Drive of Weapon With Together Bound Barrels and Breeches

Drive of Weapon With Together Bound Barrels and Breeches

Uploaded by

ihv69Copyright:

Available Formats

Drive of Weapon With Together Bound Barrels and Breeches

Drive of Weapon With Together Bound Barrels and Breeches

Uploaded by

ihv69Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Drive of Weapon With Together Bound Barrels and Breeches

Drive of Weapon With Together Bound Barrels and Breeches

Uploaded by

ihv69Copyright:

Available Formats

Drive of Weapon with Together Bound

Barrels and Breeches

JIRI BALLA

Department of weapons and ammunition

University of Defence

Kounicova 65, 662 10 Brno

CZECH REPUBLIC

jiri.balla@unob.cz http://www.unob.cz

LUBOMIR POPELINSKY

lubomir.popelinsky@unob.cz http://www.unob.cz

ZBYNEK KRIST

zbynek.krist@unob.cz http://www.unob.cz

Abstract: Eccentric crank mechanism used in a weapon with together bound barrels and breeches as an accelerator is an

example of one performance of the high rate of fire weapon. The drive of this mechanism is made by means of the

gases flowing from the barrel into the gas cylinder.

Key-Words: Eccentric crank mechanism, breech, reduced mass, cylinder, gas vent, gas flow, equation of motion

1 Introduction

In addition to two formerly known high rate of

fire weapon principles the revolver principle and the

Gatling principle (i. e. the principle with rotating

barrels) [1], [2] the third high rate of fire principle with

together bound barrels and breeches has been created.

The first weapon of this principle has been designed by

the German designer Gast at the end of the World

War I. It was 7.92mm aircraft machine gun with two

recoiling barrels but it was not used in following years

After the World War II this principle has been

redesigned by Russian designers and thus the automatic

cannons of the caliber 23 mm and 30 mm have been

created. On the base of this principle Czech designers

have designed 20mm aircraft cannon ZPL-20 utilizing

the NATO cartridge 20x102 mm and the cannon was

accepted in the armament of Czech Air Forces in the

year 2004. Main advantages of the cannon are the low

weight and relatively small dimensions at the high

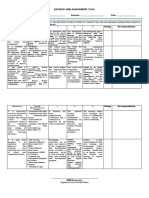

power of fire. Basic design features of the cannon, (see

Fig. 1 and Fig. 2), are the gas operated drive

accelerating the breech block carriers of both barrels,

functional link of both carriers by a pinion ensuring

their alternate motion (i. e. if the breech block carrier of

the right barrel moves backwards, the carrier belonging

to the left barrel moves forwards) and the utilization of

the crank mechanism between the breech block and its

carrier belonging to each barrel.

Fig. 1 Principle of design features

This crank mechanism together with the functional

curve in the weapon casing ensures the continuous

motion (without impacts) of the breech block when

firing. The influence of the functional curve is

transferred on the breech mechanism by means of the

roller placed on the crank. This roller meshes with the

curve.

2 Kinematics and dynamics of weapon

At the beginning of the dynamic analysis of the weapon

it is necessary to find the primary geometric relations

between links, velocities, transmission functions and

accelerations or derivatives of the transmission

functions. Found reduced mass and its derivative enter

into the equation of motion whose form can be written as

2 red

red red

d

0, 5

d

m

m x x Q

x

+ = (1)

or

red

red red

d

0, 5

d

m

m x x Q

t

+ = . (2)

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

ISSN: 1790-2769 48 ISBN: 978-960-474-140-3

First of all, the kinematic relations have to be determined

in every integration step when solving the differential

equations (1) or (2).

Since weapon kinematics depends on the displacement

of the main functional element and it is the breech block

carrier, the equation in the form (1) is mostly used, see

[5], [8].

According to [7] we apply to the vector method on the

kinematic relations between main parts of the weapon

mechanisms as it follows from the Fig. 2,

where

x - breech block carrier displacement (measured from

point A),

2

- rotation angle of crank (ABC),

3

- rotation angle of connecting rod (CD),

b

x - breech block displacement (measured from point D).

