this test method.

3.2.1 change in height—either an increase or decrease in the

1.3 The values stated in SI units are to be regarded as the vertical dimension of a test specimen, provided the change has

standard. been caused by factors other than externally applied forces,

1.4 This standard does not purport to address all of the changes in ambient temperature not conforming to the speci-

safety concerns, if any, associated with its use. It is the fied range, drying caused by evaporation, carbonation, or

responsibility of the user of this standard to establish appro- uptake of moisture.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4. Significance and Use

2. Referenced Documents 4.1 This test method is intended to provide a means of

2.1 ASTM Standards: 2 assessing the ability of a hydraulic-cement grout to retain a

C125 Terminology Relating to Concrete and Concrete Ag- stable volume during the stipulated testing period of 28 days,

gregates provided that the tendency to change height does not include

C172 Practice for Sampling Freshly Mixed Concrete the effects of drying caused by evaporation, uptake of moisture,

C219 Terminology Relating to Hydraulic Cement carbonation, or exposure to temperatures outside the range 23.0

C305 Practice for Mechanical Mixing of Hydraulic Cement 6 2.0 °C (73 6 3 °F) (Note 1). An exception is made when the

Pastes and Mortars of Plastic Consistency options described in the section on test conditions are exer-

C511 Specification for Mixing Rooms, Moist Cabinets, cised.

Moist Rooms, and Water Storage Tanks Used in the NOTE 1—This test method does not measure the change in height before

Testing of Hydraulic Cements and Concretes hardening (see Test Method C827).

1

5. Apparatus

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee 5.1 Cylinder Molds steel cylindrical molds with minimum

C09.68 on Volume Change.

Current edition approved June 15, 2010. Published July 2010. Originally wall thickness of 6 mm (1⁄4 in.) fitted with clamp assemblies for

approved in 1988. Last previous edition approved in 2005 as C1090–01(2005)´1. closing, 75 mm (3 in.) 6 1 % in inside diameter by 150 mm (6

DOI: 10.1520/C1090-10.

2

in.) 6 2 % in height (Note 2)), fitted with a removable 6-mm

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(1⁄4-in.) steel base plate that can be clamped in place with the

Standards volume information, refer to the standard’s Document Summary page on cylinder molds, top edge machined to a narrow rim as shown

the ASTM website. in Fig. 1.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

C1090 − 10

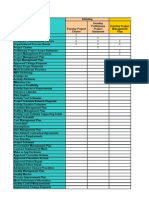

FIG. 1 Cylinder Mold with Machined (Tapered) Top Edge

NOTE 2—Satisfactory molds can be made from lengths of steel tubing

or pipe that is slit on one side parallel to the longitudinal axis and fitted

with a means of closing the vertical slit as well as a means of attaching a

base plate.

5.2 Glass Plate approximately 100 mm (4 in.) square by 6

mm (1⁄4 in.) thick, coated as thinly as possible on one surface

with a silicone-base spray or other inert material such as

mineral oil, and permitted to dry before use.

5.3 Hold-Down Weight having a mass of 1.5 kg (3 lb.) 6

1 %.

5.4 designed to support and hold one cylinder in a level,

firm position (Fig. 2), with steel rods, and a top made of

noncorroding metal, not more than 1 mm (3⁄64 in.) larger than

the diameter of the measuring shaft of the micrometer depth

NOTE 1—All parts of this bridge shall be made of a noncorroding metal.

gage, and numbered 1 to 4 (Note 3). NOTE 2—The diameter of the measuring shaft of the depth micrometer

NOTE 3—The four holes should be 30 6 2 mm (11⁄4 6 1⁄16 in.) from the shall be 3.0 6 0.4 mm (1⁄8 6 1⁄64 in. The four holes should be 25 6 1 mm

center of the hold-down device. (1 6 1⁄16 in. from the center of the cylinder as shown in Fig. 1.

