Saes P 123

Saes P 123

Uploaded by

wastazoheb_700349353Copyright:

Available Formats

Saes P 123

Saes P 123

Uploaded by

wastazoheb_700349353Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saes P 123

Saes P 123

Uploaded by

wastazoheb_700349353Copyright:

Available Formats

Engineering Standard

SAES-P-123 29 December 2021

Lighting

Document Responsibility: Electrical Systems Designs and Automation Standards

Committee

Contents

1 Scope ................................................................ 2

2 Conflicts and Deviations ................................... 2

3 References........................................................ 2

4 Definitions ......................................................... 4

5 Lighting Requirements ...................................... 5

6 Illuminance Levels .......................................... 14

Revision Summary................................................. 18

Previous Issue: 19 March 2019 Next Planned Update: 29 December 2023

Page 1 of 19

Contact: (MAHAYNRX)

©Saudi Aramco 2019. All rights reserved.

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

1 Scope

1.1 This SAES covers the minimum mandatory requirements for lighting installations.

Exception:

Except where specifically mentioned, this SAES does not apply to residential and

security lighting.

1.2 Requirements for residential lighting are found in the IES Lighting Handbook.

1.3 Security lighting requirements shall be in accordance with the SAES-O-204.

1.4 Aviation and Navigation Aids

1.4.1 For high structures and stacks, special obstruction luminaires and

warning luminaires shall be provided in accordance with SAES-B-063.

1.4.2 Piers, offshore platforms and similar structures extending into navigable

waters must be furnished with obstruction lighting as required by

SAES-M-005.

2 Conflicts and Deviations

Any conflicts between this document and other applicable Mandatory Saudi Aramco

Engineering Requirements (MSAERs) shall be addressed to the EK&RD Manager.

Any deviation from the requirements herein shall follow internal company procedure

SAEP-302.

3 References

All referenced specifications, standards, codes, drawings, and similar material are

considered part of this engineering standard to the extent specified, applying the latest

version, unless otherwise stated.

3.1 Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302 Waiver of a Mandatory Saudi Aramco Engineering

Requirement

Saudi Aramco Engineering Standards

SAES-A-112 Meteorological and Seismic Design Data

SAES-B-063 Aviation Obstruction Marking and Lighting

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 2 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

SAES-B-068 Electrical Area Classification

SAES-M-005 Design and Construction of Fixed Offshore Platforms

SAES-M-100 Saudi Aramco Building Code

SAES-O-204 Security Lighting

SAES-P-100 Basic Power System Design Criteria

SAES-P-128 Off-grid Solar Photovoltaic (PV) System with Battery

Storage

Saudi Aramco Standard Drawing

AB-036398 Street Lighting Details

3.2 Industry Codes and Standards

American Association of State Highway and Transportation Officials

AASHTO LTS-2 Standard Specifications for Structural Supports for

Highway Signs, Luminaires, and Traffic Signals

AASHTO GTB-77 Guide for Selecting, Locating, and Designing Traffic

Barriers

Illuminating Engineering Society of North America

IES Illuminating Engineering Society - Lighting Handbook

IES LM-79 Approved Method: Electrical and Photometric

Measurements of Solid-state Lighting Products

IES LM-80 Approved Method for Measuring Lumen Maintenance

of LED Light Sources

IES TM-21 Method for Projecting Lifetime for LED Sources

Tested Via IES LM-80

IES ISTMT In-Situ Temperature Measurement Test

IES LEM-3 Design Considerations for Effective Building Lighting

Energy Utilization

IES LM-5 Guide for Photometric Measurements of Area and

Sports Lighting Installations

IES LM-64 Guide for Photometric Measurements of Parking Areas

IES RP-1 Recommended Practice for Office Lighting

IES RP-7 Recommended Practice for Industrial Lighting

IES RP-8 Recommended Practice for Roadway Lighting

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 3 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

IES RP-20 Lighting for Parking Facilities

IES RP-24 Practice for Lighting Offices Containing Computer

Visual Display Terminals

IES RR-96 Lighting Ready Reference / Energy Management

Institute of Electrical and Electronic Engineers

IEEE 1453 Recommended Practice for the Analysis of

Fluctuating Installations on Power Systems

National Electrical Manufacturers Association

NEMA C136.2 Roadway and Area Lighting Equipment - Dielectric

Withstand and Electrical Transient Immunity

Requirements

International Electrotechnical Commission

IEC 62471 Photobiological Safety of Lamps and Lamp Systems

IEC 61000-3-3 Electromagnetic Compatibility (EMC) - Part 3-3

National Fire Protection Association

NFPA 70 National Electrical Code (NEC)

4 Definitions

Ambient Temperature: Average temperature of air or another medium in the vicinity

of the luminaire. Ambient temperature is expressed in degrees Celsius.

Luminaire: Apparatus which distributes, filters or transforms the light emitted from

one or more lamps and which includes all the parts necessary for fixing and protecting

the lamps and, where necessary, circuit auxiliaries together with the means for

connecting them to the electric supply. The words “luminaire” and “lamp system” are

often assumed to be synonymous. For the purposes of this standard, the word

“luminaire” is restricted to apparatus used for distributing light in general lighting,

while “lamp system” implies use of lamps in other than general lighting applications.

