CSC - 20 06 476

CSC - 20 06 476

Uploaded by

banerjeeamlanCopyright:

Available Formats

CSC - 20 06 476

CSC - 20 06 476

Uploaded by

banerjeeamlanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

CSC - 20 06 476

CSC - 20 06 476

Uploaded by

banerjeeamlanCopyright:

Available Formats

Mechanical Separation Division

Data Sheet

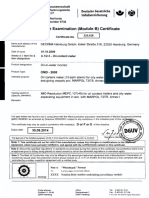

C SC 20-06-476

Complete plant systems with automatic or manual SIP for down-stream processing of fermentation broths under sterile conditions

Fields

of

application

Biotechnology, pharmaceutical and food industry

Complete plant systems with automatic SIP

Typical

product

applications

.Starter cultures for the food and pharmaceutical sectors (e.g. lactic acid bacteria). .Recovery of biomass for pharmaceutical products (e.g. E-Coli). .Treatment of genetica1ly engineered micro-organisms and vaccines, made possible by the closed machine and insta1lation concept (biocontainment). .Gentle discharge of biomass with product-damaging ce1l constituents. This clarifier incorporates the very latest developments in centrifuge construction. The basic features of this new development are: .Clarifier bowl in sanitary design. .Cleaning-in-place -capacity of the clarifier . .Steam-sterilizable (SIP) up to 1.5 bar steam pressure (127 C). .Double-acting slide-ring packing as interface to the drive chamber. .Closed product feed and gentle treatment of shear-sensitive micro-organisms due to the hydrohermetic feed system. .No product contamination due to wear of lip seals and mechanical seals as is the case with hermetically sealed machines. .Low noise pollution due to double-walled coolable hood and solids collector suitable for connection to a closed sealing system up to 1 bar overpressure. .l'Hydrostop" system for controlled partial solids ejections.

.Photoelectric control using a turbidity measurement(28) to monitor the clarified liquid. If a pre-set turbidity level is exceeded, a signal is passed to the control unit (25) which then initiates the solids ejection process.Recommended for use with translucent liquids in which the solids content is not constant or if the throughput capacity varies. This monitoring system can be installed on every standard centrifuge.

The "hydrostop"

controlled partial

system tor

solids ejections

Bowl The product enters the bowl via the inlet (1) and is clarified in this disc stack (3). Centripetal pump (26) then conveys the clarified liquid under pressure to outlet (2), where it is discharged without foam. The separated solids collect in sediment holding space and are ejected periodically via ports (6). Operating water is used only during the actual process of ejection.

When product is processed, only partial solids ejections are performed. The solids ejections is initiated by the control unit. In the case of partial solids ejection, the hydraulically operated sliding piston (20) must be opened within as short a time as possible so as to ensure that the ejection ports are opend wide enough to allow unimpeded solids ejection. The sliding piston (20) is in closed position (left side of figure) when the closing chamber (21) is full. The annular valve (7) is hydraulically opened via valve (17) (right side og fig.). The operating-water flows from the closing chamber (21) into the storage chamber (10). When the storage chamber (10) is full, the flow of liquid from the closing chamber (21) will automatically stop, although the annular piston (7) is still open ("hydrostop" system). The bowl then opens and the solids are discharged rapidly through the ejection ports (6). The amount of solids ejected depends on the liquid level in the storage chamber (10) (controlled partial solids ejection). The amount of solids to be ejected can be pre-selected by partially filling the storage chamber (10) before the solids ejection is initiated. This is done by opening valve (16) which releases water into the storage chamber (10) through the nozzle (11). After the ejection process, the closing chamber (21) is topped up via valve (16). The annular valve (7) then closes. The storage chamber empties through discharge nozzle (8). This new "hydrostop" system reduces the actual solids ejection time to less than 1/10 second. In the case of solids which are difficult to eject, a longer solids ejection cycle is initiated after several partial solids ejections, which has the effect of flushing out remaining solids while the product feed is still open.

