SAIC-W-2005 Rev 8

SAIC-W-2005 Rev 8

Uploaded by

saravananmenmathiCopyright:

Available Formats

SAIC-W-2005 Rev 8

SAIC-W-2005 Rev 8

Uploaded by

saravananmenmathiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

SAIC-W-2005 Rev 8

SAIC-W-2005 Rev 8

Uploaded by

saravananmenmathiCopyright:

Available Formats

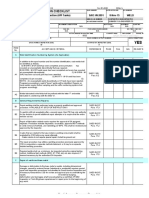

SAUDI ARAMCO ID/PID - 30-June-14 - REV 8 (Standards Cutoff -June 30 ,2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 31-Dec-14 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements (Pre-Welding)

All WPSs, PQRs, and Weld and Line Description Table shall be available

SAES-W-011,

A1 at the work site for verification of Saudi Aramco inspector.

Para. 7.1.8

Welder(s) have been issued Job Clearance Card, and that range of

SAEP-324, Sec.

A2 qualification shown matches the application of WPS being used.

5

SAEP-1160, Para

Weld joints identification system as specified in SAEP-1160 has been

6.2 & SAES-W-

A3 adopted (by approval of Weld Identification procedure) and weld joints are

011,

marked accordingly and a weld map is maintained.

Para. 16.2

Weld number & Welder symbol are to be marked adjacent to welds. SAES-W-011,

Note: Use suitable weather-proof permanent markers Para. 16.1

& materials, such as certified low-chloride (50ppm) markers for Stainless

A4

steel Note: This is an assigned unique weld ID SAEP-1160,

number to be tracked by database & shall remain intact during the Table

construction process 6.1

Welding power supplies are calibrated Note: SAES-W-011,

Sch Q requires a 6 month interval (max). Process control procedures shall Section 19 &

A5 detail intervals. BS 7570 is used for

validation when Charpy Impacts are specified. Sch Q, Attach-

Note : See SAIC-W-2011 checklist. IV Para-6

B WELD JOINT EDGE PREPARATION

Stainless steel and nonferrous materials shall be cleaned with grinding

SAES-W-011,

B1 wheels or stainless steel brushes not previously used on other materials..

Para. 11.4.3

Thermal cut surfaces of stainless steel and non-ferrous materials shall be SAES-W-011,

B2

ground to bright (unoxidized) material prior to welding. Para. 11.3.2.4

A minimum of 1.5 mm depth shall be removed by grinding/machining from

thermally cut or gouged surfaces of air-hardenable materials (e.g.,

SAES-W-011,

B3 Chrome-Moly steels or P-No 3 / 4 / 5).

Para. 11.3.2.3

Note: Saudi Aramco Inspector can specify additional NDT (MT/PT) to be

applied on the cut surfaces.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 30-June-14 - REV 8 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 31-Dec-14 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Ragged and irregular edges shall be ground or machined to bright metal. SAES-W-011,

B4 Thermally cut or gouged surfaces for all materials, including carbon steels, Para. 11.3.2.1

shall be power brushed or ground prior to welding. Para. 11.3.2.2

All holes cut for set-on nozzles, bosses, or branch connections shall be

SAES-W-011,

B5 ground smooth and the diameter of the hole shall be ± 1.6 mm of the

Para. 11.3.2.1

inside diameter of the set-on member.

Re-cut or re-beveled Fittings shall have cut surfaces examined for SAES-W-011,

B6

laminations before welding by MT or PT methods Para. 11.3.3

Oil, moisture, scale, rust, paint (except approved weldable primers),

metallic coatings (e.g. zinc) or other foreign matter, has been removed SAES-W-011,

B7

from weld surfaces at least 25mm adjacent to weld joint. Para. 11.3.1

Butt joint Internal misalignment shall not exceed 1.5 mm.

NOTE: Internal tapering by machining, back welding, or a combination

may be used to correct any misalignment. If SAES-W-011,

B8

external surfaces of the components are not aligned, the weld shall be Para. 9.3

tapered between them. [ASME B31.3, Para. 328.4.3 (2).

Buttering or weld build-up on the prepared surfaces shall not exceed the

lesser of ⅓ of the base metal thickness or 10mm without the approval of

CSD. If the buttering or buildup exceeds this, then the following

SAES-W-011,

requirements shall apply.

