MS-Remedial Action - 002-Blinding

MS-Remedial Action - 002-Blinding

Uploaded by

princethapelokomeCopyright:

Available Formats

MS-Remedial Action - 002-Blinding

MS-Remedial Action - 002-Blinding

Uploaded by

princethapelokomeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

MS-Remedial Action - 002-Blinding

MS-Remedial Action - 002-Blinding

Uploaded by

princethapelokomeCopyright:

Available Formats

Project Name: ALL SAINTS WWTW

Contract Number: SCMU5-21/22-0019

Project Number: MJCP-02/2022

Document Type: Method Statement

_______________________________________________________________________________________________

MS Number: MS-Remedial Construction MS Maturation Remedial Date: 2023/01/18

001 Tittle: Action

MS-Revision 00

1. Introduction:

The Purpose of this document is to discuss how site establishment will be done.

2. References:

a) Construction drawings f) Project Occupational health and safety specification

b) Site Instructions g) Occupational health and safety Act 1993

c) SABS 1200 G h) Construction regulations

d) Project specifications i) Project-SHE Plan

e) Approved Method statements

3. Man-Power plan, Tools and Equipment’s and PPE to be used.

3.1. Man- power plan 3.2. Tool and Equipment’s 3.3. PPE

Plant: Power tools: Hand Tools: -Overall (work suits)

- 1xConstruction Manager -None. -None -Shovels/spade - Boots

- 1xConstruction Supervisor -Straight edge - Rain suits

-Floats - Masks

-Dumpy Level -

Problem statement (s):

1. AS per SI 024 , The engineer has requested level to make a ruling on the finishing or appearance of the concrete casted on the surface as

blinding. Based on the visual inspection the engineer required that the Levels be picked to determine whether they are within the tolerance.

2. The tolerance is to be measured under SABS 1200 G ,6.2.3 (C) (4) , endorsed by the contract document page 219 ( see extracts attached below):

-

SABS 1200 G ,6.2.3 (C) (4)

-

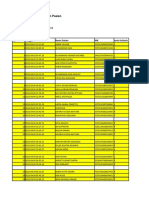

3. The Spreadsheet is attached.

Proposed Repair method.

1. The Contractor has taken readings onsite , in the presence of the RE , and the reading are attached herein for further assessment by the Engineer.

2. As guided by the level checks ,all the Levels that are outside tolerance will be treated as follows.

The levels that are below the -30mm requirement will be filled with screeds.

The Levels that are above the +15mm requirement will be cut out to level.

3. Filling :

The Surface where screeding is required will be cleaned to remove any loose material or debris. This will be done by sweeping the floors

with brooms and also sprayed with water to removed dust and hard soils.

Screed will be mixed onsite as per these proportions :

1 x 50kg , 42,5 N Cement Mixed with 3,5 Wheelbarrows of ( 1:3,5)

Once the screeds are mixed, they will be place onto the cleaned surface and be levelled using a straight edge against the levels set out on

the surface.

The treated area will be left to set( harden) and then a curing method will be applied. Water will be poured on the treated surface as a

measure to assist the are to cure.

4. Cutting :

Any surface that is above the design level by + 15mm will be trimmed off by use of a chipping hammer or drill or Grinder.

After the trimming is confirmed, the cleaning will be done and the are will be ready for the next stage of work.

5. After all the corrections are done the work will be verified by the Contractor and the Engineer. All records of inspections will be kept in the

quality file for reference.

You might also like

- Diagnostic Check Sheets PDFDocument15 pagesDiagnostic Check Sheets PDFLuisYFer1100% (1)

- Methodology For Construction of RCC Chimney ShellDocument17 pagesMethodology For Construction of RCC Chimney Shellpoovazhagan100% (3)

- Method Statement Base Slab Concreting: Page 1 of 8Document8 pagesMethod Statement Base Slab Concreting: Page 1 of 8J. Kumar Infraprojects Ltd100% (1)

- 01 Drug File MHNDocument29 pages01 Drug File MHNamit89% (19)

- Method Statement Shotcrete: Page 1 of 7Document7 pagesMethod Statement Shotcrete: Page 1 of 7J. Kumar Infraprojects Ltd100% (3)

- Method Statement For RCC WorksDocument10 pagesMethod Statement For RCC WorksSagar AliasjackeyNo ratings yet

- NeomDocument191 pagesNeomMOHAMED SAYED mohamed ali100% (1)

- METHOD Statement of BRIDGE (Major STR)Document6 pagesMETHOD Statement of BRIDGE (Major STR)venkateswara rao Pothina100% (2)

- CV-0013-002 - Method Statement For Soil Improvement WorkDocument14 pagesCV-0013-002 - Method Statement For Soil Improvement Work한상호No ratings yet

