WSDOT Errata To FOP For AASHTO T 335: Determining The Percentage of Fracture in Coarse Aggregate

WSDOT Errata To FOP For AASHTO T 335: Determining The Percentage of Fracture in Coarse Aggregate

Uploaded by

ryann mananquilCopyright:

Available Formats

WSDOT Errata To FOP For AASHTO T 335: Determining The Percentage of Fracture in Coarse Aggregate

WSDOT Errata To FOP For AASHTO T 335: Determining The Percentage of Fracture in Coarse Aggregate

Uploaded by

ryann mananquilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

WSDOT Errata To FOP For AASHTO T 335: Determining The Percentage of Fracture in Coarse Aggregate

WSDOT Errata To FOP For AASHTO T 335: Determining The Percentage of Fracture in Coarse Aggregate

Uploaded by

ryann mananquilCopyright:

Available Formats

WSDOT Errata to FOP for AASHTO T 335

Determining the Percentage of Fracture in Coarse Aggregate

WAQTC FOP for AASHTO T 335 has been adopted by WSDOT with the following changes:

Sampling and Sample Preparation

3. Method 1 – Combined Fracture Determination

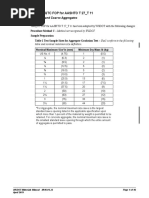

Table 1 Sample Size Method 1 (Combined Sieve Fracture) – Shall conform to the following table and

nominal maximum size definition.

TABLE 1

Sample Size

Method 1 (Combined Sieve Fracture)

Minimum Cumulative

Sample Mass

Nominal Retained on 4.75 mm

Maximum Size* (No. 4) Sieve

mm (in.) g (lb)

37.5 (1 1/2) 2500 (6)

25.0 (1) 1500 (3.5

19.0 (3/4) 1000 (2.5)

12.5 (1/2) 700 (1.5)

9.5 (3/8) 400 (0.9)

4.75 (No. 4) 200 (0.4)

*For Aggregate, the nominal maximum size sieve is the largest standard sieve opening listed in the

applicable specification upon which more than 1-percent of the material by weight is permitted to

be retained. For concrete aggregate, the nominal maximum size sieve is the smallest standard sieve

opening through which the entire amount of aggregate is permitted to pass.

4. Method 2 – Individual Sieve Fracture Determination – Method not recognized by WSDOT.

WSDOT Materials Manual M 46-01.44 Page 1 of 10

January 2024

T 335

Page 2 of 10 WSDOT Materials Manual M 46-01.44

January 2024

T 335

AGGREGATE WAQTC FOP AASHTO T 335 (23)

DETERMINING THE PERCENTAGE OF FRACTURE IN COARSE AGGREGATE

FOP FOR AASHTO T 335

Scope

This procedure covers the determination of the percentage, by mass, of a coarse aggregate

(CA) sample that consists of fractured particles meeting specified requirements in accordance

with AASHTO T 335-09.

In this FOP, a sample of aggregate is screened on the sieve separating CA and fine aggregate

(FA). This sieve will be identified in the agency’s specifications but might be the 4.75 mm

(No. 4) sieve. CA particles are visually evaluated to determine conformance to the specified

fractured criteria. The percentage of conforming particles, by mass, is calculated for

comparison to the specifications.

Apparatus

Balance or scale: Capacity sufficient for the principal sample mass, accurate to

0.1 percent of the sample mass or readable to 0.1 g and meeting the requirements of

AASHTO M 231.

Sieves: Meeting requirements of the FOP for AASHTO T 27/T 11.

Splitter: Meeting the requirements of FOP for AASHTO R 76.

Terminology

1. Fractured criteria: The specified requirement for fractured particles determined by each

agency.

2. Fractured face: An angular, rough, or broken surface of an aggregate particle created by

crushing or by other means. A face is considered a “fractured face” whenever one-half or

more of the projected area, when viewed normal to that face, is fractured with sharp and

well-defined edges. This excludes small nicks.

3. Fractured particle: A particle of aggregate having at least the minimum number of

fractured faces specified. (This is usually one or two.)

Sampling and Sample Preparation

1. Sample and reduce the aggregate in accordance with the FOPs for AASHTO R 90 and

R 76.

2. When the specifications list only a total fracture percentage, the sample shall be prepared

in accordance with Method 1. When the specifications require that the fracture be

counted and reported on each sieve, the sample shall be prepared in accordance with

Method 2.

