Jodolyo Week 2

Jodolyo Week 2

Uploaded by

mulokoziavitha9Copyright:

Available Formats

Jodolyo Week 2

Jodolyo Week 2

Uploaded by

mulokoziavitha9Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Jodolyo Week 2

Jodolyo Week 2

Uploaded by

mulokoziavitha9Copyright:

Available Formats

College of Engineering and Technology (CoET)

Weekly Report No: 02 from 21st September to 25th September 2020

Day Brief description of work performed Hours

General overview of raw water filtration mechanism in Reverse Osmosis plant

Monday (R.O). 8

General overview of water treatment in demineralization plant (D.M).

General overview on the working principle of the boiler plant.

Descriptions about working principle and role of secondary air(SA) fan,

Tuesday induced draft(ID) fan and forced draft(FD) fan were given. 8

Learning mechanism of flue gases flow from furnace to the chimney passing

through different boiler parts.

Learning functions of deaerator, economizer, condenser, air heaters, steam

drum and mud drum and ashes handling system.

Learning transportation mechanism of bagasse from milling to boiler plant.

Wednesday 8

Learning about feeding and burning mechanism of bagasse in the boiler.

Learning about SCADA operation for boiler section.

Induction to pressure reducing and de-superheating station.

Thursday

General knowledge about power generation using superheated steam(live) and

uses of exhausted steam was given. 8

Description about working principle and role of steam turbine, gearbox,

generator and condensers was given.

Learning about stepping down the generated power from 11kV to 415V for

Friday industrial uses in power house. 8

Learning about stepping up the generated power from 11kv to 33kv for

efficient transfer to KIYUNGI TANESCO STATION.

Learning about the working principle of cooling tower and lubrication of gear

box.

Total hrs. 40

Sequence of operations for main job

STEAM AND POWER GENERATION

No Operation Tools, Machinery, Equipment

1. Preparation of steam boiler

2. Control the steam inlet in the turbine Throat valve

3. Conversion of steam kinetic energy to mechanical turbine

energy

4. Reduction of high rotational speed of turbine Gear box

5. Conversion of mechanical energy into the electrical generator

energy

6. Cooling of water from turbine Cooling tower.

Signature Training Officer Date

DETAILS OF THE MAIN JOB: STEAM AND POWER GENERATION

Exhaust steam

1.5bar,170°C

r

Steam from boiler

(45bars,480°C)

MainV-steam

2

valve. GEARBOX

STEAM

Load

TURBINE G (11kV,14MW)

Cold water (25°C)

BOILER

CONDENSOR.

Condensate back to boiler Hot water

0.5bar,75°C (35°C)

COOLING

TOWER.

Feed valve.

Feed water

E-8 pump

Cooling water pump

.

DRWAN: DATE: NAME: CHECKED: DATE:

LYOMBO, JOFREY D 26/09/2020 STEAM AND POWER

GENERATION

You might also like

- Steam Power Plants (System)Document58 pagesSteam Power Plants (System)Hafzal Gani100% (2)

- WELCOME To Unit 7&8 Coal Fire Power PlantDocument21 pagesWELCOME To Unit 7&8 Coal Fire Power PlantIwan RuhiyanaNo ratings yet

- S220-Rankine Cycle Steam TurbineDocument3 pagesS220-Rankine Cycle Steam TurbineMuhammad RehanNo ratings yet

- A Report of The Vocational TrainingDocument14 pagesA Report of The Vocational TrainingAvijit palNo ratings yet

- Energy: H. Rosyid, R. Koestoer, N. Putra, Nasruddin, A.A. Mohamad, YanuarDocument9 pagesEnergy: H. Rosyid, R. Koestoer, N. Putra, Nasruddin, A.A. Mohamad, YanuarIvanNo ratings yet

- Chap 1 - Steam Power PlantDocument60 pagesChap 1 - Steam Power PlantMuhammad Qusyairi100% (2)

- Udaipur Cement Works LimitedDocument17 pagesUdaipur Cement Works LimitedBülent BulutNo ratings yet

- Steam Cycles - Lecture 2ndDocument21 pagesSteam Cycles - Lecture 2ndSaifAdamz's100% (2)

- Modul 0 Domaine AplikasiDocument35 pagesModul 0 Domaine AplikasijekiNo ratings yet