LED Reported Lifetime: Length of time expressed in hours during which 70% of the

measured initial luminous flux value is maintained, as a function of ambient temperature,

while not exceeding the reported lifetime as per LM-80.

Lumen Maintenance: Value of the luminous flux at a given time in the life of a

luminaire divided by the initial value of the luminous flux of the luminaire and expressed

as a percentage “x” of the initial luminous flux value. The lumen maintenance of a

luminaire is the effect of decrease of lumen output which is sometimes referred to as

depreciation or lumen loss factor.

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 4 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

Luminaire Efficacy: Quotient of the luminaire luminous output divided by the power

consumed by the luminaire. The efficacy is expressed in lm/W.

5 Lighting Requirements

5.1 General

5.1.1 In order to optimize the effective utilization of lighting energy, interior

and exterior lighting design requirements for new buildings shall be in

accordance with the IESNA Lighting Ready Reference / Energy

Management IES RR-96. Design components for lighting energy

management shall be per considerations in IES LEM-3.

5.1.2 Lighting design shall be in accordance with IES lighting handbook.

In addition, industrial lighting design shall be in accordance with IES

RP-7, as supplemented by this SAES.

5.1.3 Lighting systems shall be designed for energy efficient operation.

Lighting systems shall be designed to automatically turn off or

minimize lighting when it is not required. In buildings, lighting in

areas that are not continuously occupied should have accessible manual

switches and/or occupancy sensors to insure that lighting is turned off

when the area is not occupied.

5.1.4 Lighting design for parking facilities shall be in accordance with

IES RP-20.

5.1.5 Photometric measurements of sports lighting, when required shall be

performed as per the IES LM-5, supplemented by this SAES.

5.1.6 Photometric measurements of parking areas, when required shall be

performed as per the IES LM-64, supplemented by this SAES.

Commentary Note 5.1.6:

Point by point lighting calculation methods should be used to confirm

that lighting levels satisfy the minimum levels specified in Table 4.

5.1.7 Lighting system power supplies consisting of 230 volt, two wires,

400 volt, two-wire shall be acceptable. The choice of voltage and

distribution system for lighting installations shall depend on the area to

be supplied and the required lighting load.

5.1.8 Direct-control switches and switching contacts used on lighting circuits

shall have a continuous current rating of at least 1.5 times the steady-

state current of the lighting load.

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 5 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

5.1.9 Outdoor non-plant area and street luminaires can be group-controlled

by photocells.

5.1.10 Photocell switches shall be of the twist-lock type and shall incorporate

an inherent time delay to prevent spurious operations. Photocell switches

shall be suitable for continuous operation in an ambient temperature

specified in SAES-P-100.

5.1.11 Where floodlights are installed on steel towers, the towers shall be

equipped with steel service platforms located 1.5 m below the luminaires.

5.1.12 Poles for area lighting and street lighting shall meet the following

requirements:

5.1.12.1 Poles used in process areas shall be hot-dipped galvanized

steel.

Poles outside process areas shall be hot dipped galvanized

steel or seamless aluminum alloy.

Exception:

Outside plant areas, fiberglass poles in accordance with

Standard Drawing AB-036398 may be used.

5.1.12.2 Aluminum, steel, and fiberglass poles shall be provided

with a suitable wiring compartment located at a height of

not less than 150 mm nor more than 900 mm from the base.

Exception:

Off grid solar street lighting as specified in SAES-P-128.

5.1.12.3 Poles and foundations shall be designed to withstand wind

loading due to a basic wind speed value stated in

SAES-A-112 and a gust factor of 1.3 acting on the effective

projected area of the pole, bracket, and luminaires.

5.1.12.4 Lighting poles installed within 5 meters from roads having a

speed limit in excess of 50 km/h and up to 65 km/h shall

have breakaway bases per AASHTO LTS-2. For higher

speed limits, wider zones per AASHTO GTB-77 shall apply.

Poles with breakaway bases shall not have traffic guards.

5.1.13 Mounting method of luminaires shall be based on the best arrangement

for illuminance, as well as easy and safe access during installation and

maintenance.

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 6 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

Commentary Note 5.1.13:

The use of existing structural steel, equipment structure and building

walls for mounting general area floodlight fixtures is desirable.

5.2 Luminaires, Components, and their Utilization

5.2.1 Luminaires shall be marked, listed or labeled by an independent third

party laboratory (notified body) the associated certificate shall state

either that the luminaires meet appropriate designated standards or

have been tested and found suitable for use in a specified manner.

Luminaires for hazardous areas shall meet certification requirements

of SAES-P-100.

5.2.2 LED luminaires shall be used for indoor and outdoor area illumination.

Exception:

High Pressure Sodium can be used for outdoor classified area

illumination, if LED is not supported for that application.

5.2.3 The use of energy-efficient luminaires shall be maximized.

Mercury vapor, Metal Halide, halogen, and incandescent luminaires

shall not be used.

Commentary Note:

Use of efficient luminaries such as LED shall be maximized to phase

out or eliminate inefficient lighting.

5.2.4 Battery rooms shall be provided with enclosed and gasketed

(i.e., vapor-tight) corrosion-resistant luminaires.

