Utility Mapping and Site Survey

Utility Mapping and Site Survey

Uploaded by

asr.engineering2023Copyright:

Available Formats

Utility Mapping and Site Survey

Utility Mapping and Site Survey

Uploaded by

asr.engineering2023Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Utility Mapping and Site Survey

Utility Mapping and Site Survey

Uploaded by

asr.engineering2023Copyright:

Available Formats

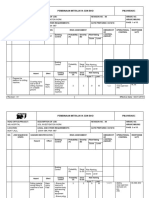

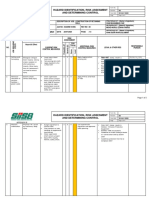

Doc No.

: SE-P01-F001

Hazard Identification, Risk Assessment & Risk Control (HIRARC) Rev : 00

Page : 1 of 1

Prepared by: Reviewed by: Approved by: New Amendment

Department : SAFETY AND HEALTH

Name: Name: Name:

Asset No. / Designated: Designated: Designated: Revision

: PROJECT JALAN AMPANG MRR2 Signature: Signature: Signature:

Area

Process / Date

: UTILITY MAPPING AND SITE SURVEY

Method 22.11.2023

*R- Routine Work Activity NR - Non-Routine Work Activity E - Emergency

HAZARD IDENTIFICATION RISK ANALYSIS RISK CONTROL

Risk Ranking

Risk Rating

Likelihood

Condition

(R/NR/E)

Existing Risk Applicable

Severity

No Person In Due Date /

Work Activity Hazard Which Can cause/ Effect Control legal / other Action Required

Charge Status

(If any) requirement

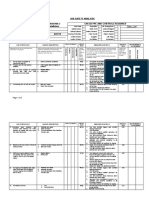

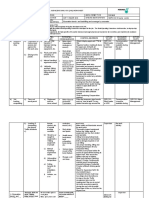

PPE Control: Wearing

1. To install traffic cone and

of safety helmet,

Stuck by high speed vehicle and fatal safety warning signage to

Moving vehicle safety shoes/boots FMA 1967,

R Potential to hit by machinery and cause 2 5 10 M indicate man at work SSS/SS A.S.A.P

and machinery and high visibility OSHA 1994

physical injury 2. To provide flagman to control

safety vest should be

traffic flow

made mandatory

PPE Control: Wearing

1. To conduct visual site

of safety helmet,

Expose to inspection prior to survey work

safety shoes/boots FMA 1967,

R sharp protuding Potential to sustain legs injury 4 3 12 M 2. Conduct tool box talk on SSS/SHO/PM A.S.A.P

and high visibility OSHA 1994

object potential hazard during survey

safety vest should be

work

made mandatory

Utility Mapping /

1 1. Consume more clean

Site Survey PPE Control: Wearing

drinnking water

of safety helmet,

2. Get frequent short break

Expose to safety shoes/boots FMA 1967,

R Potential to sustain dehydration 4 2 8 M under shaded area SHO/SSS/PM A.S.A.P

direct sun heat and high visibility OSHA 1994

3.To organize for work rotation

safety vest should be

4. Conduct toolbox talk on

made mandatory

extreme temperature hazard

PPE Control: Wearing

1. To conduct site inspection to

of safety helmet,

Expose to identify potential bees and

safety shoes/boots FMA 1967,

R stung by bess Potential to sustain serious injury 4 3 12 M snakes prior to site clearing SHO/SSS/SS A.S.A.P

and high visibility OSHA 1994

and snakes 2. Conduct toolbox talk on

safety vest should be

extreme temperature hazard

made mandatory

You might also like

- Ontario Building Code - Concepts and Code Analysis PDFDocument114 pagesOntario Building Code - Concepts and Code Analysis PDFG.A100% (6)

- Floor Epoxy PaintingDocument6 pagesFloor Epoxy PaintingHafiz M WaqasNo ratings yet

- Carpets On WallsDocument4 pagesCarpets On WallsRaja NasirNo ratings yet

- HIRADC - 001 - Installation of Earthing SystemDocument3 pagesHIRADC - 001 - Installation of Earthing SystemZhafri SyazwiNo ratings yet

- Relocation of Fire Hose Cabinet: Toyota Motor Phils. CorpDocument4 pagesRelocation of Fire Hose Cabinet: Toyota Motor Phils. CorpGem EscalanteNo ratings yet

- HSE Risk Assessment For Reinstatement Work: ContractDocument2 pagesHSE Risk Assessment For Reinstatement Work: ContractSasi KumarNo ratings yet

