Transmition Gear

Transmition Gear

Uploaded by

VuHongNhatCopyright:

Available Formats

Transmition Gear

Transmition Gear

Uploaded by

VuHongNhatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Transmition Gear

Transmition Gear

Uploaded by

VuHongNhatCopyright:

Available Formats

SEBU7125-13 107

Maintenance Section

Battery - Replace

To check the belt tension, apply 110 N (25 lb) of

force midway between the pulleys. A correctly

adjusted belt will deflect 13 to 19 mm The battery cables or the batteries should not be

(0.50 to 0.75 inch). removed with the battery cover in place. The bat-

tery cover should be removed before any servic-

Adjustment ing is attempted.

Removing the battery cables or the batteries with

the cover in place may cause a battery explosion

resulting in personal injury.

Note: Always recycle a battery. Never discard a

battery. Return used batteries to an appropriate

recycling facility.

1. Turn the key start switch to the OFF position.

Remove the key and all electrical loads.

2. Turn OFF the battery charger. Disconnect the

charger.

3. The NEGATIVE “-” cable connects the NEGATIVE

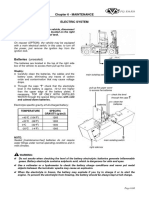

Illustration 95 g00290209 “-” battery terminal to the ground plane.

Typical illustration: (1) Adjusting nuts. (2) Mounting Disconnect the cable from the NEGATIVE “-”

bolts. battery terminal.

1. Loosen mounting bolts (2) and adjusting bolt (1). 4. The POSITIVE “+” cable connects the POSITIVE

“+” battery terminal to the starting motor.

2. Move the alternator in order to increase or Disconnect the cable from the POSITIVE “+”

decrease the belt tension. battery terminal.

3. Tighten adjusting bolt (1). Tighten mounting bolts 5. Remove the used battery.

(2). Refer to the Service Manual for the proper

torques. 6. Install the new battery.

If new belts are installed, check the belt tension again Note: Before the cables are connected, ensure that

after 20 hours of engine operation.

the key start switch is OFF.

Replacement 7. Connect the cable from the starting motor to the

POSITIVE “+” battery terminal.

Refer to the Service Manual for more information on

the procedures for the following topics: belt removal 8. Connect the cable from the ground plane to the

and belt installation procedure. NEGATIVE “-” battery terminal.

i06103470 i06064262

Battery - Replace Battery Electrolyte Level -

SMCS Code: 1401-510 Check

SMCS Code: 1401-535

When the engine has not run for long or short periods

Batteries give off combustible gases which can of time, the batteries may not fully recharge. Ensure a

explode. A spark can cause the combustible full charge in order to help prevent the battery from

gases to ignite. This can result in severe personal freezing.

injury or death.

Ensure proper ventilation for batteries that are in

an enclosure. Follow the proper procedures in or-

der to help prevent electrical arcs and/or sparks

near batteries. Do not smoke when batteries are

serviced.

108 SEBU7125-13

Maintenance Section

Battery or Battery Cable - Disconnect

2. Disconnect the negative battery terminal at the

battery that goes to the start switch. Ensure that

All lead-acid batteries contain sulfuric acid which the cable cannot contact the terminal. When four

can burn the skin and clothing. Always wear a 12 volt batteries are involved, the negative side of

face shield and protective clothing when working two batteries must be disconnected.

on or near batteries.

3. Tape the leads in order to help prevent accidental

starting.

1. Remove the filler caps. Maintain the electrolyte

level to the “FULL” mark on the battery. 4. Proceed with necessary system repairs. Reverse

the steps in order to reconnect all of the cables.

If the addition of water is necessary, use distilled

water. If distilled water is not available use clean

water that is low in minerals. Do not use artificially i05793911

softened water.

Cooling System Coolant

2. Check the condition of the electrolyte with the

245-5829 Coolant Battery Tester Refractometer. (DEAC) - Change

3. Keep the batteries clean. SMCS Code: 1350-070; 1395-044

Clean the battery case with one of the following Clean the cooling system and flush the cooling

cleaning solutions: system before the recommended maintenance

interval if the following conditions exist:

• A mixture of 0.1 kg (0.2 lb) of baking soda and • The engine overheats frequently.

