Ata 80 - Engine Starting Cor

Ata 80 - Engine Starting Cor

Uploaded by

IdrisCopyright:

Available Formats

Ata 80 - Engine Starting Cor

Ata 80 - Engine Starting Cor

Uploaded by

IdrisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ata 80 - Engine Starting Cor

Ata 80 - Engine Starting Cor

Uploaded by

IdrisCopyright:

Available Formats

AEROCONSULT LTD

AEROCONSULT LTD

737-300/400/500 (CLASSIC) TYPE

TRAINING

ATA 80- ENGINE STARTING

B737-300/400/500 (CL) TYPE TRAINING 1

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

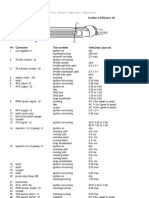

ENGINE STARTING -- ENGINE START SYSTEM - FUNCTIONAL DESCRIPTION

Purpose

The start system supplies pneumatic power for the engine starter.

Functional Description

The start system has pneumatic ducting which is used for air supply to the

pneumatic system.

The start system on the engine has these parts:

- Start valve

- Starter

- 5th stage bleed valve.

The air supply for engine starting comes from any of these sources:

- APU

- Pneumatic ground cart

- Operating opposite engine.

Engine starting requires the operation of these valves:

- Isolation valve - open

- Wing thermal anti-ice valves - closed

- Pack valves - closed

- Pressure regulating and shutoff valve (PRSOV) - open for cross bleeding from

operating engine.

With the start valve open, air from the pneumatic manifold goes to the starter and

opens the 5th stage bleed valve.

B737-300/400/500 (CL) TYPE TRAINING 2

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

B737-300/400/500 (CL) TYPE TRAINING 3

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

ENGINE STARTING -- START VALVE - FUNCTIONAL DESCRIPTION

Purpose

The start valve allows air from the pneumatic manifold to be supplied to the engine

starter.

Location

The start valve is above the starter on the left side of the engine. Two clamps

connect the start valve to the pneumatic ducting by.

Physical Description

The start valve is a solenoid controlled and pneumatically operated valve. It is spring

loaded to the closed position.

These are the parts of the valve:

- Valve body containing the disk

- Solenoid powered by 28v dc

- Electrical connector for solenoid and valve position switch

- Pneumatic actuator assembly

- Pressure relief valve

- Start bleed valve (5th stage compressor relief) pneumatic connection

- Manual drive connection and valve position indicator.

Functional Description

When the solenoid is de-energize, an internal spring and air pressure on one side of

the actuator holds the valve closed. When the solenoid energizes, pressure vents

and the other side of the actuator pressurizes.

The spring force is overcome and the valve opens. The relief valve protects the

actuator when the inlet pressure becomes excessive.

B737-300/400/500 (CL) TYPE TRAINING 4

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

B737-300/400/500 (CL) TYPE TRAINING 5

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

ENGINE STARTING -- START VALVE - MANUAL OPERATION

Training Information Point

You open the start valve manually. To do this, use a 3/8 inch square drive. Insert the

drive into the manual drive port on the valve. Access to this port is through a hole in

the left fan cowl. Next to the hole are instructions for opening and closing of the start

valve.

During manual operation of the valve, communication between the ground personnel

and the flight compartment must be maintained.

WARNING:

A 1/2 INCH VERTICAL STRIP IS PAINTED ON THE ENGINE FAN COWL AFT OF

THE START VALVE ACCESS PORT. DO NOT STEP FORWARD OF THIS LINE

WHILE ENGINE IS RUNNING. SERIOUS INJURY OR DEATH COULD RESULT

FROM BEING DRAWN INTO THE INLETOF AN OPERATING ENGINE.

CAUTION:

STARTER MAY BE DAMAGED IF START VALVE IS NOT CLOSED WHEN N2

INDICATION SHOWS 46.33% RPM.

CAUTION:

MANUAL OPERATION OF START VALVE WITHOUT AIR PRESSURE IN INLET

DUCT MAY DAMAGE VALVE.

B737-300/400/500 (CL) TYPE TRAINING 6

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

ENGINE STARTING -- ENGINE STARTER - FUNCTIONAL DESCRIPTION

Purpose

The engine starter converts compressed air pressure into rotational mechanical

energy. This energy is sufficient to accelerate the engine to starting speed.

Location

The starter is on the forward face of the accessory gearbox. The start valve is above

the starter.

