0 ratings0% found this document useful (0 votes)

6 viewsCutting Spreading 4

Cutting Spreading 4

Uploaded by

Efti Khairul AlamFabric spreading is a process where fabric plies are spread to the required length and width according to a marker dimension to prepare for cutting. There are two types of spreading: flat and stepped. Spreading can be done manually or mechanically using semi-automatic or fully automatic machines. The objectives are to correctly align the fabric plies by length and width and allow for large-scale cutting while saving fabric.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Cutting Spreading 4

Cutting Spreading 4

Uploaded by

Efti Khairul Alam0 ratings0% found this document useful (0 votes)

6 views4 pagesFabric spreading is a process where fabric plies are spread to the required length and width according to a marker dimension to prepare for cutting. There are two types of spreading: flat and stepped. Spreading can be done manually or mechanically using semi-automatic or fully automatic machines. The objectives are to correctly align the fabric plies by length and width and allow for large-scale cutting while saving fabric.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Fabric spreading is a process where fabric plies are spread to the required length and width according to a marker dimension to prepare for cutting. There are two types of spreading: flat and stepped. Spreading can be done manually or mechanically using semi-automatic or fully automatic machines. The objectives are to correctly align the fabric plies by length and width and allow for large-scale cutting while saving fabric.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views4 pagesCutting Spreading 4

Cutting Spreading 4

Uploaded by

Efti Khairul AlamFabric spreading is a process where fabric plies are spread to the required length and width according to a marker dimension to prepare for cutting. There are two types of spreading: flat and stepped. Spreading can be done manually or mechanically using semi-automatic or fully automatic machines. The objectives are to correctly align the fabric plies by length and width and allow for large-scale cutting while saving fabric.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

Fabric spreading

Fabric spreading means to spread the fabric in a

systematic way. It is a process by which plies of

fabric is spread in order to get required length and

width as per marker dimension. This is preparatory

operation for cutting of the fabric.

Fig: Fabric spreading

➢ Objects of Fabric Spreading:

1. To place the number of fabric plies to the length

of the marker plan correctly aligned as to the

length and width.

2. To cut garments in large scale and saving fabric

through the use of multi garments marker plan

and the saving in cutting time per garment that

result from cutting many piles at the same time.

3. To make every ply flat and plain.

4. At correct tension.

➢ Types of Spreading: There are two types

of spreading

1) Flat spreading

2) Stepped spreading.

• Method of fabric spreading:

1. Manual method

2. Mechanical method : a) Semiautomatic

b) Full automatic

Semiautomatic:

Spreading machine is run on the rails (two rails) which

are placed at two side of fabric spreading table surface

and operated by motor. Fabric roll is set in a

predetermined place of the machine. Spreading machine

is run from one side to the other side of table by using

electrical & mechanical motion and fabric is spreaded to

make lay.

Full automatic:

This is the improvement of semiautomatic machine.

There are so many advantage of this machine to make

fabric lay because; this machine is operated by

controlling with the help of robot and micro processor.

Techniques of Spreading:

There are four types of fabric spreading

techniques available in clothing industry:

1) Face up with same direction.

2) Face up with opposite direction.

3) Face down & face up with same direction

4) Face down & face up with opposite direction

Face up with same direction:

In this system when fabric laid on the table

its face is keep up with same direction .

Face up with opposite direction:

In this system when fabric laid on the table its

face is keep up & the fabric direction is

opposite.

Face down & face up with same direction

In this system when fabric laid on the table its

face is keep down & up with same direction.

Face down & face up with opposite direction

In this system when fabric laid on the table its

face is keep down & up but the direction are

opposite.

You might also like

- Casual Shirt Production ProcessDocument38 pagesCasual Shirt Production ProcessPrakriti83% (6)

- Fabric SpreadingDocument14 pagesFabric SpreadingVrinda Gupta100% (3)

- Types of Lay PlansDocument4 pagesTypes of Lay Plansnatarajan1234100% (2)

- Spreading and Cutting of Apparel ProductsDocument77 pagesSpreading and Cutting of Apparel ProductskbalabalaNo ratings yet

- Denim Quality ControlDocument10 pagesDenim Quality ControlEhsan HameedNo ratings yet

- Methods of SpreadingDocument10 pagesMethods of Spreadingarunkadve67% (3)

- Fabric spreading-latest-2Document26 pagesFabric spreading-latest-2samdany2007No ratings yet

- marker making methodDocument6 pagesmarker making methodsohelranap13020No ratings yet

- Presentation On Fabric Spreading: Green University of BangladeshDocument32 pagesPresentation On Fabric Spreading: Green University of Bangladeshaqsa imranNo ratings yet

- Automatic Garment Spreading MachineDocument10 pagesAutomatic Garment Spreading MachineSadia WasimaNo ratings yet

- SpreadingDocument7 pagesSpreadingsporti1412No ratings yet

- Cutting RoomDocument7 pagesCutting RoomAnkush PatidarNo ratings yet

- Cutting Room - AnkushDocument7 pagesCutting Room - AnkushAnkush PatidarNo ratings yet

- Flow of Cutting RoomDocument7 pagesFlow of Cutting RoomAnkush PatidarNo ratings yet

- Flow of Cutting RoomDocument7 pagesFlow of Cutting RoomAnkush PatidarNo ratings yet

- Flow of Cutting RoomDocument7 pagesFlow of Cutting RoomAnkush PatidarNo ratings yet

- SpreadingDocument8 pagesSpreadingsporti1412No ratings yet

- Spreading in Cutting RoomDocument11 pagesSpreading in Cutting RoomZain AlviNo ratings yet

