PUF Insulation Technical Data Sheet

Uploaded by

SagarBabuPUF Insulation Technical Data Sheet

Uploaded by

SagarBabuTechnical Data Sheet

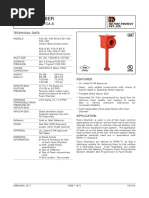

SURESEAL 35 PUF

PRODUCT

SPRAYED POLYURETHANE FOAM

DESCRIPTION

PHYSICAL DATA

SURESEAL 35 PUF is a solvent free two component sprayed

Solids : 100%

applied polyurethane foam. The product comes in a polyol and

No. of Components : Two

an isocyanate component. It is added with effective flame

Mixing Ratio : A:B / 1 : 1 by volume

retardant and combustion stops when flame is removed and it

Recommended thickness : 25 - 50 mm

doesn’t melt in fire. The materials are sprayed with plural

Compressive Strength : 180 KPa

component pump onto the substrate in liquid state, it foams on

Density : 35 kg / m³

the surface in seconds and develop into a thick insulation layer

Packing Size : PART A Polyol - 200 kg

over the surface.

PART B Isocyanate - 200 kg

Cream Time : 2 to 5 seconds

Gel Time : 11 to 14 seconds

RECOMMENDED USES

SURESEAL 35 PUF is designed for industrial and commercial

APPLICATION INSTRUCTIONS

applications as a heat and moisture barrier. It is suitable for Surface Preparation :

insulation of outer walls and decks of cold rooms to prevent

Concrete - Concrete surface should be clean and free

condensation. It is also effective for roof decks for heat

from oil, grease and other contaminants. New concrete

insulation, moisture and sound barrier.

shall be allowed to cure for at least 28 days before

application of primer. Porous and weak surfaces shall be

primed with a suitable primer prior to application of spray

ADVANTAGES

foam.

Seamless – it is a cured in-place seamless sprayed foam.

Can be applied to difficult corners Steel – Steel surface to be applied with spray foam shall

Suitable for concrete, steel, timber etc. be clean and free from oil and grease. Rusty surface

Added with flame retardant. shall be properly prepared by blasting or power tool prior

Suitable for heat, moisture and sound barrier. to application of spray foam. Anti-corrosion primer will

help to enhance the corrosion protection of the surface.

Provide conducive working place for non-insulated work

place.

Primer : Selection of primer will be accordance with the

Save air conditioning electricity bill by reducing heat type of substrate.

transfer.

Very fast installation work. Application : SURESEAL 35 PUF shall be sprayed with

a heated plural component reactor spray pump.

Cleaning : Tools and equipment must be cleaned and

flushed immediately with PLC Cleaner #2 after

application.

Tel : 603-80604584 Fax : 603-80604676 Email : email@plc.com.my Website : www.plc.com.my Rev.3/10.10

You might also like

- Foamy Slag Fundamentals and Their Practical Application To Electric Furnace Steelmaking100% (1)Foamy Slag Fundamentals and Their Practical Application To Electric Furnace Steelmaking24 pages

- Powerproof: One Component Polyurethane Dispersion Waterproofing Membrane67% (3)Powerproof: One Component Polyurethane Dispersion Waterproofing Membrane2 pages

- Highly Abrasion Resistant PU Floor Coating: DescriptionNo ratings yetHighly Abrasion Resistant PU Floor Coating: Description2 pages

- Hi Pon 50 10 Polyester PU Primer Ver 2.0 PDFNo ratings yetHi Pon 50 10 Polyester PU Primer Ver 2.0 PDF4 pages

- Polydeck 2000: UV Stable Car Park Coating SystemNo ratings yetPolydeck 2000: UV Stable Car Park Coating System2 pages

- PFP-241-2K SB: Polyfloor Primer Multipurpose SB100% (1)PFP-241-2K SB: Polyfloor Primer Multipurpose SB2 pages

- Soudal - Expertise in Sealants, PU Foams and AdhesivesNo ratings yetSoudal - Expertise in Sealants, PU Foams and Adhesives1 page

- 2 Component, Highly Abrasion Resistant PU Floor Coating: DescriptionNo ratings yet2 Component, Highly Abrasion Resistant PU Floor Coating: Description3 pages

