03 Checklists

03 Checklists

Uploaded by

Mohamed OussaidCopyright:

Available Formats

03 Checklists

03 Checklists

Uploaded by

Mohamed OussaidCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

03 Checklists

03 Checklists

Uploaded by

Mohamed OussaidCopyright:

Available Formats

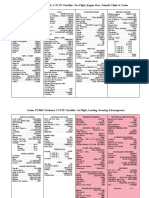

Citation 650 Series Training Manual

CHAPTER 03

CHECKLISTS

TABLE OF CONTENTS

PAGE

MAINTENANCE PREFLIGHT INSPECTION ............ 1

COCKPIT .................................................................. 1

INTERIOR / EXTERIOR ............................................ 1

CABIN ....................................................................... 1

LEFT NOSE .............................................................. 1

LEFT NOSE COMPARTMENT ................................. 1

RIGHT NOSE ............................................................ 2

RIGHT WING ............................................................ 2

RIGHT NACELLE ...................................................... 2

LOWER AFT FUSELAGE ......................................... 2

EMPENNAGE ........................................................... 2

AFT BAGGAGE COMPARTMENT ............................ 3

LEFT NACELLE ........................................................ 3

LEFT WING ............................................................... 3

CABIN DOOR ............................................................ 3

COCKPIT PREPARATION ........................................ 3

BEFORE START ....................................................... 3

STARTING ENGINES ............................................... 4

BEFORE TAXI ........................................................... 4

PARKING .................................................................. 4

SHUTDOWN ............................................................. 4

APU START (PATS APU) ......................................... 4

APU SHUTDOWN (PATS APU) ................................ 4

FOR TRAINING PURPOSES ONLY 03 - i

Citation 650 Series Training Manual

CHAPTER 03

15. Fuel Quantity/Balance ............................... CHECK 4. Emergency Exit .........................................SECURE

a. Maximum allowable asymmetric differential a. Handle lock pin REMOVE

fuel loading between tanks is 200 pounds b. Check fit of escape hatch assembly, handle

stowed, guard in place and locking pin

CHECKLISTS INTERIOR / EXTERIOR removed

5. Gear Retract Hydraulic Shutoff Valve .......... CHECK

.......................................................... HANDLE DOWN

1. Landing Lights Switches .................................... ON

6. Manual FUS TANK XFER T-Handle ............ CHECK

..................................... (OFF, IF SEEN FROM CKPT)

MAINTENANCE PREFLIGHT 2. EMER LTG Switch ............................................ ON

................................ STOWED (Airplanes -0092 & on)

INSPECTION ..................................... (OFF, IF SEEN FROM CKPT)

3. Other Lights On .................................................. ON LEFT NOSE

..................................... (OFF, IF SEEN FROM CKPT)

1. Engine/Pitot Covers ............................... REMOVED 4. Engine Anti-Ice Switches ...... ON 30 SEC THEN OFF 1. Fairing Tank Fuel Vents ............................... CLEAR

5. RAT/Pitot/Static Heat Switches ............ ON 30 SEC 2. Drain Lines ................................................... CLEAR

COCKPIT ................................................................... THEN OFF a. Check emergency landing gear and brake air

6. LH AOA Probe.................................... FREE/WARM bottle vents and alcohol bottle vent for

1. Documents/Manuals/Equip/Charts ....... ON BOARD 7. LH Static Ports ................................ CLEAR/WARM obstructions and damage

2. Oxygen System ........................................... CHECK 8. LH/RH Pitot Tubes .......................... CLEAR/WARM 3. Oxygen Blowout Disc .................................. GREEN

..............1600 to 1850 PSI indicates adequate service 9. RAT Probe....................................... CLEAR/WARM a. Green disc should be in place and intact

3. Portable Fire Extinguisher ..... SERVICED/SECURE 10. Landing Lights ................................ ILLUMINATED b. If it is missing, oxygen bottle may be empty

a. Located in quick-release holder under 11. Taxi Lights ...................................... ILLUMINATED c. The cause of the missing disc must be

copilot’s seat 12. RH Static Ports .............................. CLEAR/WARM determined

b. Pressure gage should read in the white arc, 13. RH AOA Probe ................................. FREE/WARM 4. Landing Light ....................................... CONDITION

indicating a 150 PSI charge 14. RH Wing Fairing ......................................... WARM a. Check lenses for cracks and lights for security

4. Circuit Breakers ............................................... All IN 15. RH Wing Inspection/Nay/Strobe ..... ILLUMINATED 5. NLG/Doors/Wheel/Tire/Strut............... CONDITION/