Automatic

solids

ejection

Bowl ejections are controlled automatically by control unit (25) The following operations are possible: .partial ejections .a combination of short and long partial ejections .Displacement of the liquid phase from the bowl before a total ejection .Flush ejection after every total ejection Total solids ejection sequence For total solids ejection, the closing chamber (21) is emptied via the annular valve (7) and the nozzle (8) by the addition of operating-water via valve (16). The sliding piston (20) remains open until the whole bowl contents have been ejected. The sliding piston (20) is then closed by supplying closing water via valve (17).

Control

systems

Feed and discharge

The following systems are available for controlling the automatic bowl ejections: .Time-dependent control to suit the particular operation. Recommended for use with products in which the solids content remains constant.

The produc t is fed into the centrifuge by means of a closed system of pipes. The clarified liquid is discharged foam-free and under pressure via a centripetal pump.

Hydrohermetic

product

feed

In this design the centrifuge is equipped with a hydrohermetic product feed (4). This new inlet system prevents shearing forces from acting bn the product when entering the bowl. Similar as with the fully hermetic design, the product stream is accelerated by the product itself in the filled bowl. This makes for gentle treatment and optimum clarifying efficiency, especially in the case of sensitive products and low throughput capacities.

The machine is driven by a three-phaseAC motor. Power is transferred to the bowl spindle via a centrifugal clutch and worm wheel gear. All bearings and the gear are splashlubricated from a central oil bath.

Monitoring .Lube oil sight glass .Temperature feeler and overcurrent protection in case of overload * Cooling The solids collector and the hood are of double-wall design for cooling the discharged solids (5, 9).

release for motor

.Speed measuring device .Vibration monitoring system * .Turbidity meter for monitoring the discharge * .Level probeB in the Bolids tank in case of enclosed Bolids discharge .Additional available charge parts atextra

Cleaning-in-place

(CIP)

Materials All parts coming into contact with the produc t are made of austenitic Cr-Ni-Mo stainless steel or, in the case of highly stressed bowl parts, of soft martensitic Cr-Ni-Mo steel or duplex alloys. The gaskets are made of ethylene-propylene-dienecaoutchouc (EPDM) and Polyamid.

Once the centrifugation process has been completed, the machine can be cleaned-in-place.The cleaning solution is circulated round the centrifuge and the connected system. Total ejections are initiated during CIP manua1ly or automatica1lyon the control unit via an extemal CIP control.

Steri

I ization

The stationary installation is sterilized with hot steam (127 C) under an excess pressure of 1.5 bar. The duration of sterilization is dependent on the nature of the bacteria and the number of germs. Experience suggests a time between 60 minutes. The condensate is conveyed from the lowest point of the system to the killing line. Following sterilization, the whole system is blanketed with sterile air until the next product run.

Assembly

and dismantling

the bowl are

Special tools for installing and removing included in the supply schedule.

Frame

and

drive

The cast-iran frame is equipped with brakes, a rev indicatar and an aillevel sight glass.

Additional (available

equipment at extra charge)

Camplete plant systems with autamatic ar manual SIP

Technical

data

8340 8 min 1

Bowl Speed Total bowl volume Volumen of sediment holding space (with large disc stack) Max. pressure produced by centripetal pump Three-phase AC motor Motor power Speed at 50 Hz Speed at 60 Hz Type Type of protection

4 1 4 bar 11 1500 1800 IMB5 IP55

kW min-l min-1

Weights Complete plant

net 1900 kg grass 2500 kg

Capacity Rated capacity with one channel centripetal pump with two channel centripetal pump

1400 l/h 2800 l/h

The rated capacity indicates the maximum throughput rate of the bowl. The actual operating capacity is usually lower. It depends on the particular product and on the required level of clarification.

