SEL 2240 Axion

SEL 2240 Axion

Uploaded by

junniorbsbCopyright:

Available Formats

SEL 2240 Axion

SEL 2240 Axion

Uploaded by

junniorbsbCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

SEL 2240 Axion

SEL 2240 Axion

Uploaded by

junniorbsbCopyright:

Available Formats

SEL-2240 Axion

Rugged Digital I/O, Analog I/O, Current and

Voltage Measurements, and Control for

Your Toughest Applications

The SEL Axion® is a fully integrated modular digital I/O, analog I/O, current and voltage measurement, and control

solution suitable for many utility and industrial applications. It combines the communications, built-in security, and

IEC 61131 logic engine of the SEL Real-Time Automation Controller (RTAC) family with a durable suite of I/O mod-

ules that provide high-speed, deterministic, control performance over an EtherCAT® backplane.

Major Features and Benefits

➤ High-Speed and High-Accuracy DC Analog Control. The Axion DC Analog Output module provides high-

accuracy current and voltage control signals for low-level self-wetted (sourcing) control applications.

➤ Proportional Integral Derivative (PID) Control. The PID function block provides advanced closed-loop control

for analog set points commonly used in generator and process control.

➤ Synchronized Current and Voltage Measurements. Retrieve high-accuracy current and voltage measurements

with the advantage of synchronized measurements. Multiple CT/PT modules in an Axion system sample all

measurements at the same time to ensure a common reference for all voltages and currents. This enables many

time-deterministic control applications without performing additional processing to align the measurements to a

reference. Use this capability to accomplish complex control schemes including load shedding, microgrid control,

and autosynchronization.

➤ Top of Second Synchronized Measurements. When connected to IRIG, synchronize the measurement of all

CT/PT modules to the top of the second. This enables Axions in geographically dispersed locations to run

algorithms on voltage and current measurements and provide time-aligned data from all the Axion modules. This

expands time-deterministic control capability to wide-area applications because the CT/PT measurements from

multiple Axion systems are all synchronized.

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

2

➤ Protection Against Malware and Other Cybersecurity Threats. Protect your RTAC system with exe-

GUARD®, which uses advanced cryptographic algorithms to authorize the execution of any program or service on

the system. Any tasks not approved by the whitelist are blocked from operation.

➤ RTU and PLC in a Single System. Employ the Axion’s I/O, SCADA communications, and control logic support

in many industrial and utility applications.

➤ Simple Setup With ACSELERATOR RTAC® SEL-5033 Software. Use standard device templates to build a

system, including I/O modules, quickly.

➤ Flexible I/O Selections. Choose a custom mix of digital and analog I/O modules that suit the application. Include

hundreds of points in a single panel, all connected to a deterministic EtherCAT backplane.

➤ Advanced User Authentication and System Security. Enforce LDAP user accounts to maintain security

perimeter integrity. Apply corporate logging and port control policies to comply with NERC/CIP requirements.

➤ Integrated Web-Based Human-Machine Interface (HMI). Integrate the SEL-2241 RTAC module directly into

the Axion system. The RTAC, via the embedded web server, includes a flexible graphical HMI system.

➤ Deterministic I/O Performance. Update connected I/O at a deterministic frequency; all inputs provide 1 ms

Sequential Events Recorder (SER) time stamps.

➤ More than SCADA. Go beyond SCADA by using the Axion industry-standard communications protocols to

enable multiple SCADA connections, as well as distributed control networks, among many stations.

➤ Networking Options. Implement I/O networks that use optional fiber-optic cables to provide outstanding signal

isolation and flexibility in module placement.

➤ Standard IEC 61131-3 Logic Design. Create innovative logic solutions directly in ACSELERATOR RTAC by

using editor tools such as Ladder Diagram, Tag Processor, Structured Text, or Continuous Function Chart.

➤ Redundant Power Supplies. Install optional dual SEL-2243 power couplers for applications needing redundant

power sources.

Product Overview

Functional Diagram

Touchscreen Display

Bay Control

Front Ethernet Port

Programmable

Pushbuttons and LEDs

Test Functions RTAC Module

Control Enable/Disable Including IEC 61131

Force Values logic engine and

system database

Activity Indicators

Port LEDs

Programmable LEDs EtherCAT

Protocol

Precise

Time

Communications Security Client/Server

Ports Firewall Protocols

Contact Outputs

Web Interface

Process Inputs

Optional HMI

User Administration

Logging / Alarms

Figure 1 Functional Diagram

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

3

Flexible System Architecture Power Coupler module (model SEL-2243) is a highly

reliable device that uses the same power supply technol-

Today's monitoring and control applications need flexi- ogy presently in use in SEL protective relays. Configure

ble system architectures and integrated security. The the SEL Axion to include single or redundant power

Axion meets these needs by using SEL RTAC as the sys- couplers for critical applications. In redundant configura-

tem CPU. Two configurations are possible. There can be tions, the pair of SEL-2243 modules actively share loads

an SEL-2241 RTAC module installed directly in the to supply power for the entire node. If one module should

Axion node, or the node can be connected to a stand- become unavailable, the remaining power coupler can

alone RTAC. A standalone SEL RTAC (e.g., SEL-3350) accommodate the entire node with no loss of system

connects via Ethernet to an SEL-2240 node. capability. Employ dual power couplers for installations

where you have dual power sources, one that is ac and

NOTE: The SEL-2242 backplane with 7-inch touchscreen display is only one that is dc.

compatible with the SEL-2241 RTAC module in Slot A. See the SEL-2240

Axion Bay Controller data sheet for more details.

SEL designs all Axion hardware to published standards

(see Specifications) and performs tests to verify that each

component exceeds standards by adequate margins. The

Figure 2 Modules Installed in Chassis/Backplane

Each Axion node is mounted in a chassis/backplane The node does not need to be entirely full to function

(model SEL-2242) that provides a means for each node properly. Leave empty slots for future expansion as nec-

to include a custom arrangement of modules. A single essary. Many RTU and control systems need more I/O

node can contain as many as nine modules. Use any com- points than will fit in a single Axion node. In those cases,

bination, quantity, and sequence of modules that suits the use the EtherCAT protocol to connect multiple nodes

application. together via a real-time Ethernet network. Through use

of an Axion system EtherCAT network, you can use as

many as 60 modules in a single network with no loss of

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

4

speed or determinism. The Applications section explores

several possible network configurations. In each imple-

Secure Operation

mentation, a single RTAC module provides logic func- You can use the built-in web interface to manage user

tions and data concentration for the entire network. accounts and system alarms remotely. Each user account

has a unique username, password, and assigned role that

defines system permissions. You can also configure the

RTU and PLC Functionality system to use LDAP central authentication for user

account management. There are webpages for monitor-

The Axion is both a remote terminal unit (RTU) and ing user logs and maintaining network policies.

ultra-rugged programmable logic controller (PLC). All

the modules are rated from –40°C to +85°C and can By enabling Ethernet and serial ports independently, you

optionally include conformal coating. The system is can minimize any security threat from unused but

designed to be flexible; use the right combination of enabled ports. Employ SSH encryption for remote engi-

modules and nodes, in almost any arrangement, to suit neering access to further protect the system. Combine the

the job. The SEL-2244 Digital Output Module has trip- Axion with other SEL security solutions to simply

rated contacts (30 A make, 6 A carry) to limit the need deploy a solution that meets your needs for maintaining a

for interposing relays. secure electronic perimeter for the control system.

The SEL-2241, SEL-3530, and SEL-3530-4 RTACs all

interface seamlessly with the I/O modules and provide

easy integration with other serial and Ethernet devices

Seamless System Configuration

via preinstalled communications protocols. The RTACs ACSELERATOR RTAC is a Microsoft® Windows®-com-

also support multiple SCADA/HMI channels. For high- patible configuration software for offline and online use

speed communication, use EtherCAT fieldbus connec- with the SEL-2241, SEL-3530, and SEL-3530-4 RTACs.

tions to I/O modules or optional IEC 61850 GOOSE A project in ACSELERATOR RTAC contains the complete

messaging with station IEDs. Poll data sets and reports configuration, settings, and logic for an individual RTAC

from other IEDs with optional IEC 61850 MMS client. device. Preconfigured device and I/O module templates

are available for you to quickly create all device and

With the Axion, you need no optional hardware or soft-

ware to have the programmable logic engine required for master connections for the project.

many applications. Each RTAC includes an IEC 61131 Once you create the settings for a specific device connec-

logic engine that ships preconfigured to provide access tion, improve engineering efficiency by saving a custom

for all system tags, intelligent electronic device (IED) device template for later use with similar projects. Share

and I/O data, diagnostics, alarms, security events, and custom templates via email or network for even greater

communications statistics. The RTAC provides unified savings. The application also includes complete project

tag mapping between protocols and programmable logic templates for some common project types.

that simplifies developing applications. You simply use

any necessary IED and I/O data, calculated values, and Use the intuitive ribbon interface to configure all the I/O

system tags in deterministic logic for the control of criti- modules and device connections for the project. The

cal applications. Project View in the left pane lets you organize and

quickly see everything in the project. The Tag Processor

Management of the task processing sequence and solve view facilitates the mapping of operational data between

rate in the RTAC is similar to that for traditional PACs. IEDs and SCADA. ACSELERATOR RTAC is compatible

Optimize processor use by setting the processing rate no with Microsoft Excel and other programs, so you can

faster than necessary for your application. save time and increase accuracy by copying SCADA

Task processing in the logic engine includes protocols, maps from the source document.

I/O, system management, and any custom logic pro- There is no need to install or learn more than one soft-

grams you create using Structured Text (ST), Ladder ware interface. Use the included Structured Text, Ladder

Logic Diagrams (LD), or Continuous Function Charts Diagram, or Continuous Function Chart editors to

(CFC). CFC programs are type of IEC 61131-3 Function develop custom IEC 61131 logic.