1 L (1 qt) of clean water

• Foaming is observed.

• A mixture of 0.1 L (0.11 qt) of ammonia and 1 L

(1 qt) of clean water • The oil has entered the cooling system and the

coolant is contaminated.

Thoroughly rinse the battery case with clean

water. • The fuel has entered the cooling system and the

coolant is contaminated.

Use the 1U-9921 Battery Service Tool to clean

the battery terminals. Use a wire brush to clean

the cable clamps. Clean the items until the NOTICE

surfaces are bright or shiny. DO NOT remove Use of commercially available cooling system

material excessively. Excessive removal of cleaners may cause damage to cooling system com-

material can cause the clamps to fit improperly. ponents. Use only cooling system cleaners that are

Coat the clamps and the terminals with 5N-5561 approved for Caterpillar engines.

Silicone Lubricant, petroleum jelly or MPGM.

i01492654

Note: Inspect the water pump and the water

temperature regulator after the cooling system has

Battery or Battery Cable - been drained. This procedure is a good opportunity

to replace the water pump, the water temperature

Disconnect regulator, and the hoses, if necessary.

SMCS Code: 1402-029

Drain

The battery cables or the batteries should not be

removed with the battery cover in place. The bat- Pressurized System: Hot coolant can cause seri-

tery cover should be removed before any servic- ous burns. To open the cooling system filler cap,

ing is attempted. stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

Removing the battery cables or the batteries with pressure cap slowly in order to relieve the

the cover in place may cause a battery explosion pressure.

resulting in personal injury.

1. Stop the engine and allow the engine to cool.

1. Turn the start switch to the OFF position. Turn the Loosen the cooling system filler cap slowly in

ignition switch (if equipped) to the OFF position order to relieve any pressure. Remove the cooling

and remove the key and all electrical loads. system filler cap.

SEBU7125-13 109

Maintenance Section

Cooling System Coolant (DEAC) - Change

2. Open the cooling system drain valve (if equipped). 5. Stop the engine and allow the engine to cool.

If the cooling system is not equipped with a drain Loosen the cooling system filler cap slowly in

valve, remove one of the drain plugs. order to relieve any pressure. Remove the cooling

system filler cap. Open the drain valve (if

Note: If equipped, be sure to drain the heater and equipped) or remove the cooling system drain

any related supply and return lines. plugs. Allow the water to drain. Flush the cooling

Allow the coolant to drain. system with clean water. If equipped, be sure to

flush the heater and any related supply and return

NOTICE lines. Close the drain valve (if equipped). Clean

Dispose of used engine coolant properly or recycle. the drain plugs. Install the drain plugs. Refer to the

Various methods have been proposed to reclaim Specifications Manual, SENR3130, “Torque

used coolant for reuse in engine cooling systems.

Specifications” for more information on the proper

The full distillation procedure is the only method ac-

ceptable by Caterpillar to reclaim the used coolant. torques.

For information regarding the disposal and the Cooling Systems with Heavy

recycling of used coolant, consult your Cat dealer or

consult Cat Dealer Service Tool Group: Deposits or Plugging

Outside Illinois 1-800-542-TOOL Note: For the following procedure to be effective,

Inside Illinois 1-800-541-TOOL there must be some active flow through the cooling

Canada 1-800-523-TOOL system components.

1. Flush the cooling system with clean water in order

Flush to remove any debris.

1. Flush the cooling system with clean water in order Note: If equipped, be sure to flush the heater and

to remove any debris. any related supply and return lines.

2. Close the drain valve (if equipped). Clean the drain

2. Close the drain valve (if equipped). Clean the drain

plugs. Install the drain plugs. Refer to the

plugs. Install the drain plugs. Refer to the

Specifications Manual, SENR3130, “Torque

Specifications Manual, SENR3130, “Torque

Specifications” for more information on the proper

Specifications” for more information on the proper

torques.

torques.