3. Method 1 - Combined Fracture Determination

a. Dry and cool the sample, if necessary, to sufficiently obtain a clean separation of FA

and CA material in the sieving operation.

41_T335_short_23_errata Aggregate 13-1 Pub. October 2023

WSDOT Materials Manual M 46-01.44 Page 3 of 10

January 2024

T 335

AGGREGATE WAQTC FOP AASHTO T 335 (23)

b. Sieve the sample in accordance with the FOP for AASHTO T 27/ T 11 over

the 4.75 mm (No. 4) sieve, or the appropriate sieve listed in the agency’s

specifications for this material.

Note 1: Where necessary, wash the sample over the sieve designated for the determination of fractured

particles to remove any remaining fine material, and dry to a constant mass in accordance with the

FOP for AASHTO T 255.

c. Reduce the sample using Method A – Mechanical Splitter, in accordance with

the FOP for AASHTO R 76, to the appropriate test size. This test size should

be slightly larger than shown in Table 1, to account for loss of fines through

washing if necessary.

TABLE 1

Sample Size

Method 1 (Combined Sieve Fracture)

Minimum Cumulative

Nominal Sample Mass

Maximum Size* Retained on 4.75 mm

mm (in.) (No. 4) Sieve

g (lb)

37.5 (1 1/2) 2500 (6)

25.0 (1) 1500 (3.5

19.0 (3/4) 1000 (2.5)

12.5 (1/2) 700 (1.5)

9.5 (3/8) 400 (0.9)

4.75 (No. 4) 200 (0.4)

* One sieve larger than the first sieve to retain more than 10 percent of the material using an agency

specified set of sieves based on cumulative percent retained. Where large gaps in specification sieves exist,

intermediate sieve(s) may be inserted to determine nominal maximum size.

4. Method 2 – Individual Sieve Fracture Determination

a. Dry and cool the sample, if necessary, to sufficiently to obtain a clean separation of

FA and CA material in the sieving operation. A washed sample from the gradation

determination (the FOP for AASHTO T 27/T 11) may be used.

b. If not, sieve the sample in accordance with the FOP for AASHTO T 27 over the

sieves listed in the specifications for this material.

Note 2: If overload (buffer) sieves are used the material from that sieve must be added to the next

specification sieve.

c. The size of test sample for each sieve shall meet the minimum size shown in Table 2.

Utilize the total retained sieve mass or select a representative portion from each sieve

mass by splitting or quartering in accordance with the FOP for AASHTO R 76.

41_T335_short_23_errata Aggregate 13-2 Pub. October 2023

Page 4 of 10 WSDOT Materials Manual M 46-01.44

January 2024

T 335

AGGREGATE WAQTC FOP AASHTO T 335 (23)

Note 3: Where necessary, wash the sample over the sieves designated for the determination of fractured

particles to remove any remaining fine material, and dry to a constant mass in accordance with the

FOP for AASHTO T 255.

TABLE 2

Sample Size

Method 2 (Individual Sieve Fracture)

Minimum Sample

Sieve Size Mass

mm (in.) g (lb)

31.5 (1 1/4) 1500 (3.5)

25.0 (1) 1000 (2.2)

19.0 (3/4) 700 (1.5)

16.0 (5/8) 500 (1.0)

12.5 (1/2) 300 (0.7)

9.5 (3/8) 200 (0.5)

6.3 (1/4) 100 (0.2)

4.75 (No. 4) 100 (0.2)

2.36 (No. 8) 25 (0.1)

2.00 (No. 10) 25 (0.1)

Note 4: If fracture is determined on a sample obtained for gradation, use the mass retained on the individual

sieves, even if it is less than the minimum listed in Table 2. If less than 5 percent of the total mass is

retained on a single specification sieve, include that material on the next smaller specification sieve. If

a smaller specification sieve does not exist, this material shall not be included in the fracture

determination.

Procedure

1. After cooling, spread the dried sample on a clean, flat surface.

2. Examine each particle face and determine if the particle meets the fractured criteria.

3. Separate the sample into three categories:

Fractured particles meeting the criteria

Particles not meeting the criteria

Questionable or borderline particles

4. Determine the dry mass of particles in each category to the nearest 0.1 g.

5. Calculate the percent questionable particles to the nearest 1 percent.

6. Re-sort the questionable particles when more than 15 percent is present. Continue sorting

until there is no more than 15 percent in the questionable category.