5. Cockpit Switches ...............................................SET 16. RH GEN/ALT Air Inlet .................... CLEAR/WARM ......................................................................SECURE

6. Throttles .................................................... CUTOFF 17. RH Tail Flood Light ......................... ILLUMINATED a. Chine and tread of nose tire must be in good

7. Battery Switch ............. BATT/CHECK VOLTS 1 & 2 18. Ground Recognition Light ............... ILLUMINATED condition and tire must be properly inflated to

a. Position the battery disconnect switch to 19. Aft Wing Nav Lights ........................ ILLUMINATED meet the water/slush runway operating

BATT DISC 2 to read voltage for battery 20. LH Tail Flood Light ......................... ILLUMINATED limitation

number 1, then position switch to BATT 21. LH GEN/ALT Air Inlet .................... CLEAR/WARM b. Approved nose tires must be inflated to 125

DISC 1 to obtain voltage for battery number 22. LH Wing Inspection/Nav/Strobe ..... ILLUMINATED PSIG, +5 or -5 PSIG unloaded for gross

2 23. LH Wing Fairing .......................................... WARM weight up to 21,000 pounds, and 138 PSIG

b. Position the battery disconnect switch to 24. Light Switches ................................................ OFF unloaded or 140 PSIG loaded for gross gear

NORM after checking the voltage 25. Battery Switch ................................................ OFF assembly, power steering centering

8. Gear Handle .................................DOWN/3 GREEN Mechanism, friction brake, wheel well area

9. Engine Fire Switches ................................... CHECK CABIN and doors for damage and security

c. Proper oleo strut extension of a fully fueled

10. AUX HYD PWR Switch................................NORM

a. HYD PRESS 2900 PSI MIN, VOLUME 300- airplane is approximately two inches

1. Portable Fire Extinguisher ..... SERVICED/SECURE

450 IN³ a. Located in a quick release holder near the

11. Parking Brake ..................................................SET front section of the cabin on the right side LEFT NOSE COMPARTMENT

a. Depressing the brake pedals and pulling the b. Pressure gage should read in the white arc

parking brake handle out traps applied indicating a 150 PSI charge 1. Emer Gear/Brake Press ..................... GREEN ARC

pressure to the wheel brakes 2. Door Entry Lights .............................................. OFF a. Pressure should read between 1800 and

12. AUX HYD PWR Switch................................... OFF 3. Passenger Seats ................ UPRIGHT/OUTBOARD 2050 PSI

13. Ground Power, Freon A/C or APU .................... AS a. Position seats forward and aft of the 2. Windshield Alcohol Reservoir Sight Gauge ... FLUID

.................................................................. REQUIRED emergency exit to seat track extremities for VISIBLE

14. Flaps.......................................................... CHECK unobstructed access to exit a. Ball should be at top of sight gage

FOR TRAINING PURPOSES ONLY 03 - 1

Citation 650 Series Training Manual

3. Nose Wheel Steering Accum ... 1500 ± 200 PSI MIN 7. Vortex Generators (11) .........CONDITION/SECURE 6. Thrust Reverser Buckets .................... CONDITION/

4. Left Nose Compartment Door .... SECURE/LOCKED a. Eleven vortex generators are installed on ..................................................................... STOWED

a. Check latches closed and properly engaged each wing 7. ENG/Exhaust/Bypass Ducts ......................... CLEAR

b. For additional security, the door should be key b. No more than one per wing may be missing to a. Check for fuel leakage, damage to turbine

locked dispatch for flight blades, cracks and general security

c. Remove key 8. Fuel Filler Cap ...........................................SECURE 8. Cowling (No Red Latch Ind........................ SECURE

a. Check locking latch closed and directed aft, a. Check that all fasteners are properly

RIGHT NOSE cover closed and secured

9. Fuel Tank Vent .............................................CLEAR

engaged, and access doors closed

b. Check for cracks and general security

a. Vent must be clear of obstruction and free

1. Landing Light ....................................... CONDITION

2. Right Nose Compartment Door ................ SECURE/

from damage

10. Recog/Nav/Anti-Coll Lights................ CONDITION

LOWER AFT FUSELAGE

...................................................................... LOCKED

a. Check lenses for cracks and integrity

1. Freon A/C (If Installed) .................................CLEAR

11. Static Wicks (6) ......................................... CHECK

RIGHT WING a. There should be two static wicks on the

2. Single Point Refuel Door ........... SECURE/LOCKED

3. Antennas ..............................CONDITION/SECURE

trailing edge of the aileron, three on the wing

4. FUS Fuel Tank Drains/Vents ........... DRAIN/CHECK

1. Dorsal Fin Air Inlet ........................................CLEAR trailing edge outboard of the aileron and one

5. APU Drain (If Installed) .................................CLEAR

a. A visual check can be made of the air inlet on the wing tip

6. Hydraulic Access Panel ............................. SECURE

from a position in front of the wing that will b. For dispatch no more than one static wick