NOTICE

Fill the cooling system no faster than 19 L (5 US gal) NOTICE

per minute to avoid air locks. Fill the cooling system no faster than 19 L (5 US gal)

per minute to avoid air locks.

3. Fill the cooling system with a mixture of clean

3. Fill the cooling system with a mixture of clean

water and Cat Quick Flush cooling system cleaner.

water and Cat Fast Acting Cooling System

Refer to the directions for the cleaner. For

Cleaner. Add 0.5 L (1 pt) of cleaner per

additional information on cooling system cleaners,

3.8 to 7.6 L (1 to 2 US gal) of the cooling system

refer to the One Safe Source catalog. Install the

capacity. Install the cooling system filler cap.

cooling system filler cap.

4. Start and run the engine at low idle for a minimum

4. Start and run the engine at low idle for a minimum

of 90 minutes. The coolant temperature should be

of 30 minutes. The coolant temperature should be

at least 82 °C (180 °F).

at least 82 °C (180 °F).

NOTICE

NOTICE Improper or incomplete rinsing of the cooling system

Improper or incomplete rinsing of the cooling system can result in damage to copper and other metal

can result in damage to copper and other metal components.

components.

To avoid damage to the cooling system, make sure to

To avoid damage to the cooling system, make sure to completely flush the cooling system with clear water.

completely flush the cooling system with clear water. Continue to flush the system until all signs of the

Continue to flush the system until all signs of the cleaning agent are gone.

cleaning agent are gone.

110 SEBU7125-13

Maintenance Section

Cooling System Coolant (ELC) - Change

5. Stop the engine and allow the engine to cool. 5. Start the engine. Inspect the cooling system for

Loosen the cooling system filler cap slowly in leaks and for proper operating temperature.

order to relieve any pressure. Remove the cooling

system filler cap. Open the drain valve (if i03292691

equipped) or remove the cooling system drain

plugs. Allow the water to drain. Flush the cooling Cooling System Coolant (ELC)

system with clean water. Close the drain valve (if

equipped). Clean the drain plugs. Install the drain

- Change

plugs. Refer to the Specifications Manual, SMCS Code: 1350-070; 1395-044

SENR3130, “Torque Specifications” for more Clean the cooling system and flush the cooling

information on the proper torques. system before the recommended maintenance

interval if the following conditions exist:

Fill

• The engine overheats frequently.

NOTICE • Foaming is observed.

Fill the cooling system no faster than 19 L (5 US gal)

per minute to avoid air locks. • The oil has entered the cooling system and the

coolant is contaminated.

1. Fill the cooling system with coolant/antifreeze. • The fuel has entered the cooling system and the

Refer to the Operation and Maintenance Manual, coolant is contaminated.

“Refill Capacities and Recommendations” topic

(Maintenance Section) for more information on Note: When the cooling system is cleaned, only

cooling system specifications. Do not install the clean water is needed when the ELC is drained and

cooling system filler cap. replaced.

2. Start and run the engine at low idle. Increase the Note: Inspect the water pump and the water

engine rpm to 1500 rpm. Run the engine at high temperature regulator after the cooling system has

idle for 1 minute in order to purge the air from the been drained. This is a good opportunity to replace

the water pump, the water temperature regulator and

cavities of the engine block. Stop the engine.

the hoses, if necessary.

3. Check the coolant level. Maintain the coolant level

within 13 mm (0.5 inch) below the bottom of the Drain

pipe for filling. Maintain the coolant level within

13 mm (0.5 inch) to the proper level on the sight

glass (if equipped).

Pressurized System: Hot coolant can cause seri-

4. Clean the cooling system filler cap. Inspect the ous burns. To open the cooling system filler cap,

gasket that is on the cooling system filler cap. If stop the engine and wait until the cooling system

the gasket that is on the cooling system filler cap is components are cool. Loosen the cooling system

damaged, discard the cap and install a new pressure cap slowly in order to relieve the

cooling system filler cap. If the gasket that is on pressure.

the cooling system filler cap is not damaged,

perform a pressure test. A 9S-8140 Pressurizing 1. Stop the engine and allow the engine to cool.