5.2.5 Luminaires shall be suitable for the environment where they are

installed. Luminaires installed outdoor shall be approved as weather

proof and dust tight.

Commentary Note 5.2.9:

IEC andNEMA, may have differences in classifying and defining

weather proof, rainproof, wet locations, etc. The intention of this

requirement is to have luminaire suitable for the application.

5.2.6 Luminaires and control switches shall be marked (tagged) with circuit

number and panel board number.

5.3 LED Luminaires

5.3.1 LED reported lifetime shall not be less than 50,000 hours associated

with the following conditions:

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 7 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

• Ambient temperature shall be as specified in SAES-P-100.

Exception:

25,000 hours luminaire lifetime is acceptable for luminaire rated less than

or equal to 15 W.

5.3.2 Luminaire manufacturer is required to provide the following test reports

to verify the luminaire performance (at specified wattage or higher for

the same housing) at ambient temperature as specified in SAES-P-100:

• IES LM-79 report measuring electrical and photometric characteristics

• In-Situ Temperature Measurement Test (IES ISTMT) report at

specified ambient temperature requirements

• IES LM-80 report, while insuring junction temperature and drive

current are within the ranges provided in the IES ISTMT report

(25°C for indoor and 50°C for outdoor)

• IES TM-21 calculation showing reported lifetime based on measured

LM-80 data

5.3.3 The luminaire manufacturer shall provide certificate issued by a third

party agency (notified body) verifying the luminaire’s performance

including declared luminaire lifetime and lumen maintenance based on

the ambient temperature. The third party lab shall be accredited by

international certification body.

5.3.4 Reflectors, optics, or filters shall be provided to control the glare and

harmful light spectrum to safe level. Guidelines and limits of IEC 62471

and /or the IES handbook shall be applied.

5.3.5 Additional LED Requirements:

● For color shifting, LED chip shall be within 7 steps for outdoor and

within 4 steps for indoor according to MacAdam ellipse for the life

of the luminaire.

Exception:

LED chip can be within 7 steps for Indoor High-bay luminaires.

● The LED circuitry shall prevent flicker perceptible to the unaided eye

over the voltage range specified as per IEC 61000-3-3 or IEEE 1453.

● All LED components shall be designed to tolerate between -10°C and

+50°C ambient temperature at 85% Relative Humidity (RH) during

non-operating/daytime.

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 8 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

● Current Total Harmonic Distortion (ITHD) induced into an AC

power line by a luminaire shall not exceed 20%.

● Thermal management shall be passive by design. The use of fans or

other mechanical devices shall not be allowed.

● Surge Protection shall be provided for outdoor applications.

LED Luminaires shall meet NEMAC136.2 for dielectric withstand

and electrical transient immunity requirements. The typical

combination wave test specification shall be met (i.e., 6kV-1.2/50µs,

3kA-8/20µs). When utilized, Surge Protection Devices (SPDs) shall

meet the UL 1449 requirements or equivalent. For LED lighting

photobiological hazard, the following shall be considered and

reported as specified in IES Lighting Handbook:

o Indoor lighting shall fall into Exempt Risk Group

o Outdoor and high-bay indoor lighting shall not exceed Risk Group 1

5.4 Plant Lighting

5.4.1 Street lighting design shall be in accordance with IES RP-8, as

supplemented by this SAES. As a minimum requirement, lighting shall

be provided at all street intersections in plants.

5.4.2 Series street lighting shall not be used.

Exception:

Existing series street lighting systems may be maintained and extended if

this does not require additional series lighting transformer capacity.

5.4.3 Luminaires positioned over stairways, platforms, elevated walkways and

landings shall be positioned at a height of 2,030 mm. Lower mounting

height shall be permitted for stanchion mounted luminaires provided the

luminaire is positioned outside the handrail vertical plane. The mounting

height shall be measured from the bottom of the luminaire to the floor

directly beneath.

5.4.4 Lighting of unmanned offshore platforms is at the option of the operating

proponent.

5.4.5 Area lighting of remote and unmanned on shore oil and water wells is at

the option of the operating proponent.

5.4.6 To determine suitability of luminaires for use in hazardous areas where

the maximum daily ambient temperature exceeds 40°C, the temperature

code (T-rating) shall be based on an ambient test temperature of 50°C or

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 9 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

higher. The installation shall be in accordance with NFPA 70 and the

area classification drawings as specified by SAES-B-068.

5.4.7 In plant areas photocell control of area and street lighting shall be through

a lighting contactor with a hand-off-automatic switch and provisions for

remote operation. Outside plant fence and street lighting can be grouped

and controlled by photocells.

5.5 Task Lighting

Task lighting is lighting directed to a specific surface or area to provide

illumination for visual and/or manual tasks. When general area lighting provides

the required illumination on a visual task, it shall be considered as task lighting.

Local supplementary luminaire(s) shall be required when a specific amount or

quality of lighting cannot readily be obtained by general lighting. In outdoor areas

where tasks are not required to be performed at night, task lighting is not required.

5.6 Emergency Lighting

5.6.1 In the event of a power failure, emergency lighting must be provided to

enable operating personnel to follow planned operating and shutdown

procedures. Sources of emergency lighting power include emergency

stand-by generators; station batteries, where available, providing 125-volt

direct current; battery-operated self-contained floodlights (these are the

most economical for general lighting); battery-operated luminaires.

