Manual Ir Heat Sensor D1145-2

Manual Ir Heat Sensor D1145-2

Uploaded by

ehsanrastayeshCopyright:

Available Formats

Manual Ir Heat Sensor D1145-2

Manual Ir Heat Sensor D1145-2

Uploaded by

ehsanrastayeshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Manual Ir Heat Sensor D1145-2

Manual Ir Heat Sensor D1145-2

Uploaded by

ehsanrastayeshCopyright:

Available Formats

Patol Limited

Series 5000

Type 5410 Infra-red Fire & Heat Detector

SPECIFICATION

INSTALLATION - COMMISSIONING

OPERATION - MAINTENANCE

Applicable to unit Part Numbers 720-002 / 720-012

Serial Numbers : 98538-01 Onwards

Document Ref : D1145

Issue Change Date Remarks

1 Original 18/03/09 Based on D1140

2 Table 3 - B reference corrected to D 15/11/12 Page 8

Rectory Road, Padworth Common, Reading,

Berkshire. RG7 4JD United Kingdom.

Tel : +44 (0) 118 9701 701

Patol Limited Fax : +44 (0) 118 9701 700

Email : info@patol.co.uk

Web : www.patol.co.uk

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 1 of 16

Patol Limited

INDEX

1. INTRODUCTION

1.1 General

1.2 Principles

2. EQUIPMENT DETAIL

2.1 General Description

2.2 Relay Mode

2.3 Low Power Mode

2.4 Sensor Arrangement

2.5 Specification

2.6 Operational Programmability - SIL Switch

2.7 Connections

3. INSTALLATION

3.1 Detection Coverage

3.2 Supply / Signal Cable

3.3 Purge Air Supply

4. COMMISSIONING

4.1 Cable Checks

4.2 Controller Set Up

4.3 Power Up Procedure

4.4 Purge Air Supply and Pressure Switch

4.5 Hot Body Simulation Tests

5. OPERATION

5.1 Normal

5.2 Alarm Condition

5.3 Reset

5.4 Fault Warning

5.5 Test

6. MAINTENANCE

6.1 General

6.2 Purge Air Filter

6.3 Fault Monitoring Functions

6.4 Infra-red Detection

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 2 of 16

Patol Limited

1 INTRODUCTION

1.1 General

The Patol 5000 Series of equipment is specifically designed for the protection of

establishments and systems where a movement of materials with a potential fire hazard is

a routine occurrence.

The 5410 Detector employs enhanced Infra-red monitoring technology that enables the

detection of fire initiating materials, whilst they are being transported, and before they have

reached a flame condition.

The system has many applications within industries such as Power Generation, Coal

Mining, Process Plant, Road Transportation and Rail Networks and has been specifically

designed to both meet the rigors of these environments and to provide the reliability

required.

The equipment monitors for fire and fire potential of materials in transit. The system can

detect anomalies where combustion has not yet been reached, but where there is sufficient

energy for a fire initiation upon destination arrival.

A typical example is in the coal feed systems on power stations where coal on the ‘out field

stack’ may very well smoulder with little adverse effect for long periods of time. However, if

imported to the power station it may have devastating effects on conveyor systems, holding

hoppers, blending plants etc.

Detection of hazards at temperatures below flame point including both embers and

buried hot spots.

Air purged system for Dusty environments with air pressure monitoring.

Two wire operation - Powered by direct connection to standard fire trigger circuits or

addressable loop interfaces - Signalling mode user configurable to simulate smoke &

heat detector protocols.

Patol remote controllers/interfaces available for two wire operation.

Volt free relay contact output operation selectable as standard.

Twin high integrity detection circuit channels for maximum reliability.

Unique reflective cone lensing system provides wide uniform coverage superior to

some ember/spark detectors.

Coincidence - Double Knock - option for unit detector channels as standard.

Timed auto reset / coincidence analyser circuit.

Tuned response - solar blind.

High degree of ingress protection - IP66.

Specifically designed for high EMC compliance - CE Marked.

1.2 Principles

The principle of operation is that

SOLAR

temperature dependant black body

Typical Black Body Energy Emissions

emissions occur for all materials.

These emissions range through the 320 o C 5000 RESPONSE FILTER

infra red spectrum to visible light.

Both the wavelength and level of 200 o C

peak energy emission are related to

temperature. Fig. 1

Type 5410 detectors are designed

to detect the changes in these

emissions that occur when a hot 1 2 3 4 5 6 7 8 9 10

body enters the field of view of the WAVELENGTH (Micrometres)

detector.

By the use of both optical filtering and electronic analysis of the various parameters the

system is blind to visible light from the sun or local luminaires, whilst being able to detect

relatively low temperature material moving through the field of view.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 3 of 16

Patol Limited

2. EQUIPMENT DETAIL

2.1 General Description

The 5000 Series system described here comprises two primary elements :-

Detector unit - Type 5410

Air Supply / Blower Unit

The Detector is located above the materials transit path (e.g. conveyor) by means of the

adjustable mounting bracket and aligned such that the monitored hazard passes through

the unit’s field of view. The height and angle of the sensor determine the width of the

monitored path.

The Type 5410 Detector outer case is equipped with an air hose spigot for connection of an

air supply. This is required such that a positive air pressure is maintained around the inner

module sensor “windows”.

There is a continuous air flow from the outer case optical path aperture which stops dust

settling on the inner sensor module. Also, by maintaining a positive pressure within the

enclosure, ingress of explosive gas or dust is prevented. The arrangement can permit the

unit to be employed in a Hazardous Area depending on applicable local regulations.

The air purging is essential in dusty environments such as coal conveyors, and is

recommended in even relatively clean applications. A series 5000 air purge blower and

filter unit is employed when an ‘on site’ air supply is not available. (See section 2.7)

A pressure switch is located within the unit to monitor the purge air and signals a loss of

pressure as a Fault.

