Gas Madrid - Form C

Gas Madrid - Form C

Uploaded by

Elchin AbishovCopyright:

Available Formats

Gas Madrid - Form C

Gas Madrid - Form C

Uploaded by

Elchin AbishovCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Gas Madrid - Form C

Gas Madrid - Form C

Uploaded by

Elchin AbishovCopyright:

Available Formats

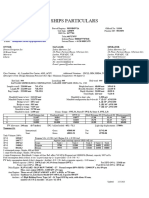

VESSEL PARTICULARS (FORM C)

LPG/C GAS MADRID

Specifications of the vessel and the gas installation which are representations by the Owners.

(A) VESSEL’S CHARACTERISTICS

PREAMBLE

Name : LPG/C GAS MADRID

Owner : GAS MADRID INC.

Flag : Monrovia, Liberia

Build : Zhejiang Shipyard, Ningbo

Date on Service : 30 April 2003

Class : LR+100 A1 (Liquefied Gas Carrier) IMO type II PG

Maximum pressure 17.6kg/cm 2; Temperature 0°C

GRT International : 4508 Suez : 4891.02

Panama :

NRT International : 1352 Suez : 3586.79

Panama : 2848

Is vessel build according to USCG regulations? : NO

RINA regulations? : NO

Japanese regulation? : NO

Has vessel received USCG approval? : NO

RINA approval? : NO

HULL

LOA : 99.79 M

LBP : 92.94 M

Breadth : 18.18 M

Depth : 7.79 M

Summer Draft : 5.60 M corresponding to Summer DWT = 3633.1

Lightweight Draft 2.79 M

M corr

Estimated draft with full cargo and full bunkers are as follows.

Product Draft Fore’ (m) Draft Aft’ (m) Draft Mean (m) Corresponding

Deadweight (t)

Propane ( 98%) 4.91 5.68 5.296 3223

Butadiene (98%) 5.28 5.75 5.511 3510

VCM (98%) 5.358 5.838 5.600 3633

Form ‘C’ – TBA 1

Propeller immersion :

At draft At 5.55 m correspond. : 100 %

At draft At 2.77 m correspond. : 58 %

At draft At m correspond. : %

COMMUNICATION EQUIPMENT

Call letter : D5GI3

Radio Station normally watched : POR / AOW

Radio MF/HF NBDP : 347739114

Radio MF/HFTEL/DSC :

VHF : 16 / 70

Satellite Communication Inmarsat ‘C’ : 463716538

463716538

Inmarsat ‘FBB’ : +870

+ 870 773

773932445

213 796

FAX : +N/A

870 783 232 945

EMAIL : gasmadrid@optiaccess.com

MACHINERY

Main Engine x 1 . Type and make : MAN B&W 5S 35 MC

. Service power : 3330 kw @ 90% MCR

No of Cylinders 5

Cyl Bore x Stroke 350mm x 1400mm

. Grade of fuel used : 380 cst @ 50deg C , RME 25 or RMG 35 ISO

8217/86

Auxiliaries x 3 Type and make : Cummins Model KTA 19-D (M)

(Electrical)

(Mechanical) :

Grade of fuel used : Marine Gas Oil DMA 8217/96

No off

Emergency Gen Type : MAN NUTZFAHRZEUG AG DO226MLE

No off : 1

Bow Thruster 1

Boiler Type : Composite boiler L YF 1.0/0.35-0.6

Evaporation : 1 Ton / hr

Max Design : 8 Tons

Pressure

Feed Water Temp : 60 deg cel.

No off : 1

Form ‘C’ – TBA 2

Exhaust Economiser Type : N/A

Evaporation :

No off :

Air Compressors Type / Capacity : SPERREHL2/105 INDUSTRI AS/ 47 Cu.M/Hr

(Main)

No off : 2

Air Compressors Type : SPERREHL2/105 INDUSTRI AS/ 47 Cu.M/Hr

(Emergency)