- Hazard Identification, Risk Assesment and Risk Control: Syarikat Muhibah Perniagaan Dan Pembinaan SDN BHDDocument3 pagesHazard Identification, Risk Assesment and Risk Control: Syarikat Muhibah Perniagaan Dan Pembinaan SDN BHDEmilia Syaifuza100% (1)

- Bird Netting & Pipe Gantry JSADocument1 pageBird Netting & Pipe Gantry JSAShakinah As SaadNo ratings yet

- TEC-223500 - MET-DoR-004 (Method Statement For The T&C of Calorifier)Document8 pagesTEC-223500 - MET-DoR-004 (Method Statement For The T&C of Calorifier)RanielNo ratings yet

- 003 Hirac Ladder SafetyDocument2 pages003 Hirac Ladder Safetyeunice.pacerstradingsNo ratings yet

- Hirarc of Soil Investigation at Gadang Construction SiteDocument21 pagesHirarc of Soil Investigation at Gadang Construction Sitemyn maliQueNo ratings yet

- JRA No 11-192 Manual Excavation For Construction of New FoundationsDocument4 pagesJRA No 11-192 Manual Excavation For Construction of New FoundationsAijaz AhmedNo ratings yet

- Ra Concrete Chipping 7514Document5 pagesRa Concrete Chipping 7514Charles DoriaNo ratings yet

- Excavation NotesDocument25 pagesExcavation NotesNilay ShahNo ratings yet

- Risk Assessment Carbon Steel Pipes Installation (Grooved & Threaded)Document6 pagesRisk Assessment Carbon Steel Pipes Installation (Grooved & Threaded)Ahmed GamalNo ratings yet

- Bus Duct Installing HiraDocument45 pagesBus Duct Installing HiraSufiyan KhedekarNo ratings yet

- Method Statement For MV Panels and Accessories Unloading.: Project NameDocument12 pagesMethod Statement For MV Panels and Accessories Unloading.: Project NameSatish SharmaNo ratings yet

- Air Conditional & Mechanical Ventilation (ACMV)Document2 pagesAir Conditional & Mechanical Ventilation (ACMV)naraNo ratings yet

- WMS of Plasterboard Ceiling Installation 1Document11 pagesWMS of Plasterboard Ceiling Installation 1Mohd Hafizi AzlanNo ratings yet

- HIRADC Assessment-INSTALLATION OF SUB SWITCH BOARDDocument6 pagesHIRADC Assessment-INSTALLATION OF SUB SWITCH BOARDTengkudin LatifNo ratings yet

- Hirarc Piling Work PDF FreeDocument4 pagesHirarc Piling Work PDF Freewan lahNo ratings yet

- Cleaning Chlorination Water Tank Risk AnalysisDocument2 pagesCleaning Chlorination Water Tank Risk AnalysisRamyNo ratings yet

- JsaDocument7 pagesJsaAnees TNo ratings yet

- 002-Soil Investigation WorkDocument15 pages002-Soil Investigation WorkDon McleanNo ratings yet

- R1937-JSA-005 Job Safety Analysis For Riser InstallationDocument3 pagesR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalNo ratings yet

- Risk Assessment Plan For - Site-Clearing-EarthworksDocument2 pagesRisk Assessment Plan For - Site-Clearing-EarthworksYe YintNo ratings yet

- Jha - Modification Erection Scaffolding Activity and Housekeeping Scaffolding MaterialDocument14 pagesJha - Modification Erection Scaffolding Activity and Housekeeping Scaffolding MaterialAliff ApamNo ratings yet

- Joinery Carpentry Risk AssessmenmtDocument4 pagesJoinery Carpentry Risk Assessmenmtadeniyi abiolaNo ratings yet

- Jsa006-Construction of Retaining WallDocument5 pagesJsa006-Construction of Retaining WallWan Muhammad Faiz100% (2)

- Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesGift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Hirarc Form - SampleDocument11 pagesHirarc Form - SampleMohd Azro Mohd NorNo ratings yet

- RA-02 Installation of Aco Tech PanelDocument7 pagesRA-02 Installation of Aco Tech PanelVaradaraju Thirunavukkarasan100% (1)

- JESA - HVAC Control WorksDocument7 pagesJESA - HVAC Control WorksResearcherNo ratings yet

- Safety Data Sheet: ARDROX 907PB AerosolDocument11 pagesSafety Data Sheet: ARDROX 907PB Aerosolabdulbaset alselwi100% (1)