- Presentazione Commerciale Scaldabagni A Pompa Di Calore - GBDocument38 pagesPresentazione Commerciale Scaldabagni A Pompa Di Calore - GB6667No ratings yet

- Power Plant-1Document32 pagesPower Plant-1marlito100% (1)

- 1 s2.0 S1359431114000167 MainDocument8 pages1 s2.0 S1359431114000167 Mainmoetaz.chaariNo ratings yet

- Vapor Power Cycles PDFDocument89 pagesVapor Power Cycles PDFPUSHKAR AGGRAWAL100% (1)

- Siwes 1Document14 pagesSiwes 1Judex OnyekabaNo ratings yet

- BoilerDocument35 pagesBoilerrizkydjonhansemitNo ratings yet

- Summer Training Report On NTPC Tanda Ambedkar NagarDocument9 pagesSummer Training Report On NTPC Tanda Ambedkar NagarNaman ShahNo ratings yet

- Swami Vivekanand Institute of Engineering & Technology: Study and Performance of Domestic RefrigeratorDocument4 pagesSwami Vivekanand Institute of Engineering & Technology: Study and Performance of Domestic RefrigeratorDhiraj DhimanNo ratings yet

- Training Report (Kbunl) 2019 Shanu PrakashDocument33 pagesTraining Report (Kbunl) 2019 Shanu PrakashShanu PrakashNo ratings yet

- Nuclear Plant Safety ConceptsDocument62 pagesNuclear Plant Safety ConceptsAmarKumarNo ratings yet

- Polygeneration of Electricity, Heat and Ultra Pure Water For Semiconductor IndustryDocument16 pagesPolygeneration of Electricity, Heat and Ultra Pure Water For Semiconductor IndustrybillNo ratings yet

- Cooling Water SystemDocument48 pagesCooling Water SystemSandeep Joshi100% (2)

- 07 Power CyclesDocument122 pages07 Power CyclesNahfi JimNo ratings yet

- Steam Turbine: Rajesh Kumar B.E-Electrical Pgdc-Thermal Power Plant Npti, NeyveliDocument44 pagesSteam Turbine: Rajesh Kumar B.E-Electrical Pgdc-Thermal Power Plant Npti, NeyveliRAJESH KUMAR100% (1)

- Numerical Investigation of The Vortex...Document8 pagesNumerical Investigation of The Vortex...Jesús MateoNo ratings yet

- Applied Thermal Engineering: Jung-In Yoon, Chang-Hyo Son, Seung-Moon Baek, Byung Hyo Ye, Hyeon-Ju Kim, Ho-Saeng LeeDocument5 pagesApplied Thermal Engineering: Jung-In Yoon, Chang-Hyo Son, Seung-Moon Baek, Byung Hyo Ye, Hyeon-Ju Kim, Ho-Saeng LeeJoseph Liev Barraza DiazNo ratings yet

- Case Study & Gains ReportDocument15 pagesCase Study & Gains ReportManoj SinghNo ratings yet

- Solahart ATMOS AIR Heat Pump Presentation V3 250221Document19 pagesSolahart ATMOS AIR Heat Pump Presentation V3 250221abhassarafNo ratings yet

- RHE311 - Rheem Heat Pump Brochure V4-2Document8 pagesRHE311 - Rheem Heat Pump Brochure V4-2AkilaJosephNo ratings yet

- Internship ReportDocument21 pagesInternship Reportthewebseries17thNo ratings yet

- Maintenance History of A Geothermal Plant: Svartsengi IcelandDocument8 pagesMaintenance History of A Geothermal Plant: Svartsengi IcelandReza Ardiansyah WeimanNo ratings yet

- Type of and Thermal Assessment of Dual Purpose Power/Desalination PlantsDocument76 pagesType of and Thermal Assessment of Dual Purpose Power/Desalination Plantsmurtada100% (1)

- Type of and Thermal Assessment of Dual Purpose Power/Desalination PlantsDocument32 pagesType of and Thermal Assessment of Dual Purpose Power/Desalination PlantsmurtadaNo ratings yet

- Efisiensi Boiler CalculatorDocument13 pagesEfisiensi Boiler CalculatorSyarifuddin DjauNo ratings yet

