Valves For Industrial Applications

Valves For Industrial Applications

Uploaded by

Dixit ChauhanCopyright:

Available Formats

Valves For Industrial Applications

Valves For Industrial Applications

Uploaded by

Dixit ChauhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Valves For Industrial Applications

Valves For Industrial Applications

Uploaded by

Dixit ChauhanCopyright:

Available Formats

7.

Calculation of the diameter of pipes

To estimate the optimal diameter of a pipe, and correspondingly the valve the following formula can

be used to get an approximate value:

Where

Q: flow in m3/sec.

D: diameter of the pipe in meter

W: flow speed in m/sec

As flow speed the following values can be used as reference:

For liquids for natural gradient

viscous liquids 0,1 up to 0,5 m/sec

Non viscous liquids 0,5 up to 1 m /sec

For pressurized lines

Inlet of pumps 0,8 up to 2 m/sec

Output of pumps 1,5 up to 3 m/sec

For gases low pressure (fans) 4 up to 15 m/sec

High pressure 15 up to 25 m/sec

For steam Saturated steam 30 up to 50 m/sec

Superheated steam 15 up to 75 m/sec (depending on the pressure)

8. Types of valves

8.1 Ball valves

The ball valve is basically a plug valve with a spherical plug and a round hole. The materials of

construction of the ball valve have been developed such that the ball valve is becoming the most

popular valve for most process applications. The valve is a quarter turn valve.

There are two primary options for the ball valve design

• Floating Ball Design - This is low cost option for the lower duties

• Trunnion Ball Design - This is a more costly option for the higher duties

The ball valve can be provided in a full-bore version, in which the internal diameter of the valve is

identical to the internal diameter of the pipe. In this design the pass of scrappers to clean the pipes is

possible (pigable design). They can also be provided in a reduced bore design allowing a smaller body

but still with relatively low head loss compared to most other valve options e.g. a 25 mm nominal bore

valve has a 20 mm reduced bore. Ball valves can be manufactures with a multi-port design for flow

diverting (three or four ways)

Date 20.04.2020 Page 7 of 17 Rev. Doc. ENT12-20 Rev.0

Ball valves can be designed as “top entry” when all the internals are accessible by removing the top

flange and allows a replacement without dismounting the valve from the pipe. Another method is to

use a three-piece body based on a central piece sandwiched between two pieces connecting the valve

to the pipework.

Others design of ball valves are:

• Top entry, in which all the internal components are accessible by dismantling the top cover,

without extracting the valve from the pipeline. Another version is to use a body of three pieces

installed between the two pieces which make the connection to the pipe.

• Twin valve, in which two independent balls are installed in one body

Top entry Doble (Twin ball)

Ball valves are available in all materials in sizes from 5 mm to over 1400 mm (and larger in special

cases). The valves can be used at pressures up to 700 bar, higher pressures are possible. The sealing

of the fluid can be achieved either by soft seat inserts, in which seats are elastomer inserts. Soft seated

valves have restrictions in the temperature limits of the elastomer used as insert, in general the

maximum temperature for soft seats is 250°C. The seats can also be designed for a metal / metal

sealing, which has no restriction in relation of the temperature and is also suitable for abrasive media.

Using metal / metal sealing, the ball and the seats must be coated with hard material to prevent

scratching when the fluid has solids in suspension.

Date 20.04.2020 Page 8 of 17 Rev. Doc. ENT12-20 Rev.0

In general ball valves are used for on-off service, the characteristic is not lineal through the movement.

There are special versions which can be used for control purposes,

One of these versions use a ball with segmented design, with which a linear characteristic can be

achieved.

In another version an orifice plate is installed at the outlet, with orifices distributed in such a way that

the requires characteristic is obtained.

8.2 Gate valves

Gate valves are generally used in the process industry for on-off service. The valve is a multi-turn valve.

The design is not suitable for throttling duty because the sealing surfaces can easily suffer from erosion

when low flows are being maintained against high differential pressures and the design give very poor

flow control characteristics.

The gate valve can be manufactured in a wide range of sizes from 5mm to above 2000mm dia. The

designs are proven and well tested.