Block Diagram (FBD) that provide more programming

flexibility than standard FBDs. The ACSELERATOR Enable remote monitoring and control functions by using

RTAC software, free of charge with purchase of an SEL the optional web-based HMI for any of the RTAC

RTAC, includes the IEC 61131-3 and Tag Processor edi- devices. Figure 3 shows an example of a screen display-

tors you will use to manage any protocol information and ing operational data and secure controls from connected

custom logic necessary for your system. I/O and other devices. Every tag in the database is avail-

able for use in HMI screens.

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

5

G1 Utility Tie

BUS A

BUS B

Figure 3 Powerful Monitoring Functions Using the Web-

Based HMI

Figure 4 Load-Shedding Topology

Deterministic System Microgrid Control Applications

Performance The SEL-2245-4 adds dozens of voltage and current

channels to the hundreds of input, output, and analog

If your application includes distributed control strategies, channels already available in a single Axion system.

sequential logic, or SER reports, the deterministic perfor- With the capability of linking Axion backplanes as far as

mance of EtherCAT will meet your needs. The software five kilometers away, the Axion is well suited to monitor

updates all I/O and time-stamps inputs with 1 ms accu- and control across distances consistent with many micro-

racy. Log any tag values and system events to provide a grid applications. In an Axion system, all CT/PT mod-

system-wide SOE report that you can view online. You ules sample at precisely the same time, ensuring a

can also use an ODBC connection to transfer the logs to common reference for all voltages and currents entering

a central database. the RTAC logic engine. This synchronized sampling

enables many unique microgrid applications, including

islanding detection, generation restoration, and dispatch

Applications algorithms.

Load Shedding for Industrial Applications

The Axion system eliminates the need for separate input,

output, and control devices for industrial and microgrid

load-shedding schemes. Combining system frequency

and power measurements with the ability to add hun-

dreds of binary inputs and outputs, the Axion combines

the measurement, logic engine, and mitigation equip-

ment into a single unit. Employing the CT/PT module’s

frequency and power elements, the powerful logic engine

in the Axion incorporates system variables into fast-act-

ing control logic for underfrequency or demand control

load shedding. Complete with the HMI, the Axion is a

standalone control system for many remedial action

schemes.

Figure 5 Offshore Microgrid

Autosynchronization Systems

Use multiple CT/PT and I/O modules to create advanced

and highly scalable autosynchronization systems. Auto-

matically adjust the governor exciter controls as neces-

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

6

sary to provide safe, secure, and unattended The following diagram illustrates use of the Axion as a

synchronization of generation onto the power system. distributed RTU communicating over DNP3 to a

With synchronized sampling from multiple CT/PT mod- SCADA master.

ules, the control algorithm for multiple governor exciters

all have access to all necessary PT measurements in the

same Axion system. Additionally, the measurements are SCADA

already time-aligned, eliminating the need to adjust to a

common reference. An added bonus is that the CT/PT

DNP

modules can be located remotely across the system and

DNP Master

provide the synchronized measurements through the

Axion’s deterministic EtherCAT network. DN

DNP SEL-3355 P

RTU RTU

G1 G2 G3

DN

P

DN

P

SEL-2240 Axion SEL-2240 Axion

Substation I/O Substation I/O

A 1 2 B RTU RTU

5

C 4 3 D

SEL-2240 Axion SEL-2240 Axion

Substation I/O Substation I/O

SEL Axion

Governor Figure 7 RTACs Distributed With RTUs

Controller

Figure 6 SEL Axion Autosynchronization System Systems that do not need autonomous operation at each

RTU can use a central SEL-2241 and communicate to the

remote nodes through the SEL-2243 Power Couplers.

Remote Terminal Unit (RTU) This architecture offers an economical solution to dis-

Remote terminal units gather digital and analog signals tributed I/O over EtherCAT at an extremely fast acquisi-

at remote sites and supply these data over a variety of tion rate. The master SEL-2241 can host all data from

industry-standard protocols (DNP3, Modbus®, LG 8979, remote nodes over DNP3 and interface directly with the

or IEC 61850) to a central supervisory control and data SCADA system. The master Axion in Figure illustrates

acquisition (SCADA) center or HMI. A master controller this functionality.

in the SCADA center can perform all logic or distribute

logic to the RTU. The SEL-2244 I/O modules are avail- EtherCAT Network Topologies

able in a variety of types to gather many types of I/O at

RTU locations. The SEL-2241 RTAC module has a vari- The SEL-2243 Power Couplers provide not only hot-

ety of industry-standard protocols by which it can inte- pluggable power supplies, but also fast EtherCAT con-

grate seamlessly with any SCADA system. Additionally, nections to remote SEL-2240 nodes. The power couplers

the versatile IEC 61131 logic engine in the RTAC can create EtherCAT links in star network topology, sequen-

meet the majority of logic requirements for small to large tial network topology, or a combination of both. Star-

automation projects. The modular design of the Axion configured topologies still use the sequential message

provides it the ability to perform as an RTU in two ways: format inherent to EtherCAT design and offer greater

as a centralized master RTU or as distributed logic in flexibility than wired sequential network topologies in

each substation. creating a network to match your physical system. Refer

to Appendix C in the ACSELERATOR RTAC SEL-5033

Systems using distributed logic at the RTU use an Software Instruction Manual for detailed information on

SEL-2241 RTAC in each Axion node, thus providing all EtherCAT.

automation capabilities of the RTAC in each RTU. This

architecture allows each RTU to function autonomously Apply single or dual power couplers in each Axion node

even if the central SCADA system is offline. Each RTAC based on connection or redundancy requirements.

can communicate with the SCADA master over DNP3, Figure illustrates a star topology for four remote

Modbus, LG 8979, IEC 61850, or SEL Fast Message. SEL-2240 nodes with single power couplers in the

remote nodes and dual couplers in the RTAC master.

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

7

RTAC Master IEC 61850 GOOSE Concentrator

Gather a variety of substation I/O with the SEL-2244

SEL-2240 Axion modules and share the data with IEC 61850 Generic

Object-Oriented Substation Event (GOOSE) messages.

Use the protocol flexibility of the RTAC to concentrate

data from non-IEC 61850 relays and convert these data

SEL-2240 Axion SEL-2240 Axion to GOOSE messages.

GOOSE

SEL-2240 Axion SEL-2240 Axion

Figure 8 EtherCAT Star Network Topology

SEL-2240 Axion

Figure illustrates connections for an EtherCAT sequen-

Substation I/O

tial topology with six Axion nodes. Each node uses a sin-

gle SEL-2243 Power Coupler to provide connections to

the previous and next node in the EtherCAT network.

SEL-300G SEL-387

RTAC Master SEL-701

Figure 11 IEC 61850 GOOSE Concentrator

SEL-2240 Axion SEL-2240 Axion SEL-2240 Axion

Synchrophasor Concentrator

Use standard protocols, such as DNP3, to move synchro-

phasor data to SCADA operation centers. Include time

stamps and time quality in the SCADA message to allow

SEL-2240 Axion SEL-2240 Axion SEL-2240 Axion

for system-wide usage of synchrophasor data. Within the

RTAC logic engine, you can perform complex math and

Figure 9 EtherCAT Sequential Network Topology

logic calculations on synchrophasor data you collect

Figure illustrates a combination of star and sequential from SEL relays and other IEEE C37.118-compliant

connections with six Axion nodes. devices.

SCADA

SEL-2240 Axion

SEL-2488

SEL-2240 Axion SEL-2240 Axion SEL-2240 Axion

SEL-351 SEL-451

SEL-2240 Axion SEL-2240 Axion SEL-2240 Axion

Figure 10 EtherCAT Hybrid Network Topology

SEL-2414 SEL-751

Remote I/O

Figure 12 Synchrophasor Concentrator

When you use single or dual power couplers, the Axion

serves as a low-cost remote I/O module. As many as

60 modules or six nodes can connect to one resident

SCADA Data Concentrator

SEL-2241 RTAC or to a separate SEL-3530 RTAC. The Use the RTAC with your protective relays and other IEDs

Axion is an excellent teleprotection device that provides as the substation SCADA data concentrator. You can

through EtherCAT a simple means for expanding the configure the RTAC to collect and view station-wide

number of I/O points available in an automation system SER and event reports. Use MIRRORED BITS® protocol to

at rapid data acquisition rates. ensure compatibility with any SEL device. Retrieve asset

optimization data from SEL or other IEDs to maintain

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

8

the best possible system reliability. Take advantage of Remotely access the RTAC through the Ethernet connec-

multiprotocol support to collect SCADA information, tion, and use any web browser to manage users, view

process control commands, and obtain SNTP/NTP time diagnostics, and access logs. Establish a remote connec-

synchronization through a single communications link to tion with any IED connected to the RTAC through engi-

each Ethernet device. Scale values and calculate logic in neering access communications channels. Use the SEL

a familiar IEC 61131 configuration environment. Enjoy Fast Message protocol to maintain SCADA control and

secure, encrypted communications to any device on the metering updates throughout the engineering access con-

substation network or serial channel. nection. Use ACSELERATOR QuickSet® SEL-5030 Soft-

ware to remotely manage protection and control settings

in attached relays.

