Rocket 7024

Rocket 7024

Uploaded by

Tim PopikCopyright:

Available Formats

Rocket 7024

Rocket 7024

Uploaded by

Tim PopikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Rocket 7024

Rocket 7024

Uploaded by

Tim PopikCopyright:

Available Formats

Hobart Rocket ® 7024

AWS E7024 (E4824*) WELDING POSITIONS:

FEATURES: BENEFITS:

• Self-removing slag system • Quick clean-up, increased productivity

• Low spatter levels • Post weld clean-up time reduced

• Smooth, soft arc • Higher welder satisfaction

• Less affected by rusty, mill scaled materials • Less preparation, more welding

• Finely rippled, flat weld face • Finished, professional appearance

• High deposition, fast fill • Easy to use with drag technique

APPLICATIONS:

• Plate fabrication • Tank fabrication • Barge construction

• Construction • Earthmoving equipment

TYPE OF CURRENT: AC, Direct Current Electrode Positive (DCEP), or Direct Current Electrode Negative (DCEN)

ARC LENGTH: Short arc or drag technique

FLAT: Use faster speed of travel; angle electrode 30° from 90°

VERTICAL-UP: Not recommended

VERTICAL-DOWN: Not recommended

OVERHEAD: Not recommended

STORAGE: 60° to 100°F, (20° to 40°C) and below 50% relative humidity or holding oven @ 100° to 120°F (38° to 49°C)

RECONDITIONING: 250° to 300°F, (121° to 149°C) for one hour @ temperature

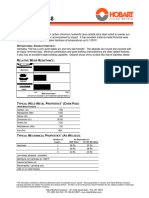

TYPICAL WELD METAL CHEMISTRY* (Chem Pad):

Weld Metal Analysis (%) AWS Spec (max)

Carbon (C) 0.05 0.15

Manganese (Mn) 0.74 1.25

Silicon (Si) 0.45 0.90

Phosphorus (P) 0.009 0.035

Sulphur (S) 0.019 0.035

Nickel (Ni) 0.07 0.30

Chromium (Cr) 0.06 0.20

Molybdenum (Mo) 0.01 0.30

Vanadium (V) 0.02 0.08

Mn + Ni + Cr + Mo + V 0.90 1.5

Note: AWS specification single values are maximums.

TYPICAL MECHANICAL PROPERTIES* (As Welded):

Mechanical Tests AWS Spec (min)

Tensile Strength 82,000 psi (562 MPa) 70,000 psi (483 MPa)

Yield Strength 70,000 psi (483 MPa) 58,000 psi (400 MPa)

Elongation % in 2” (50 mm) 26% 17%

Reduction of Area 30% to 40% Not required

TYPICAL CHARPY V-NOTCH IMPACT VALUES* (As Welded):

AWS Spec

Avg. @0°F (-18°C) 40 ft•lbs (54 Joules) Not required

*The information contained or otherwise referenced herein is presented only as “typical” without guarantee or warranty, and Hobart Brothers Company

expressly disclaims any liability incurred from any reliance thereon. Typical data are those obtained when welded and tested in accordance with the AWS

A5.29 specification. Other tests and procedures may produce different results. No data is to be construed as a recommendation for any welding condi-

tion or technique not controlled by Hobart Brothers Company.

Hobart Brothers Company 101 Trade Square East Troy, OH 45373

PH: (800) 424-1543 FX: 800-541-6607 www.hobartbrothers.com

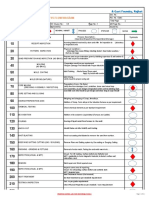

Hobart Rocket ® 7024

Diameter Type of Minimum Optimum Maximum

Inches (mm) Current Amps Amps Amps

1/8 (3.2) DCEN, AC or DCEP 130 160 170

5/32 (4.0) DCEN, AC or DCEP 180 220 245

3/16 (4.8) DCEN, AC or DCEP 200 260 300

7/32 (5.6) DCEN, AC or DCEP 250 300 340

1/4 (6.4) DCEN, AC or DCEP 300 350 380

Deposition

Diameter Type of Amps Volts Rate Deposition

Inches (mm) Current lbs/hr (kg/hr) Efficiency %

1/8 (3.2) DCEN 160 26-27 3.86 (1.8) 66.0

5/32 (4.0) DCEN 220 26-28 5.70 (2.6) 66.2

3/16 (4.8) DCEN 260 26-28 7.64 (3.5) 68.2

7/32 (5.6) DCEN 300 9.48 (4.3) 69.1

1/4 (6.4) DCEN 350 11.04 (5.0) 68.6

• Maintaining a proper welding procedure - including pre-heat and interpass temperatures - may be critical

depending on the type and thickness of steel being welded.