AIR PURGE UNIT AIR HOSE

SIGNAL/SUPPLY CABLE

AIR

AIR FILTER SENSOR

110 / 230 Vac

0o to 55o 1 to 1.5 m

Fig. 2

MONITORED MATERIALS

The unit may be user selected to either of two principal operating settings which are

referenced as :-

“Relay Mode” - Operation from a 20 to 30 Vdc supply.

“Low Power Mode” - Operation from a fire alarm trigger circuit / addressable loop.

A description of these arrangements is provided in sections 2.2 and 2.3 following.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 4 of 16

Patol Limited

2.2 Relay Mode

The unit is equipped with relays which are enabled in this mode.

A 24 Vdc (nom) supply is required to operate the unit (max current 24mA).

The unit’s volt free relay contacts are used for signalling of Fire and Fault conditions.

The Fire relay is normally de-energised and energises on an infra-red detection alarm.

The Fault relay is normally energised and de-energises on power supply removal, module

regulation failure or loss of purge air.

Refer to figure 3.

5410 SENSOR HEAD VOLT FREE CONTACTS

TRIP

FIRE RELAY

(Normally De-Energised)

ALARM

Fig.3

FAULT FAULT RELAY

(Normally Energised)

24 Vdc

SUPPLY

POWER SUPPLY

2 WIRE SUPPLY CIRCUIT

2.3 Low Power Mode

In this mode the relays are disabled and the unit’s quiescent supply current is very low and

of a similar level to conventional Smoke and Heat detectors.

By the connection of appropriate resistor values to the sensor’s “solid state” outputs the unit

will signal Normal, Fire & Fault conditions by line current levels, in a manner that permits

the unit to be connected directly to fire control panels via alarm trigger circuits, or to the

monitored inputs of addressable loop interface modules.

The unit can also be employed with the two wire connection to a remote Patol signal relay

module.

Refer to figures 4 & 5.

Fig.4

5410 SENSOR HEAD

ALARM AND

ALARM EOL RESISTORS CONVENTIONAL

* AS PER FIRE PANEL FIRE CONTROL PANEL

FAULT REQUIREMENT AND / OR

PATOL SIGNAL

SUPPLY RELAY MODULE

2 WIRE TRIGGER CIRCUIT

Solid State Output Switches

*

Fig.5

5410 SENSOR HEAD

ALARM & EOL ANALOGUE

RESISTOR ADDRESSABLE

ADDRESSABLE

LOOP INTERFACE

CONFIGURATION FIRE ALARM

AS PER FIG.2 MODULE

CONTROL PANEL

TWO WIRE CONNECTION

2 WIRE ADDRESS LOOP

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 5 of 16

Patol Limited

2.4 Sensor Arrangement

A dual detector channel sensing module is located within an ABS housing which is

mounted by means of an adjustable bracket permitting alignment in both vertical and

horizontal planes. The outer housing is equipped with an air hose spigot. The signal

cable enters through glands in both outer housing and inner module and is terminated at

screw terminals. The inner module is rated IP66.

277 120

SIGNAL CABLE

CABLE GLAND

HOSE CLIP

Fig.6 AIR HOSE

A’

SPIGOT 188

A’‘

SIDE VIEW END VIEW

ADJUSTMENT

CL

MOUNTING HOLES 4.5 Dia (3off) 14

14

HANGING PLATE

BRACKET

26

CL 92

26

FIRE TRIP LED - RED

DETECTOR WINDOWS

SYSTEM ON / NORMAL LED - GREEN 60

BRACKET

BOTTOM VIEW VIEW ON A’-A’‘

2.5 Specification

2.5.1 General

a) Outer Case:- Material : ABS

Finish : RAL 7035

b) Inner Module:- Material : Polycarbonate

Finish : RAL 7035

Ingress Rating : IP66

c) External Lamps Green Normal LED

Red Trip LED

d) Termination:- Within inner module : Two part rising clamp terminals

Cable Core Size : 2.5mm² - 14AWG

e) Temperature :- -20°C to +70°C

f) Weight:- 1.5 kg

g) Purge Air Supply:- Pressure : 4 mBar (1.6”WG)

Delivery : 5.0 litres / sec (11 cubic feet per min)

Input Fitting : 45mm (1 3/4”) dia. hose spigot

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 6 of 16

Patol Limited

Specification - Continued

2.5.2 Internal / Maintenance Features - Accessed on inner module cover removal

a) Indications:- 2 off Red LEDs - One per sensor channel

b) Controls:- Test Push-button

Reset Push-button

c) Program Switch:- Sensitivity : 4 Levels

(SIL 8 Way) Alarm Operation : ‘OR’ / ’AND’ - Latching / Auto-Reset

Auto Reset Timer : 4 Settings

2.5.3 Relay Mode - Direct Supply - Relays Enabled

a) Supply Voltage:- 20 to 30 Vdc

b) Supply Current:- Standby - 11 mA Fire (Alarm) - 26 mA (max)

c) Alarm-Trip O/P:- Fire Relay Contacts - 2 sets

Volt free change over - 30 Vdc 500 mA

Normally De-energised

c) Monitor Output:- Fault Relay Contact - 1 set

Volt free change over - 30 Vdc 500 mA

Normally Energised - De-energises on supply / air failure

2.5.4 Low Power Mode - Line current signalling via Fire Alarm Trigger Circuit

a) Supply Voltage:- 13 to 30 Vdc

b) Supply Current:- Normal / Standby - 1.8 mA (plus EOL *resistor current)

Fire (Alarm) - 5 mA (plus Alarm Load** resistor current)

Fault - <350 uA

c) Fire Output:- Solid state switch - Fit with Alarm Load** resistor

Normally Off - Alarm Load switched across supply on fire

c) Fault Output:- Solid state switch - Fit with trigger circuit EOL* resistor

Normally On - EOL open on Fault (supply <11V / air failure)

