Diarab Road

Diarab Road

Uploaded by

Hishmat EzzelarabCopyright:

Available Formats

Diarab Road

Diarab Road

Uploaded by

Hishmat EzzelarabOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Diarab Road

Diarab Road

Uploaded by

Hishmat EzzelarabCopyright:

Available Formats

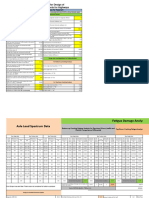

CONCRETE MIX DESIGN (ACI 211.

1)

Date Reference No. 36 MPa/2024

Client/Customer: Consultant

Project Al Riyadh Location Ksa

Class of concrete 36 Mpa Specification ACI 211-R

PRELIMINARY TEST DATA

Fine Aggregates Crushed Fine Combined Coarse Aggregates 20mm 10mm Average

% of Blending 35% 65% 100% % of Blending 60% 40% 100%

Fineness Modulus 2.690 D.R.U.W 1583 1544 1567

SP.GR.(O.D) 2.590 2.581 2.584 SP.GR (O.D) 2.589 2.589 2.589

Absorption 1.723 0.469 0.908 Absorption 1.110 1.277 1.177

Moisture Content 0.35 0.48 0.43 Moisture Content 0.34 0.53 0.42

DESIGN PARAMETERS

Specification Used

Cement Content (Min) 400 kg/mᶾ Cement Content 400 kg/mᶾ

Nominal Max. size of Agg. 20 mm Nominal Max. size of Agg. 20 mm

W/C Ratio (Max) 0.50 Weigth of Coarse Agg. 1024 kg/mᶾ

Comp. Strength(Min) 35 Mpa W/C Ratio 0.35

Required Slump Loss 200±25 mm Slump Loss 200±25 mm

Entrained Air(Max) 2% Comp. Strength @28 days 35 Mpa

DESIGN MIX

Dosage Un-corrected Corrected Batch Weight

Brand Absolute Vol.

Materials Supplier Type Batch Weight

Name m³

(%) (kg/m³) kg/m³ kg/0.045 m³

Cement City Cement OPC/SRC 1/V 0.1270 400 420 21.0

Pigment SSCI Micro Silica 0.0% 0.0000 0 0 0.0

Water Nasser Drinking Water 0.1400 140 152 7.6

Retarder DCP RPC 20 A,B & D 0.50% 0.0020 2.1 2.1 0.1

Superplasticizer DCP PC 318 F&G 1.1% 0.0044 4.7 4.7 0.2

Air 0.0200 - - -

20mm(3/4") Rmah Crusher Coarse Agg. 614 617 30.8

0.3955

10mm(3/8") Rmah Crusher Coarse Agg. 410 411 20.6

Crushed Sand Rmah Crusher Fine Agg. 322 283 14.1

0.3111

RED Sand Shuqara Fine Agg. 482 525 26.2

Total = 1.000 2375 2415 120.7

LABORATORY TRIAL MIX RESULTS

Fresh Concrete Compressive Strength(N/mm²)

Percentage of Concrete Mix

Test Results Unit 5 Days 7 Days 28 Days

Amb. Temperature 37 ᵒC 36.6 37.8 46.6

Mix Temperature 28 ᵒC 35.7 38.8 47.5

Red Sand Cement

Density 2415 kg/m³ 34.4 39.1 47.9 18.67% 12.70%

Yield - 35.6 38.6 47.3 Crushed Water

Sand 14.00%

Air Content 2.0 % 12.44%

Retarder

0.20%

Slump Loss Standard : ASTM Superplas-

Slump @ Initial 240 mm Test Specimen: Cylinder ticizer

0.44%

Slump @ 30 minut 220 mm Remarks: COMPLY 20mm(3/4")

Air

2.00%

10mm(3/8") 23.73%

Slump @ 60minute 200 mm 15.82%

Slump @ 90 minute 180 mm

As required by ACI 211.1.91 fine aggregates proportioning will be adjusted so suit variation in day- to-day gradations and moisture content.