Para. 11.3.5.1

B9 Note:

SATIP-W-

a) The buttering operation shall be witnessed by Saudi

011-01 Item 3.5

Aramco Inspection

b) The buttering shall be inspected by RT, and PT or MT after completion

of the build-up but before final welding of the joint.

Prepared Weld joint conforms for Joint Detail with an approved WPS for:

1. Bevel type and Bevel angle

2. Root Gap SAES-W-011,

B10

3. Root Face Sec 9

ASME B31.3, End Preparation Para. 328.4.2

Minimum distance between parallel butt welds and pressure containing

welds shall be 20 mm or three times the wall thickness of the joint, SAES-W-011,

B11 whichever is greater. Para. 11.16,

NOTE:The distances shall be measured between the edges of the 11.16.1, 11.16.2

adjacent cap passes.

Restrictions of "Minimum Distance between Welds" do not apply if one of

the welds has been post weld heat treated prior to making the second weld

or both welds have been post weld heat treated and inspected.

SAES-W-011,

B12 NOTE: Para. 11.16,

1) RT of the butt welds is required when minimum separation is not 11.16.2

achieved.

2) For joints other than butt welds, other appropriate inspection methods

shall be used, depending on the geometry and material.

Coated & clad or overlayed surfaces are protected from welding arc,

associated weld spatter, and damage from ground clamps or other SAES-W-011,

B13

associated equipment. Take appropriate action for protection to provide Para. 11.11

cover & ensure proper selection of grounding locations is inspected.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 30-June-14 - REV 8 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 31-Dec-14 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

C WELD JOINT DETAIL

All pressure-containing welds shall be made with multiple passes.

SAES-W-011,

C1 Socket welds shall be welded in two passes SAES-W11 Para

Para. 9.1

11.19 (SAIC-W-2037)

All nozzles, branch, and tee connections shall be made with full SAES-W-011,

C2

penetration groove welds only. Para. 9.2

SAES-W-011,

C3 Permanent backing rings or strips shall not be used.

Para. 9.4

Temporary backup strips may be used in weld joints if the backing material

is of a composition similar to the base metal or weld metal. Temporary SAES-W-011,

C4

backup shoes made of non-metallic, non-fusing material may be used. Para. 9.5

NOTE: Rebar or galvanized steel shall not be used.

For nozzles with re-pads, the nozzle attachment weld shall be SAES-W-011,

C5

completed & inspected prior to installing the re-pad. Para. 9.8

D Welding Environment

Wind shields or tents shall be required when wind is strong enough to

affect arc stability or shielding gas coverage or when deemed necessary

by SA Insp. GTAW, GMAW, or gas-shielded FCAW shall not be used for

field or yard fabrication unless adequate windshield is used. Wind velocity

SAES-W-011,

D1 in the weld area for GTAW, GMAW, or gas shielded FCAW shall not

Section 11.2.1

exceed 8 kph (2.2 m/s)

NOTE: keep other side pipe

ends closed when working with any weld process.

Welding is not done if surfaces are wet, damp, exposed to rain, or when

SAES-W-011,

D2 welders are exposed to inclement conditions such as wind blown sand,

Para. 11.2.2

dust, rain.

For field welding, remote Current controls shall be used if welding is more

SAES-W-011,

D3 than 30 m from welding power source or when welders are working in

Para. 19.1

"remote" locations (e.g., on an elevated pipe rack).

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 30-June-14 - REV 8 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 31-Dec-14 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

E Welding Consumables

A change in filler metal or deposit chemistry from A-number 1 to A-No. 2

and vice-versa is not permitted without approval.

A change from A-No. 1 to A-No. 2 is not permitted for sour service SAES-W-011,

E1

applications without requalification. Para 7.4.5

NOTE: The approval shall be obtained through the welding procedure

review process.

Filler Metal and other weld consumables at weld site are controlled as per As Referenced

E2 SAIC-W-2032 (4 & 8 hr rules, reconditioned rod use, etc.).