5.6.2 Minimum duration of emergency lighting backup time, in the event of

power failure, shall be 90 minutes.

5.6.3 In switchgear rooms and control rooms where essential activities

continue during failure of the normal lighting, a minimum emergency

illumination level of 100 lux (10 fc) shall be provided at 760 mm above

the floor.

5.6.4 Normal and emergency task lighting of at least 200 lux (20 fc) shall be

provided for the following:

A. In plant areas to illuminate equipment required for use in

emergencies, such as: emergency telephones, shutdown and

emergency isolation stations, fire water pump areas, central foam

concentrate mixing areas, fire control panels, Breathing Apparatus

& Fire Extinguisher Station, and stand-by generators.

B. In evacuation assembly areas and in offshore platform escape

capsule areas and boat landings.

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 10 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

5.6.5 Illuminated exit signs shall be manufactured and installed in accordance

with SAES-M-100 requirements. Where the direction to the exit is not

immediately apparent, an exit directional indicator shall be provided.

5.6.6 Emergency egress lighting shall be provided for the floors of requiring

means of egress, as per SAES-M-100 and this Section:

1. Control Rooms

2. Process Areas

3. Switchgear Rooms

4. In-Plant Buildings

5. Offshore Platforms

Luminaires required for emergency exit illumination shall be supplied

from separate sources of power for items 1–5 above and where required

by SAES-M-100.

Commentary Note 5.6.6:

The egress paths which will require emergency lighting will be designated

by the respective proponent for the facility based on the main emergency

routes for the facility to the emergency assembly or evacuation points,

which is documented in the facility Emergency Response Plan (ERP).

5.6.7 The floors of means of egress shall be illuminated at all points including

angles and intersections of designated corridors and passageways,

stairways, landings of stairs, and exit doors. Emergency lighting shall

provide initial illumination that is no less than a maintained maximum of

10 lux (1 fc) and a minimum at any point of 1 lux (0.1 fc) measured

along the path of egress at floor level. A maximum to minimum

illuminance uniformity ratio of 40:1 shall not be exceeded.

5.7 Building Lighting

5.7.1 Luminaires installed in the control room shall provide shadowless

illumination.

5.7.2 Lighting for control rooms shall be designed for maximum flexibility to

permit flicker-free variation of illumination levels above each group of

operator workstations. Luminaires shall be installed to minimize

reflections and glare at operating screens.

5.7.3 General illumination for offices, computer rooms, interface rooms

and general service areas shall be provided by LED luminaires.

Office lighting shall be designed as per IES RP-1. Offices containing

computer visual display terminal (VDT) shall be designed as per

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 11 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

IES RP-24. Luminaires for suspended ceilings shall be recessed

mounted and shall be self-supporting in accordance to NFPA 70.

5.7.4 Luminaires for offices and equipment rooms shall be controlled by

manual switches located at the entrance to every room.

5.8 Luminaires Performance

5.8.1 Light Loss Factors

Table 1 containing Light-Loss Factors that shall be used in computing

illuminance levels.

Table 1 – Light Loss Factors

Lamp Lumen Depreciation Luminaire Dirt Depreciation

Outdoor Industrial 0.77

HPS 0.9

Outdoor Non-industrial 0.80

Indoor Non-industrial 0.88

LED 0.9

Indoor Industrial 0.84

5.8.2 Efficiency Requirements

Table 2 – Luminaire Efficacy

Minimum Acceptable Efficacy

HPS 87 lumens/watt

LED < 15 Watt 80 lumens/watt

LED > 15 Watt 95 lumens/watt

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 12 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

5.8.3 Color Rendering Index (CRI) Requirements

Table 3 – Minimum CRI Requirements

CRI

Lighting Type

Indoor Outdoor

LED 80 70

Exception:

CRI requirements of 70 or greater can be used for Indoor High-bay

luminaires.

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 13 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

6 Illuminance Levels

The average maintained (in service) illuminance levels in Table 4 shall be used with

uniformity factors specified in the IES lighting handbook. The initial field measurement

after installation shall be no less than the specified illuminance divided by the light loss

factor (LLF) from Table 1 and other factors utilized in the design. For locations not

specified in Table 4, IES lighting handbook shall be used.

Table 4 –Average Maintained Illuminance Levels

Illuminance Working Plane (mm)

Location Lux (fc) Related Notes [#]

_______________________________ ___________ ______________________

Aircraft Hanger [10]

General Area 500 (50) (900) H [1]

Area Lighting

General Area 10 (1) Ground H

Under Pipe-ways, Trestles, & Walkways 30 (3) Ground H

Piers 200 (20) Ground H

Street Lighting (See Residential)

Offices

Regular 500 (50) (760) H

CAD Work Station 500 (50) Task -

Conference Room 500 (50) (760) H

Elevators 200 (20) Floor H

Corridors 75 (7.5) Floor H

Stairways 75 (7.5) Floor H

Washrooms 150 (15) (900) H

Control Rooms

General 500 (50) Floor H

Instrument Panels 500 (50) (1700) V [2]