QC Engineer Q.C Manager

CONCRETE MIX DESIGN (ACI 211.1)

Date Reference No. 20 MPa/2024

Client/Customer: Consultant

Project Location Ksa

Class of concrete 20 Mpa Blinding Concrete Specification ACI 211-R

PRELIMINARY TEST DATA

Fine Aggregates Crushed Fine Combined Coarse Aggregates 20mm 10mm Average

% of Blending 35% 65% 100% % of Blending 60% 40% 100%

Fineness Modulus 2.690 D.R.U.W 1583 1544 1567

SP.GR.(O.D) 2.590 2.581 2.584 SP.GR (O.D) 2.589 2.589 2.589

Absorption 1.723 0.469 0.908 Absorption 1.110 1.277 1.177

Moisture Content 0.35 0.48 0.43 Moisture Content 0.34 0.53 0.42

DESIGN PARAMETERS

Specification Used

Cement Content (Min) 250 kg/mᶾ Cement Content 300 kg/mᶾ

Nominal Max. size of Agg. 20 mm Nominal Max. size of Agg. 20 mm

W/C Ratio (Max) 0.70 Weigth of Coarse Agg. 985 kg/mᶾ

Comp. Strength(Min) 20 Mpa W/C Ratio 0.50

Required Slump Loss 200±25 mm Slump Loss 200±25 mm

Entrained Air(Max) 2% Comp. Strength @28 days 20 Mpa

DESIGN MIX

Dosage Un-corrected Corrected Batch Weight

Brand Absolute Vol.

Materials Supplier Type Batch Weight

Name m³

(%) (kg/m³) kg/m³ kg/0.045 m³

Cement City Cement OPC/SRC 1/V 0.0952 300 300 15.0

Pigment SSCI Micro Silica 0.0% 0.0000 0 0 0.0

Water Nasser Drinking Water 0.1500 150 162 8.1

Retarder Webner RPC20 A,B & D 0.50% 0.0015 1.7 1.7 0.1

Superplasticizer Webner PC 318 F&G 1.0% 0.0029 3.1 3.1 0.2

Air 0.0200 - - -

20mm(3/4") Rmah Crusher Coarse Agg. 591 593 29.7

0.3805

10mm(3/8") Rmah Crusher Coarse Agg. 394 396 19.8

Crushed Sand Rmah Crusher Fine Agg. 362 318 15.9

0.3500

RED Sand Shuqara Fine Agg. 543 590 29.5

Total = 1.000 2344 2365 118.2

LABORATORY TRIAL MIX RESULTS

Fresh Concrete Compressive Strength(N/mm²)

Percentage of Concrete Mix

Test Results Unit 3 Days 7 Days 28 Days

Amb. Temperature 37 ᵒC 17.2 20.6 24.3

Mix Temperature 28 ᵒC 16.7 21.4 25.4 Cement

Red Sand 9.52%

Density 2365 kg/m³ 16.8 22.1 26.5 21.00% Retarder

Water 0.15%

Yield - 16.9 21.4 25.4 15.00%

Super-

Air Content 2.0 % plasticizer

0.29%

Slump Loss Standard : ASTM Air

Crushed 2.00%

Slump @ Initial 250 mm Test Specimen: Cylinder Sand

14.00%

Slump @ 30 minute 230 mm Remarks: COMPLY 20mm(3/4"

)

Slump @ 60minutes 200 mm 10mm(3/8"

)

22.83%

Slump @ 90 minute 180 mm 15.22%

As required by ACI 211.1.91 fine aggregates proportioning will be adjusted so suit variation in day- to-day gradations and moisture content.

QC Engineer Q.C Manager

CONCRETE MIX DESIGN (ACI 211.1)

Date Reference No. 40 MPa/2024

Client/Customer: Consultant

Project Location Ksa

Class of concrete 40 Mpa Specification ACI 211-R

PRELIMINARY TEST DATA

Fine Aggregates Crushed Fine Combined Coarse Aggregates 20mm 10mm Average

% of Blending 35% 65% 100% % of Blending 60% 40% 100%

Fineness Modulus 2.645 D.R.U.W 1583 1544 1567

SP.GR.(O.D) 2.558 2.596 2.583 SP.GR (O.D) 2.587 2.583 2.585

Absorption 1.885 0.583 1.039 Absorption 1.340 1.756 1.506

Moisture Content 0.33 1.38 1.01 Moisture Content 0.24 0.45 0.32

DESIGN PARAMETERS

Specification Used

Cement Content (Min) 420 kg/mᶾ Cement Content 425 kg/mᶾ

Nominal Max. size of Agg. 20 mm Nominal Max. size of Agg. 20 mm

W/C Ratio (Max) 0.36 Weigth of Coarse Agg. 1001 kg/mᶾ

Comp. Strength(Min) 40 Mpa W/C Ratio 0.37

Required Slump Loss 200±25 mm Slump Loss 200±25 mm

Entrained Air(Max) 2% Comp. Strength @28 days 40 Mpa

DESIGN MIX

Dosage Un-corrected Corrected Batch Weight

Brand Absolute Vol.