There is a great number of different gate valves for specific applications.

Solid wedge Flexible wedge Split wedg

Date 20.04.2020 Page 9 of 17 Rev. Doc. ENT12-20 Rev.0

Gate valves are available in “twin” versions, in which two valves are installed in one body.

Gate valves are pigable in their full-bore version, which means that a pig can pass the valve without

interruption.

8.3 Butterfly valves

The butterfly valve is used to interrupt or regulate the flow of a fluid in a pipe, increasing or reducing

the passage section by means of a disc, called "butterfly", which rotates on an axis. By decreasing the

passage area, the pressure loss in the valve increases, reducing the flow. The valve has a quarter turn

operating system.

The main variations of this valve are the methods of sealing the disc in its closed position.

Those with a central axis have a body completely covered with an elastomer and have the advantage

that it is protected against possible corrosion of the fluid transported, in addition to being

bidirectional.

The other variations are based on offsetting the plane of the disc on the axis of rotation, allowing the

disc to close against a circular face seal (Seat) so that fluid pressure increases the sealing effect. The

modification of the axis of rotation is achieved with a single, double, or triple axis eccentricity. There

is also the variant of using metal seals, which allows the valve to be used in a wide range of fluids at

high temperatures.

The butterfly valve is suitable for many tasks as it provides an optimal solution for an on-off valve,

watertight that could supplant the gate valve. The butterfly valve is designed in diameters from 25mm

to extremely large sizes over 5000mm in diameter. Depending on the size of the valve, working

pressures of up to 100 bar can be handled.

Date 20.04.2020 Page 10 of 17 Rev. Doc. ENT12-20 Rev.0

Butterfly valves are not suitable for the passage of scrapers, they cannot be used in pipes that must be

cleaned or inspected with this system

8.4 Plug valves

The plug valve is the oldest of the valves. Plug valves have been in use for over 2000 years. This valve

has been in continuous development over recent years. The plug valve is basically, and on-off valve

based on a plug with a rectangular hole through which the fluid flows. The plug is either tapered or

cylindric is located in the valve body and can be rotated through a quarter turn to line the hole up with

the pipe when open or across the pipe when closed.

The plug can be adapted for multi-port use allow the valve to be used for diverting flow. The valve can

be engineered with a lubricated plug which uses the lubricant to enable convenient operation over a

wide range of pressures. The lubrication film also provides a seal.

The unlubricated design includes seals in the plug and requires plastic bearing systems. The valve can

include a cage between the plug and the body which includes the bearing a sealing system and allow

convenient maintenance. These valves have been specially developed for use in industries requiring

high performance operation under arduous conditions and allowing remote maintenance e.g. the

nuclear industry.

The valve is a full bore and has virtually no internal cavities but is not pigable in its standard version.

Special versions which are pigable are available on the market, but this design increases drastically the

size and weight of the valve.

Date 20.04.2020 Page 11 of 17 Rev. Doc. ENT12-20 Rev.0

8.5 Globe valves

The globe valve includes an orifice set into the body through which the fluid flows. A disc located on

the end of the spindle is engineered to move in and out along the axis of the orifice. When the disc is

moved to sit in the orifice the flow path is shut-off. The flow path is progressively increased as the

disc is moved away from the orifice.

The surface of the orifice (seat) is generally engineering as a replaceable item made from erosion

resistant material with a polished surface finish. The disc can be fitted with a soft seat if a tight shut-

off is required. For flow control duties the disc is supplied with an engineered shape (lineal, equal

percentage, etc.).

For manually operated valves the spindle screwed so that rotation of the handle moves the disc in

and out. For actuated control valves the spindle is moved in and out using a linear actuator which can

be pneumatic, hydraulic, or electric.

The fluid flow path through globe valves is such that there is normally a high fluid head loss through

the valve. The inline body design has the highest head loss, the angle pattern body design has a lower

head loss. There are certain designs of globe valves which have been engineered to have low head

loss characteristics. Globe valves are supplied in sizes from 3 mm bore through 400 mm and can be

used, size limiting at pressures up to 450 barg. Depending on the sealing systems the valves can be

used at temperatures the 600°C.