7. Calculate the percent fractured particles meeting criteria to nearest 0.1 percent. Report to

1 percent.

41_T335_short_23_errata Aggregate 13-3 Pub. October 2023

WSDOT Materials Manual M 46-01.44 Page 5 of 10

January 2024

T 335

AGGREGATE WAQTC FOP AASHTO T 335 (23)

Calculation

Calculate the percent questionable particles to the nearest 1 percent using the following

formula:

𝑄𝑄

%𝑄𝑄 � � 100

� � 𝑄𝑄 � �

Where:

%Q = Percent of questionable particles

F = Mass of fractured particles

Q = Mass of questionable or borderline particles

N = Mass of unfractured particles

Example:

97.6 𝑔𝑔

%𝑄𝑄 � � 100 � 9%

632.6 𝑔𝑔 � 97.6 𝑔𝑔 � 352.6 𝑔𝑔

Given:

F = 632.6 g

Q = 97.6 g

N = 352.6 g

Calculate the percent fractured particles to the nearest 0.1 percent using the following

formula:

𝑄𝑄

��

P� 2 � 100

� � 𝑄𝑄 � �

Where:

P = Percent of fractured particles

F = Mass of fractured particles

Q = Mass of questionable particles

N = Mass of unfractured particles

41_T335_short_23_errata Aggregate 13-4 Pub. October 2023

Page 6 of 10 WSDOT Materials Manual M 46-01.44

January 2024

T 335

AGGREGATE WAQTC FOP AASHTO T 335 (23)

Example:

97.6 𝑔𝑔

� 632.6 g

P� 2 � 100 � 62.9% Report 63%

632.6 𝑔𝑔 � 97.6 𝑔𝑔 � 352.6 𝑔𝑔

Given:

F = 632.6 g

Q = 97.6 g

N = 352.6 g

Report

On forms approved by the agency

Sample ID

Fractured particles to the nearest 1 percent.

41_T335_short_23_errata Aggregate 13-5 Pub. October 2023

WSDOT Materials Manual M 46-01.44 Page 7 of 10

January 2024

T 335

AGGREGATE WAQTC FOP AASHTO T 335 (23)

41_T335_short_23_errata Aggregate 13-6 Pub. October 2023

Page 8 of 10 WSDOT Materials Manual M 46-01.44

January 2024

T 335

AGGREGATE WAQTC FOP AASHTO T 335 (23)

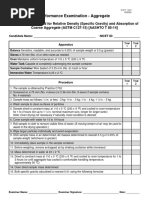

PERFORMANCE EXAM CHECKLIST

DETERMINING THE PERCENTAGE OF FRACTURE IN COARSE AGGREGATE

FOP FOR AASHTO T 335

Participant Name ______________________________ Exam Date ______________

Record the symbols “P” for passing or “F” for failing on each step of the checklist.

Procedure Element Trial 1 Trial 2

1. Sample dried and cooled, if necessary? _____ _____

2. Sample properly sieved through specified sieve(s)? _____ _____

3. Sample reduced to correct size? _____ _____

4. Each particle examined to determine if the particle meets the

fractured criteria? _____ _____

5. Particles separated into fractured, unfractured, and

questionable categories? _____ _____

6. Dry mass of each category determined to nearest 0.1 g? _____ _____

7. Questionable category resorted if more than 15 percent of total mass

falls in that category? _____ _____

8. Fractured calculation performed correctly? _____ _____

Comments: First attempt: Pass Fail Second attempt: Pass Fail

Examiner Signature ____________________________ WAQTC #:_______________

32_T335_pr_23_errata Aggregate 7-9 Pub. October 2023

WSDOT Materials Manual M 46-01.44 Page 9 of 10

January 2024

T 335

AGGREGATE WAQTC FOP AASHTO T 335 (23)

32_T335_pr_23_errata Aggregate 7-10 Pub. October 2023

Page 10 of 10 WSDOT Materials Manual M 46-01.44

January 2024

You might also like

- 60.2 Astm-C142-C142m-17Document1 page60.2 Astm-C142-C142m-17meongoc5687No ratings yet

