0 ratings0% found this document useful (0 votes)

4 viewsAls Checklist

Als Checklist

Uploaded by

rafeeqcscsCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Als Checklist

Als Checklist

Uploaded by

rafeeqcscs0 ratings0% found this document useful (0 votes)

4 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views1 pageAls Checklist

Als Checklist

Uploaded by

rafeeqcscsCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

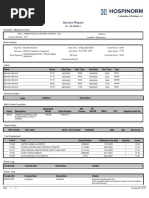

Quality System

Check for Planned Preventative Maintenance

IQ01-PQ01- 8.5.5 (7.5.1) Rev. 00 del 23/04/2018 Pag. 1 di 1

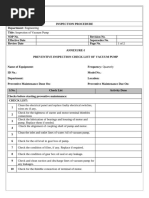

CHECK FOR PLANNED PREVENTATIVE MAINTENANCE –MEDICAL

REFRIGERATOR/FREEZERS

□ Ordinary maintenance □ Extraordinary maintenance

Model: Description: Serial Number: Technical Report Nr.:

REFRIGERATOR Attached

Execution Data:

The operations and controls envisaged for the maintenance of the equipment are reported below.

The machine must be in working condition.

Description Result

Pass Fail NA

1.Structure

1.A External:

Visual check of any breakages or structural damage- chassis/housing, wheels and brakes.

□ □ □

1.B Door:

Visual inspection of the correct assembly and the presence of gasket break.

□ □ □

1.C Door lock system :

Efficiency check of door gasket - Verification of the closure and alignment - mechanical and electrical

□ □ □

verification of the safety switch

1.D Internal and evaporator ventilation system

Visual and manual control

□ □ □

2. Electrical system and refrigeration system

2. A Wiring, electrical connections and internal devices: □ □ □

Visual and functional control

2.B Condenser and ventilation system: □ □ □

Visual and electrical check with control voltage check

Display and control:

2.C LCD /LED , keypad/touch functions , indicators, switches, lights operation □ □ □

2.D Electric power absorption check: □ □ □

Check the line cord and strain relief, fuses and supply line

2.E Check cooling system □ □ □

Condenser and Cooling fans , Compressor working

3. On-board devices

3.A Safety devices:

Intervention check by device simulation

□ □ □

Check buffer battery / backup up battery with voltage measurement and eventual replacement if needed

3.B Temperature regulation system:

Parameters check

□ □ □

Measurement of the internal temperature in the center of the chamber T. Set. …………… T. Meas. …………….

3.C Check alarms- audible and visual

High and low temperature, door open and power failure.

□ □ □

3.D Data recording/Chart recorder

Visual and functional check

□ □ □

Other:

Electrical safety test, Cleaning, Over all functional check and Labeling

□ □ □

Comment:

The equipment has been checked according to the procedures and parameters provided in the Use and Maintenance Manual.

Technician signature

You might also like

- Pre Commissioning & Commissioning - Procedure & Test Reports - MV SwitchgearDocument123 pagesPre Commissioning & Commissioning - Procedure & Test Reports - MV Switchgearpowermurugan71% (7)

- EV PDI PDS Sheet - v2Document2 pagesEV PDI PDS Sheet - v2yonatan solomon100% (3)

- ITP Electrical Rev. GenDocument8 pagesITP Electrical Rev. GenAgiesta PradiosNo ratings yet

- Lab 5Document6 pagesLab 5Tanjila Islam Ritu 1811017642No ratings yet

- Ret 670 Calculation Gsu3-87uatDocument33 pagesRet 670 Calculation Gsu3-87uatRatheesh KumarNo ratings yet

- Service Manual Beckman Coulter ACT SeriesDocument116 pagesService Manual Beckman Coulter ACT Seriesspiris0% (1)

- Electrical, Instrumentation & Safety Check ListDocument4 pagesElectrical, Instrumentation & Safety Check ListHisham Elsayed100% (2)

- RT 614Document3 pagesRT 614DALQ 04No ratings yet

- BG-QA-CL-308-14 Check List.R3.Final - Modern.090214Document3 pagesBG-QA-CL-308-14 Check List.R3.Final - Modern.090214Yousaf RichuNo ratings yet

- AC, UPS Andbattery Acceptance Criteria For EEPHQDocument20 pagesAC, UPS Andbattery Acceptance Criteria For EEPHQDanielNo ratings yet

- Downloaded From Manuals Search EngineDocument33 pagesDownloaded From Manuals Search EnginehieuhuechchNo ratings yet

- Engine Generator Set Inspection ChecklistDocument1 pageEngine Generator Set Inspection ChecklistRicardo DalisayNo ratings yet