Fig. 2 Eccentric crank mechanism of weapon

Let us write, by vector method application on the

quadrangle ACDE as independent loop, the equations

describing the mechanism geometry

2 3 b

cos cos 0 r l x x + + = (3)

and

2 3

sin sin 0 r l e + = . (4)

The known values are

A 2

, , , r AC l CD x x = = = ,

where angle

2

is set in the analytical form

following from the used cam

2 3 4 5

2 0 1 2 3 4 5

a a x a x a x a x a x = + + + + + . (5)

The Newtons iteration method, known as method of

corrections in [7], was applied to obtain two unknowns

3

and

b

x suitable for the required precision . Mostly

two or three iteration procedures were applied in every

integration step.

Differentiation of the preceding equations (3) and (4)

with respect to time yields the following equations for

the velocities - equations (6) and (7) result:

3 b 2

2 3

d d d

sin sin 0

d d d

x

r l v

t t t

+ =

, (6)

3 2

2 3

d d

cos cos 0

d d

r l

t t

+ = . (7)

The reduced mass

red

m in equations (1) or (2) is

determined from the kinetic energy of the whole

system, see [1], [2]

2 2 2

2 SP KL KL

K bbc SP KL KL 2 2 2

2 2 2 2

OJ OJ b P

OJ OJ b P 2 2 2 2

0.5 (2 2 2

2 2 2 ) (8)

v

E v m I I m

v v v

v v v

I m m m

v v v v

= + + +

+ + + +

where

v - breech block carrier velocity,

bbc

m

- breech block carrier mass,

SP

I - tooth wheel mass moment of inertia,

SP

- angular velocity of tooth wheel,

KL

I - crank mass moment of inertia,

KL

- angular velocity of crank,

KL

v - velocity of crank gravity centre,

KL

m - crank mass,

OJ

I - connecting rod mass moment of

inertia,

OJ

- angular velocity of connecting rod,

OJ

v - velocity of connecting rod gravity

centre,

OJ

m - connecting rod mass,

b

v - breech velocity,

b

m - breech mass,

P

v - cartridge belt velocity,

P

m - cartridges and links belt mass.

The right-hand side (1) or (2) is reduced force

red

Q which is given as follows:

red GA VA f P ex PP

Q F F F F F F = (9)

where

GA pA A

F S p = - driving gas force,

VA pAA AA

F S p = - braking force of air,

f

F - friction force,

p

F - resistance of the cartridge belt, depending on the

mass of the belt link and cartridge, rigidity of link

and velocity of the cartridge belt,

ex

F - cartridge extraction force from the belt,

pp

F - force of the breech rebound catch.

The system of equations enabling to solve the action in

the gas arrangement and thus also all the motion of the

weapon mechanism consists of following kinds of

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

ISSN: 1790-2769 49 ISBN: 978-960-474-140-3

equations, see [2]: equation of motion (1) and the other

describing the function of the gas drive. These equations

must be adapted for gases, for the air and for the other

conditions (e.g. in dependence on the pressure ratio

between the cylinder and the barrel.

The action of the drive system utilizing the propellant

gases must be solved for two periods depending on the

relation of the pressure of gases inside the barrel bore p

bl

and the pressure of gases inside the gas cylinder A p

A

,

see [2], [3]. If p

bl

> p

A

then the propellant gases flow

through the gas port from the barrel into the gas cylinder.

For case p

bl

< p

A

the gases flow in the opposite

direction.

These two periods influence the equations of the gas

flow in the following way.

For p

bl

> p

A

:

Equation of the energy change in the gas cylinder A

( ) ( ) ( )

A A A bl A A A pA

d

1

d

p V kR G T G T k p S v

t

= (10)

Equation of the gas mass change in the gas cylinder A

A

A cyA

A

d

d

V

G G

t w

| |

=

|

\

. (11)

For p

bl

< p

A

:

Equation of the energy change in the gas cylinder A

( ) ( ) ( )

A A A A cyA A pA

d

1 .

d

p V kRT G G k p S v

t

= + (12)

Equation of the gas mass change in the gas cylinder A

( )

A

A cyA

A

d

d

V

G G

t w

| |

= +

|

\

. (13)

