0 ratings0% found this document useful (0 votes)

7 viewsSustainable Engineering 19

Sustainable Engineering 19

Uploaded by

tve23me071Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Sustainable Engineering 19

Sustainable Engineering 19

Uploaded by

tve23me0710 ratings0% found this document useful (0 votes)

7 views26 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views26 pagesSustainable Engineering 19

Sustainable Engineering 19

Uploaded by

tve23me071Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 26

Sustainable Engineering #19

Bio fuels

Mechanical Engineering, CET 1

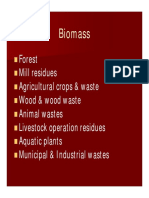

Bio mass and bio fuels

● Initial energy of the biomass-oxygen system is captured from solar

radiation by photosynthesis

● The material of plants and animals, including their wastes and

residues, is called biomass

● The initial material may be transformed by chemical and biological

processes to produce biofuels

● They are in a more convenient form, particularly liquid fuels for

transport

● May include solid fuels and gaseous fuels as well – charcoal, bio char

and gases like methane, syngas, hydrogen etc.

● The term bioenergy is sometimes used to cover biomass and biofuels

together

Mechanical Engineering, CET 2

Natural cycle

Mechanical Engineering, CET 3

Examples

● methane gas

● Hydrogen gas

● liquid ethanol

● liquid methanol

● methyl esters

● oils

● solid charcoal

Mechanical Engineering, CET 4

Classification of bio mass energy

● Thermochemical, heat

● Biochemical

● Agrochemical

Mechanical Engineering, CET 5

Thermochemical, heat

● Direct combustion - firewood

● Pyrolysis -The output depends on temperature,

type of input material and treatment process.

If output of combustible gas is the main

product, the process is called gasification

● Other thermochemical processes - break down

cellulose and starches into sugars, methanol

production

Mechanical Engineering, CET 6

Pyrolysis (destructive distillation)

Mechanical Engineering, CET 7

Methanol liquid fuel

● made from the catalytic reaction of H2 and CO at

330°C and at 150 atmosphere pressure

● 2H2 + CO → CH3OH

● Source may be synthesis gas

● liquid fuel in petroleum spark-ignition engines

● energy density of 23 MJ kg−1

● used as an ‘anti-knock’ fuel additive to enhance

the octane rating

Mechanical Engineering, CET 8

Biochemical

● Aerobic digestion - In the presence of air, microbial

aerobic metabolism of biomass generates heat with

the emission of CO2 , but not methane

not used significantly for commercial bioenergy

● Anaerobic digestion - absence of free oxygen, certain

microorganisms can obtain their own energy supply by

reacting with carbon compounds of medium reduction

level to produce both CO2 and fully reduced carbon as

CH4.

Biogas, sewage gas, landfill-gas

Mechanical Engineering, CET 9

Anaerobic digestion for biogas

Mechanical Engineering, CET 10

Accelerated rate farm digester

Mechanical Engineering, CET 11

Processes of anerobic digestion

● Hydrogenesis - Insoluble biodegradable materials, e.g. cellulose,

polysaccharides and fats, are broken down to soluble carbohydrates and

fatty acids . This occurs in about a day at 25°C in an active digester.

● Acidogenesis - Acid forming bacteria produce mainly acetic and propionic

acid . This stage likewise takes about one day at 25°C.

● Methanogenesis - Methane forming bacteria slowly, in about 14 days at

25°C, complete the digestion to a maximum

∼70% CH4 and

minimum ∼30% CO2 with

trace amounts of H2 and perhaps H2S .

H2 may play an essential role, and indeed some bacteria, e.g. Clostridium,

are distinctive in producing H2 as the final product.

● mildly acidic pH 6.6–7.0 but not more than 6.2

Mechanical Engineering, CET 12

Biochemical (cntd)

● Alcoholic fermentation - action of micro-organisms

and is therefore a fermentation process

Conventional fermentation has sugars as feedstock

Produces Ethanol

● Biophotolysis - splitting of water into hydrogen and

oxygen by the action of light.