7. APU Oil Level (If Installed) .......... CHECK/ACCESS

provide maximum visibility should be missing from each aileron

.......................................................... DOOR-SECURE

2. Engine Fan Duct/Fan...............CLEAR/CONDITION 12. Aileron/Flaps/Spoilers.........CONDITION/SECURE

8. Tail Skid................................CONDITION/SECURE

a. Assume a position forward of the wing that will a. Check aileron for freedom and hinge points

9. Static Wick on Stinger (1) ............................ CHECK

provide maximum visibility of the engine inlet for security

and visually check for obstructions or damage b. Check spoilers and flaps for security

3. Fuel Quick Drains ............................ DRAIN/CHECK EMPENNAGE

a. Drain a fuel sample from each quick drain and

check for water or contamination

RIGHT NACELLE 1. APU Inlets/Exhausts (If Installed) .................CLEAR

b. Push straight up on the drains when taking a. Visually check inlet and exhaust as closely as

1. GEN/ALT Air Inlet .........................................CLEAR

fuel samples, as the drain may lock open if it possible from the ground

2. GEN/ALT Cooling Air Exhaust ......................CLEAR

is rotated b. Check that three air intakes (two rectangular

3. Oil Level/Filler Cap/Door ............. CHECK/SECURE

4. Wing Fairing Inlet .........................................CLEAR and one round) are unobstructed

a. Check for correct level in sight gage

5. MLG DR/Wheel/Tires/Strut ...CONDITION/SECURE c. Inlet and exhaust must be clear of obstruction

b. To obtain an accurate oil check, the check

a. Check tire for wear and inflation and free of damage

must be accomplished with the engine still hot

b. Tire inflation pressure is 155 or 168 PSIG 2. PAC Heat Exchanger Exhausts .................... CLEAR

c. If in doubt about oil quantity, run engine at idle

c. Visually inspect doors and taxi light for 3. Freon A/C Exhaust (If Installed) .................. CHECK

for 5 minutes, shut down and recheck

security 4. Static Wicks ................................................. CHECK

d. The oil level must be checked within 15

d. Inspect wheel well area for damaged or 2 on bullet, 4 on stab, 2 on elevator and 2 on rudder

minutes after shutdown to obtain an accurate

broken lines and electrical wiring for condition 5. Elevator/Rudder/Trim Tab ................... CONDITION

reading

e. Check actuator and oleo for damage, leaks a. There should be one static wick on the

e. Check that filler cap is on securely, then close

and proper attachment outboard trailing edge of each elevator

and fasten access door

f. Proper oleo extension of a fully fueled b. There should be two static wicks on the

4. ENG Oil Bypass Valve Indicator .................. CHECK

airplane is approximately 5 inches when trailing edge at the top of the rudder

a. Depress inspection hole cover and visually

measured from the centerline of the lower c. Should a static wick be missing, it must be

check for popped (extended) red indicator

attaching bolt to the lower face of the upper replaced before the airplane is flown to

b. When red indicator is visible, the oil filter has

barrel assembly ensure proper control surface balance

bypassed and the cause must be determined

6. Wing Leading Edge ..............CONDITION/SECURE d. Check rudder system for proper operation if

prior to flight

a. Check stall strips (3 installed) and the airplane has been exposed to high or

5. Drain Lines ...................................................CLEAR

aerodynamic fence for damage and security gusty winds

FOR TRAINING PURPOSES ONLY 03 - 2

Citation 650 Series Training Manual

6. Horizontal Stabilizer........... CONDITION/POSITION

a. Visually check that the horizontal stabilizer is

LEFT WING 12. Cockpit Air Dist Valves (if installed) .. AS DESIRED

13. All Other Switches .......................... OFF/NORMAL

set to the same position indicated on the trim 14. Battery Switch .............................................. BATT

1. Flaps/Spoilers/Aileron...........CONDITION/SECURE

indicator during cockpit inspection 15. Battery Voltage ..................... 24 VOLTS MINIMUM

