RBDA Full en Metric Letter

RBDA Full en Metric Letter

Uploaded by

essamCopyright:

Available Formats

RBDA Full en Metric Letter

RBDA Full en Metric Letter

Uploaded by

essamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

RBDA Full en Metric Letter

RBDA Full en Metric Letter

Uploaded by

essamCopyright:

Available Formats

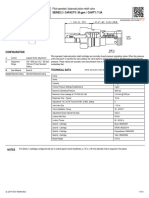

MODEL Bi-directional, direct-acting relief valve

RBDA SERIES 1 / CAPACITY: 95 L/min. / CAVITY: T-10A

sunhydraulics.com/model/RBDA

The bi-directional, direct-acting relief cartridge is a normally closed, pressure-limiting valve used to protect hydraulic

components from pressure transients. When the pressure differential between ports 1 and 2 exceeds the valve

setting, the valve starts to open, throttling flow to limit the pressure rise, regardless of the direction.

TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

Cavity T-10A

Series 1

Capacity 95 L/min.

Maximum Operating Pressure 350 bar

Factory Pressure Settings Established at 15 L/min.

Maximum Valve Leakage at Reseat 0,7 cc/min.

Response Time - Typical 2 ms

Reseat >85% of setting

Hysteresis ≤3%

Adjustment - No. of CW Turns from Min. to Max. setting 5

Valve Hex Size 22,2 mm

Valve Installation Torque 41 - 47 Nm

U.S. Patent # 11,384,857

Seal kit - Cartridge Buna: 990310007

Seal kit - Cartridge Viton: 990310006

Model Weight 0.17 kg.

CONFIGURATION OPTIONS Model Code Example: RBDALAN

CONTROL (L) ADJUSTMENT RANGE (A) SEAL MATERIAL (N)

L Standard Screw Adjustment A 1200 - 3000 psi (85-210 bar), 1500 psi N Buna-N

C Tamper Resistant - Factory Set (105 bar) Standard Setting V Viton

W 3000 - 5000 psi (210 - 350 bar), 4000

psi (280 bar) Standard Setting

c 2023 Sun Hydraulics 1 of 3

TECHNICAL FEATURES

Capacity from port 1 to port 2 is 25 GPM (95 L/min). Flow from port 2 to port 1 is rated at 10 GPM (40 L/min).

Recommended minimum setting is 1200 psi (85 bar). Note: At settings below 1200 psi (85 bar), the valve is rated for maximum transient flows of 25 GPM (95

L/min) only.

Because the modulating occurs inside the cartridge, these valves are immune to most of the problems associated with cavitation, namely noise and manifold

erosion.

The seals on the adjust screw are exposed to system pressure which means this valve can only be adjusted when the pressure is removed. The setting procedure

is; check the setting, remove the pressure, adjust the valve, check the new setting.

Valve is relatively insensitive to varying oil temperatures and oil borne contamination.

Select a spring range where the desired relief setting is approximately mid-range to high between the minimum and maximum pressure to ensure maximum valve

repeatability.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

PERFORMANCE CURVES

c 2023 Sun Hydraulics 2 of 3

c 2023 Sun Hydraulics 3 of 3

You might also like

- 2010 Citroen c3 Owners ManualDocument102 pages2010 Citroen c3 Owners ManualBrayden EaglesNo ratings yet

- Massey Ferguson: Parts CatalogueDocument523 pagesMassey Ferguson: Parts CatalogueAngel Bret SerranoNo ratings yet

- BMW E46 Code ListDocument82 pagesBMW E46 Code ListDeeJay MiniMeNo ratings yet

- RBFA Full en Metric LetterDocument2 pagesRBFA Full en Metric LetteressamNo ratings yet

- CBEALAN Full Es Metric LetterDocument2 pagesCBEALAN Full Es Metric Letternicole tapiaNo ratings yet

- Contrabalance SunHydraulicDocument2 pagesContrabalance SunHydraulicMatias Oñate ArriagadaNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- Sun Hydraulics RDDALCN Metric DatasheetDocument3 pagesSun Hydraulics RDDALCN Metric Datasheet2fqdw8s8yxNo ratings yet