STANDARD DIAMETERS AND PACKAGES: For a complete list of diameters and packaging,

please contact Hobart Brothers at (800) 424-1543, or (937) 332-5188 for International Customer Service.

Diameter 50-lb. (22.7kg)

Inches (mm) Carton

1/8 (3.2) S112944-031

5/32 (4.0) S112951-031

3/16 (4.8) S112959-031

7/32 (5.6) S112970-031

1/4 (6.4) S112981-031

CONFORMANCES AND APPROVALS:

• AWS A5.1, E7024

• ASME SFA 5.1, F-1, A-1

CAUTION:

Consumers should be thoroughly familiar with the safety precautions on the warning label posted in each shipment and in the

American National Standard Z49.1, “Safety in Welding and Cutting,” published by the American Welding Society, 550 NW LeJune

Road, Miami, FL 33126; OSHA Safety and Health Standards 29 CFR 1910 is available from the U.S. Department of Labor,

Washington, D.C. 20210

Material Safety Data Sheets on any Hobart Brothers Company product may be obtained from Hobart Customer Service or at www.hobartbrothers.com.

Because Hobart Brothers Company is constantly improving products, Hobart reserves the right to change design and/or

specifications without notice.

Hobart and Rocket are registered trademarks of Hobart Brothers Company, Troy, Ohio.

Revision Date: 130809 (Replaces 080527)

612-I, INDEX

You might also like

- Advanced Honors Chemistry Syllabus 2023Document1 pageAdvanced Honors Chemistry Syllabus 2023Anirudh KNo ratings yet

- Operating and Maintenance Manual: Brine Filtration SystemDocument14 pagesOperating and Maintenance Manual: Brine Filtration SystemTim PopikNo ratings yet

- Experiments in General Chemistry Ebbing PDFDocument2 pagesExperiments in General Chemistry Ebbing PDFKimberly0% (3)

- Cardolite Coatings Brochure PDFDocument20 pagesCardolite Coatings Brochure PDFKalyanasundaram Thirugnanasambandam100% (1)

- Hydrostatic Pressure Testing Procedure: Petronas Rapid Project Package 14 - Utilities, Interconnecting, Offsite UnitsDocument23 pagesHydrostatic Pressure Testing Procedure: Petronas Rapid Project Package 14 - Utilities, Interconnecting, Offsite UnitsYo Wee Liam100% (1)

- Rocket 7024Document2 pagesRocket 7024Tim PopikNo ratings yet

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocument2 pagesHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNo ratings yet

- Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)Document2 pagesHobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)RodrigoNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Chroma Weld 309 LT1Document2 pagesChroma Weld 309 LT1Gianfranco CopelloNo ratings yet

- Pinnacle Alloys E8018 C3Document2 pagesPinnacle Alloys E8018 C3Sajeev SivanandanNo ratings yet

- 308_308L (1)Document2 pages308_308L (1)fredNo ratings yet

- E6010 Data SheetDocument2 pagesE6010 Data SheetKhaled A MarashliNo ratings yet

- Pinnacle Alloys E8018-B6 Code and Specification DataDocument2 pagesPinnacle Alloys E8018-B6 Code and Specification DataMurad AlmoudiNo ratings yet

- HOB FC86R045X33 SpecSheetDocument2 pagesHOB FC86R045X33 SpecSheetJohn AltasNo ratings yet

- Lincoln6011 AS ES-MX PDFDocument2 pagesLincoln6011 AS ES-MX PDFJuan Novillo RamosNo ratings yet

- Fabshield X80Document2 pagesFabshield X80marco hernandezNo ratings yet

- Pinnacle Alloys E9018-M Code and Specification DataDocument2 pagesPinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Pinnacle Alloys E6013Document2 pagesPinnacle Alloys E6013rahulNo ratings yet

- E9018 M Specifications PDFDocument2 pagesE9018 M Specifications PDFMohamed MostafaNo ratings yet

- Pipeliner 7P+: Conformances Key FeaturesDocument2 pagesPipeliner 7P+: Conformances Key FeaturesAnand GNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- Quantum Arc 3Document2 pagesQuantum Arc 3nateNo ratings yet