- Art, Aesthetics, and The Brain PDFDocument567 pagesArt, Aesthetics, and The Brain PDFTran Hai Linh 22KT23No ratings yet

- Method Statement For PCC Pouring, Waterproofing & ScreedDocument9 pagesMethod Statement For PCC Pouring, Waterproofing & ScreedJoe PsNo ratings yet

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Document20 pagesMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Survey Questionnaire SampleDocument1 pageSurvey Questionnaire SampleArlyn Mimi50% (2)

- First Nursing DiagnosisDocument3 pagesFirst Nursing DiagnosisDarlene Joy FullaNo ratings yet

- Method Statement & Risk Assessment (Rams) : ClientDocument36 pagesMethod Statement & Risk Assessment (Rams) : ClientAbdul RaheemNo ratings yet

- Method Statement For Excavation & Backfilling WorksDocument46 pagesMethod Statement For Excavation & Backfilling WorksnumanqcmadaratNo ratings yet

- Op-3-32. Checklist For Supervision of Sheet Pile Installation (Excavation Work)Document3 pagesOp-3-32. Checklist For Supervision of Sheet Pile Installation (Excavation Work)Garry Yan DiazNo ratings yet

- Al OmranDocument1 pageAl OmranshahbazdgNo ratings yet

- 02 - Part A - Earth WorkDocument28 pages02 - Part A - Earth WorkpvsvprasadcivilNo ratings yet

- Toaz - Info 005 Ms Manhole Construction Sew Risk Assessment From Javeed 1 PRDocument12 pagesToaz - Info 005 Ms Manhole Construction Sew Risk Assessment From Javeed 1 PRShah MuzzamilNo ratings yet

- Method Statement For Pile Head TreatmentDocument7 pagesMethod Statement For Pile Head TreatmentJoe Ps100% (1)

- T00-O00C01-ARI-MTS-ST-0008 Method Statement For Anti Termite TreatmentDocument36 pagesT00-O00C01-ARI-MTS-ST-0008 Method Statement For Anti Termite Treatmentmuhammadibraheem5017No ratings yet

- 2 Method of Statement For RC Wall Between Feature Wall and Ramp - Rev 01 PDFDocument3 pages2 Method of Statement For RC Wall Between Feature Wall and Ramp - Rev 01 PDFJoe LeeNo ratings yet

- Op-3-53. Checklist For Concrete Casting: Work Instructions For EngineersDocument4 pagesOp-3-53. Checklist For Concrete Casting: Work Instructions For EngineersMohd MuksinNo ratings yet

- MS-Abutment and Deck SlabDocument20 pagesMS-Abutment and Deck SlabJeff AlinayaNo ratings yet

- Method Statement For Hardscape WorksDocument12 pagesMethod Statement For Hardscape WorksAnish ElmoNo ratings yet

- WMS (Method Statement For Concrete Repair Works)Document6 pagesWMS (Method Statement For Concrete Repair Works)PUI CHEE KHIANNo ratings yet

- Construction Methodology For TG Pedestal Column - R2Document11 pagesConstruction Methodology For TG Pedestal Column - R2Hariom Gupta100% (3)

- Method Statement For Finishing Work of Ramp Joint Rectification & Cement RenderingDocument8 pagesMethod Statement For Finishing Work of Ramp Joint Rectification & Cement Renderingdinidu3priyankara3saNo ratings yet

- 4.repairing For Concrete Structure MethodologyDocument4 pages4.repairing For Concrete Structure MethodologyEyutt Hghgh100% (1)

- PCC Method StatementDocument10 pagesPCC Method StatementChirag SharmaNo ratings yet

- Pavement Treatment Work For Chip Seal Rev 1.2Document7 pagesPavement Treatment Work For Chip Seal Rev 1.2Zulaika LainiNo ratings yet

- Op-3-59. Checklist For Supervision of Stone Column ConstructionDocument3 pagesOp-3-59. Checklist For Supervision of Stone Column Constructionjinwook75No ratings yet

- MS-E-02 Installation of Electrical Manhole & Underground PipeDocument8 pagesMS-E-02 Installation of Electrical Manhole & Underground PipeTan Chek Yau100% (1)

- Method StatementDocument4 pagesMethod StatementDebraj RoyNo ratings yet

- Construction Bored Pile (A4)Document14 pagesConstruction Bored Pile (A4)Ratha Men100% (1)

- (Eng) Advanced Training Concrete - Punching Design 17.1Document21 pages(Eng) Advanced Training Concrete - Punching Design 17.1Muscadin MakensonNo ratings yet