No off : Include in Main unit no. 2- use as emergency

Fuel Oil Purifier Type : Alfa Laval MOPX 205T6T -24

No off : 2

Capacity : 6900L/Hr

Lub Oil Purifier Type : Alfa Laval MMPX 43 SGP-11

No off : 1

Capacity : 3500L/Hr

Evaporator Type : Alfa Laval Copenhagen A/S JWP-26-c 80

Capacity : 10 Cu. M/Hr

Fresh Water Type : UVK J UV Disinfection plant

Sterilizer

Capacity : 6.4 Cu. m/Hr

Fresh Water Type / Capacity : N/A

Mineraliser

Waste Oil Type : OG 120C TEAMTEC MARINE PRODUCTS

Incinerator (IMO

MEPC 76 (40))

Capacity : 180.0Kcal/H – 22LH Sludge

Oily Water Separator Type : SKIT S I.U

Capacity : 1.0 m3/Hr

Sewage Treatment Type : ST-2 Marine Sewage Treatment

plant

Capacity : 1.6 m3/Day

Hot Water Set No off : 1

(Calorifier unit)

Steering Gear Type : Rolls Royce Marine AS

Duty Capacity : 125 bar

Hydraulic pump : TENFJORD PU45

unit

Speed

About 12 knots up to Beaufort scale 4 and max significant wave height of 1.25m

Form ‘C’ – TBA 3

CONSUMPTION/ DAY

Main Engine HFO HS IFO 38 About 11,5 MT/DAY +/- 5%

Auxiliary Engine DO HS MGO LOAD 1,7 MT/DAY

DISCH 2,5 MT/DAY

AT SEA 1,2 MT/DAY

IGS 2,0 MT/DAY

All figures are about, defined as +/- 5% on consumption and speed respectively.

Notes:

1. Speed and consumption figures at sea, are best estimated basis daily weather conditions are up to

Beaufort scale 4 – max.significant wave height 1.25 m, without effect of sea currents or swell, and

vessel en route under a steady course, with a net sea passage duration of at least 24 hrs.

2. Consumption figures at port, are subject to port movements, port and/or harbour, terminal

requirements, for the safe manoeuvring, approach, inland navigation, and port stay of the vessel

throughout her call.

Permanent bunker

capacity (100%)

HFO : 540.176 m3 (98%)

Diesel : 98.686 m3 (98%)

Fresh Water : 273.50 MT

Form ‘C’ – TBA 4

(B) CARGO INSTALLATIONS

1. Transportable products and respective quantities, calculated in accordance with IMO – maximum

filling formula. (Tonnes)

100% (CBM) 98% (CBM)

NO.1 CARGO TANK 2514.88 2464.58

NO.2 CARGO TANK 2515.87 2455.52

TOTAL 5030.75 4930.13

SPSV Ref. Temp. (deg. Density at Corresponding

(bar g) C.) (Ref. Temp.) Quantity (MT)

Propane 17.65 45.0 0.459 2262.93

Propylene 17.65 45.0 0.470 2317.161

B/P Mixture 17.65 45.0 0.487 2400.973

I-Butane 17.65 45.0 0.526 2593.248

N-Butane 17.65 45.0 0.548 2701.711

Butylene 17.65 45.0 0.565 2785.523

Butadiene 17.65 45.0 0.588 2898.916

V.C.M. 17.65 45.0 0.872 3015.000

Isoprene 17.65 45.0 0.656 3234.165

Pentane 17.65 45.0 0.600 2958.078

Pentene 17.65 45.0 0.611 3012.309

Note(1): In case of USCG, propylene, propane and B/P mixtures are not to be carried except the

vapour pressure of B/P mixtures is not more than 12.75 bar g, 13.0 kg/cm2 @ 45 °C

Note(2): On and after, the pressure value in parentheses is shown as a conversion value

Mixing ratio of above mentioned B/P mixtures is as follows:

Butane 35 wt% and propane 65 wt%

2. Other transportable products N/A

SPSV Ref. Temp. Density at Ref. Corresponding

(°C.) Temp. Quantity (MT)

Raffinate 1 TBA TBA TBA TBA

Raffinate 2 TBA TBA TBA TBA

C4 TBA TBA TBA TBA

3. TANKS

3.1 Design pressure (Vapour) – BV-IGC : 17.65 bar g (1.765 MPag)

- USCG : 12.40 bar g (1.200 MPag )

3.2 Valve setting : 17.65 bar g (1.765 MPag) / 12.40 bar g

(1.200 MPag ) / 7.0 bar g

3.3 Maximum vacuum obtainable : 0.5 Bar Approx.

Form ‘C’ – TBA 5

3.5 Maximum temperature acceptable : 45 °C

3.6 Minimum temperature acceptable : 0 °C

3.7 Hydrostatic Test Pressure : 26.48 bar g (2.648 MPag)

4. LOADING RATE (TONS/HOUR) – For Full Cargo Parcels

Ex-atmospheric storage with gas : 1 tank : 300 m3/hour Max.