2.5.5 Detectors

a) Configuration:- 2 off - Employing reflective cone optical focusing system

Coincident fields of view arranged as separate channels

b) Field Of View:- +5°/-15°(along transit axis path) +/-38°(across transit path)

Refer to coverage chart in section

c) Characteristic Spectral Filter : 5 - 14 µm

Sensitivity : 10 - 40 µW

Transit speed : 0.5 to 6 m/s

Response : 80 - 1000 ºC (170 - 1800 ºF) - See below

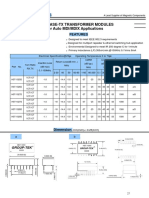

Figure 7 indicates the 250mm Dia. 100mm Dia. 50mm Dia. Fig. 7

490 sq cm 78 sq cm 19.6 sq cm

correlation between the

4

temperature and size of ‘hot

spot’ anomalies for a typical 29mm Dia.

installation to produce one or 3 6.45 sq cm

1 sq inch

m ore det ect or channel

activations at various trigger 2

level settings.

Exact response is dependant 1

on the emissivity factor of the 25mm Dia.

4.9 sq cm

monitored material, sensor

orientation and target speed. 0 100 200 300 400 500 600 700 800 900 1000

Temperature Degrees C GLOWING / VISIBLE

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 7 of 16

Patol Limited

2.6 Operational Programmability - SIL Switch

An eight pole SIL switch is located within the inner sensor module which programs the unit’s

operation. Most of the various option features are for special applications, factory test,

commissioning or maintenance purpose.

A summary of the switch functions is as follows:-

2.6.1 LED Operation - Pole 1

Normally the internal LEDs will only illuminate on ‘Alarm’ signalling. In the case of

coincident (double knock) operation the LEDs only illuminate when both channels

have triggered. This is to obviate momentary increases in line current for single

channel operations. For factory test and maintenance purpose Pole 1 of the switch

allows the LEDs to individually illuminate irrespective of operating mode. Ref. table 1.

2.6.2 Channel AND / OR selection - Pole 2

The unit can operate such that detection by either sensor channel results on an

alarm output (single knock / OR operation). Alternatively the unit may be set an

alarm output only occurs on detection by both sensor channels (double knock /

coincident / AND operation). Refer to table 1.

2.6.3 Non-latching option. - Pole 3

The sensor channels normally latch on detection. A non-latching setting is available

for maintenance, factory test and special application analysis. Refer to table 1.

2.6.4 Auto Reset operation. - Pole 4

When in double knock mode an auto reset is applied after a preset delay .

This only occurs if only a single channel has operated within the delay time. If both

channels have operated then the auto reset is prevented. The delay time is in effect

the scan period for coincidence. An option to auto reset ‘AND alarms’ is provided for

maintenance test purpose. Refer to 2.6.5 and table 1.

2.6.5 Auto Reset Delay (Scan Period) - Poles 5 & 6

The duration is set by these switch poles . Refer to table 2.

2.6.6 Sensitivity. - Poles 7 & 8

The unit detection level sensitivity is set by these switch poles. The range

approximates to 10 - 40 μW. Refer to table 3.

Pole FUNCTION

OFF Internal Channel LED’s only illuminate on alarm

1

ON Internal Channel LED’s illuminate before D/K alarm

OFF Double Knock - Coincident Output

2 Table 1.

ON Single Operation - OR - Output

OFF Latching Operation

3

ON Non-latching Operation

OFF Only single detections auto-reset after scan period

4

ON All detections auto-reset after scan period

Table 2. Table 3.

Pole AUTO RESET DELAY - SCAN PERIOD Pole SENSITIVITY (A=Most : D=Least)

5 OFF OFF ON ON 7 OFF OFF ON ON

2.6s 1.3s 0.9s 0.6s A B C D

6 OFF ON OFF ON 8 OFF ON OFF ON

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 8 of 16

Patol Limited

2.7 Connections

2.7.1 Relay Mode - Direct Supply - Relays Enabled

24Vdc

POWER SUPPLY

RESET REMOTE TEST

(OPTIONAL)

SUPPLY

1 10

+V

POSITIVE 2 11

SUPPLY

3 12

0V

NEGATIVE 4 13

TEST 5 14

FIRE

RELAY COIL 6 15

FIRE

OUTPUT 7 16

FAULT

RELAY COIL 8 17

FAULT

OUTPUT 9 18

21 OPTION - Green Normal LED extinguishes on:- Fig. 8

No Link : Loss of either Electric or Air supply.

22 Linked : Loss of Electric supply only.

2.7.2 Low Power Mode - Line Powered - Trigger Circuit Connection

FIRE ALARM PANEL

OR

ADDRESSABLE LOOP INTERFACE

REMOTE TEST

TRIGGER CIRCUIT (OPTIONAL)

SUPPLY

1 10

+V

POSITIVE 2 11

SUPPLY

3 12

0V

NEGATIVE 4 13

TEST 5 14

FIRE ALARM

RELAY COIL 6 RESISTOR 15

FIRE

OUTPUT 7 16

FAULT EOL (TRIM)

RELAY COIL 8 RESISTOR 17

FAULT

OUTPUT 9 18

21 No Link. In LP mode Green LED extinguishes on Fig. 9

either Electric supply or Air supply failure to

22 maintain correct fault current signalling.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 9 of 16

Patol Limited

3. INSTALLATION

3.1 Detection Coverage

The angle and height of mounting determine the monitored width.

Fig. 11 Fig. 12

o

A

HEIGHT o

15 o

o MONITORED

90 5 WIDTH

CONVEYOR TRANSIT PATH

Fig. 13

2m

EXAMPLE

1m

0.8m

o

o 55 o

30 45 Angle -A

o

o

0

0m 1.3m

0m 1m 2m 3m 4m 5m

MONITORED WIDTH

The example shown on the chart is for a sensor mounted 0.8m above the transit path at an

angle of 0°. This provides a maximum monitored width of 1.3m which would be suitable for

most coal conveyors. Should the most practical mounting height (e.g. 1m) produce a wider

view field than the conveyor this is perfectly acceptable, so long as the “overlap” on each

side is not so large that external hot targets, such as vehicles on an adjacent roadway, are

within the units view.