Physical Description

The starter is a single stage, axial flow, turbine -air motor. Air goes from the

pneumatic system through a start valve. The air exhausts from the starter into the

space between the engine and the fan cowl.

These starter oil system parts are on the starter:

- Oil service port with a dipstick

- Oil level sight glass

- Oil drain plug with magnetic chip detector.

Functional Description

When the start valve is open, air goes to the starter turbine wheel. This rotates the

turbine at high speed.

A reduction gear system changes this energy to low speed, high torque at the output

shaft. The output shaft drives the high pressure compressor through the accessory

gearbox. An internal clutch mechanism provides automatic disengagement at high

speed.

Training Information Point

You service the starter with oil through the service port which has a dipstick. At the

base of the starter is a drain plug with a magnetic chip detector.

B737-300/400/500 (CL) TYPE TRAINING 7

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

B737-300/400/500 (CL) TYPE TRAINING 8

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

ENGINE STARTING -- ENGINE STARTER INSTALLATION

Training Information Point

The starter attaches to the accessory gearbox adapter by a clamp. Three aligning

pins on the adapter insure proper location.

You have to remove the clamp connecting the start valve to the starter before starter

removal. The air inlet on the starter has a start valve index key for valve alignment

with the starter.

B737-300/400/500 (CL) TYPE TRAINING 9

B737-300/400/500 (CL) TYPE TRAINING COURSE

AEROCONSULT LTD

AEROCONSULT LTD

ENGINE STARTING -- START VALVE - CONTROL AND INDICATION

Functional Description

To do these things, put the engine start switch to the GND position:

- Energize the start switch holding coil

- Operate the start valve solenoid.

When the engine rpm (N2) is below 46%, the primary engine display unit supplies a

ground for the engine 1 N2 tach relay R357. This relay energizes and supplies a

ground for the start valve switch holding coil.

When the engine gets to an N2 rpm more than 46%, relay R357 deenergizes. This

releases the start switch holding coil, and the switch goes to the OFF position.

If there is no signal from the primary engine display unit, you must hold the start

switch in the GND position. You must release the switch to the OFF position to stop

the starter when N2 gets to 46% rpm.

When the start valve solenoid operates, and air is available, the start valve opens.

The valve moves a position switch from the closed to the not closed position. In the

not closed position the START VALVE OPEN amber light on P2 panel comes on.

B737-300/400/500 (CL) TYPE TRAINING 10

B737-300/400/500 (CL) TYPE TRAINING COURSE

You might also like

- Bosch 35 Pin Early Motronic Pinout (BMW 5,6,7)Document2 pagesBosch 35 Pin Early Motronic Pinout (BMW 5,6,7)Posada Burgueño Carlos67% (3)

- Ata 79 - Engine Oil CorDocument23 pagesAta 79 - Engine Oil CorIdrisNo ratings yet

- Hino P11CDocument180 pagesHino P11CВалерий Герасимов0% (1)

- 767-300 ATA 29 HydraulicDocument18 pages767-300 ATA 29 HydraulicAndres Aldunate Quezada100% (1)

- MID 130 PSID 25 Gears 1/R Engagement SystemDocument1 pageMID 130 PSID 25 Gears 1/R Engagement Systemhadi50% (2)

- BMW M5254 Checking Camshaft Timing (M52TU - M54)Document6 pagesBMW M5254 Checking Camshaft Timing (M52TU - M54)head_master100% (1)

- Mechanic Testing Federal Aviation AdministrationDocument2 pagesMechanic Testing Federal Aviation AdministrationAli TahaNo ratings yet

- TopSky Plugin For EuroScope - Developer GuideDocument61 pagesTopSky Plugin For EuroScope - Developer GuidepinaNo ratings yet

- Ata 75 - Engine Air CorDocument23 pagesAta 75 - Engine Air CorIdrisNo ratings yet

- Hydraulic Power - Introduction 737-300/400/500 MAINTENANCE TRAINING MANUALDocument9 pagesHydraulic Power - Introduction 737-300/400/500 MAINTENANCE TRAINING MANUALBYRON PAUL YANEZ BOMBONNo ratings yet

- Ata 79 Cfm/a319 - A320 - A321 - Lus - (A320 Amm) - (79-00-00-0001 6)Document7 pagesAta 79 Cfm/a319 - A320 - A321 - Lus - (A320 Amm) - (79-00-00-0001 6)Felix CortezNo ratings yet

- Schaublin 150 Catalogue 1989Document39 pagesSchaublin 150 Catalogue 1989shjefke100% (2)