- Method Statement For Survey and Setting Out (Rev 00)Document10 pagesMethod Statement For Survey and Setting Out (Rev 00)Kelvin Lau Hin HuatNo ratings yet

- Rev1 MoS - Mild Steel Truss (Anjung Blok Pentadbiran) InstallationDocument3 pagesRev1 MoS - Mild Steel Truss (Anjung Blok Pentadbiran) InstallationFauziah ShaifulNo ratings yet

- Structure Work - Method StatementDocument8 pagesStructure Work - Method StatementTousif AhmedNo ratings yet

- DPL Unit-8 Pws Csa1Document20 pagesDPL Unit-8 Pws Csa1psycinNo ratings yet

- Corrosion Control - Jack-Up - SP-CO-ENG-CON-06-01Document37 pagesCorrosion Control - Jack-Up - SP-CO-ENG-CON-06-01evenNo ratings yet

- METHOD OF STATEMENT For HDPE Pipe InstallationDocument18 pagesMETHOD OF STATEMENT For HDPE Pipe InstallationShahzaib Shahid100% (3)

- T00 O00C01 ARI MTS ST 0007 Method Statement For WaterproofingDocument18 pagesT00 O00C01 ARI MTS ST 0007 Method Statement For Waterproofingmuhammadibraheem5017No ratings yet

- Ms For Foundation Excavation and Casting.Document6 pagesMs For Foundation Excavation and Casting.botchNo ratings yet

- Method Statement Construction & Casting of Concrete Manholes P-2Document17 pagesMethod Statement Construction & Casting of Concrete Manholes P-2a.nunezNo ratings yet

- Ms Excavation WorkDocument8 pagesMs Excavation WorkAnil Kumar OmmiNo ratings yet

- Method Statement: Project No.: Project TitleDocument7 pagesMethod Statement: Project No.: Project TitleMuhammed Shafeek K TNo ratings yet

- 22503-2019-Winter-Model-Answer-Paper Msbte Study ResourcesDocument16 pages22503-2019-Winter-Model-Answer-Paper Msbte Study ResourcesToufiq Bhati100% (2)

- Method Statement of Piling Concrete For Fire Water Tank MTDocument15 pagesMethod Statement of Piling Concrete For Fire Water Tank MTahmad100% (1)

- Rev Method Statement For Concrete RepairDocument15 pagesRev Method Statement For Concrete Repairahmed atifNo ratings yet

- Basement ModelScaffoldingDocument1 pageBasement ModelScaffoldingshahbazdgNo ratings yet

- Method Statement Installation of Rock BoltDocument5 pagesMethod Statement Installation of Rock BoltJ. Kumar Infraprojects Ltd100% (2)

- Method Statement For Gayal Road Crossing and DemolitionDocument10 pagesMethod Statement For Gayal Road Crossing and DemolitionMudasser ZiaNo ratings yet

- MS For Core Walls Dowels Location Repair (Towers)Document5 pagesMS For Core Walls Dowels Location Repair (Towers)rayNo ratings yet

- MS 130 - Construction of P.S Manhole Rev 0Document9 pagesMS 130 - Construction of P.S Manhole Rev 0ahmed maherNo ratings yet

- Method Statement For Chipping and Grouting For All EDI System in PH2Document6 pagesMethod Statement For Chipping and Grouting For All EDI System in PH2vinodhyperNo ratings yet

- Method Statement Bottom Up Roof Slab Concreting: Page 1 of 10Document10 pagesMethod Statement Bottom Up Roof Slab Concreting: Page 1 of 10J. Kumar Infraprojects LtdNo ratings yet

- Prestressing Methodology Girder Casting MethodologyDocument7 pagesPrestressing Methodology Girder Casting MethodologyAkhilesh DwivediNo ratings yet

- Ms For Concrete PilesDocument16 pagesMs For Concrete PilesahmadNo ratings yet

- Final Jsa & Method StatmentDocument11 pagesFinal Jsa & Method StatmentDhaneswar SwainNo ratings yet

- Method Statement For Concreting WorksDocument10 pagesMethod Statement For Concreting WorksLy LysengNo ratings yet

- Method Statement For Application of Drywall PaintDocument6 pagesMethod Statement For Application of Drywall PaintReuben James BangaoilNo ratings yet

- Estimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesFrom EverandEstimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesNo ratings yet

- Scan-to-Me From Cns-Ug-Lab-Sh1101-Prn1.wits - Ac.za 2015-05-08 102533Document83 pagesScan-to-Me From Cns-Ug-Lab-Sh1101-Prn1.wits - Ac.za 2015-05-08 102533princethapelokomeNo ratings yet