Westfalia

Mechanical Division Separation

Separator

AG

' ~ ~~~ tn:~ C/)~~ ~.:: '"' ~

~~~ zu~ o~u a: 5~ z LU~=

a: =0-

~ '"'

~ ~

Westfalia Separator AG. Separation Technology .Werner-Habig-Strae 1 .D-59302 Oelde (F.R. Germany) Tel.: +49 (0) 2522/77-0. Fax: +49 (0) 2522/77-2488. Internet: http://www.westfalia-separator.com

O~~ a:-~ O~~ "-0.-

9997-0516-000/0597

Fe

Subiect ta madificatian

Printed

in GermaJ

You might also like

- VLB 103BDocument2 pagesVLB 103BRaghunath Majee0% (1)

- Filtrex (Eng)Document49 pagesFiltrex (Eng)hamidouhouNo ratings yet

- Omd 2005 CertDocument12 pagesOmd 2005 Certamu_more44No ratings yet

- Dmgt206 Production and Operations ManagementDocument302 pagesDmgt206 Production and Operations ManagementFerisal Firmansyah100% (3)

- Google SOPA Oral TestimonyDocument2 pagesGoogle SOPA Oral TestimonyDeepak Gupta (DG)100% (1)

- 0820 9001 000 - Moc515 Moc8015Document58 pages0820 9001 000 - Moc515 Moc8015gaby2003100% (1)

- BTPX Series BTPX 305 SDocument4 pagesBTPX Series BTPX 305 SmcsabeeraliNo ratings yet

- Disk Stack Compressing DeviceDocument22 pagesDisk Stack Compressing Deviceаа аааNo ratings yet

- CB506 - EN High Performance Decanter WestfaliaDocument2 pagesCB506 - EN High Performance Decanter WestfaliaLTE002No ratings yet

- Centrifuga Westfalia MOC 515 PDFDocument58 pagesCentrifuga Westfalia MOC 515 PDFgaju08No ratings yet

- AFPX 407 Leaflet PDFDocument2 pagesAFPX 407 Leaflet PDFยุทธนา เทียมเมืองNo ratings yet

- Parts Catalogue For 9057-566 - GEA Westfalia Sep.Document53 pagesParts Catalogue For 9057-566 - GEA Westfalia Sep.7rdstxq57qNo ratings yet

- Introduction To Direct Drive - BrochureDocument10 pagesIntroduction To Direct Drive - BrochureCentrifugal SeparatorNo ratings yet

- 9077-305 Vse 40-02-007Document1,032 pages9077-305 Vse 40-02-007gcd2008No ratings yet

- 040 - 2052 9001 041Document170 pages040 - 2052 9001 041babubhaiyya4211No ratings yet

- Equipment Used For The Beer Clarification: Prepared by Honchar IrynaDocument13 pagesEquipment Used For The Beer Clarification: Prepared by Honchar IrynaІра ГончарNo ratings yet

- RSE70 Spare Parts CatalogDocument120 pagesRSE70 Spare Parts Cataloggcd2008No ratings yet

- RSE110 eDocument6 pagesRSE110 eRaghunath MajeeNo ratings yet

- Technical Documentation: Technische DokumentationDocument524 pagesTechnical Documentation: Technische DokumentationAndhityas Piscessandhy PutraNo ratings yet

- BRO MA BilgeMaster 2012 08 en Tcm38 23448Document4 pagesBRO MA BilgeMaster 2012 08 en Tcm38 23448Alexander AkimovNo ratings yet

- 52 Filtrex BrochureDocument6 pages52 Filtrex BrochureCvitaCvitićNo ratings yet

- Afpx 517Document2 pagesAfpx 517banerjeeamlanNo ratings yet

- PX 70 - 80 - (Non EX & EX) - Foundation DrawingDocument1 pagePX 70 - 80 - (Non EX & EX) - Foundation DrawingCentrifugal SeparatorNo ratings yet

- 8A Spare Parts Catalogue Separator PDFDocument48 pages8A Spare Parts Catalogue Separator PDFjonbilbaoNo ratings yet

- SA - PA - Purifier System - Service Manual - 2006Document12 pagesSA - PA - Purifier System - Service Manual - 2006Centrifugal SeparatorNo ratings yet