2. Static Wicks (6) ........................................... CHECK

b. Check for two static wicks installed on each 16. Gear Handle ...............................DOWN/3 GREEN

3. Recog/Nav/Anti-Coll Lights.................. CONDITION

horizontal stabilizer trailing edge, one on top 17. APU ............................................................ START

4. Fuel Tank Vent .............................................CLEAR

of the vertical fin bullet fairing, and one on the GPU......................... CONNECTED (IF DESIRED)

5. FUS Tank Transfer Door ........................... CLOSED

aft end of the bullet fairing 18. Avionics/Inverters ................................ ON/INV-ON

6. Fuel Filler Cap ...........................................SECURE

7. PT2 Sensor Line Drains .. DRAIN/CHECK CLOSED 19. Warning System ................................ CHECK/OFF

7. Vortex Generators (11) .........CONDITION/SECURE

a. Drain left and right PT2 lines and verify drains 20. EFIS/CVR/GPWS/TCAS (If Installed) ........... TEST

8. Wing Leading Edge .............. CONDITION/SECURE

are fully closed 21. Stab Position ....................... VERIFY INDICATION

9. MLG DR/Wheel/Tires/Strut ...CONDITION/SECURE

8. Hydraulic Overflow Vent ...............................CLEAR 22. Rudder Bias.................................. TEST/NORMAL

10. Fuel Quick Drains .......................... DRAIN/CHECK

9. Windshield Heat Exchange Exhaust ............CLEAR 23. APU (With Hyd):

11. Engine Fan Duct/Fan.............CLEAR/CONDITION

a. Speedbrake/Spoiler........................... CHECK

12. Wing Fairing Inlet .......................................CLEAR

AFT BAGGAGE COMPARTMENT b. Aux Hyd Pwr .................................. NORMAL

c. Aileron Boost ............................... CHECK/ON

1. Battery/Cable........................CONDITION/SECURE

CABIN DOOR 24. APU/GPU:

a. PRI/SEC Trim.................................... CHECK

a. Release fasteners securing cover over

1. Precatch Button ............................................ FLUSH b. Autopilot ................... CHECK/DISENGAGED

battery compartment and ensure that the

2. PRI/SEC Door Seals ........................... CONDITION 25. No APU/GPU........... AVIONICS/INVERTERS OFF

batteries and cables are properly secured,

a. Carefully inspect primary and secondary door 26. Fuel Transfer ..................................... CHECK/OFF

that cables are not frayed or damaged and the

seals for cuts and abrasions 27. Cabin Altitude Warning Horns ................... CHECK

compartment is free of foreign objects

b. Damaged door seals may cause 28. Pressurization .................................... CHECK/SET

2. Battery Compartment Cover ......................SECURE

pressurization loss or difficulty in achieving 29. Engine Sync ................................................... OFF

3. Starter Disable Switch .............................. NORMAL

cabin pressurization; therefore, it is important 30. ENG Instruments ............................ NO WARNING

4. GPU Batt Charge Switch ...............................NORM

that both seals be carefully checked for 31. Fuel Temperature ...................................... CHECK

5. Spoiler Hold Down Accum ...................... 1500 ± 200

condition

.............................................................. PSI MINIMUM

a. Open access cover and check that the

3. Door Frame ................................................. CHECK

a. Check door frame for condition to ensure that

BEFORE START

pressure on accumulator gage does not read

no damage or foreign material will prevent the

below 1300 PSI minimum 1. Cabin Door ................................ CLOSED/LOCKED

door seals from properly engaging the frame

6. Hydraulic Accum ............ 1500 ± 200 PSI MINIMUM 2. Passenger Briefing ............................... COMPLETE

when the door is closed

a. Check that pressure indication on the 3. Seat/Seat Belts/Harness ... ADJ/SECURE/UNLOCK

hydraulic accumulator gage is above the 1300 4. Rudder Pedals....................................... ADJUSTED

PSI minimum COCKPIT PREPARATION 5. Standby Gyro ....................................... ON/CAGED

7. Accum Manual Bleed Down Valve ............ CLOSED 6. EMER LTG Switch ...........................................ARM

8. Baggage Light .................................................. OFF 1. Preflight Insp ........................................ COMPLETE 7. Battery Switch ................................................ BATT

9. Access Door .............................. SECURE/LOCKED 2. Standby Gyro ............ ON, UNCAGED, VERIFY NO 8. Generators ...... GEN (OFF FOR GPU/APU START)