- SOW 7018A11 8 SpecSheetDocument2 pagesSOW 7018A11 8 SpecSheetKmi GutierrezNo ratings yet

- 4943 MIG-TIG Data SheetDocument1 page4943 MIG-TIG Data SheetEva pinzonNo ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- Catalog Pinch Valves Series 384 en 3697516Document2 pagesCatalog Pinch Valves Series 384 en 3697516Anonymous otUd3TzINo ratings yet

- E6013 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6013 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Hobart Maxal 4943Document2 pagesHobart Maxal 4943brunizzaNo ratings yet

- Innershield NS-3M: Welding Positions Key FeaturesDocument2 pagesInnershield NS-3M: Welding Positions Key FeaturesGiancarlo BlandinoNo ratings yet

- Atom Arc 8018: Features Typical Mechanical PropertiesDocument2 pagesAtom Arc 8018: Features Typical Mechanical PropertiesFranklin Aranda ChacónNo ratings yet

- Fabcor 86 RDocument2 pagesFabcor 86 RAnonymous fj4iRr1No ratings yet

- Product Data Sheet: Afrox SpeedcraftDocument2 pagesProduct Data Sheet: Afrox SpeedcraftAdel AbduoNo ratings yet

- 4047 VictoryDocument1 page4047 VictoryEva pinzonNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- AbcDocument2 pagesAbcsurendarNo ratings yet

- E6010 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6010 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Hard Alloy 148Document2 pagesHard Alloy 148ander1246mNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- E6011 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6011 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Quantum Arc 6: Hobart Brothers LLC 101 Trade Square East Troy, OH 45373Document2 pagesQuantum Arc 6: Hobart Brothers LLC 101 Trade Square East Troy, OH 45373Gabor VatoNo ratings yet

- E7018 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7018 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Esab Origomig l405 2Document2 pagesEsab Origomig l405 2Hairu LuckyNo ratings yet

- Specifications Sheet Ez1000 8mm Eddy Current Sensor Ams en 1723544Document9 pagesSpecifications Sheet Ez1000 8mm Eddy Current Sensor Ams en 1723544heartsseven36No ratings yet

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoNo ratings yet

- 4043 VictoryDocument1 page4043 VictoryEva pinzonNo ratings yet

- Hobart Maxal 1100Document2 pagesHobart Maxal 1100jclenerNo ratings yet

- WPS-3 (Repair)Document2 pagesWPS-3 (Repair)engr.lutforrahman.bdNo ratings yet

- Wps WT-6 - SMAWDocument2 pagesWps WT-6 - SMAWpeymanNo ratings yet

- Er70s 6Document2 pagesEr70s 6Cesar ZarateNo ratings yet

- Afrox 78MR282 30142Document2 pagesAfrox 78MR282 30142Nelson ShatiNo ratings yet

- Flexible Metalic Hose Braid & AssembliesDocument44 pagesFlexible Metalic Hose Braid & AssembliesiJordanScribdNo ratings yet

- Ultracore 360 C71: Conformances Key FeaturesDocument3 pagesUltracore 360 C71: Conformances Key FeaturesYousab CreatorNo ratings yet

- Product Data Sheet: Afrox 7018-1Document2 pagesProduct Data Sheet: Afrox 7018-1Gervasio AndradeNo ratings yet

- Rhino Cast IronDocument4 pagesRhino Cast Ironabuabdo90355No ratings yet

- Excalibur 7018 MR: Conformances Key FeaturesDocument2 pagesExcalibur 7018 MR: Conformances Key FeaturesumavijayachandranmNo ratings yet

- FabCO 803Document2 pagesFabCO 803dleroux96No ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDocument2 pagesSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNo ratings yet

- Catalogo Er70s3Document3 pagesCatalogo Er70s3upedro26No ratings yet

- WL381060 SellSheet REV 11 2013Document2 pagesWL381060 SellSheet REV 11 2013Tim PopikNo ratings yet

- WindlassDocument16 pagesWindlassTim PopikNo ratings yet

- BGPS Insert BridgesDocument2 pagesBGPS Insert BridgesTim PopikNo ratings yet

- Console-Tdsu IndexDocument2 pagesConsole-Tdsu IndexTim PopikNo ratings yet

- #202 AssembliesDocument26 pages#202 AssembliesTim PopikNo ratings yet

- General Nov Drawworks 1625udbe Service Manual - CompressDocument4 pagesGeneral Nov Drawworks 1625udbe Service Manual - CompressTim PopikNo ratings yet