SCADA

SEL-2488

SEL-2240 Axion

Substation I/O

SEL-2730M

SEL-2488 SEL-2488

SEL-2240 Axion SEL-2240 Axion

Substation I/O Substation I/O

SEL-2488 SEL-2488

SEL-2411 SEL-710

SEL-551

SEL-2240 Axion SEL-2240 Axion

SEL-787

Substation I/O Substation I/O

SEL-2730M

SEL-2440 DPAC SEL-2730M

SEL-451

SEL-2414

SEL-2414 SEL-710

SEL-300G

Figure 13 SCADA Data Concentrator and HMI

Human-Machine Interface annunciators, and graphical representations that contain

control buttons, and you can then display any data in the

Use the built-in web human-machine interface (HMI) in RTAC. Once you have loaded the screens into the RTAC,

the RTAC for viewing and controlling any tags you con- you can view the screens in the RTAC web interface.

figured in the RTAC. Use ACSELERATOR Diagram Because the HMI application is web-based, multiple

Builder to develop custom HMI screens and load them users can view the HMI screens simultaneously.

into the RTAC. You can include one-line diagrams,

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

9

Figure 14 HMI One-line Diagram

The logging system in the RTAC provides comprehen- Programmable Logic/Automation

sive logging for all variables in the RTAC, including

those that connected IEDs provide. The logging system Controller

compensates for time-stamp differential among data Use the Axion as a programmable logic/automation con-

from different IEDS, so all data are in sequence and on troller (PLC/PAC) to automate your real-time tasks

the same time-stamp reference. The RTAC can log data based on a variety of input conditions and diagnostic

for changes in the state of Boolean values, changes in information. Use the powerful IEC 61131 logic engine to

string values, and changes in Boolean, analog, or string write programs in Structured Text, Function Block, or

time stamps. The RTAC can also alarm for analog values Ladder Logic. Schedule periodic tasks, or drive event-

that cross defined thresholds. Assign variables for log- driven tasks with multiple preconditions. Create function

ging in the Tag Processor, or use one of the logger func- blocks of complex tasks for simple configuration. Easily

tion blocks in IEC 61131 custom programs. replace aging PLCs implemented in Ladder Logic by

There are two user interfaces for viewing logged data. replicating the same logic or by using a conversion tool

These include a secure HTML interface and an open to translate logic to Structured Text.

database connectivity (ODBC) connection. Access the

HTML interface through a web browser connection. Use

the ODBC connection for standard data transfer between

the logged data and database or spreadsheet software.

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

10

Drag elements from ToolBox to programming area.

Right-click on the element and

use the “Input Assistant” to

help populate boxes.

Begin typing tag name

over ??? and note auto

complete feature.

Figure 15 IEC 61131 Logic Example

Intelligent Port Switch Network Gateway

Flexible communications parameters make the RTAC a The SEL-2241 RTAC has two Ethernet ports through

great choice for almost any port-switching application. which it can make serially connected devices available to

Although RTAC multitasking/multiuser and data han- high-speed networks. The RTAC supports virtual termi-

dling capabilities make it a very powerful remote auto- nal connections through the Ethernet ports. For example,

mation platform, it is still an economical choice for port- Ethernet users can establish secure Telnet sessions and

switching applications. The time-synchronization capa- communicate with an IED connected to the RTAC.

bilities of the RTAC add to its value in this application.

Engineering

Engineering SSH, TLS Encryption and

User Account Management

SEL-2730M

SEL-2488

SEL-2488

SEL-2240 Axion

SEL-2240 Axion

SEL-351 SEL-451

SEL-351 SEL-451

SEL-2414 SEL-751 SEL-2414 SEL-751

Figure 16 Intelligent Port Switch Figure 17 Network Gateway

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

11

Protocol Gateway signal from an external modulated or demodulated

source, such as a GPS satellite clock receiver,

Collect downstream data with client protocols. Then SNTP/NTP source, or serial or Ethernet protocol such as

send these data to your upstream HMI, RTU, or SCADA DNP3. If an external clock source is unavailable, the

master with server protocols, converting the data from RTAC generates an IRIG-B signal from its internal clock,

one protocol to another in the process. RTAC multitask- providing device synchronization to a common clock for

ing/multiuser and data handling capabilities make it a improved SER data analysis.

great choice for data concentration.

SEL-2488

SEL-2240 Axion

HMI

SEL-2411 Substation I/O

SEL-2730M

SEL-3355

DNP3

SEL-2488 SEL-2440 DPAC

SEL-2240 Axion SEL-751

SEL-451

Substation I/O SEL-2414

SEL-2730M

Modbus DNP3 Figure 19 Time Synchronization

DNP3

IEC 61850

SEL-2440 DPAC Security Gateway

Secure the automation network with the Axion. Enable

SEL-751

encryption for any engineering access channel or

SEL-451 SEL-2414 SCADA link. Implement system security auditing, log-

ging, and password restrictions to enforce NERC stan-

Figure 18 Protocol Converter dards. Comply with role-based requirements by

implementing per-user security profiles. Optionally,

Time-Synchronization Source incorporate serial and wireless encrypting devices to fur-

ther secure communications to any device.

Synchronize the time clocks in attached devices that

accept a demodulated IRIG-B time signal. The

SEL-2241 RTAC regenerates the demodulated IRIG-B

\

SCADA

Dial-Out

Telephone

SEL-3010

Alarm Engineering

Notification SSH, TLS Encryption and

SEL-2488 User Account Management

SEL-2240 Axion

Ethernet

SEL-2730M

Substation I/O Switch

Sensors SEL-2440 DPAC

SEL-3025 -Door

-Panel/Cabinet

-Motion

Serial -Fence

Encryption ...

SEL-751 SEL-751

Alarms

SEL-3025 -Visible

-Audible

-Lighting

...

SEL-351

Figure 20 Security Gateway

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

12

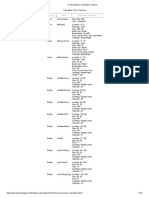

Ordering Options Table 6

Module

SEL-2244-5 Fast High-Current Digital Output

Table 1 SEL-2241 RTAC Module

Output Types 10 Form A Control Outputs

Ethernet Communi- Two Ethernet ports: 5 Form A, 5 Form B Control Outputs

cation 10/100BASE-T copper (standard) 10 Form B Control Outputs

100BASE-FX fiber-optic (optional)

100BASE-LX single-mode fiber-optic Environment Conformal coating for chemically

(optional) harsh and high-moisture environments

Web-Based HMI Basic runtime license and Diagram Table 7 SEL-2245-2 DC Analog Input Module

Builder software

Input Types ±20 mA, ±2 mA, ±10 V

Peer-to-Peer Protocols IEC 61850 GOOSE

Environment Conformal coating for chemically

Client Protocols IEC 61850 MMS harsh and high-moisture environments

Server Protocols IEC 61850 MMS

Table 8 SEL-2245-22 DC Analog Input Extended

Environment Conformal coating for chemically harsh Range Module

and high-moisture environments

Input Types 0–300 V

Table 2 SEL-2242 Chassis/Backplane Environment Conformal coating for chemically

harsh and high-moisture environments

Slot Configuration 10-Slot, 4-Slot, or Dual 4-Slot

Mounting Horizontal Surface Mount, 5Ua Table 9 SEL-2245-221 Low-Voltage (LEA) Monitoring

Horizontal Rack Mount, 5U Module

Horizontal Panel Mount, 5U (10-Slot or

Dual 4-Slot) Input Types 0–30 V peak

Environment Conformal coating for chemically harsh Environment Conformal coating for chemically

and high-moisture environments harsh and high-moisture environments

a For applications compliant with IEC 60255-27, surface-mount units

must be installed in IP4X enclosures. Table 10 SEL-2245-3 DC Analog Output Module

Output Types ±20 mA, ±10 V

Table 3 SEL-2243 Power Coupler

Environment Conformal coating for chemically

Voltage Range 24/48 Vdc or 120/250 Vac/Vdc

harsh and high-moisture environments

EtherCAT Two ports:

Communication RJ45 Ethernet (standard) Table 11 SEL-2245-4 AC Metering Module

LC fiber-optic multimode or single-mode

Input Types 0–22 A, 5–400 V

(optional)

Environment Conformal coating for chemically

Environment Conformal coating for chemically harsh and harsh and high-moisture environments

high-moisture environments

Table 12 SEL-2245-42 AC Protection Module

Table 4 SEL-2244-2 Digital Input Module

24 Vac/Vdc 125 Vac/Vdc Input Types 0–20 A, 6–300 V

Input Ratings

48 Vac/Vdc 220 Vac/Vdc

Environment Conformal coating for chemically

110 Vac/Vdc 250 Vac/Vdc

harsh and high-moisture environments

Environment Conformal coating for chemically harsh and

high-moisture environments Table 13 SEL-2245-411 Standard Current and

Low-Voltage (LEA) Monitoring Module

Table 5 SEL-2244-3 Standard Current Digital Output

Module Input Types 0–22 A, 0–30 V peak

Environment Conformal coating for chemically

Output Types 16 Form A Control Outputs

harsh and high-moisture environments

8 Form A, 8 Form B Control Outputs

16 Form B Control Outputs

Environment Conformal coating for chemically

harsh and high-moisture environments

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

13

Module Features

Front-Panel View

Lamp test

pushbutton Rack-mounted

chassis

LEDs simplify diagnostics

by indicating module status Slot identification is

visible even when in use

Rear-Panel View

Surface-mounted

chassis

Module alignment

guides make

installation a breeze

Figure 21 SEL-2242 10-Slot Chassis/Backplane

LEDs simplify diagnostics Rack-mounted Slot identification is Surface-mounted

by indicating module status chassis visible even when in use chassis

Lamp test

pushbutton

Module alignment

guides make

installation a breeze

Front-Panel View Rear-Panel View

Figure 22 SEL-2242 4-Slot Chassis/Backplane

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

14

Front-Panel View

Lamp test

pushbutton

Rack-mounted

chassis

LEDs simplify diagnostics Slot identification is

by indicating module status visible even when in use

Rear-Panel View

Surface-mounted

chassis

Module alignment

guides make

installation a breeze

Figure 23 SEL-2242 Dual 4-Slot Chassis/Backplane

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

15

LEDs simplify diagnostics Diagnostic LEDs

by indicating activity

on each serial port

Three programmable

bi-color LEDs provide

custom annunciation

All terminals are clearly

numbered for wiring

USB port for quick, and testing

convenient, system

setup and checkout

Independent Ethernet

ports may be RJ45 or LC fiber

Serial ports are

EIA-232/EIA-485

software selectable

Six independent and

Demodulated IRIG-B eighteen common-

input and output return inputs

for high-accuracy time

synchronization

Programmable

alarm contact

Figure 24 SEL-2241 RTAC Terminal-Side View Figure 26 SEL-2244-2 Digital Input Module Terminal-