Important characteristic of these equations is the

magnitude of the gas mass flow G through any cross-

section S from the state 1 to the state 2. For the sub-

critical flow it is given by the formula

2 1

1

2

1 2 2

1 1 1

2

1

k

k k

p p p

G S

k w p p

+

(

| | | |

| |

(

=

| | |

(

\

\ \

(

(14)

and for the critical flow by the formula

( )

1

2 -1

1

1

2

1

k

k

p

G S k

k w

+

| |

=

|

\

. (15)

In these two formulae is:

- discharge coefficient,

S cross-section through the gas flows,

k ratio of specific heats,

p

1

pressure in the vessel, from which the gas flows,

p

2

pressure in the vessel into which the gas flows,

w

1

specific volume of the gas in the vessel from which

the gas flows.

The influence of the air being in the cylinder on the

opposite site of the piston can be taken into

consideration utilizing also the equations of the energy

change and the mass change arranged for the air. Thus

these equations for the air cylinder A are

( ) ( )

( )

AA AA A A AA AAch AAcl

A AA pAA

d

d

1

p V k R T G G

t

k p S v

= +

+

(16)

( )

AA

AAch AAcl

AA

d

d

V

G G

t w

| |

= +

|

\

. (17)

In addition to previous equations the solution of

the action of gases in the gas cylinder A utilizes

following equations:

- instantaneous volume of the gas cylinder A is

A A0 pA

V V S x = + , (18)

- instantaneous pressure of gases in the gas cylinder A

( )

A A

A

A

p V

p

V

= , (19)

- instantaneous specific volume of gases in the gas

cylinder A

A

A

A

A

V

w

V

w

=

| |

|

\

, (20)

- instantaneous temperature of gases in the gas cylinder

A

A A

A

p w

T

R

= . (21)

The solution of the action of the air in the air cylinder

A utilizes similar equations:

AA AA0 pAA

V V S x = , (22)

AA

AA

AA

AA

V

w

V

w

=

| |

|

\

, (23)

AA AA

AA

A

p w

T

R

= , (24)

( )

AA AA

AA

AA

p V

p

V

= . (25)

Symbols used in previous equations are:

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

ISSN: 1790-2769 50 ISBN: 978-960-474-140-3

p

bl

- pressure of gases in the barrel bore,

p

A

- pressure of gases in the gas cylinder A,

t - time,

V

A

- instantaneous volume of the gas cylinder A.

V

A0

- initial volume of the gas cylinder A

R - gas constant of propellant gases,

G

A

- gas mass flow through the gas port,

T

bl

- temperature of gases in the barrel bore,

G

cyA

- gas mass flow from the gas cylinder through

the exhaust orifice,

T

A

- temperature of gases in the gas cylinder A,

S

pA

- area of the piston in the gas cylinder A,

v - velocity of the piston,

bbc

x x = - displacement of the piston,

w

A

- specific volume of gases in the gas cylinder A,

p

AA

- pressure of the air in the air cylinder A,

V

AA

- instantaneous volume of the air cylinder A,

V

AA0

- initial volume of the air cylinder A,

k

A

- ratio of specific heats of the air,

R

A

- gas constant of the air,

G

AAch

- air mass flow from the air cylinder through

the exhaust orifice,

G

AAcl

- air mass flow from the air cylinder through

the clearance of the piston rod,

S

pAA

- area of the piston in the air cylinder A,

w

AA

- specific volume of the air in the air cylinder A.

The system of differential equations was solved using

the extrapolation method, published in [2] together with

the equation of kinematics, see [7].

3 Results

The results of calculation are presented onward. The

numerical values of the input parameters belonging to

the system were obtained from technical specifications

and drawings. Due to very large numbers of inputs only

the most important there are mentioned hereto. First of

all, the significant kinematic values are:

0.065 m, 0.138 m, 0.0388 m, r l e = = =

bbc b oj

2 2

KL OJ

2.4 kg, 0.18 kg, 0.14 kg,

0.0005304 kg.m , 0.001166 kg.m .

m m m

I I

= = =

= =

The inputs belonging to the gas drive were chosen

according to design of the weapon and they were

corrected with respect to the technical experiments.