3.2 Supply / Signal Cable

The Type 5410 Detector outer case is fitted with a 20mm gland as standard, which is

suitable for cables of 6 to 12mm overall diameter. A second 20 mm gland is fitted to the

inner sensor module.

Cable terminations are made at plug-in rising clamp screw terminal connectors located

within the inner module. The terminals accept wires of up to 2.5mm² (14AWG). Refer to

section 2.7 for connections.

To access the terminals it is necessary to remove the covers / lids to both the outer case

and the inner sensor module.

The air pressure switch is located on the inside of the inner sensor module lid. The switch

wiring may be ‘un-plugged’ from the rear board by means of the two part terminal, and the

air tube ‘A’ may be removed from the rear of case nipple in order to fully remove the

module lid.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 10 of 16

Patol Limited

When re-fitting the inner module lid, the switch wires must be plugged into the rear board

(TM 19/20), and air switch tube ’A’ must be re-fitted to the nipple located at the rear of the

outer compartment. When re-fitting the outer case lid it is essential that the air switch tube

‘B’ is inserted into the neck of the air inlet spigot such that the tube end lies in the air input

hose.

VIEW WITH BOTH Fig. 14

LIDS REMOVED

Tube ‘A’

Tube ‘B’

Pressure Switch Pressure Switch Cable Glands

Air Tube Nipple

Terminals

1 10

2 11

3 12 LEDs

4 13

5 14

6 15

Adjustment 7 16 SIL Switch

8 17

Screw 9 18

19 A - ALARM - B

20 TEST RESET

1 8

Push-buttons

VIEW ON INSIDE OF

INNER MODULE LID

Tube ‘B’

Inner Module

Fig. 15

Tube ‘A’

Pressure Switch Tube Nipple

When armored cable or conduit is employed it may be most practical for these circuits to

terminate at a junction box adjacent to the detector. A flexible cable should then connect

the junction box to the Detector in order to permit adjustments to sensing alignment.

On certain sites (“Hazardous Areas” for example) it may be a requirement that all cables

are installed in conduit. In this case it is recommended that a short length of approved

flexible conduit is fitted between the 5410 Detector and an adjacent junction box. The outer

case cable gland must be replaced with an appropriate flexible conduit coupler, which

should be sealed with a suitable conduit sealant.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 11 of 16

Patol Limited

3.3 Purge Air Supply

The Sensor unit is equipped with a spigot for connection to a flexible hose. The air supply

must be capable of delivering at least 5.0 ltrs/sec at this connection and maintain a

minimum pressure of 4.0 mBar (1.6” water gauge) in order to operate the sensor’s pressure

monitoring switch.

If an “on site” air supply is not available a Series 5000 Air Purge Blower (APB) should be

employed. Some units are equipped with an easily removable and washable air filter,

however these filters are intended to preserve blower life in normal conditions. The blower

should either be installed outside the dirty/dusty area or the unit inlet piped to a clean air

environment.

Intermediate rigid ducting is most readily achieved by the use of standard µPVC pipes and

fittings. 2 m of hose is provided with each purge unit for couplings at sensor & blower.

SENSOR AIR FLOW PURGE AIR BLOWER UNIT CLEAN AIR

DUCT LENGTH

Fig. 15

In coal handling plant applications twin conveyors may be required to be monitored.

A single blower may purge both sensors by employing a “T” branch in the air ducting.

SENSOR T Branch

BLOWER AIR INPUT

UNIT

SENSOR

Fig. 16

In most applications the ‘clean air’ input will be quite close to the blower unit and sensor(s).

In the case of over-ground conveyors, sufficiently clean air is simply obtained by ducting to

the outside of the conveyor housing cladding. A minimal amount (<6m) of ducting being

used.

However, in some applications (such as under-ground tunnels) the Sensor may need to be

remote from a ‘clean air’ area.

There are limits to the distance that any APB can deliver the required air to the Sensor

which are principally dependant on the APB specification and duct bore size. Other factors

such as the ducting inner wall surface characteristic and the air temperature/pressure also

have an effect.

For these ‘long duct’ applications consideration must be given to the exact installation

ducting parameters, together with blower specifications.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 12 of 16

Patol Limited

4. COMMISSIONING

4.1 Cable Checks

The installation wiring should be checked for correct connection, continuity and insulation.

These checks should include cabling to both detector and air blower (if appropriate).

For relay mode implementation the relay coil link connections at terminals 8/17 & 9/18

should be checked. Refer to figure 8 section 2.7.1.

For line powered (trigger circuit) mode the Alarm resistor at terminals 2/8, and EOL (end of

line) resistor at terminals 3/9 should be checked for both correct value and fitment. Refer to

figure 8 section 2.7.1.

4.2 Controller Set Up

The Controller program SIL switch must be set for the required operation.

In most applications the selected operation will be for double channel coincident detection

with the unit latching until manually reset.

It is recommended that initially, detection is set to the most sensitive level.

The SIL switch setting for this “Double Knock” configuration is:-

POLE 1 POLE 2 POLE 3 POLE 4 POLE 5 POLE 6 POLE 7 POLE 8

OFF OFF OFF OFF OFF ON OFF OFF

4.3 Power Up Procedure

Note: The unit has three signaled / output states which are monitored by remote

equipment. These are referenced as Normal - Fire - Fault in the following.

For relay mode : Normal = Fire relay de-energized & Fault relay energized.

For low power mode : Normal = EOL resistor connected across trigger circuit.

Fault = EOL resistor disconnected from trigger circuit.

Fire = Alarm resistor connected across trigger circuit.