............................................ OFF FLAG, TEST, CAGE 9. GND REC Light .................................................. ON

LEFT NACELLE 3. LH/RH GYRO SLAVE Switches .....................AUTO

4. GND IDLE Switch ..........................................NORM

10. Door Unlocked Annun ............................... CHECK

11. Parking Brake (Hyd Press Required)...............SET

5. Ignition Switches ...........................................NORM 12. AUX HYD PWR Switch................................... OFF

1. ENG/Exhaust/Bypass Ducts .........................CLEAR

6. ANTI-SKID Switch .............................................. ON 13. Freon NC (If Installed) .................................... OFF

2. Thrust Rev Buckets ............. CONDITION/STOWED

7. Fuel Boost Pump Switches............................NORM 14. FMS Aux Power (If Installed) .......................... OFF

3. Oil Level/Filler Cap/Door ............. CHECK/SECURE

........................... (AS REQUIRED IF APU RUNNING) 15. Avionics/Inverters ........................................... OFF

4. ENG Oil Bypass Valve Indicator .................. CHECK

8. Fuel Computer Switches ...............................NORM

5. Drain Lines ...................................................CLEAR

9. PAC BLD SELECT Switch.............................NORM

6. GEN/ALT Cooling Air Exhaust......................CLEAR

10. Aileron/Spoiler Disconnect .............. T-HANDLE IN

7. GEN/ALT Air Inlet Exhaust ...........................CLEAR

11. Environmental Knobs ........................ 12 0’CLOCK

8. Cowling (No Red Latch Ind) ......................SECURE

FOR TRAINING PURPOSES ONLY 03 - 3

Citation 650 Series Training Manual

STARTING ENGINES SHUTDOWN

1. Either Engine ................................................ START 1. Parking Brake ....................................................SET

2. GND Idle..........................................................HIGH 2. Stabilizer Trim Backdrive Monitor ................... TEST

........ (61% N2 MINIMUM IF X-GENERATOR START) 3. AUX HYD PWR Switch..................................... OFF

3. Second Engine ............................................. START 4. Defog/Anti-Ice................................................... OFF

4. GND Idle........................................................NORM 5. Freon Air (If Installed) ....................................... OFF

5. Hydraulic Pressure ...................................... CHECK 6. Throttles .................................................... CUTOFF

6. Generators ....................................................... GEN 7. Pass Advisory Lights ........................................ OFF

7. APU .................................................... AS DESIRED 8. Standby Gyro ...................................... OFF/CAGED

8. GPU..................................... DISCONNECT/CLEAR 9. Avionics/Inverter ...................................... PWR OFF

9. Freon NC (If Installed) ........................ AS DESIRED 10. Emergency Lights ........................................... OFF

11. APU (If Installed) ............................................ OFF

BEFORE TAXI 12. Exterior Lights ................................................ OFF

13. Battery Switch ................................................ OFF

14. Control Lock ........................................... ENGAGE

1. Avionics/Inverters ............................................... ON

2. Battery ..............OFF/CHECK 24 VOLTS MIN/BATT

3. DC Volts/Amps ............................................ CHECK APU START (PATS APU)

4. If Not Previously Accomplished:

a. Speedbrake/Spoiler........................... CHECK 1. Battery Switch ................................................ BATT

b. AUX HYD PWR ...................................NORM .......................................................... (24 VOLTS MIN)

c. Aileron Boost ............................... CHECK/ON 2. APU Master Switch...................................... PRESS

d. PRI/SEC Trim.................................... CHECK 3. Lamp Test Switch ........................................ PRESS

5. Flight Controls ............................. FREE/CORRECT 4. APU Fire Test .............................................. PRESS

6. Control Lock ......................................... RELEASED 5. APU Gen Switch .................................... PRESS ON

7. Flight Instruments/Avionics.................. CHECK/SET 6. APU Bleed Air Switch ....................................... OFF

8. Fuel Quantity/Balance ................................. CHECK 7. Right FUEL BOOST PUMP ................................ ON

9. Fuel Totalizer.....................................................SET 8. Start Switch ................................................. PRESS

10. Anti-Ice Systems ....................................... CHECK 9. APU Bleed Air Switch ......................................... ON

11. Cockpit Aux Heater............................ CHECK/OFF 10. Battery Switch .............................................. BATT

12. Defog Fan.......................................... CHECK/OFF

13. Auto Temp ........................................ AS DESIRED

14. Inverters ....................................................... TEST

APU SHUTDOWN (PATS APU)