The main values are:

S

pA

= 0.000706858 m

2

,

= 0.524 if p

bl

> p

A

and = 0.01 if p

bl

< p

A

,

k = 1.26,

p

bl

= 161 MPa (beginning of the drive),

R = 350,

T

hl

= 2529 K,

k

A

= 1.4,

R

A

= 287.

The courses of the gas pressure and the temperature

were calculated using their interpolations by means of

polynomials.

The integration step 0.0001 s looked to be suitable for

the purpose.

The dependence of the input angle

2

on the breech

block carrier displacement

bbc

x is drawn in the Fig. 3

and corresponds to arrangement of the cam and size of

the main parts of the mechanism.

0 0.02 0.04 0.06 0.08 0.1

0.8

1

1.2

1.4

1.6

1.8

2

2.2

x

bbc

(m)

2

(

r

a

d

)

Fig. 3 Input angle

2

The curve course of the breech block carrier

displacement on the time represents the Fig. 4.

The time starts from the time when the projectile

overpasses the gas vent. Therefore the true time does

not begin from zero. The course of the breech block

carrier velocity is depicted in Fig. 5. There is very

interesting the velocity boost after half period of the

motion caused by the returning of the kinetic energy of

the breech to the breech block carrier. This

phenomenon is representative of these mechanisms as it

is introduced in [1], [2] or [8]. In contradistinction to

small arms operated using of the classical cycles, where

velocity of the main functional element slopes down,

here with respect to short time of the cycle, the breech

block carrier is accelerated at the second half of its

cycle.

The breech block displacement versus breech block

carrier displacement is visualized in Fig. 6. The overall

stroke is 165 mm and depends on the cartridge size

loading into the barrel. The idle period at the beginning

is necessary to exclude a random event in course of the

shot when the projectile or the high gas pressure is in the

barrel. This dwell is known as under slide, see [1], [5].

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

ISSN: 1790-2769 51 ISBN: 978-960-474-140-3

Knowledge of that period is needful for design of the

trigger mechanism as it is indicated in [4] and [8].

0 0.005 0.01 0.015 0.02

0

0.02

0.04

0.06

0.08

0.1

0.12

time (s)

x

b

b

c

(

m

)

Fig. 4 Breech block carrier displacement

0 0.005 0.01 0.015 0.02

0

1

2

3

4

5

6

7

8

9

time (s)

v

b

b

c

(

m

.

s

-

1

)

Fig. 5 Breech block carrier velocity

According to breech displacement varies its velocity as it

points to in the Fig. 7, where the maximum velocity is

approximately in the half of the breech block carrier

displacement.

At the end of the cycle the breech strikes in the rear

position on the weapon casing and in accordance with

the shape of the cam changes the final velocity. This

small impact has an advantage ensuring the termination

of the movement into the rear position of the breech in

case of conditions worsening, for example when friction

boosts for surface contamination reasons.

The Figure 8 represents the reduced mass course versus

the breech block carrier displacement as it is written in

the bracket of the equation (8). The maximal value of the

reduced mass matches to the minimal breech block

carrier velocity, see Fig. 5 as well.

0 0.02 0.04 0.06 0.08 0.1

0

0,05

0,1

0,15

x

bbc

(m)

x

b

(

m

)

Fig. 6 Breech block displacement

0 0.02 0.04 0.06 0.08 0.1

0

2

4

6

8

10

12

14

16

18

x

bbc

(m)

v

b

(

m

.

s

-

1

)

Fig. 7 Breech block velocity

0 0.02 0.04 0.06 0.08 0.1

0

5

10

15

x

bbc

(m)

m

r

e

d

(

k

g

)

Fig. 8 Reduced mass

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

ISSN: 1790-2769 52 ISBN: 978-960-474-140-3

The differentiation of the reduced mass according to x

was calculated numerically in every integration step.

The course of the gas pressure in the gas cylinder (and it

is the pressure on the driven piston connected with the

breech block carrier) typifies the Fig. 9. The pressure is

much lower than the initial gas pressure in the barrel

when the mechanism operation begins. The force driving

the whole mass creates during functional cycle the

impulse equals to the momentum whereby all parts

obtain the required velocities. The impulse course is

drawn in the Fig. 10. At the end the system gains the

maximal value. However, it is interesting that this high

rate of fire weapons are driven within entire cycle in

contrast to weapons whose rate of fire under 1000

rounds per minute. These weapons have the main

functional elements accelerated in shorter time in

consideration of the total functional cycle.