- Coal To Power 06.08.23Document38 pagesCoal To Power 06.08.23Pallab NathNo ratings yet

- Major Equipments: FOR Asam-Asam Coal Fired Steam Power Plant 2X65 MW (UNIT 3 & 4) Oleh: Arief Daru WibawantoDocument34 pagesMajor Equipments: FOR Asam-Asam Coal Fired Steam Power Plant 2X65 MW (UNIT 3 & 4) Oleh: Arief Daru Wibawantosaiful anwarNo ratings yet

- Kalina Exergy Analysis of A Dual Level Binary Geothermal Power Plant 2002 GeothermicsDocument16 pagesKalina Exergy Analysis of A Dual Level Binary Geothermal Power Plant 2002 GeothermicsHassanKMNo ratings yet

- Industrial Training, at DCCPPDocument26 pagesIndustrial Training, at DCCPPGaganil SharmaNo ratings yet

- ABSTRACT: in Inland Nuclear Power Plant Adopted Re-Recycle Water Cooling System inDocument8 pagesABSTRACT: in Inland Nuclear Power Plant Adopted Re-Recycle Water Cooling System inDSGNo ratings yet

- Problems For Chapter 8: Power Cycles: A. The Rankine CycleDocument48 pagesProblems For Chapter 8: Power Cycles: A. The Rankine CycleEUGENE AICHANo ratings yet

- RadDocument5 pagesRadVekimrzliNo ratings yet

- Gas Turbine IntroductionDocument84 pagesGas Turbine IntroductionMohammad Akram100% (4)

- implementation-of-chiller-plant-management-system-to-optimize-the-building-primary-hvac-system-energy-consumption-pdf-fileDocument6 pagesimplementation-of-chiller-plant-management-system-to-optimize-the-building-primary-hvac-system-energy-consumption-pdf-filearjunbk07No ratings yet

- Absorption Refrigeration: Kevin D. Rafferty, P.E. Geo-Heat CenterDocument4 pagesAbsorption Refrigeration: Kevin D. Rafferty, P.E. Geo-Heat CenterRichard WeimerNo ratings yet

- (Ɪ) Choose The Correct AnswerDocument3 pages(Ɪ) Choose The Correct AnswerHamadaMohassabNo ratings yet

- Maintenance History of A Geothermal Plant: Svartsengi IcelandDocument7 pagesMaintenance History of A Geothermal Plant: Svartsengi IcelandHawari Rafif NaufalNo ratings yet

- 01-Steam Power Plant 26 OctDocument64 pages01-Steam Power Plant 26 OcthuusenaliNo ratings yet

- Intership Report KTPSDocument24 pagesIntership Report KTPSPranjal singhNo ratings yet

- Q1 Mare2Document3 pagesQ1 Mare2Shena Pyponco LocaylocayNo ratings yet

- NTPCDocument32 pagesNTPC12 EC ATUL KUMAR SRIVASTAVANo ratings yet

- Chapter 7. Geothermal Power PlantDocument22 pagesChapter 7. Geothermal Power Plantdiana tahaNo ratings yet

- NTPC Training ReportDocument53 pagesNTPC Training ReportMitali SenNo ratings yet

- Lecture Note - Steam CycleDocument37 pagesLecture Note - Steam CycleSuchi Suchi SuchiNo ratings yet

- Heidemann1992 FDF Absorber PDFDocument9 pagesHeidemann1992 FDF Absorber PDFToño SandaNo ratings yet

- Chirag Sem 7 NewDocument19 pagesChirag Sem 7 Newchiragarunkar2511No ratings yet

- 03 Thermodynamic of Simple Thermal Power PlantDocument26 pages03 Thermodynamic of Simple Thermal Power PlantIbrahim SyaharuddinNo ratings yet

- Et 4Document10 pagesEt 4Aisha JainNo ratings yet

- OTEC RETDocument4 pagesOTEC RETdhanushasrinivasan18No ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- The Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattFrom EverandThe Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattNo ratings yet

- Corsair rps0137 (cp9020220) (cx550m) 381Document1 pageCorsair rps0137 (cp9020220) (cx550m) 381baihaqihanNo ratings yet

- Rating Dan Spesifikasi PMCB PDFDocument1 pageRating Dan Spesifikasi PMCB PDFrini setyoNo ratings yet