Side View

Lamp test pushbutton

and diagnostic LEDs

Diagnostic LEDs

Ethernet ports

may be RJ45 or LC fiber

All terminals are clearly

numbered for wiring

and testing

Sixteen outputs

Two Power Couplers may be all

in a node operate Form A, all Form B,

as a load-sharing or eight of each

redundant pair

Figure 27 SEL-2244-3 Standard Current Digital

Figure 25 SEL-2243 Power Coupler Terminal-Side View

Output Module Terminal-Side View

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

16

Diagnostic LEDs Diagnostic LEDs

All terminals are clearly

numbered for wiring

and testing

Ten outputs may be all

Form A, all Form B, All terminals are clearly

or five of each numbered for wiring

and testing

Four inputs for

0–300 Vdc

Figure 28 SEL-2244-5 Fast High-Current Digital Figure 30 SEL-2245-22 Analog Input Extended Range

Output Module Terminal-Side View Module Terminal-Side View

Diagnostic LEDs Diagnostic LEDs

All terminals are clearly

numbered for wiring

and testing

Sixteen inputs may All terminals are clearly

configure ±20 mA, numbered for wiring

±2 mA, or ±10 V input and testing

ranges in pairs

Four inputs for

0–30 V peak

Figure 29 SEL-2245-2 DC Analog Input Module Figure 31 SEL-2245-221 Low-Voltage (LEA) Monitoring

Terminal-Side View Module

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

17

Diagnostic LEDs

Diagnostic LEDs

All terminals are clearly

numbered for wiring

All terminals are clearly and testing

numbered for wiring

and testing

Eight outputs may

configure ±20 mA

or ±10 V output

ranges

Four CT and four PT inputs

with two-wire connections

Figure 32 SEL-2245-3 DC Analog Output Module Figure 33 SEL-2245-4 AC Metering Module Terminal-

Terminal-Side View Side View

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

18

Diagnostic LEDs Diagnostic LEDs

All terminals are clearly

numbered for wiring

and testing

All terminals are clearly

numbered for wiring

and testing

Three CT and three PT inputs Four CT and four low-voltage

with two-wire connections (LEA) inputs with two-wire

connections

Figure 35 SEL-2245-411 Standard Current and

Figure 34 SEL-2245-42 AC Protection Module

Low-Voltage (LEA) Monitoring Module

Terminal-Side View

Diagrams and Dimensions

Figure 36 SEL-2240 10-Slot Front Panel (Rack Mount)

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

19

SCHWEITZER

ENGINEERING

AXION

LABORATORIES SEL-2240

A B C D E F G H I J

LAMP ENABLED

TEST ALARM

i6459a

Figure 37 SEL-2240 10-Slot Front Panel (Panel Mount)

Figure 38 SEL-2240 4-Slot Front Panel

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

20

Figure 39 SEL-2240 Dual 4-Slot Front Panel (Rack Mount)

SCHWEITZER

ENGINEERING

AXION SCHWEITZER

ENGINEERING

AXION

LABORATORIES SEL-2240 LABORATORIES SEL-2240

A B C D A B C D

LAMP ENABLED LAMP ENABLED

TEST ALARM TEST ALARM

i6460a

Figure 40 SEL-2240 Dual 4-Slot Front Panel (Panel Mount)

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

21

RTAC

ENABLED

ALARM

1 3

COM

2 4

AUX

USB

ETH 1

ETH 2

COM COM

1 3

COM COM

2 4

IRIG-B

OUT IN

1

2 OUT 101

3

SEL-2241

i5397b

Figure 41 SEL-2241 Connections Diagram

Figure 43 SEL-2244-2 Connections Diagram

i5398d i5695b

Figure 42 SEL-2243 Connections Diagrams

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

22

Figure 44 SEL-2244-3 Connections Diagrams Figure 45 SEL-2244-5 Connections Diagrams

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

23

Figure 47 SEL-2245-22 and SEL-2245-221

Connections Diagrams

Figure 46 SEL-2245-2 Connections Diagram

Figure 48 SEL-2245-3 Connections Diagram

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

24

i6316a

Figure 49 SEL-2245-42 Connections Diagram

Figure 50 SEL-2245-4 and SEL-2245-411 Connections

Diagrams

Figure 51 SEL-2240 Dimensions for 10-Slot Rack- and Surface-Mount Chassis

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

25

TOP

7.00

[177.9]

6.56

[166.7]

CABLE ACCESS VIEW SIDE

17.75 4X Ø.25 19.76

[450.9] [Ø6.4] [501.9]

5.75

8.80

[223.5] PANEL CUTOUT 5.75

[146.1]

9.61

[244.1] [146.1]

18.31 18.31

[465.1] [465.1] .61

[15.4]

MINIMUM CLEARANCE REQUIRED

FOR MODULE REMOVAL

LEGEND

in

[mm] i9407a

Figure 52 SEL-2240 Dimensions for 10-Slot Panel-Mount Chassis

Figure 53 SEL-2240 Dimensions for Dual 4-Slot Rack- and Surface-Mount Chassis

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

26

TOP

7.00

[177.9]

6.56

[166.7]

CABLE ACCESS VIEW SIDE

17.75 4X Ø.25 19.76

[450.9] [Ø6.4] [501.9]

5.75

8.80

[223.5] PANEL CUTOUT 5.75

[146.1]

9.61

[244.1] [146.1]

18.31 18.31

[465.1] [465.1] .61

[15.4]

MINIMUM CLEARANCE REQUIRED

FOR MODULE REMOVAL

LEGEND

in

[mm] i9408a

Figure 54 SEL-2240 Dimensions for Dual 4-Slot Panel-Mount Chassis

Figure 55 SEL-2240 Dimensions for 4-Slot Rack- and Surface-Mount Chassis

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

27

Specifications

SEL-2245-3 8 AO: 0.46 kg (1.01 lb)

Compliance

SEL-2245-4 4 CT/4 PT: 0.54 kg (1.18 lb)

Designed and manufactured under an ISO 9001 certified quality

management system SEL-2245-411 4 CT/4 LEA: 0.54 kg (1.18 lb)

SEL Axion operates at the specified limits on power up as soon as the SEL-2245-42 3 CT/3 PT: 0.73 kg (1.60 lb)

device enables. Refer to the individual SEL Axion module datasheets

for compliance and type test specifications.

Module Burden

UKCA Mark Table 14 Maximum Burden Per Module for Each Node

Enclosure Protection

Maximum

IP4X Front Module Added Burden

IP2X Product Without SEL-2245-4, SEL-2245-411, and SEL-2245-42 (W) a

IP1X Product With SEL-2245-4, SEL-2245-411, or SEL-2245-42

Note: If rear terminals are accessible during normal use, the product must be SEL-2241 RTAC (Copper Ethernet) 12.5

mounted in a locked enclosure or restricted area accessible by trained

maintenance or operation personnel only. SEL-2241 RTAC (Fiber Ethernet) 15

Product Standards SEL-2242R Standard Rack-Mount Backplanes 1

IEC 60255-26:2013 - Relays and Protection Equipment: EMC SEL-2242 With Touchscreen Display 4

IEC 60255-27:2014 - Relays and Protection Equipment: Safety SEL-2243 Power Coupler (Fiber Ethernet) 5b

IEC 60825-2:2004 +A1:2007 +A2:2010 for fiber-optic communications

IEC 61850-3:2013 - Comm Systems for Power Utility Automation SEL-2243 Power Coupler (Copper Ethernet) 2.5 b

General SEL-2244-2 24 DI 2

Operating System SEL-2244-3 16 DO 8c

SEL Linux® Yellowstone running Linux kernel 3.x with real-time SEL-2244-5 10 FHCDO 6c

preemption patches SEL-2245-2 16 AI 3

Operating and Storage Temperature Range SEL-2245-22 4 AI-ER 2

–40° to +85°C (–40° to +185°F)

SEL-2245-221 4 LEA 2

Units should be stored and transported in their original packaging.

Note: Operating temperature evaluated for UL ambient 0° to 40°C. SEL-2245-3 8 AO 13

Note: The optional front-panel LCD is impaired for temperatures below SEL-2245-4 4 CT/4 PT 3

–20°C and above +70°C.

SEL-2245-411 4 CT/4 LEA 3

Operating Environment

SEL-2245-42 3 CT/3 PT 6

Pollution Degree: 2

Overvoltage Category: II Typical Burden

Feature Selections

(W)

Insulation Class: 1

Relative Humidity: 5%–95%, noncondensing No use of SEL-2241 Serial Port +5 Vdc –3

Maximum Altitude: 2000 m Each DO port not energized (SEL-2241, –0.3

SEL-2244-3, or SEL-2244-5 relay coil)

Vibration, Earth Tremors: Class 1

Each AO port not energized (SEL-2245-2) –0.7

Dimensions a

Values include worst-case real power consumption and do not

Refer to for dimensions. include worst-case ac power factor correction (0.4).

If the unit will not be used in wide temperature extremes,

Weight reduce power by up to 6%.

b Each SEL-2243 will draw a minimum of 11 W (quiescent) when

SEL-2241 RTAC: 0.670 kg (1.47 lb)

the total burden of all other modules in the node is less than

SEL-2242 19 in Backplane: 3.24 kg (7.13 lb) 11 W.

c All DO relay coils may be energized simultaneously and still

Panel Mount Bezel: 0.283 kg (0.625 lb)

meet specifications.