Consoles 500 (50) (760) V

Back of Panel 100 (10) (900) V

Process Interface Buildings 100 (10) (760) V

Dining Facilities

Dining Area (leisure, light environment) 150 (15) (760) H

Dining Area (quick service; normal 300 (30) (760) H

surroundings)

Service Area 300 (30) (900) H

Food Preparation 500 (50) (900) H

Entrance Halls 200 (20) Floor H

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 14 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

Table 4 – Average Maintained Illuminance Levels (Continued)

Illuminance Working Plane (mm)

Location Lux (fc) Related Notes [#]

_______________________________ ___________ __________________

Electrical Rooms

Vertical Face of Switchgear 300 (30) (1700) V

Battery Room 300 (30) Floor H

Electrical Substations and Switch Yards

Outdoor Switch Yards 20 (2) Ground H

General Substation (outdoor) 20 (2) Ground H

General Substation (indoor) 50 (5) Floor H

Indoor Substation Operating Aisles 150 (15) Floor H

Telephone Equipment Room 500 (50) V

Powerhouse

Platform, Stairs (draft fans level) 200 (20) Floor H

Burner Platform 150 (15) Floor H

Control Area 300 (30) (760) H

Vertical Instrument and Control Panels 300 (30) (1700) V

Control Desk 500 (50) (760) H

Gauges (by supplementary lighting) 300 (30) Task -

Water Wells 30 (3) Ground H

Control Panel 50 (5) (1700) V

Garage (non-residential)

Traffic Area 200 (20) Floor H

Plant Process Areas [11]

Walkways, Stairs, Platforms 50 (5) Floor H

Pump Rows, Valves, Manifolds 50 (5) Ground H

Heat Exchangers 50 (5) Ground H

Separator 50 (5) Top of Bay -

Cooling Towers (equip areas) 50 (5) Ground H

Compressor Areas 50 (5) Ground H

Task Lighting for Gauges, 50 (5) (1700) V

valves, instruments, control

panels, push-button stations

General Area 10 (1) Ground H

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 15 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

Table 4 – Average Maintained Illuminance Levels (Continued)

Illuminance Working Plane (mm)

Location Lux (fc) Related Notes [#]

_______________________________ ___________ __________________

Plant Non-Process Areas and Buildings

Tank Fields (Tank Farms) [9]

Ladders and Stairs 15 (1.5) Floor H

Gauging Area 30 (3) Floor H

Manifold Area 15 (1.5) Ground H

Loading Racks

General Area 50 (5) Floor H

Tank Truck (Loading Point) 100 (10) Task H

Firehouse

General Area (Interior) 200 (20) (900) H

Repairs & Service Area 750 (75) Task -

Storage (parts) 300 (30) Floor H

General Machinery (A.C. Plants, etc.)

General Aisles 200 (20) (900) V

Gauges 200 (20) (1700) V

Instruments and Relays on Panels 300 (30) (1700) V

Laboratories

Qualitative, Quantitative and Physical 500 (50) (900) H

Tests, Glassware, Washrooms 300 (30) (900) H

Fume Hoods 300 (30) Task -

Stock Rooms 150 (15) Floor H

Turbo Generators

Turbine Floor 300 (30) Floor H

Condenser, Pump, Aux. Floor 200 (20) Floor H

Gauges (by supplementary lighting) 300 (30) Task -

Warehouses

Bulk Storage (outdoor) 10 (1) Ground H

Bulk Storage (indoor) 100 (10) Floor H

Small Bin Storage 100 (10) (760) V

Small Parts Storage 200 (20) (760) V

Counter Tops 300 (30) (1200) H

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 16 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

Table 4 – Average Maintained Illuminance Levels (Continued)

Illuminance Working Plane (mm)

Location Lux (fc) Related Notes [#]

_______________________________ ___________ __________________

Work Shop (Repair Shop)

Large Fabrication 200 (20) Floor H

Bench and Machine Work 500 (50) (760) H

Crane-way, Aisles 150 (15) Floor H

Small Machine 300 (30) (760) H

Sheet Metal 200 (20) (760) H

Electrical 200 (20) (760) H

Instrument 300 (30) (760) H

Change House

Locker Room, Shower 100 (10) Floor H

Lavatory (Hammam) 200 (20) Floor H

Plant Roads, Bikeways, Parking Lots & Alleys

Roads, Bikeways (where used) 10 (1) Ground H

Parking Lots, Alleys 10 (1) Ground H

Schools

Classrooms 750 (75) (760) H

Manual Training 1000 (100) (900) H

Library 750 (75) (760) H

Corridors 200 (20) Floor H

Sports and Recreation

Swimming Pools (outdoor) 100 (10) Ground H

Football 200 (20) Ground H

Gymnasiums (general) 300 (30) Floor H

Softball (infield) 300 (30) Ground H

Softball (outfield) 200 (20) Ground H

Tennis Courts (outdoor) 300 (30) Ground H

Golf Driving Range (tee) 100 (10) Ground H

Golf Driving Range (180 m) 50 (5) Ground V

Volleyball (indoor) 100 (10) Floor H

Basketball (indoor) 300 (30) Floor H

Squash, Racquetball 500 (50) Floor H

Handball 150 (15) Floor H

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 17 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

Table 4 – Average Maintained Illuminance Levels (Continued)

Illuminance Working Plane (mm)

Location Lux (fc) Related Notes [#]

_______________________________ ___________ __________________

Residential Street Lighting

Local Road (residential) 10 (1) Pavement H

Parking Lots, Alleys 10 (1) Ground H

Sidewalks (Roadside)

Residential (Camps and Community 10 (1) Ground H

Centers) 10 (1) 1800 V [3]

Walkways Distant from roadways, 10 (1) or Ground H

and Bikeways 10 (1) 1800 V [3]

Notes: [1] H is the horizontal plane

[2] V is the vertical plane

[3] For pedestrian identification at a distance.