- Types of Spreading MachineDocument6 pagesTypes of Spreading Machineyasin husen100% (1)

- Fabric SpreadingDocument8 pagesFabric SpreadingRatul Hasan50% (2)

- Manual SpreadingDocument4 pagesManual SpreadingarunkadveNo ratings yet

- SpreadingDocument39 pagesSpreadingPratik MinjNo ratings yet

- Production AssignmentDocument18 pagesProduction AssignmentAmeesha PawarNo ratings yet

- Cutting Room Technology-1,3,4,5Document32 pagesCutting Room Technology-1,3,4,5Utsash SarkerNo ratings yet

- Study On Machineries Used in Apparel IndustryDocument16 pagesStudy On Machineries Used in Apparel IndustryMd. Rakibul HassanNo ratings yet

- Types of SpreadsDocument5 pagesTypes of SpreadsGulam RasoolNo ratings yet

- Fabric ClassificationDocument7 pagesFabric Classificationshrutiagarwal922950% (2)

- Lay PlanningDocument23 pagesLay PlanningArjun Yadav80% (10)

- GMT Unit - 2 bhttDocument21 pagesGMT Unit - 2 bhttsuriyanarayanan0308No ratings yet

- SpreadingDocument29 pagesSpreadingyuvarajNo ratings yet

- SpreadingDocument42 pagesSpreadingAmar Aditya100% (1)

- Fabric Control Devices During Garments SpreadingDocument1 pageFabric Control Devices During Garments SpreadingAnkit KumarNo ratings yet

- Fabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessDocument2 pagesFabric Spreading - Types of Fabric Spreading - Requirements of Spreading ProcessSubrata Mahapatra100% (2)

- Fabric Spreading SlidesDocument19 pagesFabric Spreading SlidesRoshnal BluestacksNo ratings yet

- AE Discussion NewDocument4 pagesAE Discussion NewIMAMA HOSSAIN SOBUJNo ratings yet

- Sewing Machines - Mechanism and SettingsDocument13 pagesSewing Machines - Mechanism and SettingsZeshan Abdullah100% (1)

- Spreading and Cutting of Apparel ProductsDocument43 pagesSpreading and Cutting of Apparel ProductsDaniela JakimovaNo ratings yet

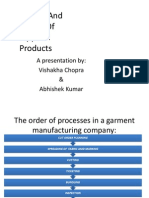

- Spreading and Cutting of Apparel ProductsDocument42 pagesSpreading and Cutting of Apparel ProductsVishakha Chopra86% (7)

- Fabric SpreadingDocument15 pagesFabric SpreadingDeepthi channaNo ratings yet

- Automation in Spreading and Cutting - Mansi, Akriti, Khushi, Nisha PDFDocument30 pagesAutomation in Spreading and Cutting - Mansi, Akriti, Khushi, Nisha PDFMansi ChandNo ratings yet

- Apparel ManufacturingDocument21 pagesApparel Manufacturingkaleabandebet7No ratings yet

- Spreading DetailsDocument20 pagesSpreading Detailsshrutiagarwal9229No ratings yet

- Plant Layout A-1.2 G-04Document34 pagesPlant Layout A-1.2 G-04Shivam SagarNo ratings yet

- Study On Industrial Sewing Machine and IllustrationsDocument15 pagesStudy On Industrial Sewing Machine and IllustrationsAlif SheikhNo ratings yet

- Lay-Up FabricDocument5 pagesLay-Up Fabrictom100% (1)

- Knitting ApparelDocument14 pagesKnitting Apparelhdinterloop2No ratings yet

- Cutting and Spreading, Use of AutomationDocument30 pagesCutting and Spreading, Use of AutomationAditi33% (3)

- Unit - 4 Flat Knitting & Warp KnittingDocument25 pagesUnit - 4 Flat Knitting & Warp Knittingsudharocky7868No ratings yet

- ID: 181-014-041 Section: A Course Title: Fabric Manufacturing Technology-2 (Lab) Course Code: TXE-304Document10 pagesID: 181-014-041 Section: A Course Title: Fabric Manufacturing Technology-2 (Lab) Course Code: TXE-304Mahmudul HasanNo ratings yet

- 02 - FAD QuestionsDocument16 pages02 - FAD Questionsmaya_muthNo ratings yet

- Garment Production Starts With The Cutting ProcessDocument3 pagesGarment Production Starts With The Cutting ProcessrajasekaranvgNo ratings yet

- Preproduction Operations:: Marker Making, Spreading, and CuttingDocument31 pagesPreproduction Operations:: Marker Making, Spreading, and Cuttingaqsa imranNo ratings yet

- Cutting Room OverviewDocument3 pagesCutting Room OverviewraindfNo ratings yet

- Knitting MCDocument18 pagesKnitting MCKumera HaileyesusNo ratings yet

- Apparel Produ Ction TechniquesDocument30 pagesApparel Produ Ction Techniquesnidhimeshram1997No ratings yet

- Artificial Intelligence in Spreading and Cutting Equipments - Mansi, Akriti, Khushi, NishaDocument30 pagesArtificial Intelligence in Spreading and Cutting Equipments - Mansi, Akriti, Khushi, NishaMansi Chand100% (1)

- Auto Spreader MRABBIDocument3 pagesAuto Spreader MRABBIঅবাকঅমিয়No ratings yet

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterRating: 3 out of 5 stars3/5 (2)

- A-Z of Sewing: The Ultimate Guide for Everyone From Sewing Beginners to ExpertsFrom EverandA-Z of Sewing: The Ultimate Guide for Everyone From Sewing Beginners to ExpertsRating: 5 out of 5 stars5/5 (1)