- HG 50T TOP DRIVE v1-RSDocument2 pagesHG 50T TOP DRIVE v1-RSTim PopikNo ratings yet

- Mechanical Face Seals enDocument26 pagesMechanical Face Seals enTim PopikNo ratings yet

- Avr 5805Document208 pagesAvr 5805Tim PopikNo ratings yet

- LECTURE 4 Organic ChemistryDocument29 pagesLECTURE 4 Organic ChemistryWiza MulengaNo ratings yet

- Lesson 11 METHOD OF SURFACE PROTECTIONDocument2 pagesLesson 11 METHOD OF SURFACE PROTECTIONjeevan basnyatNo ratings yet

- Materials Thermodynamics IiDocument28 pagesMaterials Thermodynamics IiDouglas Heringer OuverneyNo ratings yet

- NK Jain NDDSDocument3 pagesNK Jain NDDSVarsha PujariNo ratings yet

- Tech Spec For Centrifugal PumpDocument5 pagesTech Spec For Centrifugal PumpRoby Mirza100% (1)

- Annexure 3A - ITP For Alloy Steel Seamless & Forged Pipe Fittingsa234 WP11 CL2 & A 182 F11 For Normal NACE & IBRDocument3 pagesAnnexure 3A - ITP For Alloy Steel Seamless & Forged Pipe Fittingsa234 WP11 CL2 & A 182 F11 For Normal NACE & IBRPranav Jadhav100% (1)

- Why Distilled Water PDFDocument4 pagesWhy Distilled Water PDFvitez srpskiNo ratings yet

- DNV GL Commissioning Test Report ASPHALT EXPRESS (9394739)Document19 pagesDNV GL Commissioning Test Report ASPHALT EXPRESS (9394739)krishnanandhNo ratings yet

- Crystal StructureDocument16 pagesCrystal StructureᎽᎪsh ᏒᎪj sᎥᏁᎶhNo ratings yet

- Jee Mains Enthusiast Course (2024-25) Score-IDocument1 pageJee Mains Enthusiast Course (2024-25) Score-I12thexamprep.subitNo ratings yet

- Surface Cracking Mechanism of Continuously Cast Low Carbon Low Alloy Steel SlabsDocument14 pagesSurface Cracking Mechanism of Continuously Cast Low Carbon Low Alloy Steel SlabsChanthar SoeNo ratings yet

- Bioelectric Potentials: - Certain Cells of The Body Generates Their On Monitoring Signals - Excitable CellsDocument110 pagesBioelectric Potentials: - Certain Cells of The Body Generates Their On Monitoring Signals - Excitable CellsYadu KrishnanNo ratings yet

- Unconventional Machining ProcessDocument10 pagesUnconventional Machining ProcessKiran BornareNo ratings yet

- Group IIIA - BoronDocument31 pagesGroup IIIA - BoronAwatif0% (1)

- 〈206〉 AluminumDocument3 pages〈206〉 AluminumAvijit HazraNo ratings yet

- CE Series Manual 2015Document61 pagesCE Series Manual 2015Carl AzzopardiNo ratings yet

- Chem Tech ReviewerDocument3 pagesChem Tech ReviewerMae Christine PaduaNo ratings yet

- Salting In, Salting OutDocument4 pagesSalting In, Salting OutDan MihailNo ratings yet

- Engineering Plastics Polybutylene Terephthalate Technical DataDocument2 pagesEngineering Plastics Polybutylene Terephthalate Technical Dataavinashchauhan2695No ratings yet

- B 3.1 Gas ExchangeDocument51 pagesB 3.1 Gas Exchangevictoria.crausazNo ratings yet

- Physical Chemistry Practice QuestionsDocument26 pagesPhysical Chemistry Practice QuestionsDharshinydevi RamanNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Property Tables CO2Document8 pagesProperty Tables CO2Irem GunayNo ratings yet

- RCC Girder StagingDocument1 pageRCC Girder Stagingsmell2603No ratings yet

- 25.boiler Water Chemistry R1 26.06.2017Document312 pages25.boiler Water Chemistry R1 26.06.2017VINOTHINI R B.Ed100% (1)

- Amino Acids Peptides and ProteinsDocument71 pagesAmino Acids Peptides and ProteinsMike AbellanaNo ratings yet