FIG. 2 Dimensions of Micrometer Bridge

5.5 Micrometer Depth Gage having a range from 25 to 50

mm. (1.000 to 2.000 in) graduated in units not larger than 0.02

mm (0.001 in.) (Note 4). 6. Preparation of Sample

NOTE 4—The diameter of the shaft of the depth micrometer should be 6.1 Take a sample of the freshly mixed grout to be tested

3.0 6 0.4 mm (1⁄8 6 1⁄64 in.). either in accordance with Practice C172 or prepared in suffi-

5.6 Outside Micrometer Caliper, used to measure the thick- cient quantity to permit molding at least one test specimen for

ness of the plate, with a capacity of at least 12 mm (1⁄2 in.) and height-change measurements and such additional tests as may

graduated in units not larger than 0.02 mm (0.001 in.) having be required or specified.

throat depth of at least 50 mm (2.0 in.). 6.2 If the grout to be tested is blended from individual

5.7 Tamping Rod, a straight steel rod with at least the components, mix in accordance with Practice C305 (Note 6). If

tamping end rounded to a hemispherical tip of the same the grout is made using a packaged product, proceed as

diameter as the rod, 10 mm (3⁄8 in.) in diameter and at last 250 follows, unless otherwise recommended by the manufacturer.

mm (10 in.) long. 6.2.1 Use 3000 to 3500 g of dry material as required and the

proportionate amount of water required for the test. Record

5.8 Mechanical Mixer, as described in Practice C305 (Note

amounts used.

5).

6.2.2 Place mixing water in mixing bowl.

NOTE 5—This mixer has clearances between paddle and bowl that are 6.2.3 Add dry material during the first 30-s period while

suitable only for mortars made with fine aggregates that are finer than the mixing at slow speed, 140 6 5 r/min.

850-µm (No. 20) sieve. Mortars made with aggregates containing particles

coarser than the 850-µm sieve may require special clearance or a different 6.2.4 Continue mixing for 3 min, stopping the mixer for not

type of paddle to permit the mixer to operate freely and avoid damage to over 15 s after 1 min to scrape down into the batch any grout

the paddle and bowl. that may have collected on the side of the bowl.

Copyright by ASTM Int'l (all rights reserved); 2

C1090 − 10

NOTE 6—If the grout contains fine aggregate, the mixing procedure for but not to more than half the height of the cylinder. Gather and

mortar is applicable; if it does not, that for paste is applicable. tie the plastic bag just above the plunger and bridge.

6.3 Cast the sample and lock the glass plate, micrometer 8.2.3 Subsequent Storage—If after 28-days storage, as pre-

bridge, top plate, plunger, and weight into position within 4 viously described, it is desired to observe height change while

min after completion of mixing. Complete the initial measure- allowing some drying or carbonation, or both, to occur, remove

ments within 3 min after completion of these operations. the specimen from the moist room, or from being protected by

6.4 If it is required or desired to cast the specimen after a the plastic bag and damp towels, exposed to air at 50 6 4 %

longer holding period, continue mixing of either the whole or relative humidity and at the same temperature at which the test

remaining portion, as appropriate, at slow speed for the was previously maintained.

specified time and the sample cast, apparatus locked, and take

initial measurements within 3 min after completion of these 9. Procedure

operations. 9.1 Place the apparatus on a smooth, horizontal surface,

which is free of vibration or disturbance. Remove the top of the

7. Preparation of Apparatus

bridge after it has been pre-leveled parallel to the top of the

7.1 Coat the exterior seams of the cylinder mold and the mold rim by using the four lower nuts.

exterior joint between the mold and the base plate with melted

9.2 Determine consistency in accordance with Test Method

paraffin wax. Coat the interior of the cylinder mold and base

C827. Consider mixtures having a flow of less than 100 % as

plate lightly with mineral oil (Note 7). Attach the mold to the

“stiff plastic;” those having flows between 100 and 125 % are

micrometer bridge.

considered “plastic.” A “flowable” mixture shall have a flow

NOTE 7—The exterior of the mold and the base plate may be coated between 125 and 145 % when tested in accordance with Test

with paraffin wax to facilitate cleanup after completion of the test. Method C827, but not less than 30 s when tested in accordance

8. Conditioning with Test Method C939. A “fluid” mixture shall have a flow of

10 to 30 s when tested in accordance with Test Method C939.