SEL-2242 10-Slot (19 in

Rack Width) With 7 in

Touchscreen Display: 3.999 kg (8.80 lb)

CPU Processing and Memory

SEL-2243-1 HV Coupler: 0.85 kg (1.87 lb) Processor Speed: 533 MHz

SEL-2243-2 LV Coupler: 0.89 kg (1.97 lb) Memory: 1024 MB DDR2 ECC RAM

SEL-2244-2 24 DI: 0.45 kg (1.00 lb) Storage: 4 GB (2 GB reserved)

SEL-2244-3 16 DO: 0.59 kg (1.30 lb)

SEL-2244-5 10 FHCDO: 0.57 kg (1.26 lb)

SEL-2245-2 16 AI: 0.51 kg (1.12 lb)

SEL-2245-22 4 AI-ER: 0.42 kg (0.92 lb)

SEL-2245-221 4 LEA: 0.42 kg (0.92 lb)

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

28

Security Features Communications Ports (SEL-2241 RTAC)

Account Management: User Accounts Ethernet Ports (To Backplane)

User Roles

LDAP Central Authentication Ports: 1

RADIUS Central Authentication Data Rate: Automatic

Strong Passwords

Inactive Account Logouts Protocols: Dedicated EtherCAT port

Intrusion Detection: Access/Audit Logs Ethernet Ports (Terminal Side)

Alarm LED

Alarm Contact Ports: 2

Encrypted Communication: SSL/TLS, SSH, HTTPS Data Rate: 10 or 100 Mbps

Connector: RJ45 Female or LC Fiber (Multimode or

Automation Features (Protocols) Single-Mode 100 Mbps only)

Client: DNP3 Serial, DNP3 LAN/WAN, Modbus Fiber-Optic Ports (Class 1 LASER/LED)

RTU, Modbus TCP, SEL ASCII, SEL

Fast Messaging, LG 8979, IEEE C37.118, Wavelength

IEC 61850 MMS, CP2179, IEC 60870-5-

1300 nm

101/104, SNMP, SES-92, CDC Type II,

Courier, IEC 60870-5-103, Ethernet/IP Optical Connector Type

Explicit Message Client

LC

Server: DNP3 Serial, DNP3 LAN/WAN, Modbus

RTU, Modbus TCP, SEL Fast Messaging, Multimode Option

LG 8979, SES-92, IEEE C37.118, Link Budget: 11 dB

IEC 61850 MMS, IEC 60870-5-101/104,

FTP, SFTP, CDC Type II, Ethernet/IP Min. TX Power: –20 dBm

Implicit Message Adapter

Min. RX Sensitivity: –31 dBm

Peer-to-Peer: SEL MIRRORED BITS Communications,

Fiber Size: 50–200 µm

IEC 61850 GOOSE, Network Global

Variables (NGVL), Parallel Redundancy Approximate Range: 2 km

Protocol

Data Rate: 100 Mbps

Fieldbus: EtherCAT Client (in RTAC), EtherCAT

Server (I/O modules) Typical Fiber Attenuation: –2 dB/km

Engineering Access Single-Mode Option

Modes: SEL Interleaved, Direct Link Budget: 10 dB

Port Server: Map Serial Ports to IP Ports Min. TX Power: –15 dBm

Secure Web Server: Diagnostic and Communications Data Min. RX Sensitivity: –25 dBm

Fiber Size: 9 µm

Time-Code Input (Modulated IRIG-B)

Approximate Range: 15 km

Input Impedance: 2 kΩ

Data Rate: 100 Mbps

Accuracy: 500 µs

Typical Fiber Attenuation: –0.4 dB/km

Time-Code Input (Demodulated IRIG-B) Serial Ports

On (1) State: Vih > 2.2 V Ports: 4

Off (0) State: Vil < 0.8 V Types: EIA-232/EIA-485 (software selectable)

Input Impedance: 2 kΩ Data Rate: 300 to 115,200 bps

Accuracy: 500 ns Connector: DB-9 Female

Time-Code Output (IRIG-B) Time Synchronization: IRIG-B

On (1) State: Voh > 2.4 V Power: +5 Vdc power on Pin 1 (500 mA maximum

per SEL-2241)

Off (0) State: Vol < 0.8 V

USB Device Ports

Load: 50 Ω

1 Type B

Network Time Protocol (NTP) Modes

Output (SEL-2241 RTAC)

NTP Client: As many as three configurable servers

NTP Server

Mechanical Durability

10 M no-load operations

Simple Network Time Protocol (SNTP) Accuracy

DC Output Ratings

±1 ms: This does not take into account external

factors such as network switches and Rated Operational Voltage: 250 Vdc

topologies Rated Voltage Range: 19.2–275 Vdc

Precise Time Protocol (PTP) Rated Insulation Voltage: 300 Vdc

PTP Client: Peer delay request and end-to-end path Make: 30 A @ 250 Vdc per IEEE C37.90

delay supported

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

29

Continuous Carry: 6 A @ 70°C; 4 A @ 85°C Optical Connector Type

Thermal: 50 A for 1 s LC

Contact Protection: 360 Vdc, 40 J MOV Multimode Option

Operating Time (Coil Link Budget: 11 dB

Energization to Contact

Closure, Resistive Load): Pickup/Dropout time ≤8 ms typical Min. TX Power: –20 dBm

Breaking Capacity (10,000 24 Vdc 0.75 A L/R = 40 ms Min. RX Sensitivity: –31 dBm

Operations) Per 48 Vdc 0.50 A L/R = 40 ms Fiber Size: 50–200 µm

IEC 60255-0-20:1974: 125 Vdc 0.30 A L/R = 40 ms

250 Vdc 0.20 A L/R = 40 ms Approximate Range: 2 km

Cyclic Capacity 24 Vdc 0.75 A L/R = 40 ms Data Rate: 100 Mbps

(2.5 Cycles/Second) Per 48 Vdc 0.50 A L/R = 40 ms Typical Fiber Attenuation: –2 dB/km

IEC 60255-0-20:1974: 125 Vdc 0.30 A L/R = 40 ms

250 Vdc 0.20 A L/R = 40 ms Single-Mode Option

AC Output Ratings Link Budget: 10 dB

Rated Operational Voltage: 240 Vac Min. TX Power: –15 dBm

Rated Insulation Voltage: 300 Vac Min. RX Sensitivity: –25 dBm

Utilization Category: AC-15 (control of electromagnetic loads Fiber Size: 9 µm

> 72 VA) Approximate Range: 15 km

Contact Rating B300 (B = 5 A, 300 = rated insulation Data Rate: 100 Mbps

Designation: voltage)

Typical Fiber Attenuation: –0.4 dB/km

Contact Protection: 270 Vac, 40 J

Power Supply

Continuous Carry: 3 A @ 120 Vac

1.5 A @ 240 Vac AC Input Voltage (High-Voltage Model)

Conventional Enclosed Note: Single phase.

Thermal Current (Ithe)

Rating: 5A Nominal Supply Voltage: 120–240 Vac, 50–60 Hz

Rated Frequency: 50/60 ± 5 Hz Operational Voltage

Range: 85–264 Vac, 40–70 Hz

Operating Time (Coil

Energization to Contact DC Input Voltage (High-Voltage Model)

Closure, Resistive Load): Pickup/Dropout time < 8 ms typical Nominal Supply Voltage: 125–250 Vdc

Electrical Durability Make Operational Voltage

VA Rating: 3600 VA, cosø = 0.3 Range: 85–300 Vdc

Electrical Durability Break DC Input Voltage (Low-Voltage Model)

VA Rating: 360 VA, cosø = 0.3

Nominal Supply Voltage: 24–48 Vdc

Backplane (SEL-2242) Operational Voltage

Ethernet Port Range: 19.1–57.6 Vdc polarity-dependent

Note: UL operational voltage range is equal to the nominal voltage range ±10

Port: 1

percent.

Data Rate: 10/100 Mbps

Fuse Rating

Connector: RJ45 Female

High-Voltage Model, F1: 3.15 A, high breaking capacity, time lag T,

Protocol: Engineering Access 250 V (5x20 mm, T3.15AH 250 V)

Note: SEL-2242 Ethernet port is included with the optional touchscreen, High-Voltage Model, F2 8 A, high breaking capacity, time lag T,

10-slot model only. (Non-Serviceable): 60 Vdc (2.7x6.1 mm, T8A 60 Vdc)

Fuse Rating Low-Voltage Model: 6.30 A, high breaking capacity, time lag T,

250 V (5x20 mm, T6.3AH 250 V)

Non-Serviceable: 2.5 A, 125 V, time lag T

Power Consumption: See Table 14 for power per module.

Power Coupler (SEL-2243) Maximum AC Burden: 160 VA

EtherCAT Ports Maximum DC Burden: 75 W

Ports: 2 Interruptions: 30 ms @ 24 Vdc

Data Rate: Automatic 130 ms @ 48 Vdc

50 ms @ 125 Vac/Vdc

Connector: RJ45 Female or LC Fiber 100 ms @ 250 Vac/Vdc

Protocols: Dedicated EtherCAT

RJ45 Ports

Cable Length: <3 m

Fiber-Optic Ports (Class 1 LASER/LED)

Wavelength

1300 nm

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

30

The following exceptions for the IEC 61850-3 acceptance criteria for Input Thermal Derating

normal equipment functioning regarding ac power dips and

interruptions and dc voltage dips are applicable (refer to IEC 61850- SEL-2244-2 Digital Input Derating Curve

3 subclause 7.5.5, Equipment functioning, and 7.5.6, Exceptions).