- S811 Spare Part Catalogue - 881200 - 02 - 01Document51 pagesS811 Spare Part Catalogue - 881200 - 02 - 01sfsdfNo ratings yet

- DA 45 WI Part Katalog Tanpa Bowl DiscDocument72 pagesDA 45 WI Part Katalog Tanpa Bowl DiscMuhammad ArifNo ratings yet

- LO Part CatalogDocument45 pagesLO Part Catalogsourav chetiaNo ratings yet

- Instruction BookDocument186 pagesInstruction Bookjc1ceronNo ratings yet

- Instruction Manual: Mineral Oil Centrifuge With Self-Cleaning Bowl OSD 35-91-067Document214 pagesInstruction Manual: Mineral Oil Centrifuge With Self-Cleaning Bowl OSD 35-91-067Jhonathan RodriguezNo ratings yet

- SPX Seital Separation Technology - ApplicationDocument44 pagesSPX Seital Separation Technology - ApplicationmikafazNo ratings yet

- Performance To Boost Power Generation - GEA Westfalia Separator EagleclassDocument20 pagesPerformance To Boost Power Generation - GEA Westfalia Separator EagleclassbanerjeeamlanNo ratings yet

- Alfa Laval Mab 103 24 Spare Parts Manual SPCDocument58 pagesAlfa Laval Mab 103 24 Spare Parts Manual SPCJonathan LisboaNo ratings yet

- Anatomy and Knowledge: of Sondex Traditional Plate Heat ExchangersDocument21 pagesAnatomy and Knowledge: of Sondex Traditional Plate Heat ExchangersRajibNo ratings yet

- VBU Part List&Maintenance Schedule 2020-9101-000Document42 pagesVBU Part List&Maintenance Schedule 2020-9101-000Jano GoñiNo ratings yet

- Transfer Gear Pumps KF 3/100... KF 6/630Document20 pagesTransfer Gear Pumps KF 3/100... KF 6/630Jhonathan RodriguezNo ratings yet

- SA 831 - 836 - Foundation DrawingDocument1 pageSA 831 - 836 - Foundation DrawingCentrifugal SeparatorNo ratings yet

- Alfa Laval - Foodec 100, Leaflet PDFDocument2 pagesAlfa Laval - Foodec 100, Leaflet PDFImad MhannaNo ratings yet

- 2066-9001-201 OSE 5 Manual Replacement For - 200Document216 pages2066-9001-201 OSE 5 Manual Replacement For - 200gcd2008No ratings yet

- Ain Shams Engineering Journal: Mayssaa Ali Al-Bidry, Rana Abbas AzeezDocument9 pagesAin Shams Engineering Journal: Mayssaa Ali Al-Bidry, Rana Abbas Azeezهدوء السماءNo ratings yet

- VNPX 507sgd-31gc-Gcs - Parts - 2015Document70 pagesVNPX 507sgd-31gc-Gcs - Parts - 2015Centrifugal SeparatorNo ratings yet

- Separator Spares InternationalDocument8 pagesSeparator Spares InternationalAlexanderNo ratings yet

- MAB 206 Separator - O&M (Centrifuse TG) PDFDocument196 pagesMAB 206 Separator - O&M (Centrifuse TG) PDFadarsh_saxena262775% (4)

- SU 840 - Service Manual - 2003Document158 pagesSU 840 - Service Manual - 2003Centrifugal SeparatorNo ratings yet

- Solids-Retaining Centrifugal Separators: ApplicationDocument4 pagesSolids-Retaining Centrifugal Separators: ApplicationninatenaNo ratings yet

- Alfa Laval MAB206 PDFDocument196 pagesAlfa Laval MAB206 PDFThái Mai ĐìnhNo ratings yet

- v4 Parameter ListDocument16 pagesv4 Parameter ListarnoldbusaNo ratings yet

- PX 65 LeafletDocument2 pagesPX 65 LeafletrinthusNo ratings yet

- Alfa Laval - Cleaning ChemicalsDocument4 pagesAlfa Laval - Cleaning Chemicalsmustafa_beheryNo ratings yet

- WSST Oi Ose 5 10 20 40 80 enDocument2 pagesWSST Oi Ose 5 10 20 40 80 enjing qiangNo ratings yet