- Evinrude E-TEC 15-30HP Outboards BuletinDocument2 pagesEvinrude E-TEC 15-30HP Outboards Buletinfranklarabie100% (2)

- 737-300/400/500 (CLASSIC) TYPE Training: Ata 76-Engine ControlsDocument14 pages737-300/400/500 (CLASSIC) TYPE Training: Ata 76-Engine ControlsIdrisNo ratings yet

- Ata 74 - Engine Ignition CorDocument8 pagesAta 74 - Engine Ignition CorIdrisNo ratings yet

- Ata 72 - Engine CorDocument17 pagesAta 72 - Engine CorIdrisNo ratings yet

- B767 ATA 35 - OxygenDocument36 pagesB767 ATA 35 - OxygenNitinai kumphoNo ratings yet

- ATA13 Fed ExDocument31 pagesATA13 Fed Exprzytul2007No ratings yet

- Ata 37 - VacuumDocument13 pagesAta 37 - VacuumPapa Bebe FamilyNo ratings yet

- Ata 73 (PW2000)Document84 pagesAta 73 (PW2000)miguel alemanNo ratings yet

- M114700 Rev F1329945174Document40 pagesM114700 Rev F1329945174arkaaaaa100% (1)

- Thrust Reverser System Control - Deactivation-ReactivationDocument10 pagesThrust Reverser System Control - Deactivation-Reactivationphuong leNo ratings yet

- On The GroundDocument3 pagesOn The Groundroyalairmaroc737No ratings yet

- 767 - 27 Flight ControlsDocument42 pages767 - 27 Flight ControlsAndres Aldunate QuezadaNo ratings yet

- 767 - 49 ApuDocument22 pages767 - 49 ApuAndres Aldunate QuezadaNo ratings yet

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Document9 pagesEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldNo ratings yet

- 4circuit Hydraulique 737Document32 pages4circuit Hydraulique 737zeblaouarNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument58 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- 2 Engine GeneralDocument23 pages2 Engine GeneralChabou Rafik100% (1)

- Ata 71 (PW2000)Document74 pagesAta 71 (PW2000)miguel alemanNo ratings yet

- Funtional TestDocument19 pagesFuntional TestMarcelo Kenji DoiNo ratings yet

- A320 78exhaust SystemDocument8 pagesA320 78exhaust SystemSudip AcharyyaNo ratings yet

- 131-9B APU - HandbookDocument17 pages131-9B APU - Handbookary.whendraNo ratings yet

- Training Manual B 737-300/500: ATA 26 Lower Cargo Smoke Detection and Fire Suppres-Sion SystemDocument24 pagesTraining Manual B 737-300/500: ATA 26 Lower Cargo Smoke Detection and Fire Suppres-Sion Systemmohammad qaruishNo ratings yet

- Control System Electronic Unit (CSEU) : For Training Purposes OnlyDocument17 pagesControl System Electronic Unit (CSEU) : For Training Purposes OnlyTalita CumiNo ratings yet

- Ata 27 Aileron Servo Control OperationDocument2 pagesAta 27 Aileron Servo Control Operationbnolasco100% (1)

- B767 L3 ATA 24 Electrical PowerDocument232 pagesB767 L3 ATA 24 Electrical PowerOliver Irrazabal100% (1)

- Training Manual: EASA Part-66 75 Level 3Document23 pagesTraining Manual: EASA Part-66 75 Level 3Luis Enrique La Font FrancoNo ratings yet

- B - 737 - 300 - 400 - 500 - ATA - 52 Cargo DoorDocument33 pagesB - 737 - 300 - 400 - 500 - ATA - 52 Cargo DoorINFO WORKLINKNo ratings yet

- 737 300/400/500 Boeing: ATA 26 Fire ProtectionDocument125 pages737 300/400/500 Boeing: ATA 26 Fire ProtectionmaryNo ratings yet

- 11.16 Pneumatic/Vacuum (ATA 36) : Basic Maintenance Training Manual Module 11 Aircraft Structures and SystemsDocument14 pages11.16 Pneumatic/Vacuum (ATA 36) : Basic Maintenance Training Manual Module 11 Aircraft Structures and Systemsnajib0% (1)

- SECTION 10 - Front Bearing Compartment - Internal GearboxDocument8 pagesSECTION 10 - Front Bearing Compartment - Internal GearboxMichael CrivellariNo ratings yet

- A320 APU Differences.Document1 pageA320 APU Differences.Firas Naser100% (1)