8.1 Keep the air temperature at 23 6 2 °C (73 6 3 °F), and

a relative humidity of not less than 50 %. Store the test 9.3 When testing a material that does not flow easily into the

specimen at a temperature of 23 6 2 °C for the duration of the mold, fill by using three equal layers, rod each layer 15 times

test, unless otherwise specified. When it is desired to test the with the tamping rod. When testing materials that flow easily

height change of material that is permitted to be used in the into the mold, fill the mold and tap the side of the mold lightly

field at temperatures either below or above 23 6 2 °C, use such three times with the tamping rod. Use sufficient material so that

other temperatures controlled to 62 °C (3 °F) throughout after consolidation the mold is slightly overfilled.

instead of 23 6 2 °C. Record the temperature of the mixing 9.4 Carefully place the coated surface of the glass plate on

water, other materials, and of the mixture immediately after top of the test specimen as follows: Hold the plate, coated side

mixing is completed. Store the height-change apparatus in air down, with the index finger placed in the center and the thumb

at the desired test storage temperature within 62 °C before and other fingers on two opposite edges. Bring the plate, held

casting the specimen. at an angle of approximately 45°, to the beveled edge of the

8.2 Protect the test specimen from loss of moisture, absorp- cylinder mold at a point 12 mm (1⁄2 in.) from the lower edge of

tion of moisture, or reaction with carbon dioxide for the the plate. Using this contact point as a fixed hinge, lower the

duration of the test. Store the specimen in the moist room or in plate in a single motion until the excess material is extruded

laboratory air described as follows: Under either condition, the and full contact with the rim is established. Neither slide nor

specimen shall remain protected at all times during the test for use the glass plate in a screeding motion, as this will either

28 days except during removal of the glass plate and the taking smear the material on the glass or cover voids, thus making

of measurements. their detection at this time difficult. After placing the glass

8.2.1 Moist Room Storage—Immediately after taking the plate, maintain contact between the plate and the rim until the

initial measurements, cover the plunger and bridge apparatus plunger and weight have been placed.

with a plastic bag previously fitted and cut to a length that 9.4.1 Quickly examine the grout surface through the glass

extends downward to the midpoint of the specimen mold to plate for voids. If there is an area larger than 3.2 mm (1⁄8 in.) in

prevent water from dripping on the bridge, glass plate, or diameter which lacks contact with the plate, discard the entire

specimen. Then carefully place the specimen in a moist room test specimen (Note 8).

or moist cabinet meeting the requirements of Specification NOTE 8—In order to keep rejected test specimens to a minimum,

C511. operators conducting this operation for the first time have found it helpful

8.2.2 Laboratory Air Storage—Prior to casting the test to practice several times placing the plate on a cylinder filled with an

specimen, place the entire apparatus in a prefitted plastic bag easily available plain mortar before starting the test.

just large enough to be gathered and tied above the plunger and 9.5 Immediately after placing the glass plate, place the

bridge. Roll down or collapse the bag so as not to interfere with preleveled top plate of the micrometer bridge in position,

the casting operation. Immediately after taking the initial tighten wing nuts, and lower the plunger of the hold-down

measurement, place a damp, but not dripping, towel around the device until it makes contact with the top surface of the glass

outside of the lower portion of the four posts supporting the plate. To ensure firm contact between the plunger and the plate,

bridge, inside the plastic bag. The towel shall extend upward, place a 1.5-kg (3-lb) mass on the top of the plunger prior to the

Copyright by ASTM Int'l (all rights reserved); 3

C1090 − 10

tightening of the setscrew of the plunger. Following the V2 = average of at least three-micrometer depth gage read-

tightening of the setscrew, remove the mass and immediately ings at test age, mm (in.).

insert the depth micrometer shaft through the four holes located

on the top plate of the bridge until the finger rests are in full 11. Report

contact with it. Turn the shaft down and determine four initial 11.1 Report the calculated height change (either positive or

measurements from this surface to the top surface of the glass negative) at each test age. Also report the temperature and

plate covering the cylinder mold. Make measurements to the relative humidity at which the tests were performed, mixture

nearest 0.02 mm (0.001 in.). Calculate the average; do not proportions (if not prepackaged), as-mixed temperature, and

round the numerical value. While the shaft is still touching the consistency. Also report any deviations from the provisions

glass plate, use a glass marker to make a circle around the given herein.