- Transformers MergedDocument79 pagesTransformers MergedPraneetha InumarthiNo ratings yet

- ResumeDocument2 pagesResumeAnonymous sENwj8nwq100% (2)

- Three Phase Over Current + Earth Fault Relay With Highset With Communication Type Mc61CDocument4 pagesThree Phase Over Current + Earth Fault Relay With Highset With Communication Type Mc61CLuken Halis Jalil60% (5)

- 01 - Doc and Drawing Register - MOGS-Botling Plant Dtd. 04.1.12Document6 pages01 - Doc and Drawing Register - MOGS-Botling Plant Dtd. 04.1.12SaraswatapalitNo ratings yet

- Emerson - BRAVO Inverter Data SheetDocument2 pagesEmerson - BRAVO Inverter Data SheetOscar ReyesNo ratings yet

- ISolarCloud V215 QUEN Ver11 201906Document34 pagesISolarCloud V215 QUEN Ver11 201906Trong TranNo ratings yet

- Pit KunoDocument5 pagesPit KunoJohn A. CenizaNo ratings yet

- Samy CVDocument7 pagesSamy CVjoseNo ratings yet

- 11kv Kiosk Panel DrawingDocument12 pages11kv Kiosk Panel Drawingakcakoca_81No ratings yet

- Keor Hpe 60 80 GB PDFDocument2 pagesKeor Hpe 60 80 GB PDFUguudei ErdembilegNo ratings yet

- HPC 5 - Chapter 9Document3 pagesHPC 5 - Chapter 9Romah TorresNo ratings yet

- AC Coupled Microgrid SolutionDocument2 pagesAC Coupled Microgrid SolutionSyed Furqan RafiqueNo ratings yet

- Fawde 15 KVADocument4 pagesFawde 15 KVAtritiluNo ratings yet

- 02 Areva Distribution Acquisition Presentation tcm50 307707Document29 pages02 Areva Distribution Acquisition Presentation tcm50 307707Aizat RazakNo ratings yet

- Product Data Sheet 5SY4510-7: Circuit Breaker 230V 10ka, 1+N-Pole, C, 10A, D 70MMDocument4 pagesProduct Data Sheet 5SY4510-7: Circuit Breaker 230V 10ka, 1+N-Pole, C, 10A, D 70MMZallesNo ratings yet

- Manual Multi PFR Simple 06 12 enDocument3 pagesManual Multi PFR Simple 06 12 ensiti maria khiftiyahNo ratings yet

- Sen720 - 218024305 - Final ThesisDocument24 pagesSen720 - 218024305 - Final Thesisvaraprasad333kvpNo ratings yet

- Teksan Hybrid Power Systems ENG Low ResDocument6 pagesTeksan Hybrid Power Systems ENG Low Reswado11No ratings yet

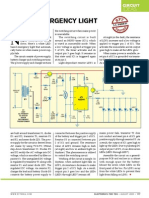

- Smart Emergency LightDocument1 pageSmart Emergency LightaassaanmkNo ratings yet

- Grid Power Control of Direct Matrix Converter Fed Three-Phase Induction GeneratorDocument14 pagesGrid Power Control of Direct Matrix Converter Fed Three-Phase Induction GeneratorInternational Journal of Power Electronics and Drive SystemsNo ratings yet

- Components of HVDC Gyanendra Sharma NPTI DelhiDocument138 pagesComponents of HVDC Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Manuel Onduleur Eolienne Ecoreote PS100Document2 pagesManuel Onduleur Eolienne Ecoreote PS100diogo_airjNo ratings yet

- Articulo HVDC 1991Document7 pagesArticulo HVDC 1991Otoniel JaramilloNo ratings yet

- Transformer Protection and Transformer FaultDocument3 pagesTransformer Protection and Transformer FaultThirumalNo ratings yet

- PQS PFC Components PBDocument12 pagesPQS PFC Components PBChristina BoydNo ratings yet

- Abb Ovb-Vbf 36 PDFDocument8 pagesAbb Ovb-Vbf 36 PDFxaristidesxNo ratings yet

- Diode Circuits: Electronics IDocument25 pagesDiode Circuits: Electronics I呼除預No ratings yet

- Voltage RegulatorDocument106 pagesVoltage Regulatorpacai1987100% (5)