Globe valves are not pigable and cannot be used in pipes which must be cleaned or inspected with

pigs.

Date 20.04.2020 Page 12 of 17 Rev. Doc. ENT12-20 Rev.0

8.6 Needle valves

The needle valve is used specifically for accurately controlling the flow of fluids at low flows and/or

micro flows. The valve is basically a globe valve with a obturator that remembers a needle. It is

generally used provided in small sizes of up to 20 mm bore, but there are manufacturers that offer

larger sizes.

Needle valves are not pigable and cannot be used in pipes which must be cleaned or inspected with

pigs.

8.7 Diaphragm valves

The diaphragm valve has no gland seal requirement. The fluid flows straight through the valve via a

chamber over which is an elastomer diaphragm. This diaphragm is normally arranged to provide no

resistance to the flow. The perimeter of the diaphragm is simply clamped to a seal face of the valve

body as a static seal.

To close off the valve the diaphragm is simply forced down into the chamber to block off the flow. The

chamber can include a weir across the flow path against which the diaphragm can be pressed to affect

a more efficient seal with reduced diaphragm distortion.

The straight through variation is effectively a full-bore valve design with all the associated benefits.

However, this option results in a much more arduous duty on the diaphragm which must be a softer

material.

This type of valve is manufactured in sizes from 6mm to 400mm and is generally limited to relatively

low fluid pressures (less than 7 bar). However, in the smaller sizes (up to 50mm) valves can be specially

engineered for use at pressures up to 30 barg. The diaphragm must be chosen to be compatible with

the fluid. Whatever the fluid the diaphragms must be replaced at regular intervals and it is advisable

to operate the valves frequently.

Date 20.04.2020 Page 13 of 17 Rev. Doc. ENT12-20 Rev.0

These valves are often used for duties which require a high degree of cleanliness as they can be

supplied lined, and polished and can be very conveniently cleaned and for transport of solids slurry.

In this last application the advantage is the low cost of the valve, the disadvantage is that the

diaphragm must be replaced very often.

Diaphragm valves can be supplied in pigable versions.

8.8 Pinch valves

The pinch valve is a theoretically ideal solution for fluid on-off duties. The valve is simple a length of

pipe made from an elastomeric material with a mechanical system for squeezing the tube closed

when a shut off is required. The valve is a true full-bore valve - there are no mechanical parts in

contact with the fluid- The operation of the valve is ideally simple; the valve can be easily engineered

as a tight-shut off valve.

The valve is often supplied with the pinch tube contained within an outer pipe between the end

flanges.

The valve has similar limitations to the diaphragm valve. The diaphragm valve is really a variation on

the pinch valve principles. Pinch valves are supplied is for diameters 25 mm - 1000 mm,

temperatures -50 C - +160 C, and pressures 0 - 50 bar.

Pinch valves can be supplied in pigable versions

Date 20.04.2020 Page 14 of 17 Rev. Doc. ENT12-20 Rev.0

8.9 Check valves

Check valves are normally auto actuated and designed to prevent reversal of flow of the fluid in the

pipe. The valves are maintained open by the flow of fluid in the forward direction and are closed by

back pressure of the fluid or by the weight of the closing mechanism or by a spring force. Various

designs are available as listed below.

• Swing check

• Tilting disc

• Ball lift type

• Disc lift type

• Piston check

• Stop check

The range of check valve sizes range from 6mm to massive units of 3000 mm diameter and more.

The swing check variation is a low pressure drop unit based on a hinged disc. This type of valve is

suitable for low velocity applications with infrequent velocity reversals. The valve can be fitted with

external weights to allow faster closure to reduce water hammer or shock pressure on flow reversal.

External systems can also be included to force the valve closed in the event of a local fire.

The tilting disc variation on the swing check valve provides improve speed of operation and pressure

performance and is probably the most popular design of check valve used in the process industry.

At the ball check valve, the function is like the piston type, in which a ball inside the body is used to

control the flow. The ball can move freely, what results in a uniform erosion and cleaning of the areas

between the ball and the seats. This makes this type of check valve ideal for viscous liquids.