0 0.005 0.01 0.015 0.02

0

2

4

6

8

10

12

time (s)

p

A

(

M

P

a

)

Fig. 9 Gas pressure in cylinder

0 0.005 0.01 0.015 0.02

0

10

20

30

40

50

60

70

i

m

p

(

N

.

s

)

time (s)

Fig. 10 Impulse of gas force in cylinder

4 Conclusion

The results given in the figures reflect a good

coincidence with the real weapon which was design

according to presented theory. The theory was verified

on the other examples of weapons patterns as it is

published in [2] for example. The course of input angle

2

depending on the cam curve, see Fig. 3 and the

equation (5), seems to be more suitable than the curves

used in the Gatling systems, which are presented in [2]

or [8]. The procedure used in this article has been

applied in the Czech research institutes and in the

Defence University in Brno as additional teaching

material for students of weapons and ammunition

branch.

References:

[1]Allsop, D. F., Balla, J., Cech, V., Popelinsky, L.,

Prochazka, S., Rosicky, J. Brasseys Essential Guide

to MILITARY SMALL ARMS. London,Washington.

Brasseys, 1997.

[2]Balla, J., Popelinsky, L. Vysokokadenn automatick

zbran. (High rate of fire weapons). (Textbook).

University of Defence. Brno (Czech Republic), 2004.

[3]Jedlicka, L., Beer, S., Videnka, M. Modelling of

pressure gradient in the space behind the projectile.

In Proceedings of the 7

th

International Conference on

System Science and Simulation in Engineering,

Venice (Italy), November 21 23, 2008.

[4]Macko, M. A simulation of the sport small arms

trigger mechanisms. In 10

th

WSEAS Int Conf on

Math Methods, Computat Tech and Intelligent Syst,

OCT 26-28, 2008 Corfu, Greece 21 23, 2008.

[5]Vitek, R. Influence of the small arm barrel bore

length on the angle of jump dispersion. In

Proceedings of the 7

th

International Conference on

System Science and Simulation in Engineering,

Venice (Italy), November 21 23, 2008.

[7] Brat, V., Rosenberg, J., Jac, V. Kinematika.

(Kinematics). SNTL, Prague (Czechoslovakia), 1987.

[8] Racek, F., Bal, T., Macko, M, ervenka, M.

Measuring and modelling of initiation mechanisms of

small arms. Proceedings of the 9

th

WSEAS

International Conference on Applied Computer

science [ACS09]. (Genova) Italy, October 17-18,

2009.

Acknowledgement

The work presented in this paper has been

supported by the research projects: SV2009-

K201, VZ FVT 402 and POV DELO 2009.

RECENT ADVANCES in APPLIED and THEORETICAL MECHANICS

ISSN: 1790-2769 53 ISBN: 978-960-474-140-3

You might also like

- Reactor Design For The Alkylation of Ethylene With Benzene To Produce EthylbenzeneDocument36 pagesReactor Design For The Alkylation of Ethylene With Benzene To Produce EthylbenzeneDyllan StoneNo ratings yet

- Computing Experiment For Unloading Dumper Truck at A Sloping PadDocument8 pagesComputing Experiment For Unloading Dumper Truck at A Sloping PadLong ThànhNo ratings yet

- Kinematic of Marine Piston-Crankshaft System: Lech MurawskiDocument8 pagesKinematic of Marine Piston-Crankshaft System: Lech MurawskiCojocaru TiberiuNo ratings yet

- Problems of The 6 International Physics Olympiad (Bucharest, 1972)Document14 pagesProblems of The 6 International Physics Olympiad (Bucharest, 1972)aditya123sridharNo ratings yet

- Fullp-J - Sznajder - Blade-Rows KONES - 2019Document8 pagesFullp-J - Sznajder - Blade-Rows KONES - 2019Janusz SznajderNo ratings yet

- Kinematics and Kinetic Analysis of The Slider-Crank Mechanism in Otto Linear Four Cylinder Z24 EngineDocument11 pagesKinematics and Kinetic Analysis of The Slider-Crank Mechanism in Otto Linear Four Cylinder Z24 Enginekiran_wakchaureNo ratings yet