Pump is used to perform the pressure test. The Loosen the cooling system filler cap slowly in

correct pressure for the cooling system filler cap is order to relieve any pressure. Remove the cooling

stamped on the face of the cooling system filler system filler cap.

cap. If the cooling system filler cap does not retain

the correct pressure, install a new cooling system 2. Open the cooling system drain valve (if equipped).

filler cap. If the cooling system is not equipped with a drain

valve, remove the cooling system drain plugs.

Allow the coolant to drain.

You might also like

- Lithium Valley User ManualDocument10 pagesLithium Valley User ManualChristine May CagaraNo ratings yet

- Boatowner's Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential SystemsFrom EverandBoatowner's Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential SystemsRating: 4.5 out of 5 stars4.5/5 (11)

- Battery Charger Repair 36V Lester 35827 - A1 PDFDocument29 pagesBattery Charger Repair 36V Lester 35827 - A1 PDFHank Rearden100% (1)

- Coach Bat. Diconnect Solenoid How It Works 5322019100Document9 pagesCoach Bat. Diconnect Solenoid How It Works 5322019100Clifton Jamison100% (1)

- Lavinia. Record - of - Equipment - For - The - Cargo - Ship - Safety - Equipment - Certificate - (Form E)Document3 pagesLavinia. Record - of - Equipment - For - The - Cargo - Ship - Safety - Equipment - Certificate - (Form E)VuHongNhatNo ratings yet

- Ferrari - Cap6.3 Manutenzione F121618 EDocument23 pagesFerrari - Cap6.3 Manutenzione F121618 EJoseph VasquezNo ratings yet

- Battery Charge Lester ElectricalDocument8 pagesBattery Charge Lester ElectricaldungnvbsNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument30 pagesMaintenance Intervals: Operation and Maintenance Manual Excerpt08088338No ratings yet

- Battery - ReplaceDocument2 pagesBattery - Replacemahmoud odehNo ratings yet

- PV MaintenanceDocument34 pagesPV Maintenanceminazgeorge745No ratings yet

- ChassisElectrical PDFDocument111 pagesChassisElectrical PDFDhany SiregarNo ratings yet

- OPzV IOM Lo Res 0520Document8 pagesOPzV IOM Lo Res 0520Franco AyalaNo ratings yet

- Troubleshooting Guide: Lestronic Ii Battery Charger For Motive Power BatteriesDocument8 pagesTroubleshooting Guide: Lestronic Ii Battery Charger For Motive Power BatteriesRomuald Eric TefongNo ratings yet

- Instructions For Use: Motive Power (Traction) Batteries With Positive Tubular PlatesDocument4 pagesInstructions For Use: Motive Power (Traction) Batteries With Positive Tubular PlatesSimona FloricelNo ratings yet

- 08 Sistema Electrico Suzuki IntruderDocument60 pages08 Sistema Electrico Suzuki Intruderbenjapana100% (4)

- Lester ChargerDocument8 pagesLester Chargertomc585No ratings yet

- BE (Body Electrical System)Document37 pagesBE (Body Electrical System)RomusNo ratings yet

- Vmax Owner Period Maint4Document11 pagesVmax Owner Period Maint4bobbyr456No ratings yet

- Batteries HoppeckeDocument4 pagesBatteries HoppeckeAbang IdungNo ratings yet

- OPzV Installation Operation ManualDocument5 pagesOPzV Installation Operation ManualFranco AyalaNo ratings yet

- Hyster A935 j16xn Europe Forklift Service Repair Manual 1590765879Document18 pagesHyster A935 j16xn Europe Forklift Service Repair Manual 1590765879Владислав ФофановNo ratings yet