- C04-E02 Rev 2 Dec 2014 Containment For Storage Tanks N PondsDocument18 pagesC04-E02 Rev 2 Dec 2014 Containment For Storage Tanks N Pondsryann mananquilNo ratings yet

- 70-TMSS-03-Rev. 01 Normal Weight Ready-Mixed Portland CementDocument38 pages70-TMSS-03-Rev. 01 Normal Weight Ready-Mixed Portland CementImran KhanNo ratings yet

- Sand Equivalent - ASTM D 2419-14Document10 pagesSand Equivalent - ASTM D 2419-14Siti Nur Ain Binti IsaNo ratings yet

- AASHTO R 46-08 (2012) - Design of SMADocument12 pagesAASHTO R 46-08 (2012) - Design of SMADani MNo ratings yet

- D0698-12R21 Masa Volumetrica Seca MaximaDocument13 pagesD0698-12R21 Masa Volumetrica Seca MaximaElena Popotla AlfaroNo ratings yet

- Cutback Asphalt (Rapid-Curing Type) : AashloDocument3 pagesCutback Asphalt (Rapid-Curing Type) : AashloNacer KisyNo ratings yet

- Concrete Thesis PDFDocument167 pagesConcrete Thesis PDFRicardo Dalisay100% (1)

- Determining The Percentage of Fracture in Coarse Aggregate Fop For Aashto T 335Document4 pagesDetermining The Percentage of Fracture in Coarse Aggregate Fop For Aashto T 335Aldrin SantosNo ratings yet

- AASHTO t255Document6 pagesAASHTO t255Sabila IhsaniNo ratings yet

- Aashto M323-13Document12 pagesAashto M323-13JUAN RAMIREZNo ratings yet

- Aashto - T240-13 RtfotDocument11 pagesAashto - T240-13 RtfotKUNCHE SAI ARAVIND SVNITNo ratings yet

- Astm C131-20Document2 pagesAstm C131-20jaheshfarhadNo ratings yet

- AASHTO TP 101 UL LAST Revised HighlightedDocument8 pagesAASHTO TP 101 UL LAST Revised HighlightedJuan Felipe Bonilla100% (1)

- AASHTO R60-12 (2020) - Sampling Freshly Mixed ConcreteDocument5 pagesAASHTO R60-12 (2020) - Sampling Freshly Mixed ConcreteErnesto Oscar VidelaNo ratings yet

- R76Document8 pagesR76Cams SenoNo ratings yet

- Astm D979-22Document4 pagesAstm D979-22roberto139No ratings yet

- As 2341.2-1993 Methods of Testing Bitumen and Related Roadmaking Products Determination of Dynamic (CoefficieDocument2 pagesAs 2341.2-1993 Methods of Testing Bitumen and Related Roadmaking Products Determination of Dynamic (CoefficieSAI Global - APACNo ratings yet

- SM en 823-2014Document20 pagesSM en 823-2014Dizzy EagleNo ratings yet

- Preparation of Bituminous Mixture Test Specimens by Means of California Kneading CompactorDocument4 pagesPreparation of Bituminous Mixture Test Specimens by Means of California Kneading CompactorMax100% (1)

- Standard Test Method For Relative Density (Specific Gravity) and Absorption of Coarse Aggregate (ASTM C127-15)Document2 pagesStandard Test Method For Relative Density (Specific Gravity) and Absorption of Coarse Aggregate (ASTM C127-15)culminasclairemaryNo ratings yet

- Determining Demulsibility of Emulsified Asphalt: Standard Test Method ForDocument2 pagesDetermining Demulsibility of Emulsified Asphalt: Standard Test Method ForROBERTO MIRANDANo ratings yet

- Tensile Stress-Strain of Carbon and Graphite: Standard Test Method ForDocument12 pagesTensile Stress-Strain of Carbon and Graphite: Standard Test Method Forsj19330No ratings yet

- AASHTO T 30, "Mechanical Analysis of Extracted AggregatesDocument12 pagesAASHTO T 30, "Mechanical Analysis of Extracted AggregatesĐức Trung TrầnNo ratings yet

- Hot Mix Asphalt (Hma) Specimens by Means of The Superpave Gyratory Compactor Fop For Aashto T 312Document4 pagesHot Mix Asphalt (Hma) Specimens by Means of The Superpave Gyratory Compactor Fop For Aashto T 312Aldrin SantosNo ratings yet