- A Slider-Crank Experiment To Determine The Action of Static ForcesDocument10 pagesA Slider-Crank Experiment To Determine The Action of Static ForcesRazali Yusoff100% (1)

- Trajectory - Tracking - of - A - Pneumatically - Driven - PDocument6 pagesTrajectory - Tracking - of - A - Pneumatically - Driven - PQuyết Nguyễn CôngNo ratings yet

- BallonbeamDocument22 pagesBallonbeamYuan HuNo ratings yet

- Flatness-Based ControlDocument6 pagesFlatness-Based ControlQuyết Nguyễn CôngNo ratings yet

- 5542-Article Text PDF-9300-1-10-20130718Document21 pages5542-Article Text PDF-9300-1-10-20130718zeinabNo ratings yet

- Allsop PopelinskyDocument10 pagesAllsop PopelinskyeventnowNo ratings yet

- Mechanics of Machines (314205) : Design, Fabrication and Analysis of Dual Can CrusherDocument10 pagesMechanics of Machines (314205) : Design, Fabrication and Analysis of Dual Can Crushersaqlain05No ratings yet

- Parametric Study of Flexibility Factor For Curved Pipe and Welding ElbowsDocument9 pagesParametric Study of Flexibility Factor For Curved Pipe and Welding Elbowsbam_1962No ratings yet

- Flutter of Rectangular Panel Supersonic Nasa Report PDFDocument16 pagesFlutter of Rectangular Panel Supersonic Nasa Report PDFSal EhNo ratings yet

- Generalpaper On Power Shift of Hydraulic ExcavatorDocument7 pagesGeneralpaper On Power Shift of Hydraulic ExcavatorShankar yadavNo ratings yet

- Dynamics of Machinery3Document18 pagesDynamics of Machinery3dearsaswatNo ratings yet

- 02Document43 pages02Vitelio PinzonNo ratings yet

- Chapter3 FluidDocument11 pagesChapter3 FluidOrlando RomeroNo ratings yet

- Heat Dynemic Gear Transmıssıon SystemDocument18 pagesHeat Dynemic Gear Transmıssıon SystemkarayagizmuhammedNo ratings yet

- 1-s2.0-S0094114X11001273-mainDocument10 pages1-s2.0-S0094114X11001273-maincrowndy lilacNo ratings yet

- RGD25 Paper N763 RiabovDocument7 pagesRGD25 Paper N763 RiabovfaisalabidinNo ratings yet

- Study of Pneumatic Speed Control System With Friction Force CompensationDocument8 pagesStudy of Pneumatic Speed Control System With Friction Force CompensationInternational Journal of Research in Engineering and ScienceNo ratings yet

- SPE-14098-PA Raghavan Well-Test Analysis For Multiphase FlowDocument10 pagesSPE-14098-PA Raghavan Well-Test Analysis For Multiphase FlowLorena CamposNo ratings yet

- Unit 4 Flywheel: StructureDocument21 pagesUnit 4 Flywheel: StructureShivam Gupta0% (2)

- Torque AnalysisDocument32 pagesTorque AnalysisrrjmaierNo ratings yet

- Understanding Valve DynamicsDocument11 pagesUnderstanding Valve Dynamicsnamiabdellatif3No ratings yet

- Feasibility Analysis of The Modified Point Mass Trajectory Model For The Need of Ground Artillery Fire Control SystemsDocument12 pagesFeasibility Analysis of The Modified Point Mass Trajectory Model For The Need of Ground Artillery Fire Control Systemscacak283No ratings yet

- Dynamic Analysis of Multi Component MooringDocument17 pagesDynamic Analysis of Multi Component MooringlithiumabcNo ratings yet

- Study of Rotor-Bearing Systems Using Campbell DiagramDocument4 pagesStudy of Rotor-Bearing Systems Using Campbell DiagrammishraenggNo ratings yet

- Optimising Slew Torque On A Mining Dragline Via A Four Degree of Freedom Dynamic ModelDocument6 pagesOptimising Slew Torque On A Mining Dragline Via A Four Degree of Freedom Dynamic Modelsoh_vakiliNo ratings yet