15. Nose Wheel Steering........................................ ON

1. APU Bleed Air .................................................. OFF

16. Exterior Lights ............................... AS REQUIRED

2. APU Gen .......................................................... OFF

3. Stop/LOP ..................................................... PRESS

PARKING 4. APU Master Switch........................................... OFF

5. Boost Pump .............................................. NORMAL

1. Thrust Reversers ........................................... STOW

2. Spoilers/Speedbrakes ............................. RETRACT

3. Flaps....................................................................UP

4. Anti-Ice ............................................................. OFF

5. RAT/Pitot/Static Heat........................................ OFF

6. BAG HTR Switch .............................................. OFF

7. CKPT AUX FAN/HEAT Switch ......................... OFF

8. W/S BLD Switch ............................................... OFF

FOR TRAINING PURPOSES ONLY 03 - 4

You might also like

- Rotate-MD-80 - Pilot Hand Book ChecklistDocument2 pagesRotate-MD-80 - Pilot Hand Book ChecklistAlejandro Martínez BaezaNo ratings yet

- King Air 350i Cockpit FlowsDocument18 pagesKing Air 350i Cockpit Flowstiandi89% (9)

- Quest Kodiak 100 - ChecklistDocument3 pagesQuest Kodiak 100 - ChecklistJoão Santos100% (2)

- Zlin 242 ChecklistDocument4 pagesZlin 242 Checklistabrarabbu1100% (1)

- Britsh Airwatys Normal Checklist ConcordeDocument5 pagesBritsh Airwatys Normal Checklist ConcordeBrittz100% (1)

- B787 ATA 22 Autoflight and ATA 34 Navigation. I Find These 2 ATA Chapters Very Complicated As It Gives Me Brain Fog While GoingDocument1 pageB787 ATA 22 Autoflight and ATA 34 Navigation. I Find These 2 ATA Chapters Very Complicated As It Gives Me Brain Fog While GoingHusam FNo ratings yet

- BE20 CAE Operating HandbookDocument174 pagesBE20 CAE Operating HandbookGabedi MoNo ratings yet

- Free EMB145 Class NotesDocument17 pagesFree EMB145 Class NotesLg123_4No ratings yet

- Atlas-Polar B747-400FCP Normal Checklist 01 APR 21Document2 pagesAtlas-Polar B747-400FCP Normal Checklist 01 APR 21Joel VitorNo ratings yet

- Challenger 601 Normals ChecklistDocument3 pagesChallenger 601 Normals ChecklistFNo ratings yet

- Normal Checklist: Model 525CDocument5 pagesNormal Checklist: Model 525CJose Otero De SantiagoNo ratings yet

- P4177 B200 Abv ChecklistDocument2 pagesP4177 B200 Abv Checklistjuan carlos moraNo ratings yet

- QRH Pa44Document52 pagesQRH Pa44Edgar Gamboa100% (2)

- C208 Grand Caravan EX Emergency ProceduresDocument23 pagesC208 Grand Caravan EX Emergency ProceduresCarlos Marquez80% (5)

- BE 350 Normals ChecklistDocument2 pagesBE 350 Normals ChecklistMiguel Ángel López Ortiz100% (2)

- A320 L3 Rev 0 ATA 00 IntroductionDocument16 pagesA320 L3 Rev 0 ATA 00 Introductionlapa_ripy31No ratings yet

- Afm G550 - Limitations PDFDocument99 pagesAfm G550 - Limitations PDFAZIZNo ratings yet

- Check List Remolque A319, A320Document3 pagesCheck List Remolque A319, A320carlosernestomoyavazquez544No ratings yet

- Cessna 152 Checklist2Document8 pagesCessna 152 Checklist2Em GomezNo ratings yet

- LibertyXL2 Checklist Version2 DogsaviationDocument1 pageLibertyXL2 Checklist Version2 DogsaviationryanlutwinNo ratings yet

- Cessna 182S ChecklistDocument15 pagesCessna 182S ChecklistTheEagle FGFSNo ratings yet

- Checklist C177RG SP FLFDocument2 pagesChecklist C177RG SP FLFLondon 1234No ratings yet

- Piper Arrow ChecklistDocument9 pagesPiper Arrow Checklistazx72No ratings yet

- Hawker 800 OMDocument206 pagesHawker 800 OMsadh94No ratings yet

- c310 Checklist 1 PDFDocument15 pagesc310 Checklist 1 PDFMarcos ValdezNo ratings yet