contact areas as the points at which later plate-thickness

measurements will be taken. 12. Precision and Bias

9.6 Release the plunger and remove the glass plate from the 12.1 Precision—Based on an analysis of results of coopera-

top of the test specimen 24 6 1⁄2 h after starting the mixing. tive tests of three materials tested at two consistencies, stored

at two storage conditions, it was concluded that separate

9.7 Immediately after removal, measure the thickness of the

precision statements are needed for flowable and fluid mix-

glass plate at the points of contact between the glass plate and

tures.

the micrometer depth gage and record to the nearest 0.02 mm

12.1.1 Flowable Mixtures—The single-operator standard

(0.001 in.).

deviation has been found to be 0.07 % (Note 9). This does not

9.8 At ages of 24 6 1⁄2 h, 3 days 6 1 h, 14 days 6 6 h, and vary with test age (up to 28 days) or with expansion (over the

28 days 6 12 h, measured from the time of contact of the dry range from 0.02 to 0.43 %). Therefore, results from two

materials and the mixing water, take four measurements properly conducted tests by the same operator on the same

directly to the top of the test specimen at the gage points. If the material should not differ by more than 0.196 % (Note 9).

rod end of the depth micrometer either contacts the specimen 12.1.1.1 The multilaboratory standard deviation has been

surface within a bubble that has formed after placing the glass found to be 0.08 % (Note 9). This does not vary with test age

plate or breaks through the surface of a hidden bubble or other (up to 28 days) or with expansion (over the range from 0.02 to

placing defect, discard the reading at that point. If less than 0.43 %). Therefore, results of two properly conducted tests on

three valid gage points remain, discard the test specimen. the same material in two laboratories should not differ by more

Measurements may be continued for additional specified peri- than 0.216 % (Note 9).

ods of time. Calculate the average; do not round the numerical 12.1.2 Fluid Mixtures—The single-operator standard devia-

value. tion has been found to be 0.11 % (Note 9). This does not vary

9.9 On completion of measurements, carefully strip the test with test age (up to 28 days) or with expansion (over the range

specimen and make careful visual examination of the cylindri- from 0.11 to 0.33 %). Therefore, results of two properly

cal surface. Discard measurements made on a specimen that is conducted tests by the same operator on the same material

cracked or otherwise manifestly faulty. should not differ by more than 0.3255 % (Note 9).

12.1.2.1 The multilaboratory standard deviation has been

10. Calculation found to be 0.11 % (Note 9). This does not vary with test age

10.1 To determine V1, correct the initial measurements by (up to 28 days) or with expansion (up to 0.43 %). Therefore,

adding the thickness of the glass plate measured at each results of two properly conducted tests on the same material in

corresponding contact point. Calculate the height change in two laboratories should not differ by more than 0.30 % (Note

percent for each age to the nearest 0.01 %, using non-rounded 9).

values for V1 and V2 as follows: NOTE 9—These numbers represent, respectively, the (1s) and (d2s)

V1 2 V2 limits as described in Practice C670.

V5 3 100 (1)

H 12.2 Bias—No statement on bias is being made because

there is no accepted reference material suitable for determining

where:

the bias in this test method.

V = height change, %,

V1 = average of at least three adjusted micrometer depth 13. Keywords

gage readings at beginning of test, mm (in.), 13.1 grout; height change; hydraulic cement; nonshrink

H = height, 152-mm (6-in.), and

grout

Copyright by ASTM Int'l (all rights reserved); 4

C1090 − 10

SUMMARY OF CHANGES

Committee C09 has identified the location of selected changes to this specification since the last issue,

C1090–01(2005)´1, that may impact the use of this specification. (Approved June 15, 2010)

(1) Revised Terminology section to reference appropriate

terminology documents under C01 and C09.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 5

You might also like

- Astm C-1231Document5 pagesAstm C-1231Sebastian TobonNo ratings yet

- Concrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForDocument9 pagesConcrete Made by Volumetric Batching and Continuous Mixing: Standard Specification Formickyfelix100% (2)

- Abrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method ForDocument7 pagesAbrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method FormickyfelixNo ratings yet

- Astm C-266Document4 pagesAstm C-266Felipe Restrepo MoncadaNo ratings yet

- C617 CappingDocument6 pagesC617 CappingTavo Suarez C100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Estimating The Permanganate Natural Oxidant Demand of Soil and Aquifer SolidsDocument5 pagesEstimating The Permanganate Natural Oxidant Demand of Soil and Aquifer SolidsmickyfelixNo ratings yet

- Using The Seismic-Reflection Method For Shallow Subsurface InvestigationDocument26 pagesUsing The Seismic-Reflection Method For Shallow Subsurface InvestigationmickyfelixNo ratings yet

- BO039M1920M DatasheetDocument21 pagesBO039M1920M DatasheetJohn LyalNo ratings yet

- Astm c1090Document5 pagesAstm c1090ivanhermalNo ratings yet

- Astm C1176-13 PDFDocument5 pagesAstm C1176-13 PDFVictor Hugo Ortiz NajeraNo ratings yet

- C 109 C 109M Compressive Strength For Hydraulic Cement Mortars PDFDocument6 pagesC 109 C 109M Compressive Strength For Hydraulic Cement Mortars PDFAboalmaail AlaminNo ratings yet

- Length Change of Hardened Hydraulic-Cement Mortar and ConcreteDocument7 pagesLength Change of Hardened Hydraulic-Cement Mortar and ConcreteEmily OrtegaNo ratings yet

- Flow of Hydraulic Cement Mortar: Standard Test Method ForDocument2 pagesFlow of Hydraulic Cement Mortar: Standard Test Method FordalalNo ratings yet

- Length Change of Hardened Hydraulic-Cement Mortar and ConcreteDocument7 pagesLength Change of Hardened Hydraulic-Cement Mortar and ConcreteChavier ManguanaNo ratings yet

- Flexural Strength of Hydraulic-Cement Mortars: Standard Test Method ForDocument6 pagesFlexural Strength of Hydraulic-Cement Mortars: Standard Test Method ForVikas SharmaNo ratings yet

- C348Document6 pagesC348Javier Mellado EliasNo ratings yet

- Time of Setting of Hydraulic Cement Mortar by Modified Vicat NeedleDocument3 pagesTime of Setting of Hydraulic Cement Mortar by Modified Vicat Needlehanat asharNo ratings yet

- Standard Practice For Making and CuringDocument6 pagesStandard Practice For Making and Curingrsoasadigmoniem2023No ratings yet

- Making and Curing Concrete Test Specimens in The Field: Standard Practice ForDocument6 pagesMaking and Curing Concrete Test Specimens in The Field: Standard Practice Formaribeldelopez lopezNo ratings yet

- Making and Curing Concrete Test Specimens in The Field: Standard Practice ForDocument6 pagesMaking and Curing Concrete Test Specimens in The Field: Standard Practice ForSurya Mahapatra100% (1)

- Astm C157-14Document7 pagesAstm C157-14Fernando ChavarriaNo ratings yet

- Astm C1698-14Document3 pagesAstm C1698-14Elias AinsworthNo ratings yet

- Astm C617 - C617M-23Document6 pagesAstm C617 - C617M-23vmuribecNo ratings yet

- ASTM-C109-C109M-20Document6 pagesASTM-C109-C109M-20mohabakr112011No ratings yet

- ASTM-C348-21Document4 pagesASTM-C348-21huynhcongly2019cldNo ratings yet

- Astm C1698 09Document4 pagesAstm C1698 09Shivam SinghNo ratings yet

- Astm C 109Document7 pagesAstm C 109Alexis DominguezNo ratings yet

- Astm C266 21Document3 pagesAstm C266 21Daniela Paola Miguel GonzálezNo ratings yet

- C341C341M 18Document4 pagesC341C341M 18Jamman Shahid ShiblyNo ratings yet

- Astm C348Document6 pagesAstm C348adolfo camayoNo ratings yet

- C490 Practice For Use of Apparatus For The Determination ofDocument5 pagesC490 Practice For Use of Apparatus For The Determination ofCarineMolzNo ratings yet