Power Supply Requirement Exceptiona

125 Vac 5 cycles 50 ms

(83,33 ms @ 60 Hz,

100 ms @ 50 Hz)

50 cycles Not applicableb

a

Voltage interruptions that are longer than the specified

interruption duration result in a device restart.

b

Equipment is not intended to be connected to power supply

ports that are directly connected to a public low-voltage

Control Outputs (SEL-2244-3 Standard Contacts)

power supply network. Mechanical Durability

Max Inrush: 17 A 10 M no-load operations

Isolation: 3100 Vdc DC Output Ratings

Redundant Installation: Each node may have one or two SEL-2243 Rated Operational Voltage: 250 Vdc

modules installed. When two are used,

they operate in load-sharing mode. Rated Voltage Range: 19.2–275 Vdc

Recommended External Overcurrent Protection Rated Insulation Voltage: 300 Vdc

Breaker Type: Standard Make: 30 A @ 250 Vdc per IEEE C37.90

Breaker Rating: 15 A or 20 A at 250 Vdc Continuous Carry: 6 A @ 70°C; 4 A @ 85°C

Current Breaking Capacity: 10 kA Continuous Carry

(UL/CSA Derating With

Grounded Neutral System: Device in series with the HOT or energized All Outputs Asserted): 5 A @ < 60°C; 2.5 A 60 to 70°C

conductor

Thermal: 50 A for 1 s

DC and Isolated Systems: Device in series with both conductors

Contact Protection: 350 Vdc, 145 J MOV protection across

Optoisolated Control Inputs (SEL-2244-2) open contacts

Operating Time (Coil

When Used With DC Control Signals:

Energization to Contact

250 Vdc ON for 200–275 Vdc OFF below 150 Vdc Closure, Resistive Load): Pickup/Dropout time ≤ 8 ms typical

220 Vdc ON for 176–242 Vdc OFF below 132 Vdc Breaking Capacity (10,000 24 Vdc 0.75 A L/R = 40 ms

125 Vdc ON for 100–135.5 Vdc OFF below 75 Vdc Operations) Per 48 Vdc 0.50 A L/R = 40 ms

110 Vdc ON for 88–121 Vdc OFF below 66 Vdc IEC 60255-0-20:1974: 125 Vdc 0.30 A L/R = 40 ms

48 Vdc ON for 38.4–52.8 Vdc OFF below 28.8 Vdc 250 Vdc 0.20 A L/R = 40 ms

24 Vdc ON for 15–30 Vdc OFF for < 10 Vdc Cyclic Capacity 24 Vdc 0.75 A L/R = 40 ms

(2.5 Cycles/Second) Per 48 Vdc 0.50 A L/R = 40 ms

When Used With AC Control Signals: IEC 60255-0-20:1974: 125 Vdc 0.30 A L/R = 40 ms

250 Vdc ON for 170.6–300 Vac OFF below 106 Vac 250 Vdc 0.20 A L/R = 40 ms

220 Vdc ON for 150.3–264 Vac OFF below 93.2 Vac AC Output Ratings

125 Vdc ON for 85–150 Vac OFF below 53 Vac

Rated Operational Voltage: 240 Vac

110 Vdc ON for 75.1–132 Vac OFF below 46.6 Vac

48 Vdc ON for 32.8–60 Vac OFF below 20.3 Vac Rated Insulation Voltage

(Excluding EN 61010-1): 300 Vac

24 Vdc ON for 14–27 Vac OFF for < 5 Vac

Utilization Category: AC-15 (control of electromagnetic

Burden/Current Draw at

loads > 72 VA)

Nominal DC Voltage: 2–6 mA (Except for 24 V, 8 mA)

Contact Rating B300 (B = 5 A, 300 = rated insulation

Rated Insulation Voltage: 300 Vac

Designation: voltage)

Rated Impulse Withstand

Contact Protection: 250 Vac, 145 J

Voltage (Uimp): 4000 V

Continuous Carry: 3 A @ 120 Vac

1.5 A @ 240 Vac

Conventional Enclosed

Thermal Current (Ithe)

Rating: 5A

Rated Frequency: 50/60 ±5 Hz

Operating Time (Coil

Energization to Contact

Closure, Resistive Load): Pickup/Dropout time <8 ms typical

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

31

Electrical Durability Make DC Transducer (Analog) Inputs (SEL-2245-2)

VA Rating: 3600 VA, cosø = 0.3

Electrical Durability Break Input Impedance

VA Rating: 360 VA, cosø = 0.3 Current Mode: 200 Ω for ±20 mA

5000 Ω for ±2 mA

Control Outputs (SEL-2244-5 Fast High-Current Contacts)

Voltage Mode: 10 MΩ

Mechanical Durability

Input Range (Maximum)

10 M no-load operations

±20 mA (transducers: 4–20 mA or 0–20 mA typical)

DC Output Ratings ±2 mA (transducers: 0–1 mA or 0–2 mA typical)

±10 V (transducers: 0–5 V or 0–10 V typical)

Rated Operational Voltage: 250 Vdc

Rated Voltage Range: 19.2–275 Vdc

Sampling Rate

Rated Insulation Voltage: 300 Vdc 1 ksps

Make: 30 A @ 250 Vdc per IEEE C37.90 Anti-Alias Filter

Continuous Carry: 6 A @ 70°C; 4 A @ 85°C Corner Frequency: 330 Hz

Continuous Carry Rolloff: 20 dBV per decade

(UL/CSA Derating With

Digital Filter

All Outputs Asserted): 5 A @ < 60°C; 2.5 A 60 to 70°C

Corner Frequency: Filter A: 16 Hz

Thermal: 50 A for 1 s

Filter B: 10 Hz

Contact Protection: 330 Vdc, 145 J MOV protection across Filter C: 0.2 Hz

open contacts

50 Hz Rejection: Filter A: > 30 dB

Operating Time (Coil Energization to Contact Closure, Resistive Load) Filter B: > 50 dB

Filter C: > 70 dB

Pickup Time: ≤12 µs at 250 Vdc, 16 µs at 125 Vdc,

65 µs at 19.2 Vdc typical (results with 60 Hz Rejection: Filter A: > 60 dB

100 kΩ resistive load) Filter B: > 70 dB

Filter C: > 70 dB

Dropout Time: ≤ 8 ms typical

Step Response

Inductive Breaking 24 Vdc 10 A L/R = 40 ms

Capacity (10,000 48 Vdc 10 A L/R = 40 ms No Filter: 3 ms (10%–90% response)

Operations) Per 125 Vdc 10 A L/R = 40 ms

IEC 60255-0-20:1974: 250 Vdc 10 A L/R = 20 ms Filter A: 23 ms (10%–90% response)

Cyclic Capacity Filter B: 35 ms (10%–90% response)

(4 Cycles/Second 24 Vdc 10 A L/R = 40 ms Filter C: 700 ms (10%–90% response)

Followed by 2 Min Idle 48 Vdc 10 A L/R = 40 ms

Thermal Dissipation) Per 125 Vdc 10 A L/R = 40 ms Common Mode Range

IEC 60255-0-20:1974: 250 Vdc 10 A L/R = 20 ms

±35 Vdc between separate inputs

AC Output Ratings ±250 Vdc all inputs to chassis

Rated Operational Voltage: 110/120/220/240 Vac Isolation

Voltage Range: 19.2–250 Vac 500 Vac between inputs

2000 Vac all inputs to chassis

Rated Insulation Voltage: 250 Vac

Make: 30 A @ 240 Vac Accuracy at 25°C

Continuous Carry: 6 A @ 70°C; 4 A @ 85°C ADC: 16 bit

Continuous Carry Voltage Inputs (±10 V): 0.25% of full scale typical

(UL/CSA Derating With 0.05% with field calibration

All Outputs Asserted): 5 A @ < 60°C; 2.5 A @ 60° to 70°C 2% of full-scale maximum

Thermal: 50 A for 1 s High Current Inputs 0.5% of full scale typical

(±20 mA): 0.1% with field calibration

Contact Protection: 250 Vac, 145 J MOV protection across 2% of full-scale maximum

open contacts

Low Current Inputs 0.5% of full scale typical

Operating Time (Coil Energization to Contact Closure, Resistive Load) (±2 mA): 0.1% with field calibration

Pickup Time: ≤12 µs at 250 Vac, 16 µs at 125 Vac, 4% of full-scale maximum

65 µs at 19.2 Vac typical (results with

100 kΩ resistive load)

Accuracy Variation With Temperature

Dropout Time: ≤ 8 ms typical Inputs: ±0.015% per °C of full scale

(±20 mA, ±2 mA, or ±10 V)

Note: Per IEC 60255-23:1994, using the simplified method of

assessment. ADC: ±0.004% per °C

Note: Make rating per IEEE C37.90-1989.

Triggered Waveform Recording

Fuse Rating

Sampling Rate: 1 kHz

Non-Serviceable: 4 A, 450 V, medium time lag M

Record Duration: 0.1 second increments from 0.5 s to 144 s

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

32

Record Pre-Trigger: 0.05 s minimum to a maximum of (record DC Analog Outputs (SEL-2245-3)

length minus 0.05 s)

Waveform File Format: COMTRADE (IEEE C37.111-1999 Current Mode

compliant) Output Range: –20.48 to +20.48 mA

DC Analog Inputs Extended Range (SEL-2245-22 in DC Load Impedance: 0–750 Ω @ 20 mA, 100 µH

Mode) Voltage Mode

Input Impedance Output Range: –10.24 to +10.24 volts

>7 MΩ Load Impedance: >2000 Ω , 1 µF

Input Range (Maximum) Step Response

0–300 V 1 ms (10%–90% response typical)

Sampling Rate Isolation

24 ksps 2000 Vdc between outputs or ground

Anti-Alias Filter Accuracy at 25°C (Outputs)

Corner Frequency: 5 kHz Current Mode: ± 0.3% of full scale typical

± 3% of full-scale worst case (average during

Rolloff: 20 dB per decade

an EMI event over a 1-second period)

Digital Filter Voltage Mode: ± 0.2% of full scale typical

Corner Frequency: Filter A: 16 Hz ± 2% of full-scale worst case (average during

Filter B: 10 Hz an EMI event over a 1-second period)

Filter C: 0.2 Hz Accuracy Variation With Temperature (Outputs)

50 Hz Rejection: Filter A: > 30 dB

±0.01% of full-scale/°K (current or voltage mode)

Filter B: > 50 dB

Filter C: > 70 dB

AC Metering Inputs(SEL-2245-4,SEL-2245-411,SEL-2245-221,

60 Hz Rejection: Filter A: > 60 dB and SEL-2245-22 Voltage Inputs in AC Mode)

Filter B: > 70 dB

Filter C: > 70 dB Frequency: 50/60 Hz

Step Response Range: 45–65 Hz

Group Delay (Pre-Filter): 5.3 ms Typical Accuracy

No Filter: 3 ms (10%–90% response) SEL-2245-4 and

SEL-2245-22: ± 0.005 Hz above 20 V

Filter A: 23 ms (10%–90% response)