- Acr Systems Inc.: Data-LoggersDocument2 pagesAcr Systems Inc.: Data-LoggersPedro Manuel Jacinto PedroNo ratings yet

- BC-10、 BC-20、 BC-30 Series Calibration Report - v1.0 - ENDocument17 pagesBC-10、 BC-20、 BC-30 Series Calibration Report - v1.0 - ENepicNo ratings yet

- IQ Procedure & Report ALP AutoclaveDocument9 pagesIQ Procedure & Report ALP AutoclavePhong LeNo ratings yet

- Competency For Checking and Use of CardiMax ECGDocument2 pagesCompetency For Checking and Use of CardiMax ECGianecunarNo ratings yet

- Gas Detection Con Trol Panel: No Ti Fier Ita LiaDocument44 pagesGas Detection Con Trol Panel: No Ti Fier Ita LiagazdaghliNo ratings yet

- Competency For Checking and Use of CardiMax ECGDocument2 pagesCompetency For Checking and Use of CardiMax ECGianecunarNo ratings yet

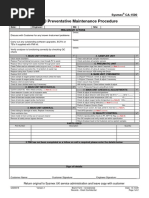

- Preventive Maintenance ChecklistDocument3 pagesPreventive Maintenance ChecklistArafat Baunto100% (2)

- 732689USBeDocument7 pages732689USBeBedoui MessaoudaNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Line Distance & Directional Ef Protection-7Sa522Document34 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Line Distance & Directional Ef Protection-7Sa522subhasish sarkar100% (1)

- CL-NG-6460-002-085 Checklist For Relay & Control Panel Scheme Check and Function Test Rev01-1Document6 pagesCL-NG-6460-002-085 Checklist For Relay & Control Panel Scheme Check and Function Test Rev01-1محمد عادلNo ratings yet

- WI-NG-6460-002-083 - Work Instruction For Panel Scheme Check and Function Tests Rev00Document9 pagesWI-NG-6460-002-083 - Work Instruction For Panel Scheme Check and Function Tests Rev00Mohamed NasrNo ratings yet

- WI-NG-6460-002-085 Work Instruction For Relay & Control Panel Scheme and Function Test Rev00Document15 pagesWI-NG-6460-002-085 Work Instruction For Relay & Control Panel Scheme and Function Test Rev00Mohamed NasrNo ratings yet

- Downloaded From Manuals Search EngineDocument128 pagesDownloaded From Manuals Search EngineRoozbeh BahmanyarNo ratings yet

- RT 512 Level Control Trainer Gunt 1178 PDF 1 en GBDocument3 pagesRT 512 Level Control Trainer Gunt 1178 PDF 1 en GBAli HadiNo ratings yet

- SMP of MCC & PCC RoomDocument4 pagesSMP of MCC & PCC Roomsanjay sharmaNo ratings yet

- Control 3-Lec4 - P&ID DiagramsDocument25 pagesControl 3-Lec4 - P&ID Diagramsmohammed abd el aleemNo ratings yet

- BWMS Commissionoing StepDocument25 pagesBWMS Commissionoing StepFanis RafaelNo ratings yet

- INSPECTION PROCEDUREDocument2 pagesINSPECTION PROCEDURECoolequipment CeeNo ratings yet

- Electrical Maintenance MapDocument4 pagesElectrical Maintenance MapScribdTranslationsNo ratings yet

- 001 - 17 Form Checklist Uji Fungsi CTDocument1 page001 - 17 Form Checklist Uji Fungsi CTAdietz satyaNo ratings yet

- Chapter 1-Introduction To Control SystemsDocument30 pagesChapter 1-Introduction To Control Systemsapi-556621129No ratings yet

- Electrical Inspection ProcedureDocument21 pagesElectrical Inspection Procedurebernard100% (1)

- SINAMICS Medium-Voltage Converters: More Productivity Through Preventive MaintenanceDocument2 pagesSINAMICS Medium-Voltage Converters: More Productivity Through Preventive MaintenanceEduardo Jose UribeNo ratings yet

- Maintenance Work Instruction: 1-AT-11025 1-AT-11110 1-AT-24111 2-AT-11025Document2 pagesMaintenance Work Instruction: 1-AT-11025 1-AT-11110 1-AT-24111 2-AT-11025hobam3297No ratings yet

- Auxiliary Relay Test Report: Sheet 1 of 1Document1 pageAuxiliary Relay Test Report: Sheet 1 of 1TariqMalikNo ratings yet

- Dokumen - Tips Installation User Maintenance Installation User Maintenance ManualDocument54 pagesDokumen - Tips Installation User Maintenance Installation User Maintenance ManualEdmond HungNo ratings yet