4.3.1 Apply power to the detector. (Connect supply or trigger circuit)

Check supply = 20 to 30 Vdc for relay mode or 13 to 30 Vdc for relay mode.

Operate detector Test PB - Check : Internal & External Red LEDs illuminate.

Operate detector Reset PB - Check : LEDs extinguish.

4.3.2 A general check of detector field of view may be conducted at this stage whilst the

module LEDs, Reset PB and SIL switch is still accessible. Refer to section 4.5.

For “Single Knock” mode Pole 3 may be set ON for non-latching alarms.

For “Double Knock” mode Pole 4 may be set ON for auto-reset.

The SIL switch must be returned to the setting of 4.2 before proceeding to 4.3.3.

4.3.3 Fit detector inner and outer lids, switch wires & air tubes . (Refer to section 3.2.)

Check that the air supply is connected and operational. If a 5000 Series blower is

employed this must be powered.

4.3.4 Check at the Detector that purge air is blowing from the optical aperture.

Check that the external Green LED is illuminated and the unit is signaling Normal.

Note : The purge air is monitored by a pressure switch located within the inner

sensor module. If the air delivery is too low to operate the switch then the detector

will signal Fault. The Green LED will extinguish (if appropriate). Refer to 4.4

4.3.5 Momentarily remove the purge air supply and check that the Green Normal LED

extinguishes (if appropriate), and the unit signals Fault for the duration of the air

supply interruption.

4.3.6 Momentarily remove the electrical supply and check that the Green Normal LED

extinguishes and the unit signals Fault for the duration of the supply interruption.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 13 of 16

Patol Limited

4.4 Purge Air Supply, Pressure Switch and Normal LED

The purge air is monitored by a pressure switch located within the inner sensor module.

The operation of the switch is dependant on the differential pressure between the air input

point to the outer detector case and the external atmosphere.

Terminals 21/22 permit selection of the Green Normal LED operation. When unlinked the

LED extinguishes on either electrical or air supply failure. If linked the LED extinguishes on

electrical supply failure only. This latter option is only permissible in Relay Mode.

Should the detector remain in Fault at stage 4.3.3, even though it is apparent that purge air

is present, the switch’s electrical connection and monitoring tubes should be checked for

correct connection / positioning.

The switch is correctly factory set to operate at approximately 3.74 mBar (1.5 inch WG).

However, should the switch setting have become incorrect for the air flow/pressure being

achieved on the installation, an on site adjustment can be made as in the following.

Check & Adjustment Procedure

Refer to section 3.2 - figures 14 & 15

4.4.1 Remove the outer case lid slowly such as to be able to check that the end of

pressure switch Tube A was resident in the air inlet spigot / hose. Check that

Tube B is fitted to the nipple at the back of the compartment.

4.4.2 Remove the inner module lid - this may require loosening of the outer case cable

gland. Check that both tubes are fitted to the pressure switch and that the switch

wires connect to the rear board via plug-in terminals 19/20.

4.4.3 If all tube and electrical connections have been correct then the pressure switch

may need adjustment:-

Un-plug terminals 19-20 and monitor with a multi-meter set to ohms. The

reading should be open circuit.

Using a screwdriver turn the adjustment screw clockwise until the switch

closes - meter indicates zero ohms.

Turn the adjustment anti-clockwise (counter-clockwise) until the switch opens.

Continue for one quarter of a turn.

4.4.4 Plug terminal 19/20 into the rear board connector and re-fit the sensor lid.

4.4.5 Re-fit the outer case lid ensuring Tube A is connected to the rear of case nipple,

and the Tube B sits in the inlet spigot / hose.

4.5 Hot Body Simulation Tests

A heat simulation test should be conducted.

The test is conducted by moving a “hot” (IR emitting) target into the view field of the Sensor

Head and observing / checking the consequential Alarm operation.

It is preferable that the “test target” is of sufficient size and temperature that the simulation

can be conducted at the plane of the monitored path (conveyor) such that the view field of

the Sensor can be validated. However, a smaller and cooler “test target” may be employed

so as to at least confirm basic operation of the sensor. It will be necessary with a “target” of

this nature to introduce it to the view field nearer to the Senor than the “monitored plane”.

When the 5410 detector is connected to fire panel via a conventional trigger circuit or

addressable loop detector interface, latched 5410 detections are normalized by Alarm

Reset operation at the fire panel. Similarly, when in relay mode, reset is conducted by

momentary supply interruption by an external push-button or other means.

Field of view test confirmation (which requires a number of alarm triggers) may more easily

be conducted when the unit’s covers are removed and the internal LEDs, Reset PB and

program SIL switch are still accessible. Refer to section 4.3.2.

If the location of the Sensor is classified as a “Hazardous Area” it will be necessary to make

special arrangements for this testing as the electrical / hot nature of the test simulation may

breach normal site regulations. It may even be that the test is precluded.

Refer to section 6.4 for information on “test targets”.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 14 of 16

Patol Limited

5. OPERATION

5.1 Normal

External Green Normal LED - On

Relay Mode:- Fault relay energized. Fire relay de-energized.

LP Mode:- End of line resistor connected across trigger circuit.

5.2 Alarm Condition

An Alarm condition will occur on abnormal Infra-red detection by the Sensor Head.

Normally this status will Latch On, however in special configurations the condition can be

set to momentary operation - auto resetting after a selected delay.

During the ALARM :-

External Red Fire Trip LED - On

Either or both internal red LED indicators illuminated.

Relay Mode:- Fire relay energized.

LP Mode:- Alarm resistor switched across trigger circuit.

5.3 Reset

Latched Alarm conditions may be normalized by :-

Momentary interruption of the supply - less than 7V.

When directly connected to a Fire Panel via a trigger circuit or addressable loop

interface this condition will occur on fire panel reset operation.

A local or remote normally closed push-button may also be implemented.

Operation of the internal Reset push-button.

5.4 Fault Warning

External Green Normal LED - Off *

Relay Mode:- Fault relay de-energized

LP Mode:- End of line resistor disconnected from trigger circuit.