- GEA Algae Separation TechnologyDocument8 pagesGEA Algae Separation TechnologyRaghunath MajeeNo ratings yet

- SenseiViewIB Show1 PDFDocument156 pagesSenseiViewIB Show1 PDFkarlo adolfoNo ratings yet

- FESX 512S-35CG - Parts - 2010Document68 pagesFESX 512S-35CG - Parts - 2010Centrifugal SeparatorNo ratings yet

- Vdocuments - MX Mineral Oil Centrifuge Ose 5-91-0374Document81 pagesVdocuments - MX Mineral Oil Centrifuge Ose 5-91-0374Miti RacuNo ratings yet

- MMPX 404 Bowl AssemblyDocument2 pagesMMPX 404 Bowl AssemblySANDEEPNo ratings yet

- 9.5 Oil Purifier - Maintenance ManualDocument104 pages9.5 Oil Purifier - Maintenance Manualsumitchandwaniseros equiptransNo ratings yet

- VNPX 310SGV-34 - Parts - 2013Document54 pagesVNPX 310SGV-34 - Parts - 2013Centrifugal Separator100% (1)

- FOPX614System DescriptionDocument20 pagesFOPX614System DescriptionJerry ChenNo ratings yet

- TD - GSC 15-06-177 - Ecoplus - EN - KL - 4Document2 pagesTD - GSC 15-06-177 - Ecoplus - EN - KL - 4banerjeeamlanNo ratings yet

- Afpx 810xgv-14cg-74cg - Parts - 2011Document79 pagesAfpx 810xgv-14cg-74cg - Parts - 2011Centrifugal SeparatorNo ratings yet

- CSC 20 06 476 PDFDocument5 pagesCSC 20 06 476 PDFยุทธนา เทียมเมืองNo ratings yet

- Phamplet of Bio-Vacuum Toilet SystemDocument25 pagesPhamplet of Bio-Vacuum Toilet Systemedbtc6759No ratings yet

- GEA Westfalia Separator Soline: Advanced Soymilk ProcessingDocument12 pagesGEA Westfalia Separator Soline: Advanced Soymilk ProcessingbanerjeeamlanNo ratings yet

- Performance To Boost Power Generation - GEA Westfalia Separator EagleclassDocument20 pagesPerformance To Boost Power Generation - GEA Westfalia Separator EagleclassbanerjeeamlanNo ratings yet

- DA - Cold Milk Procool ENDocument8 pagesDA - Cold Milk Procool ENbanerjeeamlanNo ratings yet

- Cleaning TechnologyDocument71 pagesCleaning TechnologybanerjeeamlanNo ratings yet

- Pulsation Systems: Setting The Standard For Durable and Consistent PulsationDocument8 pagesPulsation Systems: Setting The Standard For Durable and Consistent PulsationbanerjeeamlanNo ratings yet

- SDS 024 A4Document4 pagesSDS 024 A4banerjeeamlanNo ratings yet

- Production of Biodiesel With Separators PDFDocument4 pagesProduction of Biodiesel With Separators PDFbanerjeeamlanNo ratings yet

- CE Conformity 9997 1213 010Document6 pagesCE Conformity 9997 1213 010banerjeeamlanNo ratings yet

- Butterfly Valves T-SmartDocument100 pagesButterfly Valves T-SmartbanerjeeamlanNo ratings yet

- WSG - Westfalia Separator Ecoforce enDocument16 pagesWSG - Westfalia Separator Ecoforce enbanerjeeamlanNo ratings yet

- 2 Gear Drive Decanters 010807Document4 pages2 Gear Drive Decanters 010807banerjeeamlanNo ratings yet

- 2010 Datasheet Mixer 160 280 enDocument2 pages2010 Datasheet Mixer 160 280 enbanerjeeamlanNo ratings yet

- Bilgemaster 200 PDFDocument7 pagesBilgemaster 200 PDFbanerjeeamlanNo ratings yet

- WSST FW Varipond enDocument6 pagesWSST FW Varipond enbanerjeeamlanNo ratings yet

- Chevron Alba FSU EN - LQDocument2 pagesChevron Alba FSU EN - LQbanerjeeamlanNo ratings yet

- Decanter Control DCU7000Document4 pagesDecanter Control DCU7000banerjeeamlanNo ratings yet