SEL-2245-411 and

Filter B: 35 ms (10%–90% response) SEL-2245-221: ± 0.005 Hz above 500 mV

Filter C: 700 ms (10%–90% response) Worst-Case Accuracy

Common Mode Range SEL-2245-4 and

SEL-2245-22: ± 0.01 Hz above 20 V

±250 Vdc between separate inputs

±250 Vac all inputs to chassis SEL-2245-411 and

SEL-2245-221: ± 0.01 Hz above 500 mV

Isolation

Phase Rotation: ABC, ACB

2500 Vrms between separate inputs

2500 Vrms all inputs to chassis Input Configuration: 3-Wire Delta, 4-Wire Wye

Accuracy at 25°C Update Interval

ADC: 16 bit Fundamental Metering: 200 Hz

Inputs: 0.25% of full scale typical RMS Metering: 5 Hz

3% of full scale worst case Current Inputs Phase and Neutral

Accuracy Variation With Temperature (Inputs) INOM: 1 A or 5 A (no setting required)

±0.015% per °C of full scale Measurement Range: 0.050–22 A Continuous

22–100 A Symmetrical for 25 s

Triggered Waveform Recording

Thermal Withstand Limit: 500 A for 1 s

Sampling Rate: 1, 2, 4, 8, 24 kHz

Typical Accuracy: ± 0.1% Fundamental @ fNOM and > 0.6 A

Record Duration: 0.1 second increments from 0.5 s to 144 s ± 0.1% RMS @ fNOM and > 0.6 A

Record Pre-Trigger: 0.05 s minimum to a maximum of (record Worst-Case Accuracy: ± 2% ± 0.005 A Fundamental

length minus 0.05 s) ± 1% ± 0.005 A RMS

Waveform File Format: COMTRADE (IEEE C37.111-1999 Angle

compliant)

Range: ± 180°

Typical Accuracy: ± 0.1° Fundamental @ fNOM and > 0.6 A

Worst-Case Accuracy: ± 2° @ fNOM

Burden: < 0.1 VA @ INOM

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

33

Voltage Inputs (SEL-2245-4 and SEL-2245-22 in AC Mode) Power and Power Factor Per Phase and Three-Phase (SEL-2245-411)

VNOM: 300 V PA, PB, PC, 3P

Measurement Range: 5–400 L-N, 9–693 L-L Vac Typical Accuracy: 0.1% @ PF ≥ 0.5

Fundamental/RMS

5–300 L-N, 9–520 L-L Vac Worst-Case Accuracy: 2%

Fundamental/RMS (UL) QA, QB, QC, 3Q

Maximum: 600 L-N, 1039 L-L Vac Fundamental/RMS Typical Accuracy: 0.1% @ PF ≤ 0.98

for 10 s

Worst-Case Accuracy: 2%

Typical Accuracy: ±0. 1% Fundamental @ fNOM and > 20 V

± 0.1% RMS@ fNOM SA, SB, SC, 3S

Worst-Case Accuracy: ±2% Fundamental @ fNOM Typical Accuracy: 0.1%

±1% RMS plus ±0.05 V Worst-Case Accuracy: 2%

Angle PFA, PFB, PFC, 3PF

Range: ±180° Typical Accuracy: 0.1% @ Unity PF

Typical Accuracy: ±0.1° @ fNOM and >20 V Worst-Case Accuracy: 2%

Worst-Case Accuracy: ±2° @ fNOM

Synchrophasor

Burden: < 0.1 VA

Conformance: IEEE C37.118.1-2011 as amended by

LEA Voltage Inputs (SEL-2245-411 and SEL-2245-221 IEEE C37.118.1a-2014

IEEE C37.118.2-2011

VNOM: 1.5 V

Accuracy: Level 1 as specified by IEEE C37.118

Measurement Range: 30 Vac peak

0.05–22 Vac RMS Measurements: Software selectable (P or M class)

Maximum: 300 VL-N RMS for 10 s (surge) Voltage: VA, VB, VC, VS

Typical Accuracy: ± 0. 1% RMS@ fNOM and >50 mV Current: IA, IB, IC, IN

± 0.1% Fundamental @ fNOM and >50 mV Positive-Sequence: V1, I1

Worst-Case Accuracy: ± 3% ±1 mV @ fNOM Fundamental/RMS Periodic: Frequency and df/dt

Angle Processing Rate: 120 Hz

Range: ± 180° Message Rates 1, 2, 4, 5, 10, 12, 15, 20, 30, 60, and 120*

Typical Accuracy: ± 0.1° @ fNOM and > 50 mV (60 Hz nominal): (messages/second)

Worst-Case Accuracy: ± 2° @ fNOM Message Rates 1, 2, 5, 10, 25, 50, and 100*

(50 Hz nominal): (messages/second)

Burden: < 0.1 VA

* This message rate is only supported on the SEL-2245-4 and SEL-2245-411

Sequence Components (SEL-2245-4) Axion modules and requires an SEL-3350, SEL-3555, or SEL-3560 RTAC.

Values: I0, I1, I2, V0, V1, V2 Triggered Waveform Recording (SEL-2245-4, SEL-2245-411,

SEL-2245-22, and SEL-2245-221)

Typical Accuracy

Sampling Rates: 1, 2, 4, 8, 24 kHz software selectable

Magnitude: ± 0.2% @ fNOM and V > 6.7 V, I > 0.6 A

Record Duration: 0.1 second increments from 0.5 s to

Angle: ± 0.2° @ fNOM and V > 6.7 V, I > 0.6 A

specified maximum for each sample rate.

Worst-Case Accuracy

Maximum Record 6 s @ 24 kHz

Magnitude: ±3% @ fNOM and V > 6.7 V, I > 0.6 A Duration: 18 s @ 8 kHz

36 s @ 4 kHz

Angle: ± 0.2° @ fNOM and V > 6.7 V, I > 0.6 A 72 s @ 2 kHz

Power and Power Factor Per Phase and Three-Phase (SEL-2245-4) 144 s @ 1 kHz

PA, PB, PC, 3P Record Pre-Trigger: 0.05 s minimum to a maximum of (record

length minus 0.05 s)

Typical Accuracy: 0.1% @ PF > 0.1

Waveform File Format: COMTRADE (IEEE C37.111-1999

Worst-Case Accuracy: 2% compliant)

QA, QB, QC, 3Q AC Protection Inputs (SEL-2245-42)

Typical Accuracy: 0.1% @ PF < 0.9

Frequency

Worst-Case Accuracy: 2%

Rated: 50/60 Hz

SA, SB, SC, 3S

Range: 40–90 Hz

Typical Accuracy: 0.1%

Typical Accuracy: ± 0.005 Hz above 20 V

Worst-Case Accuracy: 2%

Worst-Case Accuracy: ± 0.01 Hz above 20 V (±0.1 Hz for < 2.5

PFA, PFB, PFC, 3PF cycles during transients)

Typical Accuracy: 0.1% @ PF > 0.1 Phase Rotation

Worst-Case Accuracy: 2% ABC, ACB

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

34

Input Configuration Power and Power Factor (Per-Phase and Three-Phase)

3-Wire Delta, 4-Wire Wye Values: PA, PB, PC, PAB, PBC, PCA

QA, QB, QC, QAB, QAC, QCA

Update Interval SA, SB, SC, SAB, SBC, SCA

Fundamental Metering: 250 Hz PFA, PFB, PFC, P3, Q3, S3, PF3

RMS Metering: 250 Hz Accuracy: ±1%, typical

RMS Window Size: 1 cycle THD and Noise (Accuracy)

AC Current Channels ±5% of measurement plus ±0.25%

Nominal Current: 1 ARMS or 5 ARMS (no setting required) Synchrophasors

Current Range Rating Conformance: IEEE C37.118.1-2011 as amended by

(With DC Offset at IEEE C37.118.1a-2014

X/R = 10, 1.5 Cycles): 0.1–91 A IEEE C37.118.2-2011

Operational Range: 0.1–300 ARMS Accuracy: Level 1 as specified by IEEE C37.118

Measurement Range: 0.1–20 ARMS Measurements: Software selectable (P or M Class)

Thermal Withstand Limit: 15 ARMS continuous Voltage: VA, VB, VC

500 ARMS for one second Current: IA, IB, IC

Fundamental Measurement Accuracy Positive-Sequence: V1, I1

Magnitude: ±0.1%, typical, ±0.001 A Periodic: Frequency and df/dt

±2%, worst case, ±0.001 A

Processing Rate: 120 Hz

Phase: ±0.1°, typical at fNOM and current > 0.4 A

±1°, over full rated temperature range Message Rates (60 Hz 1, 2, 4, 5, 10, 12, 15, 20, 30, 60, and 120*

±2°, worst case nominal): (messages/second)

RMS Measurement Accuracy Message Rates (50 Hz 1, 2, 5, 10, 25, 50, and 100*

nominal): (messages/second)

Magnitude: ±0.1%, typical, ±0.001 A

±2%, worst case, ±0.001 A * Message rates are supported on the SEL-3350, SEL-3555, and SEL-3560.

Burden: <0.1 VA Triggered Waveform Recording

AC Voltage Channels Sampling Rates: 1, 2, 4, 8, 24 kHz software selectable

Rated Range: 67–240 VL-N Transient Fault Record Length

Note: Rated Range refers to the IEEE C37.118 rating system. Individual Records as 24 s for 24 kHz

Long as: 72 s for 8 kHz

Operational Range: 0–300 VL-N 144 s for 4 kHz

Accuracy Range: 6.7–300 VL-N 288 s for 2 kHz

576 s for 1 kHz

Rated Insulation Voltage: 300 VL-N continuous

600 VL-N for ten seconds Pre-Fault Time: 0.05 s to (max. event length – 0.05 s)

Isolation (Galvanic Isolated Channels) Data Format: IEEE C37.111-2013 COMTRADE

Channel-to-Ground: 2.5 kVRMS for one minute File Naming: IEEE C37.232 COMNAME

Channel-to-Channel: 2.5 kVRMS for one minute Fuse Rating

Fundamental Measurement Accuracy Non-Serviceable: 2.5 A, 125 V, time lag T

Magnitude: ±0.1%, typical, plus ±0.05 V

±3%, worst case, plus ±0.05 V

Phase: ±0.1° @ fNOM, typical

±1° @ fNOM, over full rated temperature

range

±2° @ fNOM, worst case

RMS Measurement Accuracy

Magnitude: ±0.1%, typical, plus ±0.05 V

±3%, worst case, plus ±0.05 V

Burden: <0.01 VA @ 67 V

Impedance >500 kΩ

Sequence Components

Values: I0, I1, I2, V0, V1, V2

Note: Sequence components are of the fundamental frequency.