- Spey PowerplantyDocument3 pagesSpey PowerplantyvcNo ratings yet

- Bombardier CRJ 00-Environmental Control SystemDocument42 pagesBombardier CRJ 00-Environmental Control SystemVincent GuignotNo ratings yet

- Jet Engine Journey Poster PDFDocument1 pageJet Engine Journey Poster PDFanurag kumarNo ratings yet

- Eec - Pcu - FadecDocument9 pagesEec - Pcu - FadecWilliam XavierNo ratings yet

- E3 Intake&CompressorDocument51 pagesE3 Intake&CompressorTam HoNo ratings yet

- ATA 05 Limits Maintenance ChecksDocument51 pagesATA 05 Limits Maintenance ChecksRafael Nuñez100% (1)

- TCDS 767Document59 pagesTCDS 767Sean Naz100% (1)

- 737 300/400/500 Boeing: ATA 36 PneumaticDocument51 pages737 300/400/500 Boeing: ATA 36 PneumaticmaryNo ratings yet

- Engines, APU R 01Document73 pagesEngines, APU R 01Syed Salman Uddin100% (1)

- Ata 77 - Engine Indicating CorDocument23 pagesAta 77 - Engine Indicating CorIdrisNo ratings yet

- Apu B 767Document103 pagesApu B 767gm&o100% (1)

- 80.00.00.022 14-APR-2021 31-MAR-2022 Closed A320-200N, A321-200N, A321-200NX 80-11 Iae LLC Pratt & Whitney To Confirm Availability of ICARE FunctionDocument4 pages80.00.00.022 14-APR-2021 31-MAR-2022 Closed A320-200N, A321-200N, A321-200NX 80-11 Iae LLC Pratt & Whitney To Confirm Availability of ICARE FunctionjivomirNo ratings yet

- 737NG Genfam PresentationDocument48 pages737NG Genfam PresentationsebastienNo ratings yet

- 4o - Encontro Anual de Investidores Da Embraer - Programa EMBRAER 170-190Document58 pages4o - Encontro Anual de Investidores Da Embraer - Programa EMBRAER 170-190AHMEDNo ratings yet

- 5 12Document8 pages5 12IvomadnessNo ratings yet

- CFM56 3book2t Shoot PDFDocument10 pagesCFM56 3book2t Shoot PDFDiniswari Alrino100% (1)

- CFM 56-3 Specific Operating InstructionsDocument7 pagesCFM 56-3 Specific Operating InstructionsHubert LindenthalerNo ratings yet

- Airbus AC A380 20131201Document380 pagesAirbus AC A380 20131201laxmans20No ratings yet

- Pilot k50 Horizontal 3 Phase ReciprocatingDocument14 pagesPilot k50 Horizontal 3 Phase ReciprocatingSobh AnwarNo ratings yet

- Pilot k25p Industrial Petrol ReciprocatingDocument14 pagesPilot k25p Industrial Petrol ReciprocatingPepeNo ratings yet

- Ata 56 - Windows CorDocument15 pagesAta 56 - Windows CorIdrisNo ratings yet

- Nigerian Civil Aviation AuthorityDocument13 pagesNigerian Civil Aviation AuthorityIdrisNo ratings yet

- HHBJJBHBDocument12 pagesHHBJJBHBIdrisNo ratings yet

- HJJJHHHDocument30 pagesHJJJHHHIdrisNo ratings yet

- Basic Helicopter Power Plant ExaminationDocument10 pagesBasic Helicopter Power Plant ExaminationIdrisNo ratings yet

- Development of Source Era Electronics Prototyping PlatformDocument12 pagesDevelopment of Source Era Electronics Prototyping PlatformIdrisNo ratings yet

- Basic Ame Pressurised Metal Airframe Examination: Option C. To The LeftDocument19 pagesBasic Ame Pressurised Metal Airframe Examination: Option C. To The LeftIdrisNo ratings yet

- Police Duplicate Records2 - Final PDFDocument195 pagesPolice Duplicate Records2 - Final PDFIdrisNo ratings yet

- Pressurisation Airframe Exams 2018Document16 pagesPressurisation Airframe Exams 2018IdrisNo ratings yet

- Advisory Circular NCAA-AC-PEL 025Document25 pagesAdvisory Circular NCAA-AC-PEL 025IdrisNo ratings yet

- Ajani Et Al v5n1sDocument13 pagesAjani Et Al v5n1sIdrisNo ratings yet

- Airframe Control and RiggingDocument17 pagesAirframe Control and RiggingIdrisNo ratings yet