- Preflight Checklist C170 Bifold PortraitDocument3 pagesPreflight Checklist C170 Bifold PortraitRaph 1123No ratings yet

- Checklist PA 28 180 C GWDEDocument4 pagesChecklist PA 28 180 C GWDEjdmansilla1980No ratings yet

- Check List Cessna AerobatDocument5 pagesCheck List Cessna AerobatDavid VelandiaNo ratings yet

- Cessna U206G Stationair Checklist Pre-Flight Cessna U206G Stationair Checklist EMERGENCYDocument2 pagesCessna U206G Stationair Checklist Pre-Flight Cessna U206G Stationair Checklist EMERGENCYjuan carlos sosa cuellarNo ratings yet

- c310 ChecklistDocument15 pagesc310 Checklistjiminyf16No ratings yet

- C182T G1000 ChecklistDocument2 pagesC182T G1000 ChecklistcrguanapolloNo ratings yet

- Turbo Commander 690B Checklist PDFDocument30 pagesTurbo Commander 690B Checklist PDFAviacion Jlp90% (10)

- Checkliste Piper Archer IIDocument8 pagesCheckliste Piper Archer IIJosías GenemNo ratings yet

- PA44-180 Quick Reference Handbook: Revision 1.4 - 21 January 2016Document52 pagesPA44-180 Quick Reference Handbook: Revision 1.4 - 21 January 2016alilounahdisteNo ratings yet

- Piper Pa-28r-201 Arrow - Normal ProceduresDocument2 pagesPiper Pa-28r-201 Arrow - Normal ProceduresSinan ÖzNo ratings yet

- KAC90GTx Memory Limitations REV1 0 Apr2016Document2 pagesKAC90GTx Memory Limitations REV1 0 Apr2016Vladimir Quintero Y Claudia OrozcoNo ratings yet

- Check List 172NDocument1 pageCheck List 172Njose matosNo ratings yet

- Cessna 172 SP ChecklistDocument8 pagesCessna 172 SP ChecklistDustin Jones100% (1)

- A2A 172R Checklist PDFDocument2 pagesA2A 172R Checklist PDFBrunoViniciusNo ratings yet

- Pilot Checklist Hawker800XPDocument2 pagesPilot Checklist Hawker800XPBayu ChandraNo ratings yet

- Piper Pa-28r-201 Arrow - Emergency ProceduresDocument2 pagesPiper Pa-28r-201 Arrow - Emergency ProceduresSinan ÖzNo ratings yet

- Lista de Chequeo Piper 2021 - 230110 - 184126Document29 pagesLista de Chequeo Piper 2021 - 230110 - 184126Carolina ReyesNo ratings yet

- Q400 QRHDocument197 pagesQ400 QRHadex100% (2)

- King Air B200 Operating Handbook 2010Document174 pagesKing Air B200 Operating Handbook 2010Vorrataa KulkeitpravatNo ratings yet

- Check-List DA-20 RAS - BunDocument11 pagesCheck-List DA-20 RAS - BunMiGutzu100% (2)

- Preflight Inspection: King Air 200 2A-1Document20 pagesPreflight Inspection: King Air 200 2A-1ravaiyamayank100% (1)

- FTC Checklist 4Document14 pagesFTC Checklist 4aaronjudeeeNo ratings yet

- Cessna TU206G Stationair C-FCSY Checklist - Pre-Flight, Engine Start, Takeoff, Climb & CruiseDocument2 pagesCessna TU206G Stationair C-FCSY Checklist - Pre-Flight, Engine Start, Takeoff, Climb & CruiseRIZAL A S0% (1)

- Pre-Start: Secure The A/CDocument8 pagesPre-Start: Secure The A/CRadek P EleroNo ratings yet

- 172SP ChecklistDocument2 pages172SP ChecklistDawitNo ratings yet

- Print Pilatus PC12-NG - 2 - PC-12 NG Normal Proc Short Checklist Rev 0 PDFDocument2 pagesPrint Pilatus PC12-NG - 2 - PC-12 NG Normal Proc Short Checklist Rev 0 PDFKevin ChenNo ratings yet

- 1978 Cessna 152 ChecklistDocument3 pages1978 Cessna 152 ChecklistNick KaraiskosNo ratings yet

- Rotate-MD-80 - Pilot Hand Book ChecklistDocument2 pagesRotate-MD-80 - Pilot Hand Book ChecklistAhmed MohammedNo ratings yet