- Sampling and Testing Grout: Standard Test Method ForDocument6 pagesSampling and Testing Grout: Standard Test Method Formirwais100% (1)

- Length Change of Hardened Hydraulic-Cement Mortar and ConcreteDocument7 pagesLength Change of Hardened Hydraulic-Cement Mortar and ConcretemameniqNo ratings yet

- ASTM C157-08 Syandard Test Method For Length Change of Concrete PDFDocument7 pagesASTM C157-08 Syandard Test Method For Length Change of Concrete PDFSami Louis100% (1)

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Document10 pagesCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Chuwaka OlanNo ratings yet

- Astm C187Document3 pagesAstm C187MonserratNo ratings yet

- Astm C185Document4 pagesAstm C185MuhammadRomadonNo ratings yet

- ASTM C1019-24Document8 pagesASTM C1019-24ArashNo ratings yet

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersDocument5 pagesUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersSherif MohamedNo ratings yet

- Making and Curing Concrete Test Specimens in The Field: Standard Practice ForDocument6 pagesMaking and Curing Concrete Test Specimens in The Field: Standard Practice Formanuel davilaNo ratings yet

- BO3 Om GAj WMB KUDocument4 pagesBO3 Om GAj WMB KUFatah FatahNo ratings yet

- C1140C1140M-11 Preparación y Ensayo de Especímenes de Paneles de Concreto Lanzado (Shotcrete)Document3 pagesC1140C1140M-11 Preparación y Ensayo de Especímenes de Paneles de Concreto Lanzado (Shotcrete)SusanaTorresGonzálezNo ratings yet

- Preparing and Testing Specimens From Shotcrete Test Panels: Standard Practice ForDocument3 pagesPreparing and Testing Specimens From Shotcrete Test Panels: Standard Practice ForJorge Luis Arévalo LópezNo ratings yet

- Drying Shrinkage C596 22657 PDFDocument4 pagesDrying Shrinkage C596 22657 PDFsddNo ratings yet

- Astm C 131-14Document5 pagesAstm C 131-14Edika Espinoza100% (1)

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Document10 pagesCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Jose CanciobelloNo ratings yet

- Astm C109Document6 pagesAstm C109nicol pomaNo ratings yet

- Retraccion Del Hormigon EnsayoDocument5 pagesRetraccion Del Hormigon Ensayorodrigoagro1No ratings yet

- Astm C596Document3 pagesAstm C596soyyosiyotunoNo ratings yet

- ASTM-C232-C232M-20Document3 pagesASTM-C232-C232M-20pankaj rawatNo ratings yet

- ASTM C143 C143M 03 Slump of Hydraulic CementDocument4 pagesASTM C143 C143M 03 Slump of Hydraulic CementJavier Sigüeñas BarrantesNo ratings yet

- Astm C109 C109M 12Document6 pagesAstm C109 C109M 12Ahmed FawziNo ratings yet

- C495 M - 12Document3 pagesC495 M - 12Lila Ester Ashook VillarrealNo ratings yet

- Flow of Hydraulic Cement Mortar: Standard Test Method ForDocument2 pagesFlow of Hydraulic Cement Mortar: Standard Test Method ForJaime Arnaldo Montelongo GarciaNo ratings yet

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersDocument5 pagesUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersqsegaqgNo ratings yet

- Length Change of Hardened Hydraulic-Cement Mortar and ConcreteDocument7 pagesLength Change of Hardened Hydraulic-Cement Mortar and ConcretejoseNo ratings yet

- Bleeding of Concrete: Standard Test Methods ForDocument5 pagesBleeding of Concrete: Standard Test Methods ForMaanvir SatyaNo ratings yet

- C 266 - 99 - Qzi2ni1sruqDocument5 pagesC 266 - 99 - Qzi2ni1sruqtechnicalsajaNo ratings yet

- Astm C470.C470M 2009Document4 pagesAstm C470.C470M 2009Carlos GuerraNo ratings yet