Date 20.04.2020 Page 15 of 17 Rev. Doc. ENT12-20 Rev.0

The lift check valve has a seat design like a globe valve. The disc is generally in the shape of a piston or

a ball.

Lift check valves are particularly suitable for high pressure service where the flow rate is high. On lift

check valves the disc is precisely guided and fits snugly on the dash. The lift check valves are suitable

for installation in horizontal or vertical pipes with up flow.

Piston check valves are used to avoid problems in the piping and pumping systems (cavitation)

avoiding any reversal of the flow. They are opened by the passage of the fluid and use a spring to close

them. They also keep the pipes full of fluid if the pumping equipment is stopped.

Date 20.04.2020 Page 16 of 17 Rev. Doc. ENT12-20 Rev.0

Stop check valve. In the stop verification configuration, the stem head floats on the balloon disk (i.e. it

is not connected). Stop check valves have two main purposes: 1) as a globe valve, they isolate or

regulate flow, and 2) modified as a check valve, they prevent reverse flow. In other words, they are

generally used as a globe valve to start or stop media flow, but they also act as a check valve to

automatically close in the event of pressure loss, thus preventing back flow that could cause damage.

to equipment such as boilers or pumps.

Because of this, having a stop check valve is like having two valves in one. The inner disc, which is not

attached to the stem, functions as a lift control that allows the freely move up and down when the

stem is raised to adjust opening and closing. This controls the flow rate, but when a return flow occurs,

the disconnected disc works like a piston control and closes quickly, thus preventing reverse flow into

the boiler. If necessary, the stem can be lowered manually to stop flow or close completely.

These valves are mainly used in power plants, among others, in applications such as boiler circulation,

generation of steam and boiler feed water, turbine cooling, starting water and safety systems.

If the passage of scrapers is required in the check valves, the corresponding version must be selected.

Date 20.04.2020 Page 17 of 17 Rev. Doc. ENT12-20 Rev.0

You might also like

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Valve Types and ApplicationsDocument82 pagesValve Types and Applicationsrajeshn1100% (1)

- Valve Case StudyDocument10 pagesValve Case StudycynthiaNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Darcy's Law Exercise and ProblemsDocument23 pagesDarcy's Law Exercise and ProblemsWandy Gunawan100% (7)

- Plug ValveDocument5 pagesPlug ValveNyoman RakaNo ratings yet

- Control Valve TypesDocument30 pagesControl Valve Typesgad480No ratings yet

- Gate ValvesDocument13 pagesGate Valvesyessa gamuedaNo ratings yet

- Valves Used in Fire Protection SystemDocument20 pagesValves Used in Fire Protection SystemrashalNo ratings yet

- SectionDocument14 pagesSectionFelicia TanNo ratings yet

- Product Range: Gate Valve / Sluice ValveDocument6 pagesProduct Range: Gate Valve / Sluice ValveTanmoy DuttaNo ratings yet

- Making of Most of ValvesDocument12 pagesMaking of Most of ValvesShaikh MateenNo ratings yet

- BioChem Pinch Valve User ManualDocument33 pagesBioChem Pinch Valve User ManualthynameisraymondNo ratings yet

- A Needle Valve Is A Type of Valve Having A Small Port and A ThreadedDocument3 pagesA Needle Valve Is A Type of Valve Having A Small Port and A ThreadedNhat Thanh DangNo ratings yet

- A Ball Valve À Boisseau SphériqueDocument5 pagesA Ball Valve À Boisseau Sphériqueفوزي بنصرNo ratings yet

- Different Valve Types, Applications & SuitabilityDocument10 pagesDifferent Valve Types, Applications & SuitabilityGrazel MDNo ratings yet

- Isolation Valves - Linear MovementDocument9 pagesIsolation Valves - Linear MovementEmad A.AhmadNo ratings yet

- Piping AuxiliariesDocument12 pagesPiping AuxiliariesarchitNo ratings yet

- These Are Two Different Types of Ball ValvesDocument18 pagesThese Are Two Different Types of Ball Valvesgabi_nanaNo ratings yet

- Ball ValveDocument3 pagesBall ValveSwapvaibNo ratings yet

- Process Valv HandbookDocument14 pagesProcess Valv Handbookdenim89100% (2)