- MBR Decanter 9997 1227 020Document8 pagesMBR Decanter 9997 1227 020banerjeeamlanNo ratings yet

- Instant Coffee 9997 1323 020Document12 pagesInstant Coffee 9997 1323 020banerjeeamlanNo ratings yet

- 2 Gear DriveDocument4 pages2 Gear DrivebanerjeeamlanNo ratings yet

- Pharmaceutical Biotechnology 9997 8203 030Document32 pagesPharmaceutical Biotechnology 9997 8203 030banerjeeamlanNo ratings yet

- RR - Decanter GEA WS Ecoforce FishMaster CF 6000 Separating Decanter enDocument2 pagesRR - Decanter GEA WS Ecoforce FishMaster CF 6000 Separating Decanter enbanerjeeamlanNo ratings yet

- GEA Westfalia Separator WatchMaster PlusDocument2 pagesGEA Westfalia Separator WatchMaster PlusbanerjeeamlanNo ratings yet

- Note 1440423033Document17 pagesNote 1440423033Siva GaneshNo ratings yet

- Kamal Khandelwal: Experience SummaryDocument6 pagesKamal Khandelwal: Experience Summarykamal khandelwalNo ratings yet

- 2303, BG 7 Version161107Document10 pages2303, BG 7 Version161107Aliezhea HannelieNo ratings yet

- ISDocument3 pagesISMohan PrasadNo ratings yet

- FUSION ManualDocument119 pagesFUSION ManualRodrigo GarciaNo ratings yet

- En Ferro DampDocument2 pagesEn Ferro DampDamian SzczypieńNo ratings yet

- Jira ManualDocument376 pagesJira ManualMukesh3208100% (1)

- 6 Sigma and LeanDocument35 pages6 Sigma and LeanEslam MedhatNo ratings yet

- Thrust CalculationDocument24 pagesThrust Calculationvivek anandNo ratings yet

- NBC ToiletDocument11 pagesNBC ToiletAnish S NairNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- Maternity Notification Form2010 FillinDocument1 pageMaternity Notification Form2010 Fillinsophistikatie50% (2)

- One-Piece Toilet: CW166B CW166PBDocument1 pageOne-Piece Toilet: CW166B CW166PBcvpn55No ratings yet

- Danish Cover LetterDocument3 pagesDanish Cover Letterapi-291285561No ratings yet

- Aw & GN: BOQ SHEET NRDocument2 pagesAw & GN: BOQ SHEET NRGodwin IwekaNo ratings yet

- Tufted Carpet Miss AtiyyahDocument14 pagesTufted Carpet Miss Atiyyahjannah0808No ratings yet

- Divertion Timur Edit BuyaDocument10 pagesDivertion Timur Edit BuyaImam GozaliNo ratings yet

- Travelmate p243m PDFDocument271 pagesTravelmate p243m PDFjedfishNo ratings yet

- CB SchemeDocument3 pagesCB SchemeJane MarekNo ratings yet

- Phenoline 353 PDSDocument2 pagesPhenoline 353 PDSGerson SuarezNo ratings yet

- DP7 00 Integ MicrosoftDocument232 pagesDP7 00 Integ MicrosoftMike Avalos GonzalezNo ratings yet

- Sound Waves and MusicDocument8 pagesSound Waves and MusicJose RattiaNo ratings yet

- Part List Kyocera 205c-255cENPLR4Document53 pagesPart List Kyocera 205c-255cENPLR4nandersonlydyedsonNo ratings yet

- Mentoring Pag 2013Document11 pagesMentoring Pag 2013api-188978784No ratings yet

- Books To UseDocument1 pageBooks To Usesimu.upadhyayaNo ratings yet

- Activity 4 TyroneDocument3 pagesActivity 4 TyroneTyrone Pagal100% (1)

- MC 0069-01 SYS Analysis and DesignDocument14 pagesMC 0069-01 SYS Analysis and DesignshrikrushNo ratings yet

- The O2 Site Layout Map Fe5d7a954eDocument1 pageThe O2 Site Layout Map Fe5d7a954epaulwilliamarnoldNo ratings yet