- Maintenance Instruction For Superlight Sl-2Document15 pagesMaintenance Instruction For Superlight Sl-2Scripd4dogsonlyNo ratings yet

- Fluke - Troubleshooting Engine Electrical SystemsDocument4 pagesFluke - Troubleshooting Engine Electrical Systemsmantencion CRINo ratings yet

- BC335 Battery Charger REV 4Document16 pagesBC335 Battery Charger REV 4ozje2017No ratings yet

- Testing Starter MotorsDocument4 pagesTesting Starter MotorslitieuduyNo ratings yet

- Installation and Operation Manual Work MVR - ENDocument2 pagesInstallation and Operation Manual Work MVR - ENwyatt-jangoNo ratings yet

- Hawker Perfect Plus Instruction For Use EnglishDocument4 pagesHawker Perfect Plus Instruction For Use EnglishfredrikNo ratings yet

- 4 Remplacement Des BatteriesDocument2 pages4 Remplacement Des BatteriesAliHabesNo ratings yet

- VRLA - Operating Instruction - Engl (Incluyento S100L, Solo Inglés... )Document7 pagesVRLA - Operating Instruction - Engl (Incluyento S100L, Solo Inglés... )David MonederoNo ratings yet

- I SectionDocument34 pagesI Sectionm606pazNo ratings yet

- Heavy Duty Battery Boosters / ChargersDocument15 pagesHeavy Duty Battery Boosters / ChargersJohann SGNo ratings yet

- Electrical and Ignition: Battery, Charging and Starting SystemDocument15 pagesElectrical and Ignition: Battery, Charging and Starting SystemJim LassNo ratings yet

- Basement WatchdogDocument12 pagesBasement WatchdogFrank SmithNo ratings yet

- 62kwh Current Sensor Diagnosis ProcedureDocument2 pages62kwh Current Sensor Diagnosis ProcedureluipirNo ratings yet

- BRAKEDocument16 pagesBRAKEJahir FrutosNo ratings yet

- Eaton 9X55 Batteries PDFDocument16 pagesEaton 9X55 Batteries PDFEdwin RTNo ratings yet

- Uninterruptible Power Supply (UPS) Internal Batteries Removal and ReplacementDocument2 pagesUninterruptible Power Supply (UPS) Internal Batteries Removal and ReplacementDawood QureshiNo ratings yet

- Manual Io Flooded Flat Plate Battery - GB3696Document3 pagesManual Io Flooded Flat Plate Battery - GB3696ivanrrsistemasNo ratings yet

- Inverex s1200 XP SolarDocument15 pagesInverex s1200 XP SolarSalman ArainNo ratings yet

- Belinus Energiewall HV Installation Manual en V1 2022Document69 pagesBelinus Energiewall HV Installation Manual en V1 2022tasoNo ratings yet

- Brake System PDFDocument9 pagesBrake System PDFdiego diaz100% (1)

- Electrical and Ignition: Battery, Charging System and Starting SystemDocument18 pagesElectrical and Ignition: Battery, Charging System and Starting SystemmartinbexnerNo ratings yet

- Optimate 4 InstructionsDocument8 pagesOptimate 4 InstructionsTatayoyoNo ratings yet

- Makita BatteryDocument80 pagesMakita BatteryΒΑΣΙΛΕΙΟΣ ΒΑΣΙΛΑΚΗΣNo ratings yet

- Minnkota Onboard DC ChargerDocument9 pagesMinnkota Onboard DC Chargerwfmiller02No ratings yet

- SMF Data SheetDocument7 pagesSMF Data SheetASdasdasNo ratings yet

- Isuzu 4HK1-6HK1 Wiring Diagram and Trobleshooting ManualDocument513 pagesIsuzu 4HK1-6HK1 Wiring Diagram and Trobleshooting Manualwagner demezNo ratings yet

- Alternator Install - AutoDocument4 pagesAlternator Install - AutoSharon ScottNo ratings yet

- T322 - 69NT20 551 300 - To - 399 PDFDocument95 pagesT322 - 69NT20 551 300 - To - 399 PDFSerhiiNo ratings yet