- Isolation Valve Linear MovementDocument8 pagesIsolation Valve Linear MovementAjit PatilNo ratings yet

- Design and Analysis of High Pressure Globe Valve Body With Two ElementsDocument6 pagesDesign and Analysis of High Pressure Globe Valve Body With Two ElementsCarlos HinostrozaNo ratings yet

- ValvesDocument82 pagesValvespuru55980100% (1)

- 1.1 Introduction To Gate ValveDocument15 pages1.1 Introduction To Gate ValveSURESHNo ratings yet

- Valve & Type of ValesDocument82 pagesValve & Type of Valesvipinct83% (6)

- Additional_Valves and Control ValvesDocument113 pagesAdditional_Valves and Control ValvesNiña GabrielleNo ratings yet

- Ball ValvesDocument14 pagesBall ValvesMalik DaniyalNo ratings yet

- Types of FittingsDocument22 pagesTypes of Fittingsroronoa zoro100% (1)

- Butterfly ValveDocument8 pagesButterfly Valveswapnil PATIL100% (1)

- ValvesDocument108 pagesValvesGautam Wayse100% (1)

- Types of ValvesDocument6 pagesTypes of ValvesersgdNo ratings yet

- Diaphragm ValveDocument4 pagesDiaphragm ValveNyoman RakaNo ratings yet

- ASCEDocument14 pagesASCEpaulo_rieloffNo ratings yet

- 4 Guidance On Valve Type SelectionDocument86 pages4 Guidance On Valve Type SelectionKrista OneillNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveKannan Kris100% (1)

- Isolation ValvesDocument10 pagesIsolation ValvesnotiadraNo ratings yet

- Asce PDFDocument14 pagesAsce PDFpaulo_rieloffNo ratings yet

- Butterfly Valve Info PDFDocument14 pagesButterfly Valve Info PDFCS100% (1)

- ValvesDocument22 pagesValvesimsarvesh05No ratings yet

- (A) 12.02 Pipeline Ancillaries - Isolation Valves - Rotary Movement (Spirax-Sarco, 2005)Document14 pages(A) 12.02 Pipeline Ancillaries - Isolation Valves - Rotary Movement (Spirax-Sarco, 2005)lyly209No ratings yet

- ValvesDocument42 pagesValvesSundara MoorthyNo ratings yet

- Fisher Control Valve Sourcebook - Power and Severe ServiceDocument220 pagesFisher Control Valve Sourcebook - Power and Severe Servicemtrj59100% (1)

- Check Valves (83BS)Document2 pagesCheck Valves (83BS)Anwar SyedNo ratings yet

- Gate Valve For Piping (Api 600, 602, 603) : Key SpecificationsDocument14 pagesGate Valve For Piping (Api 600, 602, 603) : Key Specificationsswapnil PATILNo ratings yet

- Introduction To ValvesDocument6 pagesIntroduction To ValvesMohamed Al-OdatNo ratings yet

- Large Size Quarter Turn Control Valves Can Improve Safety in PipelinesDocument19 pagesLarge Size Quarter Turn Control Valves Can Improve Safety in PipelinesgpuzoneNo ratings yet

- Valves: Training Centre Monday, April 21, 2014Document77 pagesValves: Training Centre Monday, April 21, 2014Abdullah Sabry Azzam100% (1)

- Globe ValveDocument6 pagesGlobe ValveNyoman RakaNo ratings yet

- Well HeadDocument13 pagesWell Headmuhammadtayyab_87100% (1)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Centrifugal PumpDocument16 pagesCentrifugal PumpJag MasterNo ratings yet

- SDM 143 eDocument20 pagesSDM 143 eseaqu3st100% (1)

- Text Book List 2006 - 2007: University of Bristol Department of Civil EngineeringDocument9 pagesText Book List 2006 - 2007: University of Bristol Department of Civil EngineeringAssad Mohammed AliNo ratings yet

- Concentric Reducer (FRP)Document3 pagesConcentric Reducer (FRP)Zed WangNo ratings yet