- D2172D2172M 17Document10 pagesD2172D2172M 17mehdiNo ratings yet

- Astm C143 C143M 20Document3 pagesAstm C143 C143M 20Mohaa rabiaNo ratings yet

- Amount of Water Required For Normal Consistency of Hydraulic Cement PasteDocument3 pagesAmount of Water Required For Normal Consistency of Hydraulic Cement PasteThurain Aung KyawNo ratings yet

- Vicat ApparatusDocument5 pagesVicat ApparatusFeras TemimiNo ratings yet

- AASHTO - T 245-15 - Resistance To Plastic Flow of Asphalt Mixtures Using Marshall AppartusDocument8 pagesAASHTO - T 245-15 - Resistance To Plastic Flow of Asphalt Mixtures Using Marshall AppartusTamanna JerinNo ratings yet

- Astm A706 A706m 22Document4 pagesAstm A706 A706m 22alvaradolu85No ratings yet

- Aashto T 119M-T 119-2013Document7 pagesAashto T 119M-T 119-2013MilonNo ratings yet

- Is 8887 (2004) - Bitumen Emulsion For Roads (Cationic Type)Document17 pagesIs 8887 (2004) - Bitumen Emulsion For Roads (Cationic Type)arjun kumar50% (2)

- d6931 PDFDocument4 pagesd6931 PDFaimen qayyumNo ratings yet

- Bituminous Mix DesignDocument4 pagesBituminous Mix DesignWaqas Ahmad AbbasiNo ratings yet

- The Multiple-Stress Creep-Recovery (MSCR) Test and SpecificationDocument42 pagesThe Multiple-Stress Creep-Recovery (MSCR) Test and SpecificationVinayaka RamNo ratings yet

- ASTM D 4791 (Flat and Elongated Particles)Document8 pagesASTM D 4791 (Flat and Elongated Particles)Rafael EstradaNo ratings yet

- Astm D546Document2 pagesAstm D546Mohamed Maamoun T.No ratings yet

- Galva PulseDocument4 pagesGalva PulseAlex CrispimNo ratings yet

- Astm D6913 D6913M 17Document11 pagesAstm D6913 D6913M 17rsoasadigmoniem2023No ratings yet

- Astm c1090Document5 pagesAstm c1090ivanhermalNo ratings yet

- Contractor Test Report Client Hot Mix Asphalt Analysis Marshall Method AASHTO T 245, T 164, T 209 & ASTM D 6927 Rashid Contracting Est. Saudi AramcoDocument1 pageContractor Test Report Client Hot Mix Asphalt Analysis Marshall Method AASHTO T 245, T 164, T 209 & ASTM D 6927 Rashid Contracting Est. Saudi Aramcoعباس حمزة الحسينNo ratings yet

- Astm D7585 D7585M 10 2022Document4 pagesAstm D7585 D7585M 10 2022Carlos LovoNo ratings yet

- Resistance To Plastic Flow of Bituminous Mixtures Using Marshall ApparatusDocument10 pagesResistance To Plastic Flow of Bituminous Mixtures Using Marshall ApparatusRichar DiegoNo ratings yet

- ASTM E 1778 - 98aDocument3 pagesASTM E 1778 - 98atomNo ratings yet

- C31_C31M-24bDocument7 pagesC31_C31M-24bMariela RamírezNo ratings yet

- T 217Document4 pagesT 217macc13No ratings yet

- Astm C31 C31M 23Document4 pagesAstm C31 C31M 23sahitawa8No ratings yet

- Astm D4533D4533M-15Document6 pagesAstm D4533D4533M-15Sandra LopesNo ratings yet

- Evaluation of AASHTO T 324 Hamburg - PDFDocument26 pagesEvaluation of AASHTO T 324 Hamburg - PDFnishant100% (1)

- ASTM C1019 GroutingDocument4 pagesASTM C1019 GroutingTrung Hieu Nguyen100% (1)

- Department of Civil Engineering: Transportation Engineering-II Lab CIEN-4202Document47 pagesDepartment of Civil Engineering: Transportation Engineering-II Lab CIEN-4202Adnan AhmadNo ratings yet

- AASHTO T27 (2020) - Sieve Analysis of Fine and Coarse AggregatesDocument10 pagesAASHTO T27 (2020) - Sieve Analysis of Fine and Coarse AggregatesErnesto Oscar VidelaNo ratings yet