Certain biological organisms produce, or can be

made to produce, hydrogen in biophotolysis

Commercial exploitation of these effects has not yet

occurred

Mechanical Engineering, CET 13

Ethanol production

Mechanical Engineering, CET 14

Ethanol fuel use

● 95% ethanol, used directly in modified and

dedicated spark-ignition engines;

● Mixed with the fossil petroleum in dry conditions to

produce gasohol, as used in unmodified spark-

ignition engines, perhaps retuned;

● as an emulsion with diesel fuel for diesel

compression engines (this may be called diesohol,

but is not common).

Mechanical Engineering, CET 15

Agrochemical

● Fuel extraction - liquid or solid fuels may be

obtained directly from living or freshly cut plants

natural rubber latex, turpentine

● Biodiesel and esterification

Mechanical Engineering, CET 16

Bio diesel - definition

● Biodiesel, - a fuel comprised of mono-alkyl

esters of long chain fatty acids derived from

vegetable oils or animal fats,

● Biodiesel Blend - a blend of biodiesel fuel with

petroleum-based diesel fuel, designated BXX,

where XX represents the volume percentage of

biodiesel fuel in the blend

● The US National Biodiesel Board defines

"biodiesel" as a mono-alkyl ester

Mechanical Engineering, CET 17

Biodiesel Blends

● 100% biodiesel is referred to as B100

● 20% biodiesel, 80% petrodiesel B20

● 5% biodiesel, 95% petrodiesel is labeled B5

● 2% biodiesel, 98% petrodiesel is labeled B2

Blends of 20% biodiesel and lower can be used

in diesel equipment with no, or only minor

modifications

Mechanical Engineering, CET 18

Advantages of bio diesel

● Reduces lifecycle greenhouse gases by 86

percent

● Lowers particulate matter by 47 percent, reduces

smog and makes our air healthier to breathe

● Reduces hydrocarbon emissions by 67 percent

● For every unit of fossil energy it takes to produce

biodiesel, 3.5 units of renewable energy are

returned

Mechanical Engineering, CET 19

Raw materials

● Vegetable oil - rapeseed, soybean, coconut, etc.

● Animal fat feedstock,

● Other non-edible raw materials such as frying oil,

jetropha etc.

● Waste vegetable oil (WVO) – rejected oil after cooking

● Algae, which can be grown using waste materials such

as sewage and without displacing land currently used

for food production.

● Sewage Sludge

Mechanical Engineering, CET 20

Transesterification

● is the process of exchanging the organic group R″ of

an ester with the organic group R′ of an alcohol.

● alcohol + ester → different alcohol + different ester

● often catalyzed by the addition of an acid or base

catalyst

● homogeneous catalysis, alkali catalysis (sodium or

potassium hydroxide; or the corresponding alkoxides)

is a much more rapid process than acid catalysis

● used to convert fats (triglycerides) into biodiesel

Mechanical Engineering, CET 21

Process flow

Mechanical Engineering, CET 22

Advantages of bio fuels

● inexhaustible source of energy

● Produces a wide range of products and services

● Increase in local ‘cash flow’ by trade and employment

● The use of sustainable biofuels in place of fossil fuels

abates the emission of fossil-CO 2 and so reduces the

forcing of climate change

● Production of bio mass acts as a temporary carbon sink

● Bio fuels produces lesser sulphor compunds on

combustion

Mechanical Engineering, CET 23

Disadvantages

● The main dangers of extensive biomass fuel use are

deforestation

soil erosion

displacement of food crops by fuel crops

● Poorly controlled biomass processing or combustion can certainly produce

unwanted pollution

● cost of biomass collection is usually too large and too complex for economic

development

● Burning of biomass wont return nitrogen back into soil

● The cost of bio fuel production is more expensive than the conventional

fossil fuels.