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- CBEWLJN Full en Metric A4Document2 pagesCBEWLJN Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBCA Es Metric A4Document1 pageCBCA Es Metric A4martin.riosNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- CBGA Full en Us A4Document2 pagesCBGA Full en Us A4Epul HaqNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveMuhtadin RizkiNo ratings yet

- DBAFMCV924 Full en Metric LetterDocument6 pagesDBAFMCV924 Full en Metric LetterMechanical2022No ratings yet

- RGFA Full en Metric LetterDocument4 pagesRGFA Full en Metric LetteressamNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24ADocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9No ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedDocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedVinit ChoudharyNo ratings yet

- Sun Hydraulics CWEL Technical SpecificationsDocument1 pageSun Hydraulics CWEL Technical SpecificationsJustinNo ratings yet

- Sun Hydraulics RVCALANDocument2 pagesSun Hydraulics RVCALANService - Anda Hydraulics Asia Pte LtdNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaNo ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Sun Hydraulics RDDA-LCNDocument3 pagesSun Hydraulics RDDA-LCNJustinNo ratings yet

- Cbcalin ValveDocument2 pagesCbcalin ValveArun51092No ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- RDDA - Direct-Acting Relief ValveDocument3 pagesRDDA - Direct-Acting Relief ValveD ŠpokauskasNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance Valveதமிழன் இராமசாமிNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveJavier AriasNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- CBCA Full en UsDocument3 pagesCBCA Full en UsDavid PNo ratings yet

- RDDA Es Metric A4Document1 pageRDDA Es Metric A4Daniel GómezNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveAlaa saidNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument2 pagesModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- Modelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaDocument1 pageModelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaErasmo LimaNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveANDRESNo ratings yet

- FQCA Full Es Metric A4Document2 pagesFQCA Full Es Metric A4Sara SaritaNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument1 pageModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- DMDAMAN Full en Us LetterDocument3 pagesDMDAMAN Full en Us LetterjmmcaptainNo ratings yet

- Electro-Prop ValveDocument2 pagesElectro-Prop Valvemaikel.mNo ratings yet

- CACLLGN en Us A4Document1 pageCACLLGN en Us A42fqdw8s8yxNo ratings yet

- RDDALDN Full en Us A4Document3 pagesRDDALDN Full en Us A4clark jonesNo ratings yet

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 pagesModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNo ratings yet

- FDBA en Metric LetterDocument1 pageFDBA en Metric LetterY.EbadiNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- Direct-Acting Relief Valve: DownloadDocument2 pagesDirect-Acting Relief Valve: Downloadaristi51No ratings yet

- RSBC Full en Us A4Document2 pagesRSBC Full en Us A4Mykola TitovNo ratings yet

- CKCD Full en Metric A4Document2 pagesCKCD Full en Metric A4Nelson CruzNo ratings yet

- RDBALAN Full en Metric A4Document2 pagesRDBALAN Full en Metric A4David AltarribaNo ratings yet

- Valvula Contrabalance CBGA LIN HCLDocument2 pagesValvula Contrabalance CBGA LIN HCLcarlos pachecoNo ratings yet

- DMDAMNN224-ECT en Us LetterDocument2 pagesDMDAMNN224-ECT en Us LetterLUIS SANCHEZ SANZCHEZNo ratings yet

- 2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01Document2 pages2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01controlorNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Downloads - Paro SoftwareDocument4 pagesDownloads - Paro SoftwareessamNo ratings yet

- Adobe Acrobat Reader - Free PDF ViewerDocument2 pagesAdobe Acrobat Reader - Free PDF VieweressamNo ratings yet

- FLeX Series 2-Stage, Solenoid-Operated Adjustable Relief Valve, Normally VentedDocument8 pagesFLeX Series 2-Stage, Solenoid-Operated Adjustable Relief Valve, Normally VentedessamNo ratings yet

- RPEI Full en Metric LetterDocument4 pagesRPEI Full en Metric LetteressamNo ratings yet

- Re92076 - 2022 02 16Document76 pagesRe92076 - 2022 02 16essamNo ratings yet

- Control Devices HM, HS5 and EO Series 1X: AmericasDocument76 pagesControl Devices HM, HS5 and EO Series 1X: AmericasessamNo ratings yet