- SM Large MK IV Adt Rev 0 Jan 07 MiscDocument46 pagesSM Large MK IV Adt Rev 0 Jan 07 MiscMIANo ratings yet

- VIA Truck Silverado Truck Battery RemovalDocument9 pagesVIA Truck Silverado Truck Battery RemovaljjmokieNo ratings yet

- Owner'S Manual: Model No. 200,71440Document14 pagesOwner'S Manual: Model No. 200,71440Jecko OfficialNo ratings yet

- Maintenance: OS030EC (C801) OS/SS030BE (D826)Document10 pagesMaintenance: OS030EC (C801) OS/SS030BE (D826)Hector PuacNo ratings yet

- Dragon Power 300AH LiFePO4 Battery ManualDocument30 pagesDragon Power 300AH LiFePO4 Battery Manualmastech.shaunNo ratings yet

- SAFT Compact IO-ENDocument2 pagesSAFT Compact IO-ENDavid FuentesNo ratings yet

- Owner'S Manual For Minn Kota Onboard DC Alternator Battery Chargers Models: MK-1-DC, MK-2-DC, MK-3-DCDocument9 pagesOwner'S Manual For Minn Kota Onboard DC Alternator Battery Chargers Models: MK-1-DC, MK-2-DC, MK-3-DCЯрослав БогдановNo ratings yet

- 54225399Document20 pages54225399domicepisul972No ratings yet

- Sunbridge 1000Document18 pagesSunbridge 1000cayod14246No ratings yet

- Steering Mechanism: MaintenanceDocument16 pagesSteering Mechanism: MaintenanceZoltán RozinkaNo ratings yet

- Xfcflex eDocument27 pagesXfcflex eIntercambio de ManualesNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Temperature of Operating MediaDocument1 pageTemperature of Operating MediaVuHongNhatNo ratings yet

- Using Thermistors To Enhance Thermal Protection For Battery Management SystemsDocument3 pagesUsing Thermistors To Enhance Thermal Protection For Battery Management SystemsVuHongNhatNo ratings yet

- 00001Document88 pages00001VuHongNhatNo ratings yet

- DinhrutDocument3 pagesDinhrutVuHongNhatNo ratings yet

- Ro-Ro Handbook v4Document241 pagesRo-Ro Handbook v4VuHongNhat100% (10)

- MAN-Service Experience 2002 PDFDocument14 pagesMAN-Service Experience 2002 PDFVuHongNhatNo ratings yet

- Maths For MarinersDocument154 pagesMaths For MarinersVuHongNhatNo ratings yet

- SummaryDocument115 pagesSummaryVuHongNhatNo ratings yet

- 905 - Crankshaft & Thrust BearingDocument19 pages905 - Crankshaft & Thrust BearingVuHongNhatNo ratings yet

- 904 - Crosshead With Connecting RodDocument19 pages904 - Crosshead With Connecting RodVuHongNhatNo ratings yet

- L42-MC - Exhaust ValveDocument9 pagesL42-MC - Exhaust ValveVuHongNhatNo ratings yet

- 903 - Cylinder LinerDocument13 pages903 - Cylinder LinerVuHongNhatNo ratings yet

- Blohm Voss Fin StabilizerDocument31 pagesBlohm Voss Fin StabilizerVuHongNhatNo ratings yet

- BI/Surveymonkey Sequestration Poll ResultsDocument13 pagesBI/Surveymonkey Sequestration Poll Resultswhickey9402No ratings yet

- Amelita Constantino and Michael Constantin VS Ivan Mendez GR 57227 May 14 J 1992Document1 pageAmelita Constantino and Michael Constantin VS Ivan Mendez GR 57227 May 14 J 1992Abdullah JulkanainNo ratings yet

- Edexcel IAL Mathematics Formula BookDocument30 pagesEdexcel IAL Mathematics Formula BookThanuj Perera100% (3)