A fault warning may occur for any of the following:-

Low / failed supply.

Supply less than 20V in Relay Mode.

Supply less than 13V in LP Mode. (Note:- An Alarm will remain latched below the fault

threshold so long as the Reset voltage is not reached.)

Unit internal power regulation circuit fault.

Loss of Purge Air *

The output will automatically normalize on rectification of the fault.

5.5 Test

Operation of the sensor’s internal Test push-button simulates an alarm as per 5.2.

A remote test push-button has identical result if implemented.

*Note:- Linking terminals 21 & 22 provides an option where Purge Air failure results in

‘Fault’ signalling but the Green LED will remain illuminated whilst electrical supply is

maintained. The option can only be employed in Relay Mode.

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 15 of 16

Patol Limited

6. MAINTENANCE

6.1 General

It is recommended that a System Log Book / File is raised at the Commissioning Stage and

that the system configuration and initial settings recorded. These should include:-

Operation configuration and Sensitivity - SIL switch set-up.

Supply voltage.

Subsequently all system events should be recorded in the log.

These should include all maintenance activity, changes to settings, Fault warnings and

Alarm occurrences. (including cause and actions taken ).

An operational regime should be developed that includes both frequent inspection of the

Sensor for undue accumulation of dust, and to confirm air (blower) operation. The regime

may encompass use of the Test facility to check basic operation.

In addition, the system should be subjected to a periodic service as defined in the

following.

6.2 Purge Air Filters (if fitted)

Some blower units have integral air filters, and some installations may employ ducting

filters. If installed these should be removed and washed using a warm water soap solution.

The use of solvent cleaners is not recommended for Patol Series 5000 blowers.

6.3 Fault Monitoring Functions

Tests should be conducted to confirm the correct operation of the fault monitoring circuits :-

6.3.1 Purge Air Pressure - Check as per 4.3.5

6.3.2 Supply Failure - Check as per 4.3.6

6.4 Infra-red Detection

A heat simulation test should be conducted by moving a “hot” (IR emitting) target into the

view field of the Sensor and checking the consequential Alarm operation.

It is preferable that the “test target” is of sufficient size and temperature to enable

simulation at the plane of the monitored path (conveyor) in order to validate the view field of

the Sensor . Smaller and/or cooler “test targets” may be used closer to the Sensor so as to

at least confirm basic operation of the Sensor.

Fig.7 in Section 2.5 indicates the relationship between the surface area and temperature

required for triggering at the various trip settings.

It may be necessary to make special arrangements for this testing as the electrical / hot

nature of the test simulation may breach normal site regulations. It may even be that the

test is precluded.

Potential “test targets” are :-

Type 5501 Infra-red Radiator - Test and Commissioning Platen - Patol product.

100W Lamp Bulb - (The Sensor responds to the glass temperature - not the visible light).

Domestic Flat Iron (smoothing iron).

Electrical or Catalytic soldering iron.

Note : Infra-red LED Torches are NOT suitable for testing 5000 Series equipment.

Rectory Road, Padworth Common, Reading,

Patol Limited Berkshire, United Kingdom. RG7 4JD

Tel: +44 (0) 118 9701701 email : info@patol.co.uk

Fax: +44 (0) 118 9701700 Web: www.patol.co.uk

Series 5000 - Manual 5410 D1145 - Issue 2 - 15 November 2012 Page 16 of 16

You might also like

- Operation ManualDocument186 pagesOperation ManualehsanrastayeshNo ratings yet

- Solar Power Bank With Wireless Battery Project-1Document26 pagesSolar Power Bank With Wireless Battery Project-1Mahesh KaleNo ratings yet

- Installation & Operating Manual Fire Detection Unit Itx 6340Document13 pagesInstallation & Operating Manual Fire Detection Unit Itx 6340erode els erode100% (3)

- Super PTI' Guidelines For Very Sensitive Cargo Container: Reefer ProceduresDocument4 pagesSuper PTI' Guidelines For Very Sensitive Cargo Container: Reefer ProceduresSamo SpontanostNo ratings yet

- Chill Premier Friedrich Parts ManualDocument94 pagesChill Premier Friedrich Parts ManualHernan RomeroNo ratings yet

- 5200236-00A - Salwico AC-IR-3Fq - M - EN - 2020 - KDocument4 pages5200236-00A - Salwico AC-IR-3Fq - M - EN - 2020 - Kmachedon stefanNo ratings yet

- Informatsiya Drager Polytron Ir PDFDocument4 pagesInformatsiya Drager Polytron Ir PDFSandip JoardarNo ratings yet

- Xgard Bright: Addressable Fixed Point Gas Detector With DisplayDocument4 pagesXgard Bright: Addressable Fixed Point Gas Detector With DisplayPunyawich FungthongjaroenNo ratings yet

- DOR-4046-Manual de Instalare - ENGDocument8 pagesDOR-4046-Manual de Instalare - ENGmihai_gamaNo ratings yet

- I4series Datasheet CODS303Document4 pagesI4series Datasheet CODS303b.leite.domNo ratings yet

- Operating Manual: Infrared Point Gas Detector GD10-P00Document28 pagesOperating Manual: Infrared Point Gas Detector GD10-P00bango7886No ratings yet

- 5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorDocument4 pages5200236-00A - Salwico AC-IR-3Fq - Addressable-Conventional IR Flame DetectorcembozNo ratings yet

- DOP6001R-Instruction_manual_ENGDocument18 pagesDOP6001R-Instruction_manual_ENGayaan.zoya2023No ratings yet

- Manual de Instalare Bariera IR DOP 6001 - ENGDocument14 pagesManual de Instalare Bariera IR DOP 6001 - ENGDorin SimioanaNo ratings yet