Revision Summary

29 December 2021 Editorial revision to:

- Change the revision cycle from three years(19 March 2022) to five years (19 March

2024)

- check the SAEP-301 compliance

19 March 2019 Major revision. The new revision incorporates various major comments generated during

the workshop attended by standard stakeholders such as CSD, Power Systems

Engineering Department, FPD, SAPMT, and five lighting manufacturers.

3 September 2014 Major revision after conducting the value engineering session and incorporate comments

received on Light Emitting Diode (LED) requirements in the standard.

Summary of Change Form

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 18 of 19

Saudi Aramco: Company General Use

Document Responsibility: Electrical Systems Designs and Automation Stds. Committee SAES-P-123

Issue Date: 29 December 2021

Next Planned Update: 29 December 2023 Lighting

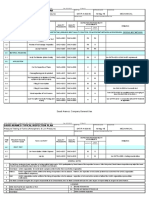

No. Paragraph No. Change Type Technical Change

Mandate the use of LED luminaires for indoor

Modification

5.2 Luminaires, and outdoor area illumination.

1 Components, and their Eliminate the life cycle cost analysis requirement

Utilization Modification due to mandating LED and eliminating other in-

efficient lightings.

Improve the design of lighting systems to be

3 6. Illuminance Levels Modification average maintained illuminance levels instead of

the minimum illuminance levels.

Improve the light loss factor according to the

Modification latest technological advancements in the

4 5. Lighting requirements industry.

Minimize the use of photocells to be grouped

Modification

photocell instead of individual installations.

Saudi Aramco: Company General Use

©Saudi Aramco 2019. All rights reserved. Page 19 of 19

Saudi Aramco: Company General Use

You might also like

- Saes P 100Document31 pagesSaes P 100wastazoheb_700349353No ratings yet

- 15-TMSS-07 R.0Document12 pages15-TMSS-07 R.0wastazoheb_700349353No ratings yet

- Saes P 113Document12 pagesSaes P 113wastazoheb_700349353100% (1)

- SAES-B-069 Editorial Revision (10-28-2021)Document11 pagesSAES-B-069 Editorial Revision (10-28-2021)Daniel Meana100% (1)

- Saes P 119Document24 pagesSaes P 119harisNo ratings yet

- Materials System SpecificationDocument17 pagesMaterials System Specificationnadeem shaikh100% (1)

- Saep 287Document13 pagesSaep 287OMER ELFADILNo ratings yet

- Saes o 201Document15 pagesSaes o 201Abdulrahim ShaikhNo ratings yet

- Saes P 100Document26 pagesSaes P 100Hussein Zeyada100% (1)

- Saes B 014Document39 pagesSaes B 014Ahmed100% (2)

- 14 Samss 533 PDFDocument14 pages14 Samss 533 PDFMudabbir HussainNo ratings yet

- Saes S 040Document22 pagesSaes S 040nadeem shaikhNo ratings yet

- 10270Document2 pages10270Mekhman67% (3)

- SAES-P-101 Vendors List For Electrical EquipmentDocument9 pagesSAES-P-101 Vendors List For Electrical EquipmentfaisalqrNo ratings yet

- SAES P 123 Lighting Standard SDocument18 pagesSAES P 123 Lighting Standard SMohammed Afzal AliNo ratings yet

- Saes A 005Document37 pagesSaes A 005Ziyad ShaathNo ratings yet

- SAES P 123 LightingDocument19 pagesSAES P 123 LightingMuhammad Shahid100% (1)

- Saes G 115Document9 pagesSaes G 115junaidNo ratings yet

- Saes T 911Document60 pagesSaes T 911RijoNo ratings yet

- SAES-P-101 - Regulated Vendors List For Electrical Equipment PDFDocument11 pagesSAES-P-101 - Regulated Vendors List For Electrical Equipment PDFMd Waseem KhanNo ratings yet

- 18-SAMSS-625 - Outside Plant - Fiber Optic Cable Specifications (Single Mode and Multi Mode)Document16 pages18-SAMSS-625 - Outside Plant - Fiber Optic Cable Specifications (Single Mode and Multi Mode)medication abbasNo ratings yet

- Index SaesDocument20 pagesIndex SaesAmr HeshamNo ratings yet

- Saes B 067 PDFDocument12 pagesSaes B 067 PDFRashid ArshadNo ratings yet

- Saes S 070Document2 pagesSaes S 070Naushad AlamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- SAEP-127 - Security and Control of Saudi Aramco Engineering DataDocument9 pagesSAEP-127 - Security and Control of Saudi Aramco Engineering DataAnonymous PkAjjOZB100% (1)

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishNo ratings yet

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document5 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Faris WahedNo ratings yet