- Study Questions.: Pressurized Airframe SectionDocument14 pagesStudy Questions.: Pressurized Airframe SectionIdrisNo ratings yet

- Airframe Continuation!...Document11 pagesAirframe Continuation!...IdrisNo ratings yet

- G8.2 - Mass & BalanceDocument24 pagesG8.2 - Mass & BalanceIdrisNo ratings yet

- Gas Turbine Engine Construction: Intake and DuctsDocument49 pagesGas Turbine Engine Construction: Intake and DuctsIdrisNo ratings yet

- Police Duplicate Records2 - Final PDFDocument195 pagesPolice Duplicate Records2 - Final PDFIdrisNo ratings yet

- DFA1101GZ5AD6J-907 Spare Parts Catalog - 2006-06 - English PDFDocument253 pagesDFA1101GZ5AD6J-907 Spare Parts Catalog - 2006-06 - English PDFWeifang Power100% (1)

- PMR Steam KitsDocument1 pagePMR Steam KitsPeanut d. DestroyerNo ratings yet

- ECSAL FM600 Centrifuge ManualDocument4 pagesECSAL FM600 Centrifuge ManualzzapiNo ratings yet

- Lab Manual Cycle I: Velammal Engineering CollegeDocument27 pagesLab Manual Cycle I: Velammal Engineering CollegeRanjit Rajendran100% (1)

- Work Shop Manual GR 3 - 4 Matr 1-5302-556Document33 pagesWork Shop Manual GR 3 - 4 Matr 1-5302-556sasa oljacaNo ratings yet

- An Overview of Six Stroke EngineDocument6 pagesAn Overview of Six Stroke Engineabhijith thankachanNo ratings yet

- SupraDocument22 pagesSupraroniNo ratings yet

- AE All NotesDocument140 pagesAE All NotesSahil Verma 1802872No ratings yet

- Application Engineering Bulletin: Electronic Engine Features - Engine Protection Automotive Industrial G-Drive MarineDocument60 pagesApplication Engineering Bulletin: Electronic Engine Features - Engine Protection Automotive Industrial G-Drive MarineMiguel Angel Cortes PrietoNo ratings yet

- 4A FE Throttle AdjustmentsDocument7 pages4A FE Throttle AdjustmentsPedro Alonzo Mercado ZavalaNo ratings yet

- Fuel Lift Pump (Feed Pump or Transfer Pump)Document12 pagesFuel Lift Pump (Feed Pump or Transfer Pump)ahmed jemalNo ratings yet

- 02b.2.13 Maintenance ACTROS Model Telligent Gearshift & Manual Shift - MastDocument35 pages02b.2.13 Maintenance ACTROS Model Telligent Gearshift & Manual Shift - Mastmhmmad.almahdi24No ratings yet

- Isky Timing ChartDocument1 pageIsky Timing ChartLuis Fernando ZampieriNo ratings yet

- O-320-E1F&E2F Parts Catalog PC-203-4Document77 pagesO-320-E1F&E2F Parts Catalog PC-203-4Nathaniel LuraNo ratings yet

- FL (Fuel System)Document40 pagesFL (Fuel System)alberto menesesNo ratings yet

- 08 PistonDocument40 pages08 PistonnareshNo ratings yet

- Bajaj Pulsar 200ns PDFDocument5 pagesBajaj Pulsar 200ns PDFNeymar RiveraNo ratings yet

- Yamaha Ft50cehdx 2007Document80 pagesYamaha Ft50cehdx 2007Ray Cepeda MenaNo ratings yet

- Install Chevy 4.3L & 5.7L Vortec Distributor - DIY ForumsDocument24 pagesInstall Chevy 4.3L & 5.7L Vortec Distributor - DIY Forumspg89gx82t2No ratings yet

- Introduction To Gas Turbines For Non-EngineersDocument9 pagesIntroduction To Gas Turbines For Non-EngineersKrishna MyakalaNo ratings yet

- Brochure HideaDocument20 pagesBrochure Hideacontato.motorfactoryNo ratings yet

- Theory of Engine OperationDocument19 pagesTheory of Engine OperationGabriel Dela Cruz LagmanNo ratings yet

- 7 MBDocument11 pages7 MBBintang Al'fat AslamNo ratings yet

- Operator'S Manual: Generating Set and Industrial EnginesDocument62 pagesOperator'S Manual: Generating Set and Industrial EnginesubayNo ratings yet