- Making and Curing Concrete Test Specimens in The Field: Standard Practice ForDocument6 pagesMaking and Curing Concrete Test Specimens in The Field: Standard Practice ForAbid HussainNo ratings yet

- Astm C1107 C11021M 09Document2 pagesAstm C1107 C11021M 09Raul Ibarra MartinezNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Developing Appropriate Statistical Approaches For Groundwater Detection Monitoring ProgramsDocument15 pagesDeveloping Appropriate Statistical Approaches For Groundwater Detection Monitoring ProgramsmickyfelixNo ratings yet

- Fiber-Reinforced Concrete: Standard Specification ForDocument7 pagesFiber-Reinforced Concrete: Standard Specification FormickyfelixNo ratings yet

- Latex Agents For Bonding Fresh To Hardened ConcreteDocument2 pagesLatex Agents For Bonding Fresh To Hardened ConcretemickyfelixNo ratings yet

- In-Place Density of Unhardened and Hardened Concrete, Including Roller Compacted Concrete, by Nuclear MethodsDocument5 pagesIn-Place Density of Unhardened and Hardened Concrete, Including Roller Compacted Concrete, by Nuclear MethodsmickyfelixNo ratings yet

- Chemical Admixtures For Use in Producing Flowing ConcreteDocument9 pagesChemical Admixtures For Use in Producing Flowing Concretemickyfelix100% (1)

- Coal Fly Ash and Raw or Calcined Natural Pozzolan For Use in ConcreteDocument5 pagesCoal Fly Ash and Raw or Calcined Natural Pozzolan For Use in ConcretemickyfelixNo ratings yet

- Splitting Tensile Strength of Cylindrical Concrete SpecimensDocument5 pagesSplitting Tensile Strength of Cylindrical Concrete SpecimensmickyfelixNo ratings yet

- Determining Density of Structural Lightweight Concrete: Standard Test Method ForDocument4 pagesDetermining Density of Structural Lightweight Concrete: Standard Test Method FormickyfelixNo ratings yet

- Lightweight Aggregates For Structural ConcreteDocument4 pagesLightweight Aggregates For Structural ConcretemickyfelixNo ratings yet

- Lightweight Aggregates For Insulating ConcreteDocument3 pagesLightweight Aggregates For Insulating ConcretemickyfelixNo ratings yet

- Sampling and Testing Fly Ash or Natural Pozzolans For Use in Portland-Cement ConcreteDocument10 pagesSampling and Testing Fly Ash or Natural Pozzolans For Use in Portland-Cement ConcretemickyfelixNo ratings yet

- Total Evaporable Moisture Content of Aggregate by Drying: Standard Test Method ForDocument3 pagesTotal Evaporable Moisture Content of Aggregate by Drying: Standard Test Method FormickyfelixNo ratings yet

- Packaged, Dry, Combined Materials For Concrete and High Strength MortarDocument5 pagesPackaged, Dry, Combined Materials For Concrete and High Strength MortarmickyfelixNo ratings yet

- Determination of Temporary Ditch Check Performance in Protecting Earthen Channels From Stormwater-Induced ErosionDocument8 pagesDetermination of Temporary Ditch Check Performance in Protecting Earthen Channels From Stormwater-Induced ErosionmickyfelixNo ratings yet

- Lightweight Aggregates For Concrete Masonry UnitsDocument4 pagesLightweight Aggregates For Concrete Masonry UnitsmickyfelixNo ratings yet

- Consolidated Drained Triaxial Compression Test For SoilsDocument11 pagesConsolidated Drained Triaxial Compression Test For SoilsmickyfelixNo ratings yet

- Highway Traffic Monitoring Truth-in-Data: Standard Practice ForDocument5 pagesHighway Traffic Monitoring Truth-in-Data: Standard Practice FormickyfelixNo ratings yet

- Measuring Deflections Using A Portable Impulse Plate Load Test DeviceDocument5 pagesMeasuring Deflections Using A Portable Impulse Plate Load Test Devicemickyfelix100% (1)

- Air-Entraining Admixtures For ConcreteDocument4 pagesAir-Entraining Admixtures For ConcretemickyfelixNo ratings yet