● Modification in conventional fossil fueled engine is required to suit some bio

fuels

Mechanical Engineering, CET 24

References

● Renewable Energy Resources - Second edition - John Twidell and Tony

Weir - Taylor & Francis

● The Biodiesel Handbook - Gerhard Knothe, Jon Van Gerpen, Jürgen Krahl -

AOCS Press

● Bio-diesel biodegradable alternative fuel for diesel engines - Dr. Gadepalli

Ravi Kiran Sastry , Readworthy Publications (P) Ltd

● Renewable and alternative energy resources : a reference handbook /

Zachary A. Smith and Katrina D. Taylor

Mechanical Engineering, CET 25

Thank you

Mechanical Engineering, CET 26

You might also like

- 2023 Winter 22530Document6 pages2023 Winter 22530Pravin Muchandi100% (1)

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationRating: 3 out of 5 stars3/5 (1)

- Robotics and AI chemistryDocument89 pagesRobotics and AI chemistrytamimbaig33No ratings yet

- Lect 05 Biomass Energy - Part 1Document33 pagesLect 05 Biomass Energy - Part 1Reanna TabujaraNo ratings yet

- Kartik SeminarDocument15 pagesKartik SeminarADITYA DHURIANo ratings yet

- Renewable Resources (2016)Document40 pagesRenewable Resources (2016)Lindelwa MthembuNo ratings yet

- Bioenergy Introduction PresentationDocument34 pagesBioenergy Introduction PresentationNeil Shrestha-BirtchNo ratings yet

- Biogas TechnologyDocument35 pagesBiogas Technologyraghunath670743No ratings yet

- Alternative FuelsDocument30 pagesAlternative FuelsSatish HS0% (1)

- Biomass PDFDocument35 pagesBiomass PDFKanish MahatoNo ratings yet

- 1.1 Background: "Optimization of Synthesis of Biodiesel Using Membrane"Document5 pages1.1 Background: "Optimization of Synthesis of Biodiesel Using Membrane"Ganesh ShindeNo ratings yet

- Srikant HDocument20 pagesSrikant HSrikanth DesaiNo ratings yet

- Methanol ASPEN PlusDocument23 pagesMethanol ASPEN PlusAravind BudarajuNo ratings yet

- Fuel Policy and Future FuelsDocument75 pagesFuel Policy and Future FuelsKrishnamoorthy VijayalakshmiNo ratings yet

- BiodieselDocument25 pagesBiodieselmano19me019No ratings yet

- Thermo Lecture 3Document38 pagesThermo Lecture 3ABAASA ABANiNo ratings yet

- JMI ESc BiomassDocument33 pagesJMI ESc BiomassAJKNo ratings yet

- AimDocument6 pagesAimAnuj KrNo ratings yet

- Alternative FuelsDocument33 pagesAlternative FuelsUmerNo ratings yet

- What Is Anaerobic Digestion Process For Producing Biogas?Document5 pagesWhat Is Anaerobic Digestion Process For Producing Biogas?Tony DeligiorgisNo ratings yet

- Substitute SNG From BiomassDocument39 pagesSubstitute SNG From Biomassakgupta1946No ratings yet

- Sangeetha Krishnamoorthi, M. Prabhahar, M. Saravana Kumar & S. SendilvelanDocument8 pagesSangeetha Krishnamoorthi, M. Prabhahar, M. Saravana Kumar & S. SendilvelanTJPRC PublicationsNo ratings yet

- On Biodiesel by AbhishekDocument16 pagesOn Biodiesel by AbhishekSumit PanchalNo ratings yet

- EET435 M4 Ktunotes - inDocument53 pagesEET435 M4 Ktunotes - inanakha venugopalNo ratings yet

- Alternative Fuels ExtraDocument82 pagesAlternative Fuels ExtraGrishaanNo ratings yet

- PTT 352 Environmental Engineering Anaerobic Waste Into MethaneDocument27 pagesPTT 352 Environmental Engineering Anaerobic Waste Into MethanefeliciaNo ratings yet

- SessionII Uzun PDFDocument26 pagesSessionII Uzun PDFElizabeth VerdianaNo ratings yet

- Harus Selesai Hari IniDocument11 pagesHarus Selesai Hari IniZefanya Maranatha MangunsongNo ratings yet

- Alternate Fuels For Internal Combustion EnginesDocument14 pagesAlternate Fuels For Internal Combustion Enginesalso swiftNo ratings yet