- Occupational Health and Safety Policy 2023-2024Document1 pageOccupational Health and Safety Policy 2023-2024princethapelokomeNo ratings yet

- Vision Statement FY - 2024Document1 pageVision Statement FY - 2024princethapelokomeNo ratings yet

- Q4Document6 pagesQ4princethapelokomeNo ratings yet

- 2018 Final ExamDocument4 pages2018 Final ExamprincethapelokomeNo ratings yet

- Jagersfontein ReportDocument36 pagesJagersfontein ReportprincethapelokomeNo ratings yet

- Access Road Calculations-Rev 00Document1 pageAccess Road Calculations-Rev 00princethapelokomeNo ratings yet

- Biological Reactor Excavation LevelsDocument6 pagesBiological Reactor Excavation LevelsprincethapelokomeNo ratings yet

- Siemens RWD62 (O3342)Document10 pagesSiemens RWD62 (O3342)nicholas6678No ratings yet

- SSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Document14 pagesSSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Shrishanti Kale100% (1)

- Checklist - Backup Device - Petzl ASAP-LOCKDocument1 pageChecklist - Backup Device - Petzl ASAP-LOCKMax BeeksNo ratings yet

- Me3112 2 Lab Dynamic Balancing Amp Gyroscopic EffectsDocument12 pagesMe3112 2 Lab Dynamic Balancing Amp Gyroscopic EffectsDenise Isebella LeeNo ratings yet

- DP Pump TechDocument48 pagesDP Pump TechDewesh SinghNo ratings yet

- Urinary System Disorders - Dr. Swami Karmananda Saraswati, MB, BS (Syd.)Document2 pagesUrinary System Disorders - Dr. Swami Karmananda Saraswati, MB, BS (Syd.)Omkar GorantlaNo ratings yet

- TPG 3 (Stringset)Document4 pagesTPG 3 (Stringset)rostyo tioNo ratings yet

- Skills Related Physical Fitness Components F23Document15 pagesSkills Related Physical Fitness Components F23Imane ImnidaNo ratings yet

- AGARD FLIGHT TEST TECHNIQUE SERIES VOLUME 21 Flying Qualities Flight Testing of Digital Flight Control SystemsDocument124 pagesAGARD FLIGHT TEST TECHNIQUE SERIES VOLUME 21 Flying Qualities Flight Testing of Digital Flight Control SystemsDavid Russo100% (1)

- FAR3000 Operator's Manual PDFDocument463 pagesFAR3000 Operator's Manual PDFHerdian Trias SumadinataNo ratings yet

- M1 02QDocument6 pagesM1 02QChryssa EconomouNo ratings yet

- Chemistry PDFDocument78 pagesChemistry PDFNicholas SaahNo ratings yet

- TGL 44Document188 pagesTGL 44Christina GrayNo ratings yet

- RLDA Proposal 26072021Document25 pagesRLDA Proposal 26072021ar_sksharmaNo ratings yet

- HW Active To Passive Voice Convertion QuestionsDocument3 pagesHW Active To Passive Voice Convertion Questionsanjali pratapNo ratings yet

- Roth 10e Nclex Chapter 16Document4 pagesRoth 10e Nclex Chapter 16jennaaahhhNo ratings yet

- Competency Assessment of Batangas Marine Protected Area and Bantay Dagat NetworksDocument12 pagesCompetency Assessment of Batangas Marine Protected Area and Bantay Dagat NetworksIOER International Multidisciplinary Research Journal ( IIMRJ)No ratings yet

- Vibration Assisted EDMDocument13 pagesVibration Assisted EDMSanjay KumarNo ratings yet

- Pure Substance MixtureDocument7 pagesPure Substance MixtureVikashNo ratings yet

- Chi Squer Test SuperDocument81 pagesChi Squer Test SuperPataki SandorNo ratings yet

- SATIP F 001 01 Fired HeaterDocument3 pagesSATIP F 001 01 Fired Heatermohammedtaufeeq8No ratings yet

- Proposals On The Source-Destination Tra C Matrix Estimation For Ip-Based VpnsDocument6 pagesProposals On The Source-Destination Tra C Matrix Estimation For Ip-Based Vpnsmohitagrawal2491No ratings yet

- Diare September 180922Document8 pagesDiare September 180922anggaNo ratings yet

- Enquiry: Alpha Adriatic Shipmanagement Pte. LTDDocument2 pagesEnquiry: Alpha Adriatic Shipmanagement Pte. LTDDelta Marine ServicesNo ratings yet

- ABB, FPNO-21 PROFINET Fieldbus Adapter ModuleDocument158 pagesABB, FPNO-21 PROFINET Fieldbus Adapter ModuleHans ShiNo ratings yet