Return 2 tanks : 600 m3/hour max.

Remarks:

* Based on maximum velocity of 6.5 metres/sec except VCM, and 4.0 meters/sec for VCM

in the liquid piping.

* If cargo temperature is less than 0 °C, shore heater to be used. If ship heater used, max rate is 250 m3

per hour.

* Loading by shore pump only, proper size gas return line to be connected

* Subject to both ship and shore tanks being under favourable conditions

5. CARGO PUMPS

5.1 Type : Deswell 150 - 4 - 1

Make : DESMI

How many : 2

Maximum specific gravity : 0.948

5.2 Capacity (CMB/Hour) : 300 m3/hour Max (EACH)

Two speed or variable speed : Fixed One Speed

Rated kW (each) 130KW

Working pressure maximum : 12 bar

5.3 Location : Cargo Tank after dome

Removable : No

5.4 Booster pumps : NO

Type :

Maker :

5.5 Capacity (CMB/Hour) : N/A

Working pressure :

5.6 Location : N/A

5.7 Time to discharge a full liquid cargo using all pumps against back pressure at pump

1 bar : about 8 hours for LPG

5 bars : about 12 hours for LPG

10 bars : about 18 hours for LPG

5.8 Nominal back pressure when working : Cannot in series

In series corresponding head : N/A

Maximum back pressure : N/A

Nominal pressure at rail (propane) : N/A

5.9 What amount of cargo remains in tanks after completion pumping before stripping:

- liquid : About 1.0 m3 per one tank

- vapour : Depends on Vapour pressure

Form ‘C’ – TBA 6

6. STRIPPING

6.1 Stripping system, if any : NIL

6.2 Time required to remove all traces of liquid cargo as stated in 5.9 for:

- LPG : about 3 hours

7. CARGO COMPRESSORS

7.1 Type : TINE 5.12 / 6.1 / 0

Make : Kohler & Horter

How many : 2

Piston displacement : N/A

Rated Kw : 110 KW

Stroke : 150mm

Max discharge pressure : 19.5 bar

Pressure differential : 4.0 bar

Rate : 550 m3 / Hr (Approx)

No of Revolutions :

7.2 Are compressors oil free : YES

7.3 Can they reliquefy VCM without risk : NO

7.4 State time to bring full cargo of butane : N/A

to atmospheric pressure from

8. INERT GAS SYSTEM

8.1 Does the vessel use inert gas? : YES (NITROGEN SYSTEM)

If so, state utilization and quantities : For Inerting

8.2 Can the vessel produce inert gas? : YES

If so, state type and composition of gas produce: Nitrogen 99.5% Oxygen 0.5%

Discharge Capacity : 250 m3

8.3 Maximum production obtainable : 220 m3

NOTE:- Above quantities obtained at engine room temperature 45 C

8.4 State if there are storage facilities for inert gas onboard: N/A

- Size : N/A

- Pressure : N/A

8.5 State if any shore supply of nitrogen may be required: : N/A

- for what purpose : N/A

- what quantities : N/A

9. GAS FREEING

9.1 State method used giving all details : Nitrogen Plant / Fans / Compressors

9.2 State time required including stripping : 60 hours

Form ‘C’ – TBA 7

10. CHANGING GRADE

10.1 From completion discharge of cargo Propane, time required in hours and inert gas in CBM

required to reach a tank and gas installation atmosphere of less than 100 ppm of Propane in

Vapour phase.