- Experimental Evidence of Near-Field Superluminally Propagating Electromagnetic FieldsDocument17 pagesExperimental Evidence of Near-Field Superluminally Propagating Electromagnetic FieldsphysicsnoleNo ratings yet

- Hidraulik System With Matlab PDFDocument8 pagesHidraulik System With Matlab PDFrobinsongiraldoNo ratings yet

- Centrifugal Compressor Map Prediction and Modification - NewDocument16 pagesCentrifugal Compressor Map Prediction and Modification - Newpreetham108No ratings yet

- Notes Final Corrd 8-9-11-DistDocument168 pagesNotes Final Corrd 8-9-11-DistirenerefaatNo ratings yet

- Transm Dynamics and ControlDocument17 pagesTransm Dynamics and ControlTimon2005100% (1)

- On The Vibration of Composite Bar in Plan MotionDocument6 pagesOn The Vibration of Composite Bar in Plan MotionChelva PrabaharanNo ratings yet

- Model of A Nozzle-Flapper Type Pneumatic Servo Valve and Differential Pressure Control System DesignDocument6 pagesModel of A Nozzle-Flapper Type Pneumatic Servo Valve and Differential Pressure Control System DesignEric KerrNo ratings yet

- 1Document19 pages1mohan890No ratings yet

- Models - Sme.aluminum Extrusion Fsi PDFDocument26 pagesModels - Sme.aluminum Extrusion Fsi PDFasmaaNo ratings yet

- DETC2007/XXX: The Multiobjective Optimization of A Prismatic DriveDocument9 pagesDETC2007/XXX: The Multiobjective Optimization of A Prismatic Drivemikesmith71poleNo ratings yet

- Stress Analysis and Weight Reduction of A One-CyliDocument18 pagesStress Analysis and Weight Reduction of A One-CyliAnonymous K3FaYFlNo ratings yet

- OSTIV2021 SchwochowDocument5 pagesOSTIV2021 SchwochowJan SchwochowNo ratings yet

- The Post Buckling Behaviour of Bending ElementsDocument23 pagesThe Post Buckling Behaviour of Bending ElementsrkafinaNo ratings yet

- Two Stage Electro-Hydraulic Servo ValveDocument4 pagesTwo Stage Electro-Hydraulic Servo ValveabhijitmukhNo ratings yet

- Thin CylinderDocument16 pagesThin CylinderPranksterz StarzNo ratings yet

- ExercisesDocument58 pagesExercisesmjdaleneziNo ratings yet

- Flkange Design 1Document10 pagesFlkange Design 1arkadjyothiprakashNo ratings yet

- DOM Unit-IDocument48 pagesDOM Unit-IRamanathan DuraiNo ratings yet

- Mixing Time of Refining Vessels Stirred by Gas InjectionDocument8 pagesMixing Time of Refining Vessels Stirred by Gas InjectionПетр СамосийNo ratings yet

- Nonlinear Controller Design For Inverted Pendulum Cart System On Uncertain SlopeDocument9 pagesNonlinear Controller Design For Inverted Pendulum Cart System On Uncertain SlopeDavid KunNo ratings yet

- Model Adaptive Control Tire Test MachineDocument14 pagesModel Adaptive Control Tire Test MachinesiritapeNo ratings yet

- Mathematical Modeling of Mechanical Systems and Electrical SystemsDocument49 pagesMathematical Modeling of Mechanical Systems and Electrical SystemsMary DunhamNo ratings yet

- Chapter-Ii Introduction To ModellingDocument50 pagesChapter-Ii Introduction To ModellingAHMEDNo ratings yet

- Cracked Continuous Rotors Vibrating On Nonlinear BearingsDocument10 pagesCracked Continuous Rotors Vibrating On Nonlinear BearingslucastcNo ratings yet

- Reviews in Computational ChemistryFrom EverandReviews in Computational ChemistryAbby L. ParrillNo ratings yet

- Student Contract TrainingDocument44 pagesStudent Contract TrainingCezz SerenoNo ratings yet

- Balanced and Unbalanced ForcesDocument3 pagesBalanced and Unbalanced Forcesapi-372007393% (15)