- Field Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Groundwater SamplersDocument15 pagesField Pneumatic Slug (Instantaneous Change in Head) Tests To Determine Hydraulic Properties of Aquifers With Direct Push Groundwater SamplersmickyfelixNo ratings yet

- Astm C 215Document7 pagesAstm C 215mickyfelixNo ratings yet

- Preformed Polychloroprene Elastomeric Joint Seals For BridgesDocument4 pagesPreformed Polychloroprene Elastomeric Joint Seals For BridgesmickyfelixNo ratings yet

- Advantages S7-1200 To S7-200Document35 pagesAdvantages S7-1200 To S7-200Jesus CayoNo ratings yet

- Iec60034-29 (Ed1 0) BDocument8 pagesIec60034-29 (Ed1 0) BArizal MaulanaNo ratings yet

- Forms, Scaffolding and StagingDocument50 pagesForms, Scaffolding and StagingHiro Exalion100% (1)

- 12 HMB Am-50Document65 pages12 HMB Am-50khasim1997No ratings yet

- LG Monitor L1730BBUHM - Chassis CL-62Document32 pagesLG Monitor L1730BBUHM - Chassis CL-62tavi100% (1)

- Weblogic Stdout Rotaion ProblemsDocument5 pagesWeblogic Stdout Rotaion Problemsvali07No ratings yet

- EGGPEGAA PDF 29mar23Document38 pagesEGGPEGAA PDF 29mar23Tida Nicholas NyahunzviNo ratings yet

- Fully Corrected Numerical ExerciseDocument36 pagesFully Corrected Numerical ExerciseJigar Goswami100% (1)

- Ib Renovation EstimateDocument17 pagesIb Renovation Estimatesuhail sanadiNo ratings yet

- CarsonDocument5 pagesCarsonMarko IstenicNo ratings yet

- 2017 BG CatalogueDocument200 pages2017 BG Catalogueazeemahmedkhan021No ratings yet

- Study of Compounds NotesDocument17 pagesStudy of Compounds NotesDivya RajendranNo ratings yet

- Software Requirements Specification For: COMSATS University Islamabad, Park Road, Chak Shahzad, Islamabad PakistanDocument44 pagesSoftware Requirements Specification For: COMSATS University Islamabad, Park Road, Chak Shahzad, Islamabad PakistanaddiNo ratings yet

- AISC Engg Journal 92 PDFDocument174 pagesAISC Engg Journal 92 PDFIlham setyabudiNo ratings yet

- DatasheetDocument2 pagesDatasheetHanzla KhanNo ratings yet

- Fire QAPDocument2 pagesFire QAPSuryadev singhNo ratings yet

- Test Lamp W867CDocument1 pageTest Lamp W867CDiana de la RosaNo ratings yet

- Introduction To Power BIDocument50 pagesIntroduction To Power BIsuad.hseqNo ratings yet

- Creating An OrderDocument2 pagesCreating An Orderpraveen nNo ratings yet

- Microscopy & MicrometryDocument4 pagesMicroscopy & MicrometryChristine Jo Ann ZuñigaNo ratings yet

- Examination Report - SH DamDocument59 pagesExamination Report - SH DamsarvannnNo ratings yet

- PMP IttoDocument70 pagesPMP Ittoabirami.narayanan857No ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- SPE-37054-MS (Bit Torque Calculation) PDFDocument9 pagesSPE-37054-MS (Bit Torque Calculation) PDFWindy MartdianzahNo ratings yet

- Box Ford Metric Thread ChartDocument1 pageBox Ford Metric Thread Chartd3xterNo ratings yet

- Penstock Lightduty WeirDocument5 pagesPenstock Lightduty WeirMohamed RamadanNo ratings yet

- Amicus Professional Manual enDocument6 pagesAmicus Professional Manual enelganchoNo ratings yet

- IB 70-8738.rev2. Feb 2011 PDFDocument12 pagesIB 70-8738.rev2. Feb 2011 PDFoktaykeskin1No ratings yet

- 35 MRJN - Color Code Chart - Rev. 02Document1 page35 MRJN - Color Code Chart - Rev. 02احمد حسنNo ratings yet