Materials Supplier Type Batch Weight

Name m³

(%) (kg/m³) kg/m³ kg/0.045 m³

Cement City Cement OPC / SRC I/V 0.1349 425 425 21.3

Pigment SSCI Micro Silica 0.0% 0.0000 0 0 0.0

Water Alanzy Drinking Water 0.1573 157 169 8.5

Retarder DCP RPC 20 A,B & D 0.50% 0.0021 2.3 2.3 0.1

Superplasticizer DCP PC 317 F&G 1.25% 0.0053 5.8 5.8 0.3

Air 0.0200 - - -

20mm(3/4") Rmah Crusher Coarse Agg. 601 603 30.1

0.3872

10mm(3/8") Rmah Crusher Coarse Agg. 400 402 20.1

Crushed Sand Rmah Crusher Fine Agg. 265 268 13.4

0.2932

RED Sand Shuqara Fine Agg. 492 497 24.9

Total = 1.000 2349 2372 118.5

LABORATORY TRIAL MIX RESULTS

Fresh Concrete Compressive Strength(N/mm²)

Percentage of Concrete Mix

Test Results Unit 3 Days 7 Days 28 Days

Amb. Temperature 37 ᵒC

Mix Temperature 28 ᵒC Cement

Red Sand

Density 2372 kg/m³ 17.59% 13.49%

Crushed

Yield - Sand Water

11.73% 15.73%

Air Content 2.0 %

Retarder

Slump Loss Standard : ASTM 0.21%

Super-

Slump @ Initial mm Test Specimen: Cylinder plasticizer

0.53%

Slump @ 30 minut mm Remarks: COMPLY Air

10mm(3/8" 20mm(3/4" 2.00%

Slump @ 60minute mm ) )

15.49% 23.23%

Slump @ 90 minute mm

As required by ACI 211.1.91 fine aggregates proportioning will be adjusted so suit variation in day- to-day gradations and moisture content.

QC Engineer Q.C Manager

CONCRETE MIX DESIGN (ACI 211.1)

Date Reference No. 50 MPa/2024

Client/Customer: Consultant

Project Location Ksa

Class of concrete 50 Mpa Specification ACI 211-R

PRELIMINARY TEST DATA

Fine Aggregates Crushed Fine Combined Coarse Aggregates 20mm 10mm Average

% of Blending 35% 65% 100% % of Blending 55% 45% 100%

Fineness Modulus 2.645 D.R.U.W 1583 1544 1565

SP.GR.(O.D) 2.558 2.596 2.583 SP.GR (O.D) 2.587 2.583 2.585

Absorption 1.885 0.583 1.039 Absorption 1.340 1.756 1.527

Moisture Content 0.33 1.00 0.77 Moisture Content 0.24 0.45 0.33

DESIGN PARAMETERS

Specification Used

Cement Content (Min) 450 kg/mᶾ Cement Content 490 kg/mᶾ

Nominal Max. size of Agg. 20 mm Nominal Max. size of Agg. 20 mm

W/C Ratio (Max) 0.50 Weigth of Coarse Agg. 1001 kg/mᶾ

Comp. Strength(Min) 50 Mpa W/C Ratio 0.32

Required Slump Flow 650±150 mm Slump Flow 650±150 mm

Entrained Air(Max) 2% Comp. Strength @28 days 50 Mpa

DESIGN MIX

Dosage Un-corrected Corrected Batch Weight

Brand Absolute Vol.

Materials Supplier Type Batch Weight

Name m³

(%) (kg/m³) kg/m³ kg/0.045 m³

Cement City Cement OPC SRC I/V 0.1556 490 490 24.5

Pigment SSCI Micro Silica 0.0% 0.0000 0 0 0.0

Water Alanzy Drinking Water 0.1568 157 171 8.5

Retarder DCP RPC 20 A,B & D 0.40% 0.0020 2.2 2.2 0.1

Superplasticizer DCP PC 677 F&G 1.1% 0.0054 5.9 5.9 0.3

Air 0.0200 - - -

20mm(3/4") Rmah Crusher Coarse Agg. 551 552 27.6

0.3872

10mm(3/8") Rmah Crusher Coarse Agg. 450 452 22.6

Crushed Sand Rmah Crusher Fine Agg. 247 249 12.4

0.2731

RED Sand Shuqara Fine Agg. 458 462 23.1

Total = 1.000 2361 2384 119.1

LABORATORY TRIAL MIX RESULTS

Fresh Concrete Compressive Strength(N/mm²)