- Schedule DDocument19 pagesSchedule DNATIONAL BASICS COMPANYNo ratings yet

- Part I - 02 Incident Reporting and InvestigationDocument2 pagesPart I - 02 Incident Reporting and InvestigationMuhammad RizwanNo ratings yet

- Inspection ProcedureDocument13 pagesInspection ProcedureSantosh Kumar100% (1)

- Arabian Fal Training Matrix - Non Base Crew UpdateDocument15 pagesArabian Fal Training Matrix - Non Base Crew UpdateastutesureshNo ratings yet

- Gi-0006 003Document8 pagesGi-0006 003khrayzie bhoneNo ratings yet

- 16 Samss 520Document11 pages16 Samss 520HatemS.MashaGbeh100% (1)

- G.I 6.030 Traffic Vehicle Safety 2018-SupplementsDocument10 pagesG.I 6.030 Traffic Vehicle Safety 2018-SupplementsFrancis VinojNo ratings yet

- Environmental Health Code 2022 Saehc-S-17 Public Health NuisancesDocument4 pagesEnvironmental Health Code 2022 Saehc-S-17 Public Health NuisancesAhmed ShoreemNo ratings yet

- Saes-L-410 2021-2024Document26 pagesSaes-L-410 2021-2024jinujoseNo ratings yet

- Saudi Aramco Typical Inspection Plan: LEAK TESTING (Per SAES-A-004) 15-Nov-17Document10 pagesSaudi Aramco Typical Inspection Plan: LEAK TESTING (Per SAES-A-004) 15-Nov-17Syed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- Work Progress PMCC Item No: Saudi Aramco: Company General UseDocument18 pagesWork Progress PMCC Item No: Saudi Aramco: Company General UseEswari AnandNo ratings yet

- 175 320300Document1 page175 320300sridhar100% (1)

- Saep 744Document7 pagesSaep 744Anonymous 4IpmN7OnNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Testing Guide LinesDocument4 pagesSaudi Aramco Pre-Commissioning Form: Testing Guide LinesSathiya SeelanNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanDomie Neil Bucag SalasNo ratings yet

- Saudi Arabian Oil Company (Saudi Aramco) : ContentDocument2 pagesSaudi Arabian Oil Company (Saudi Aramco) : Contentiftikhar ahmadNo ratings yet

- Summary of SAES-P-111Document5 pagesSummary of SAES-P-111Afzal Asif100% (2)

- Summary of SAES-J-902Document7 pagesSummary of SAES-J-902Afzal Asif100% (1)

- Saep 309Document22 pagesSaep 309brecht1980No ratings yet

- New Revision of SAES-S-040Document22 pagesNew Revision of SAES-S-040luke lucky100% (1)

- Saep 378Document67 pagesSaep 378Anonymous 4IpmN7OnNo ratings yet

- Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument19 pagesSaudi Arabian Oil Company (Saudi Aramco) General Instruction ManualEagle Spirit100% (1)

- UPDATE JHAH DETAILS Upgradation of HVAC System at Dental Lab at BLDG # 54 DHAHRANDocument37 pagesUPDATE JHAH DETAILS Upgradation of HVAC System at Dental Lab at BLDG # 54 DHAHRANjaheerasalam299No ratings yet

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument5 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualMd Azizul Mawla Bhuiyan100% (1)

- 0150 - 100 Hazardous Materials Communication Program (HAZCOM)Document13 pages0150 - 100 Hazardous Materials Communication Program (HAZCOM)Tiffany ColemanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistAnonymous S9qBDVkyNo ratings yet

- Safety Instruction Sheets For Plant Piping and Cross-Country PipelinesDocument35 pagesSafety Instruction Sheets For Plant Piping and Cross-Country PipelinesRaj Bindas50% (2)

- Hempel'S Topaz Matt Emulsion 588meDocument2 pagesHempel'S Topaz Matt Emulsion 588meKalaiyazhagan ElangeeranNo ratings yet

- Saep 122Document12 pagesSaep 122Tahir MubeenNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydrotest) SAIC-A-2013 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydrotest) SAIC-A-2013 15-Dec-09 MechEagle SpiritNo ratings yet

- Saep 44Document17 pagesSaep 44AbdullahNo ratings yet

- Schedule B - Attachment IDocument27 pagesSchedule B - Attachment Imunna100% (2)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument13 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualJithuRajNo ratings yet

- Saic H 2023Document2 pagesSaic H 2023Sivaratnam NavatharanNo ratings yet

- Saes P 123Document18 pagesSaes P 123HatemS.MashaGbehNo ratings yet

- 20-TMSS-02 R.1 (Not Applicable)Document26 pages20-TMSS-02 R.1 (Not Applicable)wastazoheb_700349353No ratings yet

- 15-TMSS-05 R.1Document20 pages15-TMSS-05 R.1wastazoheb_700349353No ratings yet

- 20-TMSS-01 R.0Document30 pages20-TMSS-01 R.0wastazoheb_700349353No ratings yet

- 15-TMSS-02 R.1Document15 pages15-TMSS-02 R.1wastazoheb_700349353No ratings yet

- 15-TMSS-06 R.0Document13 pages15-TMSS-06 R.0wastazoheb_700349353No ratings yet

- 11 TMSS 10 R0Document0 pages11 TMSS 10 R0renjithas2005No ratings yet

- 11-TMSS-12 R.0 (Not Applicable)Document14 pages11-TMSS-12 R.0 (Not Applicable)wastazoheb_700349353No ratings yet