- KAN-TAURUS High Build Epoxy Finish: CharacteristicsNo ratings yetKAN-TAURUS High Build Epoxy Finish: Characteristics2 pages

- Polypoxy FC: Solvent Free Epoxy Resin CoatingNo ratings yetPolypoxy FC: Solvent Free Epoxy Resin Coating2 pages

- 2 TDS Bostik-Ultralevel-Eul-2000-17-Kg-Epoxy-Self-Levelling-UnderlayNo ratings yet2 TDS Bostik-Ultralevel-Eul-2000-17-Kg-Epoxy-Self-Levelling-Underlay2 pages

- TDS - Polpox EC 945 LV + Hardener EP 945 LV-1No ratings yetTDS - Polpox EC 945 LV + Hardener EP 945 LV-12 pages

- Polypoxy SL 40: Epoxy Resin Based Self Levelling Floor ToppingNo ratings yetPolypoxy SL 40: Epoxy Resin Based Self Levelling Floor Topping2 pages

- Polypoxy BF: Epoxy Repair Putty and Blow Hole FillerNo ratings yetPolypoxy BF: Epoxy Repair Putty and Blow Hole Filler2 pages

- Hi-Vinyl 1102 CF Etching Primer (Ver 4.0)No ratings yetHi-Vinyl 1102 CF Etching Primer (Ver 4.0)4 pages

- UMA Advanced Technology Primer Sealer Bonder (White) : Technical Data XIM-03No ratings yetUMA Advanced Technology Primer Sealer Bonder (White) : Technical Data XIM-032 pages

- Hi Pon 50 01 Polyurethane Top Coat Ver 12.0No ratings yetHi Pon 50 01 Polyurethane Top Coat Ver 12.04 pages

- Abecote 341: Concrete Dust Proofer and Surface Hardening CompoundNo ratings yetAbecote 341: Concrete Dust Proofer and Surface Hardening Compound2 pages

- Klb-System Polyurethan: Product InformationNo ratings yetKlb-System Polyurethan: Product Information6 pages

- Polyrepair Lw35: Lightweight Concrete Repair MortarNo ratings yetPolyrepair Lw35: Lightweight Concrete Repair Mortar2 pages

- Nippon Bodelac 9000 Alkyd Resin Enamel: DescriptionNo ratings yetNippon Bodelac 9000 Alkyd Resin Enamel: Description2 pages

- EC Tech Report High Performance Polyurethanes: PDFFrom EverandEC Tech Report High Performance Polyurethanes: PDFVincentz Network GmbH & Co. KGNo ratings yet

- Your Boarding Pass To VISHAKHAPATNAM - AIR INDIANo ratings yetYour Boarding Pass To VISHAKHAPATNAM - AIR INDIA2 pages

- 6-44-0002 Rev 5 (HOT INSU FOR VESSEL, PIPING & EQP)0% (1)6-44-0002 Rev 5 (HOT INSU FOR VESSEL, PIPING & EQP)53 pages

- Anusha 2019 IOP Conf. Ser. Mater. Sci. Eng. 548 012011No ratings yetAnusha 2019 IOP Conf. Ser. Mater. Sci. Eng. 548 0120118 pages

- Sound and Vibration Considerations of Some Materials For Automotive Engineering ApplicationsNo ratings yetSound and Vibration Considerations of Some Materials For Automotive Engineering Applications14 pages

- (Paul E. Minton) Handbook of Evaporation Technology - 170-182100% (1)(Paul E. Minton) Handbook of Evaporation Technology - 170-18213 pages

- Evaluating Sieve Tray Flooding in A Distillation Column Using Kister and Haas and Fair's CorrelationsNo ratings yetEvaluating Sieve Tray Flooding in A Distillation Column Using Kister and Haas and Fair's Correlations10 pages

- Formulation and Development of Sulphate Free ShampNo ratings yetFormulation and Development of Sulphate Free Shamp14 pages

- Matindok Gas Development Project (MGDP) Check List System Dehydration UnitNo ratings yetMatindok Gas Development Project (MGDP) Check List System Dehydration Unit7 pages

- BakerHughes BruceWright NewCokerDefoamer CokingCom May2011No ratings yetBakerHughes BruceWright NewCokerDefoamer CokingCom May20119 pages