Time required: TBA

10.2 Can this operation be carried out at sea? : YES

10.3 Can the ship measure the number of ppm in vapour phase? : YES

10.4 Has vessel deck tank for changing grade/cooling operations? : NO

10.5 Deck tanks : NIL

Capacity :

Purpose :

11. COOLING BEFORE LOADING : N/A

12. CARGO HEATER

12.1 Type : Shell & Tube Heat Exchanger

12.2 Inside Diameter : 856 mm

12.3 Overall length : 8100 mm

12.4 Cargo flow rate : 214 t/hr (Propylene)

12.5 Min Inlet Temp : -48 deg cel.

12.6 Min Outlet Temp : 0 deg cel.

12.7 Required Sea water Capacity : 600 m3

12.8 Design Pressure : 15 bar (Working Pressure)

12.9 Hydrostatic Test Pressure : 37.5 bar

12.10 Tightness Test Pressure :

12.0 State discharging rate for propane to be brought from atmospheric pressure

Loading rate for Propane – 48 C / 0 C: about 214 Mt/hr

13. CARGO VAPORIZER

In case vapour gas is needed to feed compressors, can vessel produce its own if no shore

available:

No

14. REFRIGERATING APPARATUS NA

14.1 Is it independent of cargo? : NA

Is so, state cooling agents : NA

14.2 What minimum temperature can be maintained : NA

14.3 What time required at sea to lower by 1oC the full cargo of : NA

15. MEASURING APPARATUS

What gauges on board?

Type : Float type level gauge

Location : At each cargo tank dome

16. SAMPLES

Form ‘C’ – TBA 8

16.1 State how tank atmosphere samples can be taken and where from?

Standard of fitting? : Standard threaded fitting

16.2 Same question for cargo : Standard threaded fitting

16.3 Are sample bottles available on board? : No

17. CARGO LINES

17.1 Is ship fitted with a port and starboard cargo manifold? : YES

17.2 Position of cargo manifold

- distance from stern (AP) (S / P) : 55.2 M

- distance form stem (FP) (S / P) : 44.6 M

- height above deck : 1.5 m for Liquid manifold

- distance from ship’s rail : 2.5 M

- underside keel to manifold : 9.29 M

17.3 Liquid line

- flange-size : 8 in.

- type : ASA 300

Gas line

- flange-size : 4 in.

- type : ASA 300

17.4 What reducers on board? :

For Liquid line (low temperature)

8"/3001bsx10"/300lbs

8"/3001bsx10"/1501bs

8"/3001bs x 8"/1501bs

8"/3001bs x 6"/3001bs

For Vapor line (normal temp.)

4"/3001bsx6"/3001bs

4"/3001bs x 6"/1501bs

4"/300lbs x 4"/1501bs

4"/300lbs x 3"/3001bs

17.5 Is ship fitted with stern discharge? NO

- Liquid line - diameter : N/A

- flange – size : N/A

- type : N/A

18. HOSES

Are serviceable hoses available on board? : None

18.1 Two pieces, each : N/A

Length : N/A

Diameter : N/A

Form ‘C’ – TBA 9

Flange-size : N/A

Type : N/A

Bending radius : N/A

18.2 Minimum temperature acceptable : N/A

Maximum pressure acceptable : N/A

18.3 For what products are hoses suitable? : N/A

19. DERRICKS

- Hose cranes : One

- Where situated : Midship near manifold

- Lifting capacity : 4 tonnes

- Working radius : 360 deg

20. SPECIAL FACILITIES

20.1 How many grades can be segregated? : NONE

20.2 How many cooled? : N/A

20.3 Can vessel sail with slack cargo tanks? : YES (But needs to be more than 60%

Full)

Form ‘C’ – TBA 10

You might also like

- Lytron Manual and SchematicsDocument38 pagesLytron Manual and Schematicsbruce hu100% (2)

- OFM Data Tables, Variables, Data Dictionary, and CatalogDocument93 pagesOFM Data Tables, Variables, Data Dictionary, and CatalogVictor SanchoNo ratings yet

- BW Tokyo Gasform CDocument8 pagesBW Tokyo Gasform CAndi IrfanNo ratings yet

- Ficha MSC GRANDIOSADocument1 pageFicha MSC GRANDIOSAJose Fernandez DiazNo ratings yet