- Brick Work BSM Jha - 1Document3 pagesBrick Work BSM Jha - 1Dwitikrushna Rout0% (1)

- Installation & Testing of Underground Drainage PipingDocument7 pagesInstallation & Testing of Underground Drainage PipingamalNo ratings yet

- Hira - NRV ServicingDocument11 pagesHira - NRV ServicingAbzad HussainNo ratings yet

- Hirarc Method State-Plaster CeilingDocument1 pageHirarc Method State-Plaster CeilingMr LiuNo ratings yet

- 9-1 Moem Hirarc Feb 2017Document1 page9-1 Moem Hirarc Feb 2017PHH9834No ratings yet

- Welding Works JSA HSE ProfessionalsDocument1 pageWelding Works JSA HSE ProfessionalsAli Kazi100% (1)

- Risk Assesment Material HandlingDocument2 pagesRisk Assesment Material Handlingelize100% (1)

- Project Title: TBA: Client: ContractorDocument5 pagesProject Title: TBA: Client: ContractorIzza HalimNo ratings yet

- Cleaning Chlorination Water Tank Risk AnalysisDocument2 pagesCleaning Chlorination Water Tank Risk AnalysisRamyNo ratings yet

- Risk Assessment For Demolition of Slab - Book Store-HCNSDocument4 pagesRisk Assessment For Demolition of Slab - Book Store-HCNSappu pocom3No ratings yet

- Grand Toolbox (Monthly)Document3 pagesGrand Toolbox (Monthly)Suresh Praba PNo ratings yet

- LIFTING PLAN Ofloading Old ContainersDocument5 pagesLIFTING PLAN Ofloading Old Containerssubajit bhattacharjeeNo ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install Jhafatimah100% (1)

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraNo ratings yet

- Risk Assessment - AC Duct Cleaning - Updated 12-07-2022Document7 pagesRisk Assessment - AC Duct Cleaning - Updated 12-07-2022Amal SaNo ratings yet

- JHA - Plumbing WorksDocument1 pageJHA - Plumbing WorksBilly Joe BreakfastNo ratings yet

- JHA For To Carryout Activities During Unloading of Product From Ship Rev00Document4 pagesJHA For To Carryout Activities During Unloading of Product From Ship Rev00Sreekumar100% (1)

- 02 PTW Risk AssessmentDocument22 pages02 PTW Risk Assessmentzaim100% (2)

- ISLA JHA Temfacil ConstructionDocument2 pagesISLA JHA Temfacil Constructionaasafety06No ratings yet

- SDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiDocument5 pagesSDS - Fenomastic Enamel Semigloss - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDocument4 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- Risk Assessment For Installtion of Sprinkler SystemDocument11 pagesRisk Assessment For Installtion of Sprinkler SystemRAMY ABOU AL DAHABNo ratings yet

- Excavation and Trenching Procedure PDFDocument38 pagesExcavation and Trenching Procedure PDFjohn michael medinaNo ratings yet

- HIRADC Assessment-INSTALLATION OF BUSDUCTDocument6 pagesHIRADC Assessment-INSTALLATION OF BUSDUCTTengkudin LatifNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Manhole Construction - ShoringDocument1 pageManhole Construction - Shoringasr.engineering2023No ratings yet

- METHOD STATEMENT - Open Excavation Rev 1Document4 pagesMETHOD STATEMENT - Open Excavation Rev 1asr.engineering2023No ratings yet

- METHOD STATEMENT - Pipe Jacking Rev 1Document3 pagesMETHOD STATEMENT - Pipe Jacking Rev 1asr.engineering2023No ratings yet

- METHOD STATEMENT - Manhole Construction Rev 1Document4 pagesMETHOD STATEMENT - Manhole Construction Rev 1asr.engineering2023No ratings yet

- WMS Pipe To Manhole Connection 2Document8 pagesWMS Pipe To Manhole Connection 2asr.engineering2023No ratings yet

- WMS Installing Precast Concrete Ring Using Sinking MethodDocument4 pagesWMS Installing Precast Concrete Ring Using Sinking Methodasr.engineering2023No ratings yet

- Leakage TestDocument3 pagesLeakage Testasr.engineering2023No ratings yet

- Risk Management - Event Management Plan For Open and Club EventsDocument24 pagesRisk Management - Event Management Plan For Open and Club EventsMazlenashahNo ratings yet