- Idp Photo w ManualDocument2 pagesIdp Photo w Manualahmedteleb55No ratings yet

- IR400 Data SheetDocument2 pagesIR400 Data Sheets muraNo ratings yet

- Fiber Optic Cable Sensor: Available As PDF Only Status: 10.10.2016Document16 pagesFiber Optic Cable Sensor: Available As PDF Only Status: 10.10.2016Amila BalasooriyaNo ratings yet

- Manual RFD 2FTNDocument31 pagesManual RFD 2FTNvishnuNo ratings yet

- SmokeDocument4 pagesSmokeabdalla4ever1989No ratings yet

- COSMO Manual I56-3747Document4 pagesCOSMO Manual I56-3747leandro FigueiredoNo ratings yet

- Smoke Detector ManualDocument4 pagesSmoke Detector ManualKarthik VelNo ratings yet

- fsb-200 Install Sheeti56-2424-04rDocument18 pagesfsb-200 Install Sheeti56-2424-04rcarlos yepezNo ratings yet

- Espetrofotometro UV-Visible GENOVA PDFDocument35 pagesEspetrofotometro UV-Visible GENOVA PDFArdo IsküllNo ratings yet

- DUR-4047 Manual de Instalare - ENGDocument11 pagesDUR-4047 Manual de Instalare - ENGDorin SimioanaNo ratings yet

- SD Op921Document4 pagesSD Op921Mohammad FathiNo ratings yet

- Infosheet Ir Heat Sensor D1185-3Document2 pagesInfosheet Ir Heat Sensor D1185-3Fabián Roberto NoyaNo ratings yet

- Series 2-Wire Loop Test/ Maintenance ModuleDocument2 pagesSeries 2-Wire Loop Test/ Maintenance ModuleArgile-assholeNo ratings yet

- System Sensor - COSMOD2W-ManualDocument4 pagesSystem Sensor - COSMOD2W-ManualglennbbenoitNo ratings yet

- Data Acquisition System123Document22 pagesData Acquisition System123asifuitNo ratings yet

- C2 E2 F1, Climatic Environmental and Fire With Stand Test On Dry Type TransformerDocument27 pagesC2 E2 F1, Climatic Environmental and Fire With Stand Test On Dry Type Transformerkrmurali2000No ratings yet

- 31-00441 - A - C7355B - Quick Start GuideDocument8 pages31-00441 - A - C7355B - Quick Start Guideammar.career2No ratings yet

- Jenway 6300 Spectrophotometer - User manual_2Document18 pagesJenway 6300 Spectrophotometer - User manual_2sabrinedjihaneNo ratings yet

- Polytron FX - Old, Obsolete DatasheetDocument2 pagesPolytron FX - Old, Obsolete DatasheetMohamed NaserNo ratings yet

- PDA10D2 ManualDocument16 pagesPDA10D2 Manualg3188605831No ratings yet

- Jenway Spectrophotometer 6305 ManualDocument19 pagesJenway Spectrophotometer 6305 Manualhendreen ibrahimNo ratings yet

- K85001-0606 - Smoke Detectors With Auxiliary FunctionsDocument4 pagesK85001-0606 - Smoke Detectors With Auxiliary Functionsjuan aleamnNo ratings yet

- AACULP - INST-EN-kidde - LHDC - C - Installation - Instructions - 17-07-19Document16 pagesAACULP - INST-EN-kidde - LHDC - C - Installation - Instructions - 17-07-19lalwinNo ratings yet

- Truealarm Smoke Detectors: FeaturesDocument4 pagesTruealarm Smoke Detectors: FeaturescostaNo ratings yet

- FSP-951-SELFT Intelligent Photoelectric Self-Test Smoke SensorDocument4 pagesFSP-951-SELFT Intelligent Photoelectric Self-Test Smoke SensorDinaNo ratings yet

- DetTronics GasDetector PIRECLDocument51 pagesDetTronics GasDetector PIRECLyasfin1990No ratings yet

- Manual Espctrofotômetro Jenway Mod GenovaDocument34 pagesManual Espctrofotômetro Jenway Mod GenovaSheron CogoNo ratings yet

- Flame Rod ManualDocument14 pagesFlame Rod ManualDekorresleyNo ratings yet

- BS-100 Dust Monitor User ManualDocument22 pagesBS-100 Dust Monitor User ManualsamcruiseatcNo ratings yet

- Det Tronics: Infrared Hydrocarbon Gas Detector Pointwatch Eclipse Model PireclDocument51 pagesDet Tronics: Infrared Hydrocarbon Gas Detector Pointwatch Eclipse Model PireclYasfin Safir100% (1)

- FDO181 - Smoke Detector (Đầu báo khói)Document4 pagesFDO181 - Smoke Detector (Đầu báo khói)shark.nguyenhoangNo ratings yet

- FSP951 I56-6519Document2 pagesFSP951 I56-6519Marcelo Fabián OrtizNo ratings yet

- 820mo User Manual v1.2Document41 pages820mo User Manual v1.2Cristiano PonteNo ratings yet

- ThorLabs PM100D ManualDocument75 pagesThorLabs PM100D ManualpicassaaNo ratings yet

- Data Sheet enUS 2700120843Document3 pagesData Sheet enUS 2700120843Forward MyanmarNo ratings yet

- D355PL InstallationDocument4 pagesD355PL InstallationWilly LeonNo ratings yet

- Uputstvo Za FireRay 2000Document16 pagesUputstvo Za FireRay 2000Ivan MihajlovicNo ratings yet

- FSP-951 Detector de FumaçaDocument2 pagesFSP-951 Detector de FumaçaRicardo Alves da SilvaNo ratings yet

- ProReact Analogue Installation Manual A1162Document16 pagesProReact Analogue Installation Manual A1162careNo ratings yet

- Gabinete Detector Ducto DNR - DST1,5Document2 pagesGabinete Detector Ducto DNR - DST1,5rodrigo munozNo ratings yet

- Cerberus® PRO: Detectors and PeripheralsDocument4 pagesCerberus® PRO: Detectors and PeripheralsaskarNo ratings yet