- Yokota Flight Training Center Checklist Cessna 172MDocument18 pagesYokota Flight Training Center Checklist Cessna 172MMinaNo ratings yet

- CHList-V E90 Long 1.1Document2 pagesCHList-V E90 Long 1.1TulioNo ratings yet

- B4oh AllDocument178 pagesB4oh AllJunior Monteiro100% (1)

- B737 800 ChecklistsDocument2 pagesB737 800 ChecklistslebanzayNo ratings yet

- F14 GerDocument11 pagesF14 GerKjell27No ratings yet

- Section: I BodyDocument130 pagesSection: I BodyDaniel ReyesNo ratings yet

- C172 Nav II ChecklistDocument2 pagesC172 Nav II Checklisterik_xNo ratings yet

- Faa P100 Normal Checklist Faa QRH 10Document2 pagesFaa P100 Normal Checklist Faa QRH 10Franco DeottoNo ratings yet

- B1900D Normal ChecklistDocument2 pagesB1900D Normal Checklistchhetribharat08100% (1)

- Ils W 15 SBCTDocument1 pageIls W 15 SBCTgameplayPSNo ratings yet

- 081 - Principles of Flight - QuestionsDocument39 pages081 - Principles of Flight - QuestionsEASA ATPL Question Bank100% (5)

- Integrated Avionics SystemsDocument23 pagesIntegrated Avionics SystemsAnurag RanaNo ratings yet

- Aileron ReversalDocument28 pagesAileron Reversalmatrixrajiv34No ratings yet

- ILS Run Profile PDFDocument5 pagesILS Run Profile PDFcmge_2005No ratings yet

- Phenom 100 ProfilesDocument10 pagesPhenom 100 ProfilesNIGGANo ratings yet

- Servo Hydraulic Technology in Flight ControlDocument73 pagesServo Hydraulic Technology in Flight ControlSalih ÜnalNo ratings yet

- 737 ACH CPT Procedures 10x21 PDFDocument12 pages737 ACH CPT Procedures 10x21 PDFNeethNo ratings yet

- A109 SP Update 03-2018Document30 pagesA109 SP Update 03-2018Abhishek Kumar SinghNo ratings yet

- Preflight After Takeoff: Normal ChecklistDocument1 pagePreflight After Takeoff: Normal ChecklistSava xNo ratings yet

- Aips 2020 28Document2 pagesAips 2020 28294rahulNo ratings yet

- KMIA ILS Runway 09 Approach ChartDocument1 pageKMIA ILS Runway 09 Approach ChartRichard SteelNo ratings yet

- ASW22 BLV 2Document20 pagesASW22 BLV 2Rene QueirozNo ratings yet

- EASA-TCDS-A.319 - Jezow Sailplanes - Issue - 02 - TempDocument50 pagesEASA-TCDS-A.319 - Jezow Sailplanes - Issue - 02 - TempMachneNo ratings yet

- Aerobask Panthera Checklist Normal v3.0Document3 pagesAerobask Panthera Checklist Normal v3.0Justinfm100% (1)

- Conception Aero Aeroelastic It eDocument42 pagesConception Aero Aeroelastic It eTom Krishna LeeNo ratings yet

- Approved Model List (AML) ForDocument11 pagesApproved Model List (AML) ForJuan C BalderasNo ratings yet

- IR Training Manual v1.53 PDFDocument127 pagesIR Training Manual v1.53 PDFskynorth100% (1)

- Airfoil: The Oshkosh Airfoil ProgramDocument4 pagesAirfoil: The Oshkosh Airfoil ProgramFernando VazquezNo ratings yet

- Hochiminh, Vietnam VVTS/SGN: .Eff.27.Jun.0001ZDocument2 pagesHochiminh, Vietnam VVTS/SGN: .Eff.27.Jun.0001ZAnish LahaNo ratings yet

- DC9 Speed Booklet.: Landing 46 TDocument3 pagesDC9 Speed Booklet.: Landing 46 TRichard Lund100% (1)

- 04 Sgas - Asuncion, Paraguay Rev 18 04-Sep-20Document27 pages04 Sgas - Asuncion, Paraguay Rev 18 04-Sep-20Mijael OrellanaNo ratings yet

- B744 SIM ProfileDocument6 pagesB744 SIM ProfilekotaroyanoyanokotaroNo ratings yet

- EK389 15feb2018 RGN DXBDocument51 pagesEK389 15feb2018 RGN DXBM A INo ratings yet

- Aviation MnemonicsDocument5 pagesAviation Mnemonicslunefiekert0% (1)