- Scientech 71: Best Choice For Your PCB LabDocument2 pagesScientech 71: Best Choice For Your PCB LabSourabh HajraNo ratings yet

- Wavecom Usb Drivers InstallationDocument4 pagesWavecom Usb Drivers InstallationAjit DashNo ratings yet

- Resolved That The Military Be Allowed To Use Propaganda in School - AFFIRMATIVEDocument3 pagesResolved That The Military Be Allowed To Use Propaganda in School - AFFIRMATIVEMaria Reylan GarciaNo ratings yet

- CS3235 SemI 2017 18 FinalProjectsDocument104 pagesCS3235 SemI 2017 18 FinalProjectsJulius Putra Tanu SetiajiNo ratings yet

- Conical Solar StillDocument27 pagesConical Solar StillAbhijeet EkhandeNo ratings yet

- Answer: 6 Explanatio N: Looking at The Diagram in Rows, The Central Circle EqualsDocument17 pagesAnswer: 6 Explanatio N: Looking at The Diagram in Rows, The Central Circle EqualspiyushNo ratings yet

- Sensing The Virtual, Building The Insensible - Brian MassumiDocument28 pagesSensing The Virtual, Building The Insensible - Brian MassumiNur YavuzNo ratings yet

- 5 SBM AssessmentDocument11 pages5 SBM AssessmentHosain Said Usman Jr.No ratings yet

- Municipality Contenion FrontlinesDocument51 pagesMunicipality Contenion FrontlinesCedric ZhouNo ratings yet

- Pds Nexiuszoomevo enDocument6 pagesPds Nexiuszoomevo enMarketing Ecosains HayatiNo ratings yet

- Outlook For The Next Framework Programme: 29 January 2018, Radisson Blu, BrusselsDocument2 pagesOutlook For The Next Framework Programme: 29 January 2018, Radisson Blu, BrusselsAndrea StavrouNo ratings yet

- Unit 1: Introduction To MarketingDocument61 pagesUnit 1: Introduction To MarketingLokesh GowdaNo ratings yet

- G10 4TH NotesDocument6 pagesG10 4TH Notesmarife gupaalNo ratings yet

- Paraphrasing in CounsellingDocument4 pagesParaphrasing in CounsellingJansen BigTummyGuy SunNo ratings yet

- Dftact Observation ToolDocument2 pagesDftact Observation ToolMARK TORRENTENo ratings yet

- ESRI - ArcGISDocument7 pagesESRI - ArcGISDuong NgoNo ratings yet

- EngiLab Beam.2D ManualDocument126 pagesEngiLab Beam.2D ManualIvanEspenianoNo ratings yet

- Cetpa Infotech Pvt. LTD.: Autodesk Inventor Autodesk Inventor TrainingDocument2 pagesCetpa Infotech Pvt. LTD.: Autodesk Inventor Autodesk Inventor TrainingHarish VermaNo ratings yet

- The Taj Human Resource and ProceduresDocument12 pagesThe Taj Human Resource and Proceduresanmolpreet_singh100% (2)

- Journal of SociolinguisticsDocument16 pagesJournal of Sociolinguisticsanon_239378530No ratings yet

- Tower of HanoiDocument32 pagesTower of HanoiDHRUV RAINo ratings yet

- RPH M27 - HAIWAN LIAR Selasa 2023Document3 pagesRPH M27 - HAIWAN LIAR Selasa 2023Nor Zulaikha Binti LaungahNo ratings yet

- Goutham Raj Konda - Resume 2022Document2 pagesGoutham Raj Konda - Resume 2022goutham raj konda jangamNo ratings yet

- Hello Secondary 3 The First PartDocument22 pagesHello Secondary 3 The First PartAhmedNo ratings yet

- 2010 Guidance Navigation Control Ebook Data SheetDocument7 pages2010 Guidance Navigation Control Ebook Data Sheetajitjk123No ratings yet

- Skill Set Lean Six Sigma Orange Belt v3.2Document23 pagesSkill Set Lean Six Sigma Orange Belt v3.2Bhanuprasad sridharaNo ratings yet

- Hindu Editorial Vocabulary May 2024Document32 pagesHindu Editorial Vocabulary May 2024Ashish SabuNo ratings yet