Percentage of Concrete Mix

Test Results Unit 3 Days 7 Days 28 Days

Amb. Temperature 37 ᵒC

Mix Temperature 28 ᵒC Red Sand Cement

16.39% 15.56%

Density 2384 kg/m³ Crushed

Sand

Yield - 10.92% Water

Air Content 2.0 % 15.68%

Retarder

Slump Loss Standard : ASTM 0.20%

Slump Flow @ Initial 700 mm Test Specimen: Cylinder Super-

plasticizer

Slump Flow @ 30 minute 700 mm Remarks: COMPLY 20mm(3/4") 0.54%

10mm(3/8" Air

) 23.23%

Slump Flow @ 60minutes 650 mm 2.00%

15.49%

Slump Flow @ 90 minutes 650 mm

As required by ACI 211.1.91 fine aggregates proportioning will be adjusted so suit variation in day- to-day gradations and moisture content.

QC Engineer Q.C Manager

You might also like

- Admixture Pada Campuran BetonDocument54 pagesAdmixture Pada Campuran BetonDanny100% (2)

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument6 pagesTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- Additives For A Challenging Cement MarketDocument5 pagesAdditives For A Challenging Cement MarketkidcatNo ratings yet

- Mekanika Tanah 2Document30 pagesMekanika Tanah 2Anggardha YanotamaNo ratings yet

- Phase Diagram of Soil: V DefineDocument14 pagesPhase Diagram of Soil: V DefineSqueak DollphinNo ratings yet

- Seminar ReportDocument21 pagesSeminar ReportTheWatchdogs WatchdogNo ratings yet

- Flexible Pavement Design IRC37 2001 1Document5 pagesFlexible Pavement Design IRC37 2001 1Chatnoir NoirNo ratings yet

- MSA CalculationDocument6 pagesMSA CalculationARTI PALEKARNo ratings yet

- Conc M40 Mix DesignDocument21 pagesConc M40 Mix DesignNisar ShaikhNo ratings yet

- Soil Stabilization From Mechanical MethodsDocument21 pagesSoil Stabilization From Mechanical MethodslazamNo ratings yet

- Gradation of Filter Material: (Waduk Telagawaja)Document7 pagesGradation of Filter Material: (Waduk Telagawaja)Ady Darwiyasa Manson BatNo ratings yet

- Concrete Mix Design ProcedureDocument9 pagesConcrete Mix Design ProcedureSaroj BhattaraiNo ratings yet

- (ASTM C136) Sieve Analysis of Fine and Coarse Aggregates Coarse Aggregates 19MmDocument8 pages(ASTM C136) Sieve Analysis of Fine and Coarse Aggregates Coarse Aggregates 19MmHussein BeqaiNo ratings yet

- Pengujian Dynamic Cone Penetrometer (DCP) CBR From DCP Test: Dipanjaitan DipanjaitanDocument31 pagesPengujian Dynamic Cone Penetrometer (DCP) CBR From DCP Test: Dipanjaitan DipanjaitanNaldo LumbantoruanNo ratings yet

- Chp0200 Geometric Design andDocument54 pagesChp0200 Geometric Design andangelbarba100% (2)

- Dynamic Cone Penetrometer Test (D C P)Document5 pagesDynamic Cone Penetrometer Test (D C P)eko bari wNo ratings yet

- Cement Stablize of SoilDocument10 pagesCement Stablize of Soilالزهور لخدمات الانترنيتNo ratings yet

- Proyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Document4 pagesProyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Ikhromul Khoirul AqshomNo ratings yet

- Brick CalculatorDocument3 pagesBrick CalculatorP.v.KumarNo ratings yet

- Peak Runoff Prediction by The Rational Method (PDF) - 201404301105569714Document5 pagesPeak Runoff Prediction by The Rational Method (PDF) - 201404301105569714Wan-WanNo ratings yet

- Department of Civil Engineering - Materials Testing LaboratoryDocument24 pagesDepartment of Civil Engineering - Materials Testing LaboratoryChris JosephNo ratings yet

- Haryana TestDocument1 pageHaryana TestPankaj SherwalNo ratings yet

- BearingDocument2 pagesBearingSameer ShashwatNo ratings yet

- Void Ratio (E) Vs Pressure (Kpa)Document4 pagesVoid Ratio (E) Vs Pressure (Kpa)Antariksa PrianggaraNo ratings yet