Welders have issue slips at site. Check these to SATR-W-2010. SAIC-W-2032

Welding consumables shall be the same brand, type, maximum size

specified on WPS / PQR for welding processes as follows:

SAES-W-011,

A) GMAW electrode specified on WPS with impact toughness reqmt

E3 Para. 7.4.4,

B) SAW flux used for PQR

Para. 7.4.8

C) FCAW electrode used for PQR

D) WPS/PQR with "G" designation consumable (AWS A 5.5 Table 2)

GTAW Practices (Consumable Control, Technique, Purging) are SAES-W-011,

E4

acceptable and in place before work. Section 11

F Preheat

If a weld joint is wet or has surface moisture or condensation, it shall be

dried by heating for a distance of 100 mm from the weld joint and shall be SAES-W-011,

F1

warm to the hand before welding unless a greater preheat temperature is Para. 12. 3

required.

Preheat temperature specified in the WPS or complying to following are

applied:

A) Required/recommended preheat listed in ASME B31.3 Tables.

B) Pre-heat temps from SASD AE-036451 (8 pgs) for ASME P-No. 1 SAES-W-011,

F2

materials, including API grades up to and including X60. Para. 12.1

C) Preheat value listed in Tables 3A and 3B for SMAW process.

D) For steels with SMYS above 60 ksi, (incl API grades X65 or greater)

Temperature are determined by CSD

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 30-June-14 - REV 8 (Standards Cutoff -June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 31-Dec-14 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Preheat temperatures shall be established over a minimum distance of 75

SAES-W-011,

F3 mm on each side of the weld. Preheat temperature specified (WPS, etc.) is

Para. 12.5

obtained prior to & maintained during welding.

Temperature-indicating crayons, thermocouples, or contact pyrometers

shall be used to measure preheat & interpass temps. SAES-W-011,

F4

Temperature indicating crayons are prohibited for any weld joint to be Para. 12.4

coated, or that will have a heat-shrink sleeve installed on it.

On wall thickness exceeding 25mm, preheat is done from the same side

as the welding. Heat source is removed for 1 minute prior to measuring the SAES-W-011,

F5

temperature. (allow temperature equalization). Para. 12.6

Perform frequent checks to maintain preheat temps during welding

G Reports Preparation

Complete details of inspected Joints are recorded on SATR-W-2005 and SAEP-1160

G1

SATR-W-2006 Para 6.1

REMARKS:

ATTACHMENTS:

1.SAES-W-011, Welding Requirements for On-Plot Piping, (16 Dec 2013)

2. SAEP-1160 Tracking and Reporting of Welding, NDT and Pressure Testing for Capital Projects ,(10 July 2011)

3. ASME B31.3, Process Piping (2012 Edition)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved:

Name, Organization, T&I Witnessed QC Record Reviewed Work Verified

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechDocument4 pagesSaudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechAnonymous S9qBDVky100% (1)

- Alloy 800H Material and Fabrication Challenges Associated With The Mitigation of Stress Relaxation CrackingDocument11 pagesAlloy 800H Material and Fabrication Challenges Associated With The Mitigation of Stress Relaxation CrackingGeorge SalsburyNo ratings yet

- VW TL 217 2016Document8 pagesVW TL 217 2016Bartek HajaNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Toyota Production SystemDocument37 pagesToyota Production Systemjaiswalswatin87100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- Saic W 2005Document1 pageSaic W 2005Abdelaziz MohamedNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- SAIC-W-2007 Rev 8Document6 pagesSAIC-W-2007 Rev 8saravananmenmathiNo ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- SAIC-W-2086 In-Process Welding Inspection PDFDocument5 pagesSAIC-W-2086 In-Process Welding Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- SAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld InspectionDocument5 pagesSAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld Inspectionاحمد حسنNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldDocument6 pagesSaudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldManoj KumarNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldpravinNo ratings yet

- SAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresDocument4 pagesSAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- SAIC-W-2081 Receiving Inspection of Welding Consumables (EE)Document2 pagesSAIC-W-2081 Receiving Inspection of Welding Consumables (EE)karioke moha100% (1)

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldDocument13 pagesSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- SAIC-E-2005 Recvg Insp of AirCooled Heat ExchDocument5 pagesSAIC-E-2005 Recvg Insp of AirCooled Heat ExchAnonymous S9qBDVkyNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- SAIC W 1312 Pre WeldingDocument3 pagesSAIC W 1312 Pre Weldingmohamed mubinNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldjeswinNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- SAIC-P-3008 Rev 7 FinalDocument10 pagesSAIC-P-3008 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- SAIC-L-2112 Rev 7Document7 pagesSAIC-L-2112 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- SAIC-M-1001 Rev 7 (Final)Document5 pagesSAIC-M-1001 Rev 7 (Final)ryann mananquilNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldAbdul Khaleem KhanNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- SAIC-P-3008 Rev 3Document9 pagesSAIC-P-3008 Rev 3YaserNo ratings yet