- Surface Tension of Water From: AlcoholDocument4 pagesSurface Tension of Water From: AlcoholSkandar EverestNo ratings yet

- SHIPPARTICULLAR Gas-ElixirDocument12 pagesSHIPPARTICULLAR Gas-Elixirdharmawan100% (1)

- Gas CerberusDocument10 pagesGas CerberusImranNo ratings yet

- dati tecniciDocument9 pagesdati tecnicioceanusking3No ratings yet

- Eco ElysiumDocument10 pagesEco ElysiumPrem KumarNo ratings yet

- Epic Bali - Form-CDocument10 pagesEpic Bali - Form-Ccorobceanu.andrei900No ratings yet

- Eco NicalDocument13 pagesEco Nicalluizfellipe95No ratings yet

- Gas Houston Form CDocument7 pagesGas Houston Form CElchin AbishovNo ratings yet

- Data Sheet For MercuryDocument5 pagesData Sheet For MercuryMohamed hamza souissiNo ratings yet

- Compressor Specifications - © Bristol Compressors International, IncDocument1 pageCompressor Specifications - © Bristol Compressors International, IncWall Art VenezuelaNo ratings yet

- BW Liberty Gas Form CDocument8 pagesBW Liberty Gas Form Cvalter AssunçãoNo ratings yet

- Eco ArcticDocument13 pagesEco ArcticLins RexineNo ratings yet

- BW Messina Gasform C 1Document8 pagesBW Messina Gasform C 1sufiyan.madreNo ratings yet

- Data Sheet Diesel EngineDocument3 pagesData Sheet Diesel EngineTaufiq HidayatNo ratings yet

- Datasheet H2930uabc MetricoDocument1 pageDatasheet H2930uabc MetricoRodrigo J. MarqueziniNo ratings yet

- Fairchem Blueshark Vessel ParticularDocument4 pagesFairchem Blueshark Vessel Particularbhavana kholaNo ratings yet

- TSTPP ABB 500 MW Steam TurbineDocument11 pagesTSTPP ABB 500 MW Steam TurbineDenkaNo ratings yet

- Ship Particular MBDocument2 pagesShip Particular MBromi.arvNo ratings yet

- Shadeed - MEAE - Dubai - UAEDocument1 pageShadeed - MEAE - Dubai - UAEEdiNo ratings yet

- Line 7D: 160/36 Cat BRT Raw White/ 1001 NA NADocument6 pagesLine 7D: 160/36 Cat BRT Raw White/ 1001 NA NAbheenwaramNo ratings yet

- Havila Clipper SpecificationDocument4 pagesHavila Clipper SpecificationPriyanshu JoshiNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Catalogo Equipo Aire Acondicionado Portatil TGMDocument1 pageCatalogo Equipo Aire Acondicionado Portatil TGMSolucionesenfrio saNo ratings yet

- N ORHAN - Gas Form CDocument11 pagesN ORHAN - Gas Form CImranNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- Sandra Tide 2 Page Brochure 1293Document2 pagesSandra Tide 2 Page Brochure 1293Manuel LabradorNo ratings yet

- Ship's Particulars (Hampshire)Document1 pageShip's Particulars (Hampshire)Emil-Junior IordacheNo ratings yet

- LTKL 068 DSDocument2 pagesLTKL 068 DSnick.lee0602No ratings yet

- T3 ME Performance Record Jan TemplateDocument5 pagesT3 ME Performance Record Jan TemplateMuhd Khir RazaniNo ratings yet

- MCP HamburgDocument3 pagesMCP HamburgalbustamanteNo ratings yet

- TEMA Sheet + Overall SummaryDocument2 pagesTEMA Sheet + Overall Summarykevindomz54No ratings yet

- M.T. Energy R: Type: Delivered: Class: TonnageDocument2 pagesM.T. Energy R: Type: Delivered: Class: TonnageHergheligiu VasileNo ratings yet

- D 4 A 742Document7 pagesD 4 A 742Mujahid Gill0% (1)

- TSTPP Turbine InterlocksDocument39 pagesTSTPP Turbine InterlocksDenkaNo ratings yet

- Machinery List MV YutakaDocument7 pagesMachinery List MV Yutakarandy warouwNo ratings yet