- Astm Ac20Document3 pagesAstm Ac20Juan QuiñonesNo ratings yet

- AATCC 173 CMC:小色差合格率计算Document5 pagesAATCC 173 CMC:小色差合格率计算Fernando Carlos De la hoz TorresNo ratings yet

- Inspection & Testing Plan For Crusher Production-Sub Base: INF-AP-QUA-ITP-08 Rev. 0 Date: 04.07.2018Document2 pagesInspection & Testing Plan For Crusher Production-Sub Base: INF-AP-QUA-ITP-08 Rev. 0 Date: 04.07.2018jerin sam kurianNo ratings yet

- Viscosity-Graded Asphalt Binder For Use in Pavement ConstructionDocument3 pagesViscosity-Graded Asphalt Binder For Use in Pavement ConstructionHugo EscalanteNo ratings yet

- Is 5816 Splitting Tesile Strength of Concrete Method of Test 182112830 PDFDocument11 pagesIs 5816 Splitting Tesile Strength of Concrete Method of Test 182112830 PDFDeven PatleNo ratings yet

- Ductility of Asphalt Materials: Standard Test Method ForDocument5 pagesDuctility of Asphalt Materials: Standard Test Method ForJan Bakos100% (1)

- Aashto Fractured FaceDocument6 pagesAashto Fractured FaceChesterMercadoNo ratings yet

- T27 T11 (SIeve ANalysis)Document46 pagesT27 T11 (SIeve ANalysis)Don Procopio IINo ratings yet

- atm_baseaggrDocument52 pagesatm_baseaggrFiorela Coila HolgadoNo ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Saic-M-1069 Rev 7 (Final)Document3 pagesSaic-M-1069 Rev 7 (Final)ryann mananquilNo ratings yet

- Astm D 2041 PDFDocument4 pagesAstm D 2041 PDFrajeshji_00067% (3)

- WSDOT Errata To FOP For AASHTO T 30: Mechanical Analysis of Extracted AggregateDocument16 pagesWSDOT Errata To FOP For AASHTO T 30: Mechanical Analysis of Extracted Aggregateryann mananquilNo ratings yet

- Astm D3549-03Document3 pagesAstm D3549-03cristian_agp100% (1)

- ASTM C219-07 Standard Terminology Relating To Hydraulic CementDocument3 pagesASTM C219-07 Standard Terminology Relating To Hydraulic Cementryann mananquilNo ratings yet

- SATIP-Q-006-02 Rev 7 (Final) Conventional & Sulfur Extended Asphalt PavingDocument3 pagesSATIP-Q-006-02 Rev 7 (Final) Conventional & Sulfur Extended Asphalt Pavingryann mananquilNo ratings yet

- Saic-M-1067 Rev 7 (Final)Document3 pagesSaic-M-1067 Rev 7 (Final)ryann mananquilNo ratings yet

- C03-F02 Rev 0 Sep 2014 Stormwater Open Ditch Typ DetailsDocument6 pagesC03-F02 Rev 0 Sep 2014 Stormwater Open Ditch Typ Detailsryann mananquilNo ratings yet

- C03-F04 Rev 1 Mar 2015 Headwall Typ DetailsDocument3 pagesC03-F04 Rev 1 Mar 2015 Headwall Typ Detailsryann mananquilNo ratings yet

- C02-S03 Rev 2 Sep 2016 Geotechnical Engineering-Investigation and DesignDocument16 pagesC02-S03 Rev 2 Sep 2016 Geotechnical Engineering-Investigation and Designryann mananquilNo ratings yet

- C02-S05 Rev 1 Jun 2018 Ground Improvement Using Jet GroutingDocument11 pagesC02-S05 Rev 1 Jun 2018 Ground Improvement Using Jet Groutingryann mananquilNo ratings yet

- C02-S06 Rev 1 Mar 2018 Driven PilesDocument21 pagesC02-S06 Rev 1 Mar 2018 Driven Pilesryann mananquilNo ratings yet

- C02-S04 Rev 2 Jun 2018 Ground Improvement Using Stone ColumnsDocument11 pagesC02-S04 Rev 2 Jun 2018 Ground Improvement Using Stone Columnsryann mananquilNo ratings yet

- Saic-Q-1067 Rev 1 (Final)Document2 pagesSaic-Q-1067 Rev 1 (Final)ryann mananquilNo ratings yet