- Saic S 4058Document6 pagesSaic S 4058Engr IrfanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saic D 2023Document2 pagesSaic D 2023razzak.me.enggNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldDocument23 pagesSaudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldIrshad IqbalNo ratings yet

- Satr-W-2020Document1 pageSatr-W-2020Joni Carino SuniNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- SAIC-W-2031 In-Process Welding Inspection of Hot TapDocument2 pagesSAIC-W-2031 In-Process Welding Inspection of Hot TapAnonymous S9qBDVkyNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- ORIONDocument4 pagesORIONAlon CarlosNo ratings yet

- 2.3 Crushing and BlendingDocument10 pages2.3 Crushing and BlendingYhaneNo ratings yet

- Iso 4015 2022Document10 pagesIso 4015 2022Manav BajajNo ratings yet

- Ch6. Solid Waste ManagementDocument50 pagesCh6. Solid Waste ManagementAbdullahi turkiNo ratings yet

- 150lb Style T (316ss) StrainerDocument1 page150lb Style T (316ss) StrainerLuis GarciaNo ratings yet

- Weekly Report Villa 4Document12 pagesWeekly Report Villa 4Belqis NaufaliaNo ratings yet

- Introduction To CAD/CAM/CAE: Human-Centered CAD LabDocument32 pagesIntroduction To CAD/CAM/CAE: Human-Centered CAD LabRaghuNo ratings yet

- NCSI Aegis-SpecsDocument18 pagesNCSI Aegis-SpecsahmetNo ratings yet

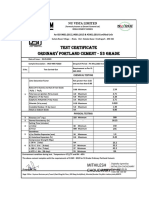

- TC-NVL - Infracem - Opc WK-19-2023-7DDocument1 pageTC-NVL - Infracem - Opc WK-19-2023-7DSirajul IslamNo ratings yet

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarNo ratings yet

- POYATOS Company ProfileDocument1 pagePOYATOS Company ProfilepembangunanNo ratings yet

- Grillete CMDocument1 pageGrillete CMjm467191No ratings yet

- Developing A Continuous Improvement CultureDocument30 pagesDeveloping A Continuous Improvement Culturesrinivasrdd78No ratings yet

- Concrete Pour CardDocument2 pagesConcrete Pour CardDharma Pratap LamgadeNo ratings yet

- Smaw Schedule PlanDocument6 pagesSmaw Schedule PlanJonh CastilloNo ratings yet

- Drill 1Document3 pagesDrill 1Izz Eddin SubohNo ratings yet

- WRT and WD Tech Data SheetDocument2 pagesWRT and WD Tech Data Sheetdwinanto.lrsNo ratings yet

- Zwaluw Polyflex 422 - en 1Document2 pagesZwaluw Polyflex 422 - en 1Angelo Carlo MalabananNo ratings yet

- Hopelex Af 3100Document2 pagesHopelex Af 3100FarizNo ratings yet

- Astm A965x 2021aDocument7 pagesAstm A965x 2021aamitNo ratings yet

- Vulcan Expert+ Calibration Datasheets (Dec 2020)Document6 pagesVulcan Expert+ Calibration Datasheets (Dec 2020)Paula InesNo ratings yet

- Letter Head Quotaion FormatDocument1 pageLetter Head Quotaion Formatjmbaccnts2017No ratings yet

- J4 PDFDocument1 pageJ4 PDFRvin Jay Cabontocan MarianoNo ratings yet

- MDO Transfer PumpDocument1 pageMDO Transfer PumpsuranovoleksandrNo ratings yet

- Chapter 5 - CNC ToolingDocument50 pagesChapter 5 - CNC ToolingDani AbHalimNo ratings yet

- Star Cement 43gdeDocument1 pageStar Cement 43gdesudhaNo ratings yet

- Heidelberg SM 74-5 PH L 102454Document1 pageHeidelberg SM 74-5 PH L 102454Service Presse Nouvelle Imprimerie ModerneNo ratings yet