- 7ut - Transformer Diff Relay TestDocument25 pages7ut - Transformer Diff Relay TestAnoss Olier100% (2)

- EMCP1 Manual 7C1000.PDF Versión 1Document75 pagesEMCP1 Manual 7C1000.PDF Versión 1German E.100% (1)

- IQOQThermometerDocument9 pagesIQOQThermometerrizvi ahmadiNo ratings yet

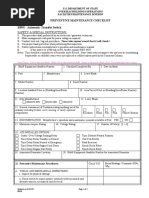

- Safety & Special Instructions:: Preventive Maintenance Checklist E09H - Automatic Transfer SwitchDocument2 pagesSafety & Special Instructions:: Preventive Maintenance Checklist E09H - Automatic Transfer SwitchEdward SchenkNo ratings yet

- 7sa Line Distance Relay TestDocument34 pages7sa Line Distance Relay Testsubhasish sarkarNo ratings yet

- OQ Conducitivity MeterDocument8 pagesOQ Conducitivity MeterMohsin AliNo ratings yet

- CBLM Level Master ManualDocument50 pagesCBLM Level Master ManualKelvin BharathNo ratings yet

- ADAC E3-P16 Generator Maintenance R2Document6 pagesADAC E3-P16 Generator Maintenance R2Noy FloresNo ratings yet

- Automatic and DDC Control Fundamentals and Energy Conservation For HVAC Equipment - Battelle - CompactDocument42 pagesAutomatic and DDC Control Fundamentals and Energy Conservation For HVAC Equipment - Battelle - Compactilikefree100% (2)

- Examples of Safety Critical Devices and Associated TestDocument3 pagesExamples of Safety Critical Devices and Associated TestGTMNo ratings yet

- Kia Cadenza Air Conditioner ServiceManualDocument210 pagesKia Cadenza Air Conditioner ServiceManualbastian norambuenaNo ratings yet

- Pvtrin Checklist Practical Tips On PV Installations enDocument22 pagesPvtrin Checklist Practical Tips On PV Installations enyavuz772100% (2)

- Excitation System & Governor ChecksheetDocument1 pageExcitation System & Governor ChecksheetNazim MirzaNo ratings yet

- LCU Check SheetDocument1 pageLCU Check SheetNazim MirzaNo ratings yet

- 3-Phase DG Testing ProcedureDocument10 pages3-Phase DG Testing Proceduredipankarbiswas2024elecNo ratings yet

- WI-NG-6460-002-084 Work Instruction For LCC Panel Scheme Check and Function Test Rev00Document9 pagesWI-NG-6460-002-084 Work Instruction For LCC Panel Scheme Check and Function Test Rev00Mohamed NasrNo ratings yet

- Electrical AlarmsDocument6 pagesElectrical AlarmsCiprian MariusNo ratings yet

- M177 PDFDocument47 pagesM177 PDFRAUL ALEXANDER CHAMORRO TOBARNo ratings yet

- Rel670 - Line DistanceDocument17 pagesRel670 - Line DistanceRatheesh KumarNo ratings yet

- Sysmex CA-1500 - PMI - ProDocument2 pagesSysmex CA-1500 - PMI - ProBakhrom KasimovNo ratings yet

- RT 674 Flow Level Control Demonstration Unit Gunt 1241 PDF - 1 - en GBDocument3 pagesRT 674 Flow Level Control Demonstration Unit Gunt 1241 PDF - 1 - en GBAmarNo ratings yet

- Scope of Work-Ali - CHTQTN21081076Document3 pagesScope of Work-Ali - CHTQTN21081076Brian ReyesNo ratings yet

- AJC Uniclave 77 - User Manual - 2Document2 pagesAJC Uniclave 77 - User Manual - 2rafeeqcscsNo ratings yet

- Maintenance-Report ULT-Freezers EngDocument6 pagesMaintenance-Report ULT-Freezers EngrafeeqcscsNo ratings yet

- Skoda Superb II (B6) - Heating, Air Conditioning - Free PDFDocument4 pagesSkoda Superb II (B6) - Heating, Air Conditioning - Free PDFrafeeqcscsNo ratings yet

- How Do I Pair My Rigel Device Via Bluetooth On Windows 10 - Seaward SupportDocument1 pageHow Do I Pair My Rigel Device Via Bluetooth On Windows 10 - Seaward SupportrafeeqcscsNo ratings yet

- Tympanic Thermometer PRO6000 - Checklist: NotesDocument1 pageTympanic Thermometer PRO6000 - Checklist: NotesrafeeqcscsNo ratings yet