- Cement Testing Week No 37Document1 pageCement Testing Week No 37DNYANESHWAR PATILNo ratings yet

- Penetration BitumenDocument7 pagesPenetration BitumennabihahNo ratings yet

- Combined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationDocument9 pagesCombined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationAndrew MwambaNo ratings yet

- Hydrology ReportDocument60 pagesHydrology ReportpanikarickyNo ratings yet

- Foundation EngineeringDocument45 pagesFoundation EngineeringPhilip NguyenNo ratings yet

- Blending For DLCDocument12 pagesBlending For DLCAjit P. SinghNo ratings yet

- Sieve AnalysisDocument8 pagesSieve AnalysisJJ KohNo ratings yet

- Hydro Culv 21Document10 pagesHydro Culv 21Víctor García García ErasoNo ratings yet

- Group Pile Subgrade Reaction-Meyerhof 1976Document12 pagesGroup Pile Subgrade Reaction-Meyerhof 1976Probal ProsoilNo ratings yet

- Mix Design and Pie Chart RepresentationDocument40 pagesMix Design and Pie Chart RepresentationKuldeep ChakerwartiNo ratings yet

- CC Design forDLC 100 MMDocument14 pagesCC Design forDLC 100 MMamit singhNo ratings yet

- Nabll Mix DesignDocument29 pagesNabll Mix DesignPIDCL WITH SUBUDHINo ratings yet

- Diameter in MM.: Grain Size AnalysisDocument13 pagesDiameter in MM.: Grain Size AnalysisImran KhanNo ratings yet

- Sub-Regional Transport Enhancement Project: Atterrberg Limits TestDocument14 pagesSub-Regional Transport Enhancement Project: Atterrberg Limits Testsakar shresthaNo ratings yet

- Sieve Analysis GraphDocument6 pagesSieve Analysis GraphDeserie JoyNo ratings yet

- Pi FormDocument4 pagesPi FormJoshua NdaloNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- Calculation of Safe Bearing CapacityDocument2 pagesCalculation of Safe Bearing CapacityDaljit624No ratings yet

- Vas Design and Infrastructure Consultants PVT LTD: Concrete Cores Test Result of HaryanaDocument2 pagesVas Design and Infrastructure Consultants PVT LTD: Concrete Cores Test Result of HaryanaPankaj SherwalNo ratings yet

- Mix Design SheetDocument8 pagesMix Design SheetmudithaNo ratings yet

- Unlocked Pavement 1.2.1Document18 pagesUnlocked Pavement 1.2.1amit singhNo ratings yet

- GEO Rock Mass Mapping ProformaDocument1 pageGEO Rock Mass Mapping Proformaklau avNo ratings yet

- Trichy Tollway Private Limited: Ijm (India) Infrastructure LimitedDocument24 pagesTrichy Tollway Private Limited: Ijm (India) Infrastructure LimitedSureshKumarNo ratings yet

- FT003 - Aggregate Impact Value TestDocument15 pagesFT003 - Aggregate Impact Value Testjjksite voyantsNo ratings yet

- Soil LabDocument30 pagesSoil LabAnonymous eg41HYENo ratings yet

- Triaxial Test (Astm D2850-87) : Project: Kanaan - Location II Location: Kaltim Borehole/Depth: BH03 / 17.00 - 17.50 MDocument8 pagesTriaxial Test (Astm D2850-87) : Project: Kanaan - Location II Location: Kaltim Borehole/Depth: BH03 / 17.00 - 17.50 MAziz PrayogaNo ratings yet

- Test Report On The California Bearing Ratio AASHTO T 193 - 99Document1 pageTest Report On The California Bearing Ratio AASHTO T 193 - 99Dominto MicoNo ratings yet

- Inspection Test PlanDocument15 pagesInspection Test PlanWHITE SHADOWNo ratings yet

- Atterberg Limit TestDocument1 pageAtterberg Limit TestAkram MuzakkiNo ratings yet

- Seive 2Document6 pagesSeive 2Abbas tahmasebi poorNo ratings yet

- Grain Size Analysis For SoilsDocument11 pagesGrain Size Analysis For SoilsyogananthanNo ratings yet

- 3.0 Electrical All Drawings City Library Cum Incubation CentreDocument6 pages3.0 Electrical All Drawings City Library Cum Incubation CentreVinay RajNo ratings yet

- Mix Design M - 30 NEWDocument6 pagesMix Design M - 30 NEWRajeev ReddyNo ratings yet