- Chapter 24: Torsional Vibrations: (A) Shaft of Varying Diameters. (B) Torsionally Equivalent ShaftDocument8 pagesChapter 24: Torsional Vibrations: (A) Shaft of Varying Diameters. (B) Torsionally Equivalent ShaftNazmus Sakib100% (1)

- Floating Ball Valve - 8100R21Document12 pagesFloating Ball Valve - 8100R21demblavalvesltd1989No ratings yet

- ВО9412ВО 2022 04 12 14 55Document8 pagesВО9412ВО 2022 04 12 14 55AtochkavNo ratings yet

- Mercedes-Benz Fault Error Codes/Diagnostic Trouble Codes (DTC)Document25 pagesMercedes-Benz Fault Error Codes/Diagnostic Trouble Codes (DTC)Thuyết Rau MáNo ratings yet

- Generac 3500XL GeneratorDocument20 pagesGenerac 3500XL GeneratorThaddeus KosciuszkoNo ratings yet

- BMW Z4 M Coupe 2007 Owner - S ManualDocument50 pagesBMW Z4 M Coupe 2007 Owner - S ManualcayberrahmadakNo ratings yet

- STRiDA Owner's Manual - EnglishDocument30 pagesSTRiDA Owner's Manual - EnglishMalo Malo MaloNo ratings yet

- 300tdi Defender Oil SpecDocument10 pages300tdi Defender Oil SpecsebgohgkNo ratings yet

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342Document10 pagesPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342EstebanNo ratings yet

- 3,0 Liter GM 2011 USA Combilift Service ManualDocument333 pages3,0 Liter GM 2011 USA Combilift Service ManualNeoz CuandonNo ratings yet

- 4×4 Magazine Australia-July 2023Document134 pages4×4 Magazine Australia-July 2023Daniel RomulusNo ratings yet

- BMW E46 1999 - 2005 Ignition System Service ManualDocument21 pagesBMW E46 1999 - 2005 Ignition System Service Manualajib_09No ratings yet

- Massey Ferguson 2605 TRACTOR Service Parts Catalogue Manual (Part Number 3906192)Document14 pagesMassey Ferguson 2605 TRACTOR Service Parts Catalogue Manual (Part Number 3906192)hujiao6607280100% (1)

- Tab. Carga XCMG-QY60KDocument10 pagesTab. Carga XCMG-QY60KPauloCatu100% (1)

- SNF-FDSS-WRD BrochureDocument4 pagesSNF-FDSS-WRD BrochureAnil KumarNo ratings yet

- Project 2023Document9 pagesProject 2023khan amirNo ratings yet

- Valve Tappets - Lifters.cam FollowersDocument4 pagesValve Tappets - Lifters.cam FollowersPankaj BuddhdevNo ratings yet

- Spare Parts List: Riders R316 T AWD, 967291701, 2017Document57 pagesSpare Parts List: Riders R316 T AWD, 967291701, 2017DejanNo ratings yet

- Safety Relief Valves Test Bench: Makali Valves & Engineering ServicesDocument3 pagesSafety Relief Valves Test Bench: Makali Valves & Engineering Servicessajid789No ratings yet

- Manual JD English c13960Document53 pagesManual JD English c13960Ardhana ArdhanaNo ratings yet

- Spare Parts - TFC45HDocument513 pagesSpare Parts - TFC45HRafael Pádua OliveiraNo ratings yet

- How To Modify A Fridge Compressor Into A Silent AiDocument5 pagesHow To Modify A Fridge Compressor Into A Silent AiDazz DazzNo ratings yet

- CC Croma 1.9 2.4 JTD PDFDocument5 pagesCC Croma 1.9 2.4 JTD PDFMichal ChrenkoNo ratings yet

- Barossa ATV - Silverhawk 250 E1RF - Spare Parts ListDocument45 pagesBarossa ATV - Silverhawk 250 E1RF - Spare Parts ListgabysurfNo ratings yet

- Dasar Mesin Elektrik G-M SajaDocument45 pagesDasar Mesin Elektrik G-M SajaFelly AntaNo ratings yet

- Cummins QSB Technical DataDocument3 pagesCummins QSB Technical DataAwanNo ratings yet

- 5.-Vitas-Gate-Valves - ValvitaliaDocument24 pages5.-Vitas-Gate-Valves - Valvitaliajuan carlos suaNo ratings yet