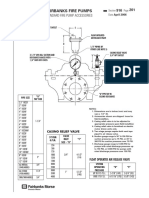

- Fire Pump AccessoriesDocument23 pagesFire Pump AccessoriesMuhammad ArslanNo ratings yet

- Operation & Maintenance: Period Highlight: Manpower PlanningDocument1 pageOperation & Maintenance: Period Highlight: Manpower PlanningMuhammad Prima JayaNo ratings yet

- Sub Module 13.14 HYDRAULIC (ATA 29)Document55 pagesSub Module 13.14 HYDRAULIC (ATA 29)UMAMA ALEEMNo ratings yet

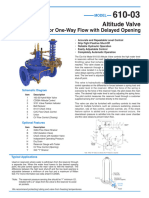

- Altitude Valve: For One-Way Flow With Delayed OpeningDocument4 pagesAltitude Valve: For One-Way Flow With Delayed Openingramon duldulaoNo ratings yet

- Lecture 8 - Control ValvesDocument35 pagesLecture 8 - Control ValvesMohamed SalaheldinNo ratings yet

- Salah MansiaDocument5 pagesSalah Mansiakhalel shalaldahNo ratings yet

- Wet Riser NewDocument19 pagesWet Riser NewFaiz SalimNo ratings yet

- Experiment 1 Control ValvesDocument26 pagesExperiment 1 Control Valvesabu hassan100% (1)

- 7235 EngDocument1 page7235 EngMarlon TurnerNo ratings yet

- Check ValvesDocument8 pagesCheck ValvesNilesh MistryNo ratings yet

- Valve Standard TableDocument8 pagesValve Standard TableAmit PandeyNo ratings yet

- DACE Labour Norms Plastic Piping Tables V2Document3 pagesDACE Labour Norms Plastic Piping Tables V2Amir AbazaNo ratings yet

- ML11139A273 - Owner's Report of Inservice Inspection, Form NIS-1San Onofre Nuclear Generating Station, Unit 3 - 2011Document255 pagesML11139A273 - Owner's Report of Inservice Inspection, Form NIS-1San Onofre Nuclear Generating Station, Unit 3 - 2011EnformableNo ratings yet

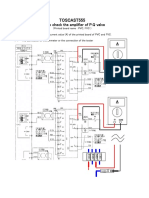

- PQ TOS555 How To Check PQ Amplifier (During Pump Run)Document3 pagesPQ TOS555 How To Check PQ Amplifier (During Pump Run)mike100% (1)

- LS-32001-BCR Benchtop Reactor Teaching Unit Process Flow Dia PDFDocument1 pageLS-32001-BCR Benchtop Reactor Teaching Unit Process Flow Dia PDFMohammad Amir AliNo ratings yet

- Hydraulics 1Document50 pagesHydraulics 1Vivek Verma100% (2)

- Hydraulics in Civil and Environmental EngineeringDocument3 pagesHydraulics in Civil and Environmental EngineeringDanNo ratings yet

- Brake SystemDocument3 pagesBrake SystemThahirullah KhalidNo ratings yet

- Perhitungan Buble To SCFH SCFMDocument1 pagePerhitungan Buble To SCFH SCFMCold HeartNo ratings yet

- DM-2208-0626A - DC Mobile HydraulicsDocument7 pagesDM-2208-0626A - DC Mobile HydraulicsARIEF PRIYANTONo ratings yet

- Scc500e Hyd SchematicDocument34 pagesScc500e Hyd Schematicبيشوى هيبةNo ratings yet

- Mahalakshmi Service Station - Majjigepura PesoDocument1 pageMahalakshmi Service Station - Majjigepura PesoDileep K MahadevaiahNo ratings yet

- Project Name Mount Meru India PVT - LTD Date Project No 447 Rev. No System Softener System Preapared By: BOQ Checked byDocument1 pageProject Name Mount Meru India PVT - LTD Date Project No 447 Rev. No System Softener System Preapared By: BOQ Checked byKunjan SutharNo ratings yet

- CE309 Water Resources Engineering PDFDocument3 pagesCE309 Water Resources Engineering PDFAshker DxNo ratings yet

- 6 P 54202Document1 page6 P 54202Robles DreschNo ratings yet