Accuracy

Magnitude: ±1%, typical

Angle: ±0.5°, typical

SEL-2240 Data Sheet Schweitzer Engineering Laboratories, Inc.

35

Technical Support

We appreciate your interest in SEL products and services. If you have questions or comments, please contact us at:

Schweitzer Engineering Laboratories, Inc.

2350 NE Hopkins Court

Pullman, WA 99163-5603 U.S.A.

Tel: +1.509.338.3838

Fax: +1.509.332.7990

Internet: selinc.com/support

Email: info@selinc.com

Schweitzer Engineering Laboratories, Inc. SEL-2240 Data Sheet

36

© 2021–2024 by Schweitzer Engineering Laboratories, Inc. All rights reserved.

All brand or product names appearing in this document are the trademark or registered 2350 NE Hopkins Court • Pullman, WA 99163-5603 U.S.A.

trademark of their respective holders. No SEL trademarks may be used without written Tel: +1.509.332.1890 • Fax: +1.509.332.7990

permission. SEL products appearing in this document may be covered by U.S. and Foreign

selinc.com • info@selinc.com

patents.

Schweitzer Engineering Laboratories, Inc. reserves all rights and benefits afforded under

federal and international copyright and patent laws in its products, including without lim-

itation software, firmware, and documentation.

The information in this document is provided for informational use only and is subject to

change without notice. Schweitzer Engineering Laboratories, Inc. has approved only the

English language document.

*PDS2240-01*

This product is covered by the standard SEL 10-year warranty. For warranty details, visit

selinc.com or contact your customer service representative.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

SEL-2240 Data Sheet Date Code 20240419

You might also like

- IEC 104 and 61850 TrainingDocument50 pagesIEC 104 and 61850 Trainingdien.ledien2000hNo ratings yet

- Az 104 PDFDocument24 pagesAz 104 PDFJohnsonNo ratings yet

- Gateway ProConOSDocument32 pagesGateway ProConOSNorbertoNo ratings yet

- SEL-2240 Axion: Modular Real-Time Automation ControllerDocument16 pagesSEL-2240 Axion: Modular Real-Time Automation ControllerJulian Pineda100% (1)

- Moxa - 2012 Master CatalogDocument660 pagesMoxa - 2012 Master CatalogQuantumAutomationNo ratings yet

- Setting Up Remote Access To Intouch: Maury BeckDocument32 pagesSetting Up Remote Access To Intouch: Maury BeckHalilNo ratings yet

- Digsi 4: DIGSI Is Talking XMLDocument72 pagesDigsi 4: DIGSI Is Talking XMLAlfredo RisueñoNo ratings yet

- 2 - HMI SCADA RoadmapForBalticsDocument37 pages2 - HMI SCADA RoadmapForBalticsguy426No ratings yet

- SYS600 - Modbus Master ProtocolDocument70 pagesSYS600 - Modbus Master ProtocolAbhijit JNo ratings yet

- Monitoring of Ethernet Messages: IEC 61850 SeminarDocument36 pagesMonitoring of Ethernet Messages: IEC 61850 SeminarIDI EnergyNo ratings yet

- SE WhitePaper Letter DNP3 v6Document11 pagesSE WhitePaper Letter DNP3 v6Vic BaltNo ratings yet

- Chapter7 - Remote Access ServicesDocument18 pagesChapter7 - Remote Access ServicesPhi NamNo ratings yet

- SIPROTEC 5 Application Note: SIP5-APN-013: Teleprotection Scheme With SIPROTEC 5 Devices Edition 2012-04-10Document12 pagesSIPROTEC 5 Application Note: SIP5-APN-013: Teleprotection Scheme With SIPROTEC 5 Devices Edition 2012-04-10gustavoNo ratings yet

- BOM RTU560 General Day1Document107 pagesBOM RTU560 General Day1SALVADORNo ratings yet

- FST Dfs Dnp3 EthernetDocument4 pagesFST Dfs Dnp3 EthernetEric DunnNo ratings yet

- Understanding The Modbus ProtocolDocument5 pagesUnderstanding The Modbus ProtocolsatishNo ratings yet

- Document of AB SoftwareDocument84 pagesDocument of AB SoftwareJosePerezNo ratings yet

- J Regulatory Control Function PDFDocument22 pagesJ Regulatory Control Function PDFDinar LubisNo ratings yet

- ? Protection Testing Series - Practical Examples of UseDocument72 pages? Protection Testing Series - Practical Examples of UseMohamed Tayre100% (1)

- Pelco Migration Guide: Expanded Recording CapabilitiesDocument8 pagesPelco Migration Guide: Expanded Recording CapabilitiesLuis SamaniegoNo ratings yet

- Siprotec PRP HSR v1 ProfileDocument2 pagesSiprotec PRP HSR v1 Profilejunaid_libraNo ratings yet

- GS 85a7c01-16en007Document10 pagesGS 85a7c01-16en007zhang012mike0727No ratings yet

- SYS600 Status CodesDocument196 pagesSYS600 Status CodesAbhijit JNo ratings yet

- Chapter1 - Active DirectoryDocument74 pagesChapter1 - Active DirectoryjustmquanNo ratings yet

- Easergy MiCOM Px30-Px40 - Catalog 2020 - NRJCAT19835EN - 180920Document28 pagesEasergy MiCOM Px30-Px40 - Catalog 2020 - NRJCAT19835EN - 180920Дима КрипулевичNo ratings yet

- Test Suite - DIGSI5Document12 pagesTest Suite - DIGSI5Matija KosNo ratings yet

- 6MU805 Manual A5 V040303 UsDocument162 pages6MU805 Manual A5 V040303 UsNoppadolRojsakthavornNo ratings yet

- Pelco VideoXpert Enterprise V 3.8Document10 pagesPelco VideoXpert Enterprise V 3.8Fazz YaakubNo ratings yet

- Chapter1 - Active DirectoryDocument19 pagesChapter1 - Active Directoryvanconghao041002No ratings yet

- Introduction of DNP3.0 ProtocolDocument13 pagesIntroduction of DNP3.0 ProtocolXIONGNo ratings yet

- 5 - Traffic Generation of Iec 61850 Sample ValueDocument6 pages5 - Traffic Generation of Iec 61850 Sample Valuerodrigocomunian1No ratings yet

- Principles of NetworkingDocument57 pagesPrinciples of Networkingscoffy shaNo ratings yet

- Catalog Moxa Master Catalog 2016Document880 pagesCatalog Moxa Master Catalog 2016pasikx2No ratings yet

- Fieldbus-An Introduction - PpsDocument85 pagesFieldbus-An Introduction - Ppsdanghoang1987No ratings yet

- Zenon Batch ControlDocument2 pagesZenon Batch ControlrobertharrisonNo ratings yet

- Ethernet I/P Best Practices & TopologiesDocument68 pagesEthernet I/P Best Practices & TopologiesmeledathNo ratings yet

- KW Multiprog QuickstartDocument76 pagesKW Multiprog QuickstartRafaelNo ratings yet

- SCL Config Microgrid Final PDFDocument9 pagesSCL Config Microgrid Final PDFFerreira CarlosNo ratings yet

- Archestra System Platform 2012 R2 With Intouch 2012 R2 Getting Started GuideDocument68 pagesArchestra System Platform 2012 R2 With Intouch 2012 R2 Getting Started GuideMuhammad IbrahimNo ratings yet

- Scada RtuDocument7 pagesScada RtuBộ Môn DieuKhienhocNo ratings yet

- Husky Brochure-Web PDFDocument31 pagesHusky Brochure-Web PDFhiralalnhpcNo ratings yet

- Day 3 - 10.45 - 12.15 Reydisp Manager IEC61850 Practical - Part 3Document83 pagesDay 3 - 10.45 - 12.15 Reydisp Manager IEC61850 Practical - Part 3ginot_7No ratings yet

- Reyrolle 7SR10 Platform: Protecting Grid With ConfidenceDocument48 pagesReyrolle 7SR10 Platform: Protecting Grid With ConfidenceKunjan DalwadiNo ratings yet

- Easergy Studio V9.2.0 Release Notes: Note #14Document8 pagesEasergy Studio V9.2.0 Release Notes: Note #14Abdenour YahiNo ratings yet

- SYS600 - Modbus Slave ProtocolDocument58 pagesSYS600 - Modbus Slave ProtocolJOSENo ratings yet

- IEC 61850 Server Configuration Tool Users GuideDocument136 pagesIEC 61850 Server Configuration Tool Users GuideJuan PavezNo ratings yet

- 04.licenciamiento Del MicroSCADADocument10 pages04.licenciamiento Del MicroSCADALiz Victoria Bautista CardenasNo ratings yet

- SYS600 - Programming Language SCIL PDFDocument394 pagesSYS600 - Programming Language SCIL PDFAnonymous 9VcxlFErfNo ratings yet

- Moxa Tech Note - Using DNP3 With The NPort SeriesDocument11 pagesMoxa Tech Note - Using DNP3 With The NPort SeriesDarshan SunnyNo ratings yet

- Chapter6 - DNS v2Document11 pagesChapter6 - DNS v2Phan Minh TríNo ratings yet

- Ge Cimplicity: Installation Checklist Document Release Date: March 26, 2019Document21 pagesGe Cimplicity: Installation Checklist Document Release Date: March 26, 2019farabbNo ratings yet