- Al Jaber 70Document4 pagesAl Jaber 70laaxNo ratings yet

- Technical Data Compressor: Model 104G7800 115V/60Hz 1Document6 pagesTechnical Data Compressor: Model 104G7800 115V/60Hz 1bryanzapien33No ratings yet

- CR37KQ-PFT-240BNDocument1 pageCR37KQ-PFT-240BNأبو زينب المهندسNo ratings yet

- sc18mlx 104l2138 R404a-R507a 230v 60hz 06-2022 DsDocument4 pagessc18mlx 104l2138 R404a-R507a 230v 60hz 06-2022 DsAlex GarethNo ratings yet

- Ship Particular Bintang Fortuna CBFDocument2 pagesShip Particular Bintang Fortuna CBFViki RamadhaniNo ratings yet

- Data Sheet CV-Sapphire PDFDocument1 pageData Sheet CV-Sapphire PDFthehoang12310No ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- KNT-001-TS-ME6-DS-002 - 3 - Mechanical DataSheet For Seawater Lift PumpsDocument10 pagesKNT-001-TS-ME6-DS-002 - 3 - Mechanical DataSheet For Seawater Lift PumpsAnh ChiếnNo ratings yet

- Model: C1500 D6 Frequency: 60 HZ Fuel Type: Diesel: Generator Set Data SheetDocument3 pagesModel: C1500 D6 Frequency: 60 HZ Fuel Type: Diesel: Generator Set Data SheetJose VarelaNo ratings yet

- Fisa Tehnica AHU-11 PDFDocument8 pagesFisa Tehnica AHU-11 PDFLiviu ToaderNo ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- Specification Sheet Rev 1Document12 pagesSpecification Sheet Rev 1nishanth NTNo ratings yet

- Circulation Calculation and DNB CurveDocument5 pagesCirculation Calculation and DNB Curveanil peralaNo ratings yet

- Technical Data Compressor: Model 104G7550 115V/60Hz 1Document6 pagesTechnical Data Compressor: Model 104G7550 115V/60Hz 1Camilo CarreñoNo ratings yet

- MarvelDocument2 pagesMarvelShridhar AmatiNo ratings yet

- EM2X3125UDocument4 pagesEM2X3125UJavier ValenzuelaNo ratings yet

- Data Sheet of Filtered WaterCentrifugal PumpDocument2 pagesData Sheet of Filtered WaterCentrifugal Pumpsajeesh5113699No ratings yet

- MV Amfitriti Ship'S Particulars: Paloma ShippingDocument3 pagesMV Amfitriti Ship'S Particulars: Paloma ShippingNimesh Perera100% (1)

- Rich Gas Pre Cooler - E101 A-BDocument4 pagesRich Gas Pre Cooler - E101 A-B29031978No ratings yet

- MV ABBA SpecificationDocument2 pagesMV ABBA SpecificationAlexander Diete-kokiNo ratings yet

- MAJ DS2 06 MEC DST 0004_C Data Sheet for Electrostatic DehydratorDocument4 pagesMAJ DS2 06 MEC DST 0004_C Data Sheet for Electrostatic Dehydrator胡子No ratings yet

- Ship'S Particulars: Load Mark Draught Freeboard Displacement DeadweightDocument2 pagesShip'S Particulars: Load Mark Draught Freeboard Displacement DeadweightSantharam Mariner0% (4)

- Amal-18 Sta DDR#18 29-02-2020Document30 pagesAmal-18 Sta DDR#18 29-02-2020eng7mohamed7hashimNo ratings yet

- Julia Landon College Preparatory and Leadership Development School Curriculum Paper 2009-2010 Seventh Grade Pre-Algebra Ms. HamlowDocument3 pagesJulia Landon College Preparatory and Leadership Development School Curriculum Paper 2009-2010 Seventh Grade Pre-Algebra Ms. HamlowsdhamlowNo ratings yet

- Defender - Accessory Fitting InstructionsDocument312 pagesDefender - Accessory Fitting InstructionsMiguel Seral PérezNo ratings yet