- Concrete MIx Design SummaryDocument4 pagesConcrete MIx Design SummaryAmarNo ratings yet

- Standard Deviation Calculation SheetDocument3 pagesStandard Deviation Calculation SheetH.b. DawudNo ratings yet

- M25 (PPC)Document2 pagesM25 (PPC)Jagdev Guleria100% (1)

- M25 (PPC)Document2 pagesM25 (PPC)Jagdev GuleriaNo ratings yet

- Synthesis and Performances of Polycarboxylate SupeDocument13 pagesSynthesis and Performances of Polycarboxylate SupeRaqi IzdiharaNo ratings yet

- Civil Miniproject VamshiKrishnaDocument56 pagesCivil Miniproject VamshiKrishnapvr123pvr67% (3)

- Structuro W422Document2 pagesStructuro W422m.basim.technitalNo ratings yet

- Dynamon MS603Document4 pagesDynamon MS603sugi zhuangNo ratings yet

- TR Super Plasticizer 03Document20 pagesTR Super Plasticizer 03Mostafa Hussein AbdouNo ratings yet

- TDS - Glenium Ace 456Document3 pagesTDS - Glenium Ace 456vasantsunerkarNo ratings yet

- PCE ProcessDocument7 pagesPCE Processzuber shaikhNo ratings yet

- Saturation Point of Superplast PDFDocument8 pagesSaturation Point of Superplast PDFKevin ChumánNo ratings yet

- Brochure Admixtures For Concrete enDocument12 pagesBrochure Admixtures For Concrete enrezartNo ratings yet

- Glo Concrete ViscoflowDocument3 pagesGlo Concrete ViscoflowarkarNo ratings yet

- Effect of Superplasticizer Dosage On WorDocument6 pagesEffect of Superplasticizer Dosage On WorLee TaiNo ratings yet

- 02 MCT Product Data SheetsDocument12 pages02 MCT Product Data SheetskunalscribduomNo ratings yet

- Effect of Chemical Structure of Polycarboxylate-Based Superplasticizers On Workability Retention of Self-Compacting ConcreteDocument9 pagesEffect of Chemical Structure of Polycarboxylate-Based Superplasticizers On Workability Retention of Self-Compacting ConcreteMohsen TennichNo ratings yet

- Perma Plast PC - 502 - Perma Construction Aids PVT - LTDDocument3 pagesPerma Plast PC - 502 - Perma Construction Aids PVT - LTDAbinash Chandra PalNo ratings yet

- Important Compatability Superlasticizes Portland CementDocument23 pagesImportant Compatability Superlasticizes Portland CementAliAliNo ratings yet

- Item 311Document64 pagesItem 311Jansen WongNo ratings yet

- Admixture (Revise)Document7 pagesAdmixture (Revise)Mohammad BurhanNo ratings yet

- UHPFRC PortfolioDocument67 pagesUHPFRC Portfoliolanecastoldi100% (1)

- Influence of Cement Ageing and Addition Time On The Performance of Superplastics PDFDocument10 pagesInfluence of Cement Ageing and Addition Time On The Performance of Superplastics PDFTran Huynh NamNo ratings yet

- Sikament - 294Document2 pagesSikament - 294paizintun1995No ratings yet

- DR VijayabaskarDocument30 pagesDR Vijayabaskarjeffkarthick1No ratings yet

- Ritemix Pcr300 Tds 0Document2 pagesRitemix Pcr300 Tds 0Joy Oco MañiboNo ratings yet

- ProjectDocument13 pagesProjectFE3056 NAGARAJ.SNo ratings yet

- Rheological Properties and Microstructure of Fresh Cement Pastes With Varied Dispersion Media and SuperplasticizersDocument9 pagesRheological Properties and Microstructure of Fresh Cement Pastes With Varied Dispersion Media and SuperplasticizersBattsengel NomindelgerNo ratings yet

- Effect of Mixing Energy On Fresh Properties of SCC: IndroductionDocument6 pagesEffect of Mixing Energy On Fresh Properties of SCC: Indroductionindian royalNo ratings yet

- Chemical Admixture - MonographDocument67 pagesChemical Admixture - MonographUrvasi Vandana TalapalaNo ratings yet

- Roles of SuperplasticizerDocument2 pagesRoles of SuperplasticizerRAHUL DasNo ratings yet

- Water: - A Key Ingredient, Plays A Significant Role - Water QualityDocument11 pagesWater: - A Key Ingredient, Plays A Significant Role - Water QualitySteven KuaNo ratings yet