- SAIC-M-1003 Rev 7 (Final)Document4 pagesSAIC-M-1003 Rev 7 (Final)ryann mananquilNo ratings yet

- Saic-Q-1066 Rev 1 (Final)Document3 pagesSaic-Q-1066 Rev 1 (Final)ryann mananquilNo ratings yet

- SAIC-M-1001 Rev 7 (Final)Document5 pagesSAIC-M-1001 Rev 7 (Final)ryann mananquilNo ratings yet

- Road Modified BitumenDocument8 pagesRoad Modified Bitumenryann mananquilNo ratings yet

- BS 812-106Document9 pagesBS 812-106wafikmh4100% (1)

- 70.1 Astm D5821-13 (2017)Document2 pages70.1 Astm D5821-13 (2017)meongoc5687No ratings yet

- 3480-Article Text-6540-1-10-20210306Document6 pages3480-Article Text-6540-1-10-20210306TECH MACNo ratings yet

- خرسانة عملي الفصل الاول والثانيDocument58 pagesخرسانة عملي الفصل الاول والثانيAhmed AlyasNo ratings yet

- High Performance Concrete: Shanagonda Akhila, Kolla Aswani ChandhDocument6 pagesHigh Performance Concrete: Shanagonda Akhila, Kolla Aswani ChandhAli_nauman429458No ratings yet

- 1.1. Imported Backfill MaterialsDocument5 pages1.1. Imported Backfill MaterialsKrishna SankarNo ratings yet

- Three Indexes To Characterise Crushing and Screening of Reclaimed Asphalt PavementDocument15 pagesThree Indexes To Characterise Crushing and Screening of Reclaimed Asphalt PavementRaj SinghNo ratings yet

- Project Report PDFDocument41 pagesProject Report PDFAKRAMA HASANNo ratings yet

- ACI 126.3R-99 Guide To Recommended Format For Concrete in Materials Property DatabaseDocument50 pagesACI 126.3R-99 Guide To Recommended Format For Concrete in Materials Property DatabasematiasregisNo ratings yet

- Ballast FormatsDocument12 pagesBallast Formats906rahulNo ratings yet

- Sampling and Testing Calcium Chloride For Roads and Structural ApplicationsDocument3 pagesSampling and Testing Calcium Chloride For Roads and Structural ApplicationsCheong Fung TingNo ratings yet

- Lecture 2Document47 pagesLecture 2InfragNo ratings yet

- Lab Report Fine Aggregate A13 PDFDocument10 pagesLab Report Fine Aggregate A13 PDFNur NabilahNo ratings yet

- Materials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingDocument4 pagesMaterials Finer Than 75 - M (No. 200) Sieve in Mineral Aggregates by WashingmirwaisNo ratings yet

- Project ReportDocument41 pagesProject ReportAashu chaudhary100% (1)

- Concrete Technology Lab-Manual - English - FinalDocument49 pagesConcrete Technology Lab-Manual - English - Finalanandswami2562006No ratings yet

- Sieving For Perfect Quality Control: MillingDocument12 pagesSieving For Perfect Quality Control: MillingAndri FitriyadiNo ratings yet

- FST 313-316 MDocument1 pageFST 313-316 MRachael JosephNo ratings yet

- 2022-13-Johnson 1994 Grain Size From Thin SectionsDocument15 pages2022-13-Johnson 1994 Grain Size From Thin SectionsIan Yain BonavittaNo ratings yet

- Sieve Analysis Test Calculations & Particle Size Distribution CurveDocument6 pagesSieve Analysis Test Calculations & Particle Size Distribution CurveZeeshan aliNo ratings yet

- Chapter 2 Hot Mix DesignDocument68 pagesChapter 2 Hot Mix DesignChin Thau WuiNo ratings yet

- Elongation Index and Flakiness IndexDocument3 pagesElongation Index and Flakiness IndexBillal BhuttaNo ratings yet

- FPM Lab ManualrevisedDocument67 pagesFPM Lab ManualrevisedChirag MantriNo ratings yet

- Engineering Properties of Mechanically Stabilized SubbaseDocument11 pagesEngineering Properties of Mechanically Stabilized Subbaseambachew abebeNo ratings yet

- Manual On Pavement Design PDFDocument31 pagesManual On Pavement Design PDFAnil Kumsr T B100% (3)