- Selim Raihan - Inequality and Public Policy in AsiaDocument20 pagesSelim Raihan - Inequality and Public Policy in AsiaWasif ArefinNo ratings yet

- Pre - Colonial Era in The PhilippinesDocument42 pagesPre - Colonial Era in The Philippinesglaide lojeroNo ratings yet

- 3 HACCP Complex FoodDocument4 pages3 HACCP Complex FoodAssumta RamosNo ratings yet

- Case 4 - Top Dog and UnderdogDocument1 pageCase 4 - Top Dog and UnderdogMarjorie PereiraNo ratings yet

- Magsumbol Vs People Case DigestDocument1 pageMagsumbol Vs People Case DigestSittie Rania CANDOTANNo ratings yet

- Ret. Lt. Gen. Jacinto C. Ligot, Et Al. vs. Republic of The Philippines Represented by The Anti-Money Laundering Council Frozen Assets in Civil Forfeiture Cases PDFDocument24 pagesRet. Lt. Gen. Jacinto C. Ligot, Et Al. vs. Republic of The Philippines Represented by The Anti-Money Laundering Council Frozen Assets in Civil Forfeiture Cases PDFPeterD'Rock WithJason D'ArgonautNo ratings yet

- Decision Making Models Techniques and ProcessesDocument25 pagesDecision Making Models Techniques and ProcessesJayaneela PrawinNo ratings yet

- N1 FitnessDocument84 pagesN1 FitnessDiana PruneanNo ratings yet

- DLL-science2 Week 1 22-23Document3 pagesDLL-science2 Week 1 22-23Sheena Claire dela Pe?No ratings yet

- CHAPTER 9-BIODIVERSITY - Part 3Document39 pagesCHAPTER 9-BIODIVERSITY - Part 3Matthew JarilloNo ratings yet

- Ra 69 Safe Ship To Ship OperationsDocument6 pagesRa 69 Safe Ship To Ship OperationsArif Ayub100% (1)

- Outcome Based Education WordDocument7 pagesOutcome Based Education Wordsp2056251No ratings yet

- Plani Vjetor KL 3 VJETOR 2022-2023Document2 pagesPlani Vjetor KL 3 VJETOR 2022-2023Nexhmije HushiNo ratings yet

- Consent Form For SBIDocument2 pagesConsent Form For SBIannajoy natividadNo ratings yet

- Online Auction System ReportDocument26 pagesOnline Auction System Reportbalabala5780No ratings yet

- Think Big Act Small - PDFDocument90 pagesThink Big Act Small - PDFThomas BondeNo ratings yet

- Radiation Generating Equipment AssesmentDocument27 pagesRadiation Generating Equipment AssesmentAjith kumarNo ratings yet

- Act of Settlement 1701 UKDocument4 pagesAct of Settlement 1701 UKPs Emma100% (1)

- Apex'i AFC2 WiringDocument64 pagesApex'i AFC2 WiringDave_B0% (1)

- Summative Assessment - Introduction To Python Programming - Y8Document17 pagesSummative Assessment - Introduction To Python Programming - Y8Aisha AnwarNo ratings yet

- Homework Solver FreeDocument8 pagesHomework Solver Freeafmtjbyaz100% (1)

- Que. 1. Explain Product Life Cycle. ? AnsDocument9 pagesQue. 1. Explain Product Life Cycle. ? Ansviga1880No ratings yet

- Adobe Scan 27 Jan 2024Document2 pagesAdobe Scan 27 Jan 2024kardinyenduNo ratings yet

- Kubernetes SecurityDocument156 pagesKubernetes Securitysalinob813No ratings yet

- GoMechanic OrderBill NullDocument6 pagesGoMechanic OrderBill NullmeherNo ratings yet

- Moonlight English Sample Y4 - 240925 - 083057Document57 pagesMoonlight English Sample Y4 - 240925 - 083057hadeelheadzNo ratings yet

- Badly Drawn Roy: Directed by Alan ShannonDocument11 pagesBadly Drawn Roy: Directed by Alan ShannonLiam ClarkeNo ratings yet