- Solution Manual For Engineering Mechanics, Statics - Sheri D. Sheppard, Thalia Anagnos, Sarah L. BillingtonDocument24 pagesSolution Manual For Engineering Mechanics, Statics - Sheri D. Sheppard, Thalia Anagnos, Sarah L. BillingtonMaher MahmoodNo ratings yet

- SA-AMI-000-HECM-620200 - CALCULATION FOR SHEET PILES CALCULATIONS FOR COOLING WATER PIPE - Rev1Document10 pagesSA-AMI-000-HECM-620200 - CALCULATION FOR SHEET PILES CALCULATIONS FOR COOLING WATER PIPE - Rev1nurtureherbNo ratings yet

- Datasheet DBV50E-22AZZ0S02 1081113 enDocument8 pagesDatasheet DBV50E-22AZZ0S02 1081113 enMuharrem yapıcıNo ratings yet

- MEMB221 Lab ManualDocument66 pagesMEMB221 Lab ManualRynda BlyndaNo ratings yet

- Integral TABLA PDFDocument1 pageIntegral TABLA PDFOscar Torres GonzNo ratings yet

- 1 - PEDDINSERT - Insertion MachinesDocument26 pages1 - PEDDINSERT - Insertion MachinesMohamed AbdalhakamNo ratings yet

- Druck Dpi605 ManualDocument234 pagesDruck Dpi605 ManualFR PERANo ratings yet

- Ict S2Document13 pagesIct S2LEOPOLDNo ratings yet

- Bien Tan Veichi Ac80b ManualDocument10 pagesBien Tan Veichi Ac80b ManualnammauhutmatNo ratings yet

- Troubleshooting and Prevention of Cracking in Induction Hardening Os Steels - Part 2Document8 pagesTroubleshooting and Prevention of Cracking in Induction Hardening Os Steels - Part 2Jader PitangueiraNo ratings yet

- Influence of Motivation and Organizational Commitment On Work Satisfaction and Employee PerformanceDocument8 pagesInfluence of Motivation and Organizational Commitment On Work Satisfaction and Employee PerformanceNely Noer SofwatiNo ratings yet

- Wireless Keypad Clavier Sans Fil: Instruction Manual / Mode D'emploiDocument2 pagesWireless Keypad Clavier Sans Fil: Instruction Manual / Mode D'emploiLilian Vivanco AndradeNo ratings yet

- SEE EXAM TIME TABLE NOV DEC 2019rDocument9 pagesSEE EXAM TIME TABLE NOV DEC 2019rPradhumna AdhikariNo ratings yet

- MSAN MA5600T Basic OperationDocument110 pagesMSAN MA5600T Basic OperationIptech solutionsNo ratings yet

- 1 SGSN-MME IntroductionDocument42 pages1 SGSN-MME IntroductionRakesh MoriNo ratings yet

- Solid Work Manual Stuffing BoxDocument45 pagesSolid Work Manual Stuffing Boxk.dharmasenthil100% (3)

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- Solutions To LP Practice Problems: X Z 125 0 5 3.125 0 Z 150 0 6 3.75 0 Z 175 0 7 4.375 0 Z 200 0 8 5 0Document11 pagesSolutions To LP Practice Problems: X Z 125 0 5 3.125 0 Z 150 0 6 3.75 0 Z 175 0 7 4.375 0 Z 200 0 8 5 0KLASDJAKLNo ratings yet

- NWZ-4610 Instruction ManualDocument120 pagesNWZ-4610 Instruction ManualТодор ТодоровNo ratings yet

- Forward Chaining and Backward ChainingDocument11 pagesForward Chaining and Backward ChainingMonir AhammodNo ratings yet

- Caret Package Infographic PDFDocument1 pageCaret Package Infographic PDFAli HabibNo ratings yet

- Turnouts On Curves - WebinarDocument58 pagesTurnouts On Curves - WebinarVINAYKUMAR MOURYANo ratings yet

- Phy MergedDocument31 pagesPhy MergedharjitjammujohalNo ratings yet

- Chain ComplexesDocument9 pagesChain Complexessticker592No ratings yet

- COMPETENCIES MATH Grades 7 - 9Document19 pagesCOMPETENCIES MATH Grades 7 - 9Unime PlazaNo ratings yet