- 9515 177 70 EnglitpdfDocument1 page9515 177 70 EnglitpdfrafeeqcscsNo ratings yet

- Service Report: Hospital / Medical CenterDocument4 pagesService Report: Hospital / Medical CenterrafeeqcscsNo ratings yet

- Cure IirDocument1 pageCure IirrafeeqcscsNo ratings yet

- Operating Manual - Dead Air WorkstationsDocument20 pagesOperating Manual - Dead Air WorkstationsrafeeqcscsNo ratings yet

- Refrigerator Operation Manual: I.series™ and Horizon Series™Document36 pagesRefrigerator Operation Manual: I.series™ and Horizon Series™rafeeqcscsNo ratings yet

- Service Report: Hospital / Medical CenterDocument1 pageService Report: Hospital / Medical CenterrafeeqcscsNo ratings yet

- T Rec G.664 199907 S!!PDF eDocument19 pagesT Rec G.664 199907 S!!PDF eparadhi navyaNo ratings yet

- Cag 1737Document5 pagesCag 1737AONLANo ratings yet

- Company Law Study Material FinalDocument183 pagesCompany Law Study Material Finalshivam_2607No ratings yet

- Key Phrasal Verb P1Document8 pagesKey Phrasal Verb P1Phạm Thu TrangNo ratings yet

- REM 103 Assignment 1 - GASPAR - GCDN2019T29514Document1 pageREM 103 Assignment 1 - GASPAR - GCDN2019T29514Zoey AlexaNo ratings yet

- MI Room R1 21 MayDocument1 pageMI Room R1 21 MayBijay Krishna DasNo ratings yet

- Stock Market Analysis Using Supervised Machine LearningDocument4 pagesStock Market Analysis Using Supervised Machine Learningdeshmukhneha833No ratings yet

- Olympics ProjectDocument3 pagesOlympics Projectapi-484189309No ratings yet

- Report Internship NLCDocument39 pagesReport Internship NLCjaganNo ratings yet

- Nov2021 CPE Assessment of KSU FinancesDocument52 pagesNov2021 CPE Assessment of KSU FinancesWKYTNo ratings yet

- Computer Science Core Concerns Separation of ConcernsDocument3 pagesComputer Science Core Concerns Separation of ConcernsRajan ManroNo ratings yet

- Types Social EntrepreneursDocument20 pagesTypes Social EntrepreneursShreya LalNo ratings yet

- Lecture2 Chapter4 - BCD To Excess-3 Code Converter DesignDocument19 pagesLecture2 Chapter4 - BCD To Excess-3 Code Converter DesignAyesha HussainNo ratings yet

- TAT TestDocument5 pagesTAT TestIrsa ZaheerNo ratings yet

- Finale Quick Reference Guide For MacintoshDocument40 pagesFinale Quick Reference Guide For Macintosh14GroganNo ratings yet

- 02 Biology Viva Questions 2023-24 B South FinalDocument2 pages02 Biology Viva Questions 2023-24 B South Finalvarshithajadhav6No ratings yet

- Dyslipidemia: Darmono SSDocument35 pagesDyslipidemia: Darmono SSLa Ode Rinaldi0% (1)

- 2464 8451 1 PBDocument6 pages2464 8451 1 PBSuwenda MadeNo ratings yet

- Abdulrahman Bakri: ProfileDocument2 pagesAbdulrahman Bakri: ProfileM3dn aNo ratings yet

- ArewqDocument2 pagesArewqilovevdkNo ratings yet

- Checklist of 30 Warning Signs of Potential TroubleDocument2 pagesChecklist of 30 Warning Signs of Potential TroubleMNo ratings yet

- Inversion LemmaDocument2 pagesInversion LemmaSina AghliNo ratings yet

- Swedish ReferenceDocument20 pagesSwedish ReferenceAndres Sotil FalconNo ratings yet

- Group 7 Pavement Design and ConceptDocument52 pagesGroup 7 Pavement Design and ConceptMaria Divina Romero TabuaNo ratings yet

- 1968 Gibson Johnny SmithDocument4 pages1968 Gibson Johnny SmithLuisNo ratings yet

- Calculations Biogas ProductionDocument4 pagesCalculations Biogas ProductionTony Deligiorgis100% (5)

- Gap Analysis Deadline: May 26Document3 pagesGap Analysis Deadline: May 26Karla Therese Licos100% (3)

- Easy Tortilla SoupDocument1 pageEasy Tortilla SoupShelby SheppardNo ratings yet

- Paging MessagesDocument51 pagesPaging MessagesFatima AjmalNo ratings yet