- 12-TMSS-04 R.0Document19 pages12-TMSS-04 R.0wastazoheb_700349353No ratings yet

- 11 TMSS 02 R0Document0 pages11 TMSS 02 R0renjithas2005No ratings yet

- 12-TMSS-01 R.0Document18 pages12-TMSS-01 R.0wastazoheb_700349353No ratings yet

- Saes P 111Document27 pagesSaes P 111wastazoheb_700349353No ratings yet

- Saes P 107Document26 pagesSaes P 107wastazoheb_700349353No ratings yet

- 1953-File Utama Naskah-6037-2-10-20200429Document20 pages1953-File Utama Naskah-6037-2-10-20200429taufik hidayatNo ratings yet

- Chapter 3: System Software Chapter 3: System Software: The Power Behind The PowerDocument8 pagesChapter 3: System Software Chapter 3: System Software: The Power Behind The Powerravi198522No ratings yet

- Maharata TeachingsDocument535 pagesMaharata Teachingsronald.wederfoortNo ratings yet

- Gmail - Booking Confirmation On IRCTC, Train - 03260, 25-Oct-2024, SL, WFD - DDUDocument1 pageGmail - Booking Confirmation On IRCTC, Train - 03260, 25-Oct-2024, SL, WFD - DDUb3116261No ratings yet

- Load Banks CatalogDocument10 pagesLoad Banks CatalogMehmet Cem AteşNo ratings yet

- MST5350B MilestoneSemiconductorDocument10 pagesMST5350B MilestoneSemiconductorJR RegisNo ratings yet

- Water Lifting Devices10Document22 pagesWater Lifting Devices10viahulNo ratings yet

- Wasla 2017-18Document29 pagesWasla 2017-18Ankit SinghNo ratings yet

- how to prevent clickjacking in react js-掘金Document4 pageshow to prevent clickjacking in react js-掘金ShamsNo ratings yet

- FCC Series 11 High Pressure Globe Control ValvesDocument15 pagesFCC Series 11 High Pressure Globe Control ValvesBASKARNo ratings yet

- 6-PL Approved Notification With Annexture-V - 042023 - 210423Document44 pages6-PL Approved Notification With Annexture-V - 042023 - 210423Sid MadishettyNo ratings yet

- FBES 01 Book-The-Steel-Book V07.01.0818 WEBDocument116 pagesFBES 01 Book-The-Steel-Book V07.01.0818 WEBrenandNo ratings yet

- WSRelease NotesDocument17 pagesWSRelease Notesmouth aldibesNo ratings yet

- 6th Sem SyllabusDocument33 pages6th Sem SyllabusAsli AccountNo ratings yet

- LG Stylus 2 Plus - Schematic DiagarmDocument126 pagesLG Stylus 2 Plus - Schematic Diagarmangel berrioNo ratings yet

- Relatorio Dimensional Comparativo - Peça 5710448 - 1 - Rev01 - 21022024Document16 pagesRelatorio Dimensional Comparativo - Peça 5710448 - 1 - Rev01 - 21022024kethlynrescanmNo ratings yet

- 663cfd30b44620b0b48d7518 D Ishani P Resume 2024Document1 page663cfd30b44620b0b48d7518 D Ishani P Resume 2024anmol2026shuklaNo ratings yet

- IECEx CSA 16.0042X 005Document7 pagesIECEx CSA 16.0042X 005muhammad nazmiNo ratings yet

- Slim and Lightweight: Extremely FlexibleDocument2 pagesSlim and Lightweight: Extremely FlexibleJose Rosas SandovalNo ratings yet

- 1 Uphsd Ab3 Resmet Gaming SigningDocument138 pages1 Uphsd Ab3 Resmet Gaming SigningJorge Balganion TamayaoNo ratings yet

- MET 2024 BrochureDocument12 pagesMET 2024 Brochureaniket.pnaNo ratings yet

- Computer Aided Drawing 15th Week (1)Document26 pagesComputer Aided Drawing 15th Week (1)dururyusuf52No ratings yet

- Capstan and Turret LatheDocument6 pagesCapstan and Turret Latheabbasnjjarkhatirkolai57No ratings yet

- QuizDocument3 pagesQuizMary Joy EnriquezNo ratings yet

- Biometric API Specification V2 20Document12 pagesBiometric API Specification V2 20kundan7739000749No ratings yet

- 4-A Assembly of ComputerDocument2 pages4-A Assembly of ComputerGladys GaleraNo ratings yet

- AI in Contemporary WarfareDocument2 pagesAI in Contemporary WarfareKhadija AsifNo ratings yet

- Uchenna ReportDocument9 pagesUchenna Reportuvjn kmlNo ratings yet

- Digital Daily Time Record DTR September 2021Document2 pagesDigital Daily Time Record DTR September 2021Vhien CamorasNo ratings yet

- Warehouse Inspection Checklist TemplateDocument6 pagesWarehouse Inspection Checklist TemplateDeathless LoveNo ratings yet