- DO Analyser ManualDocument24 pagesDO Analyser ManualambeshNo ratings yet

- Fuente Fcps 24s6eDocument12 pagesFuente Fcps 24s6eGuido RuizNo ratings yet

- NPS/ 001 / 014 - Technical Specification For Overhead Line Fault Passage IndicatorsDocument19 pagesNPS/ 001 / 014 - Technical Specification For Overhead Line Fault Passage IndicatorskotiniNo ratings yet

- Installation Manual EnUS 16566339211Document6 pagesInstallation Manual EnUS 16566339211Hoằng PhạmNo ratings yet

- Siemens Photoelectric Smoke DetectorDocument5 pagesSiemens Photoelectric Smoke DetectorEngineering TFINo ratings yet

- RTU-485 Manual enDocument14 pagesRTU-485 Manual enjrobertoamaralNo ratings yet

- FSC-851 IntelliQuad Multi-Criteria Det DN-60412Document2 pagesFSC-851 IntelliQuad Multi-Criteria Det DN-60412Anonymous Mw2nwE6AjNo ratings yet

- D7050 Addressable Photoelectric Smoke and Smoke Heat Detector HeadsDocument3 pagesD7050 Addressable Photoelectric Smoke and Smoke Heat Detector HeadsBrillit RuizNo ratings yet

- Pressure GaugeDocument2 pagesPressure GaugeehsanrastayeshNo ratings yet

- Ep203 LPCB Eng Manual Dfu0002032 R6Document45 pagesEp203 LPCB Eng Manual Dfu0002032 R6ehsanrastayeshNo ratings yet

- Solo Quick Start Guide OnlineDocument8 pagesSolo Quick Start Guide OnlineehsanrastayeshNo ratings yet

- Fdoot 221Document138 pagesFdoot 221ehsanrastayeshNo ratings yet

- Trident 2500R: Rental Duty Trailer Load Bank 1500-2500KWDocument8 pagesTrident 2500R: Rental Duty Trailer Load Bank 1500-2500KWAlfonso Alberto ArguelloNo ratings yet

- ToTronics Bluetooth 5.0 Transmitter-Receiver PDFDocument34 pagesToTronics Bluetooth 5.0 Transmitter-Receiver PDFdacadab579No ratings yet

- RM - 20LZ50 LG+RM-20LA66K+Service+Manual+Document29 pagesRM - 20LZ50 LG+RM-20LA66K+Service+Manual+AlessandroNo ratings yet

- Hall Effect and Its ApplicationsDocument10 pagesHall Effect and Its ApplicationssenthilkumarNo ratings yet

- Project Report Format 2022-23Document11 pagesProject Report Format 2022-23line follower robotNo ratings yet

- PowerPhase HD 220 WebDocument2 pagesPowerPhase HD 220 WebAlexandre RibeiroNo ratings yet

- AUTOMATION & Drives PDFDocument127 pagesAUTOMATION & Drives PDFMartinez 100No ratings yet

- Magnap Tsd800-30 DatasheetDocument9 pagesMagnap Tsd800-30 DatasheetPaul CholewaNo ratings yet

- GPS Compass Operator ManualDocument89 pagesGPS Compass Operator ManualVM ServicesNo ratings yet

- DatasheetDocument15 pagesDatasheetjesus cautivoNo ratings yet

- Datasheet 3Document6 pagesDatasheet 3alan segundo garcia chotaNo ratings yet

- Unit 3 VLSIDocument93 pagesUnit 3 VLSIPraba KaranNo ratings yet

- Panasonic Tnpa5935-1ld km29 Chassis Led-DriverDocument2 pagesPanasonic Tnpa5935-1ld km29 Chassis Led-DriverJonathan Da SilvaNo ratings yet

- Canon NB-4L Battery Adapter by Florian - ThingiverseDocument4 pagesCanon NB-4L Battery Adapter by Florian - ThingiversecogitorNo ratings yet

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDocument11 pagesEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavNo ratings yet

- Improved Multilevel Hysteresis Current Regulation and Capacitor Voltage Balancing Schemes For Flying Capacitor Multilevel InverterDocument12 pagesImproved Multilevel Hysteresis Current Regulation and Capacitor Voltage Balancing Schemes For Flying Capacitor Multilevel InverterMehdi YahiNo ratings yet

- MOS Capacitor - StructureDocument22 pagesMOS Capacitor - Structurerounak aliNo ratings yet

- Tdep MaterialDocument109 pagesTdep MaterialGOVERNMENT POLYTECHNIC THAKURDWARANo ratings yet

- 3X Siga2 PDFDocument13 pages3X Siga2 PDFamjadjaved033148No ratings yet

- LogoDocument3 pagesLogoConan VicNo ratings yet

- 4096-Stage Low-Noise BBD Analog Delay Line V3205D/SD: General DescriptionDocument4 pages4096-Stage Low-Noise BBD Analog Delay Line V3205D/SD: General DescriptionDmedNo ratings yet

- ANRITSU S251C DatasheetDocument5 pagesANRITSU S251C DatasheetYANdalfNo ratings yet

- Electrical Design Standards SummaryDocument1 pageElectrical Design Standards SummaryAimee Bianca RamosNo ratings yet

- MDT340Document2 pagesMDT340ALLURI RAJUNo ratings yet

- 300KG High Frequency Induction Melting Furnaceinstruction Book KGYSc-3250Document24 pages300KG High Frequency Induction Melting Furnaceinstruction Book KGYSc-3250Ang NanhNo ratings yet

- Automatic Voltage Regulator Chassis Standard Accessories: Feet and The Base Frame. EngineDocument1 pageAutomatic Voltage Regulator Chassis Standard Accessories: Feet and The Base Frame. Enginerv100% (1)

- ws27 29 PDFDocument3 pagesws27 29 PDFbilalNo ratings yet