- Msds Hilti CP 636Document5 pagesMsds Hilti CP 636Basava N100% (1)

- Unit Ig1: Management of Health and SafetyDocument15 pagesUnit Ig1: Management of Health and SafetyVikash Kumar RayNo ratings yet

- RTV106 - MSDSDocument4 pagesRTV106 - MSDSchamarahewaNo ratings yet

- Ficha Técnica Lubricante Omega 73Document12 pagesFicha Técnica Lubricante Omega 73juan felipe diazgranados santosNo ratings yet

- CSS NCII-Institutional Assessment ToolDocument13 pagesCSS NCII-Institutional Assessment ToolPinky GumogdaNo ratings yet

- 2a. TESDA-OP-CO-01-F11 CBC EIM NC II FINAL AND CONSOLIDATEDDocument67 pages2a. TESDA-OP-CO-01-F11 CBC EIM NC II FINAL AND CONSOLIDATEDRommel SelgaNo ratings yet

- Installation, Operation, & Maintenance Manual: Monorail Tarca SystemDocument32 pagesInstallation, Operation, & Maintenance Manual: Monorail Tarca SystemBosko Ginz JadibataNo ratings yet

- Behaviour Based SafetyDocument26 pagesBehaviour Based SafetyTarun Kakkar0% (1)

- APPROVED TRAINING INSTITUTION LIST SEPTEMBER 2023 FinDocument10 pagesAPPROVED TRAINING INSTITUTION LIST SEPTEMBER 2023 Finedmund ndegwaNo ratings yet

- Plinth Concreting JSA HSE ProfessioanlsDocument1 pagePlinth Concreting JSA HSE ProfessioanlsmarietabereNo ratings yet

- Sun2000 - (75ktl, 100ktl, 110ktl, 125ktl) Series User ManualDocument156 pagesSun2000 - (75ktl, 100ktl, 110ktl, 125ktl) Series User ManualAli ArsalanNo ratings yet

- 3060 LR Conv Generic ManualDocument25 pages3060 LR Conv Generic ManualJorge Isaias Arenas PerezNo ratings yet

- fLmOMkiHTESrm1LCcfyC - Asset Integrity Management and Reliability of Oil and Gas AssetsDocument4 pagesfLmOMkiHTESrm1LCcfyC - Asset Integrity Management and Reliability of Oil and Gas AssetsMuhammad AdnanNo ratings yet

- Food Quality and Food Safety: Learning ObjectivesDocument24 pagesFood Quality and Food Safety: Learning ObjectivesShanti Swaroop Chauhan shanti.chauhanNo ratings yet

- Electrical Safety Inspection Checklist-FDocument2 pagesElectrical Safety Inspection Checklist-FGyanendra Narayan Nayak89% (9)

- Construction Health and Safety - Cost or InvestmentDocument75 pagesConstruction Health and Safety - Cost or InvestmentLameck Makura100% (4)

- Food Processing and Quality Control NTVQ Level 1 - 3Document69 pagesFood Processing and Quality Control NTVQ Level 1 - 3Khan Mohammad Mahmud HasanNo ratings yet

- Ebook Construction Safety - Hinze, JimmieDocument360 pagesEbook Construction Safety - Hinze, JimmieSai Krishna.NNo ratings yet

- WDDE-EN-00 (20161226) Workshop ManualDocument526 pagesWDDE-EN-00 (20161226) Workshop ManualAl Furkhan100% (1)

- Bosch Ebike Owner Manual 20mhp MY23Document38 pagesBosch Ebike Owner Manual 20mhp MY23Alin UtaNo ratings yet

- 1J ECSA LMIAppformDocument39 pages1J ECSA LMIAppformdarl1No ratings yet

- SM LM1330 LM1333 ENDocument415 pagesSM LM1330 LM1333 ENAfterek100% (1)

- Mechanical Workshop SafetyDocument56 pagesMechanical Workshop SafetyParishey JahanzaibNo ratings yet

- Fox-15 HSQDocument10 pagesFox-15 HSQMuhammad NazriNo ratings yet

- Introduction To General Ethics and Ethical Values (Group1)Document9 pagesIntroduction To General Ethics and Ethical Values (Group1)Donna MelgarNo ratings yet

- ABB GK Reference Book List 2024Document3 pagesABB GK Reference Book List 2024WissamMamouNo ratings yet

- Core IstructE ObjectivesDocument5 pagesCore IstructE ObjectivesRonnie SmithNo ratings yet