- The Use of Nonconventional Fuels To Internal Combustion EnginesDocument10 pagesThe Use of Nonconventional Fuels To Internal Combustion EnginesshyleshaNo ratings yet

- Thermo Chemical DegradationDocument32 pagesThermo Chemical DegradationN.R. RishiNo ratings yet

- 13 Alternative FuelsDocument23 pages13 Alternative Fuelsxemovi7309No ratings yet

- Biogas Power PlantDocument130 pagesBiogas Power PlantRahul Tomar100% (4)

- Bio Fuels (Alternative Fuels)Document30 pagesBio Fuels (Alternative Fuels)sad dawsNo ratings yet

- Biodiesel - en InglesDocument7 pagesBiodiesel - en InglesAdolfo Chaves GoyenecheaNo ratings yet

- Biodiesel 3Document6 pagesBiodiesel 3Katerine CarvalhoNo ratings yet

- Comparing The Reactivity of Transition Metals With AcidsDocument20 pagesComparing The Reactivity of Transition Metals With AcidsDukshan KumarNo ratings yet

- NCPG Unit-4Document52 pagesNCPG Unit-4Adhi SheshuNo ratings yet

- Production of Ammonia by Biomass GasificationDocument220 pagesProduction of Ammonia by Biomass GasificationAdeel Arif100% (1)

- Alternative Fuels For I.C. Engine - Solid, Liquid and Gaseous FuelsDocument21 pagesAlternative Fuels For I.C. Engine - Solid, Liquid and Gaseous FuelsSatya NarayanaNo ratings yet

- Biodiesel Production-Current State of The Art and ChallengesDocument10 pagesBiodiesel Production-Current State of The Art and ChallengesMaka MagnaretogneNo ratings yet

- Setiadi 2018 IOP Conf. Ser. Earth Environ. Sci. 105 012103Document8 pagesSetiadi 2018 IOP Conf. Ser. Earth Environ. Sci. 105 012103rodsNo ratings yet

- Biodiesels: Under The Supervision Of: Prof. S.K. Shukla Department of Mechanical Engineering IIT (BHU), Varanasi-221005Document31 pagesBiodiesels: Under The Supervision Of: Prof. S.K. Shukla Department of Mechanical Engineering IIT (BHU), Varanasi-221005shantanubanerjee.mec24No ratings yet

- Hydrogen Gas,Eyob,Feye,Nahi,ChereDocument23 pagesHydrogen Gas,Eyob,Feye,Nahi,Cherenahomabe2No ratings yet

- Estimation of Production CostDocument10 pagesEstimation of Production Costrussell_mahmoodNo ratings yet

- An Experimental Study On Biodiesel Extracted From Waste Cooking Oil and Its Emission Characteristics IJERTCON088Document4 pagesAn Experimental Study On Biodiesel Extracted From Waste Cooking Oil and Its Emission Characteristics IJERTCON088Shanu KumarNo ratings yet

- Alternatives Fuel For IC EngineDocument4 pagesAlternatives Fuel For IC Engineroshansonawane077No ratings yet

- Bioethanol: Roselen, Wanxi, EugeniaDocument36 pagesBioethanol: Roselen, Wanxi, EugeniaGhulam RabbaniNo ratings yet

- 47 - 219 - TS4 ADocument52 pages47 - 219 - TS4 Aslv_prasaadNo ratings yet

- Project ReportDocument54 pagesProject Reportjadhavakshay610No ratings yet

- Biogas IntroductionDocument75 pagesBiogas IntroductionRohan JindalNo ratings yet

- Section2 3 Wang LiuqiDocument35 pagesSection2 3 Wang Liuqitsar_philip2010No ratings yet

- 22OIL205 Nutra.Document18 pages22OIL205 Nutra.Prathamesh PhadtareNo ratings yet

- Chapter 4 - Thermochemistry and FuelsDocument25 pagesChapter 4 - Thermochemistry and FuelsZaidan AlsallalNo ratings yet

- FDGDHDFHDocument24 pagesFDGDHDFHKarthi Keyan R KNo ratings yet

- Biofuel: Hydrotreating of Vegetable Oil To Produce Renewable Diesel Fuel IBUKUN OLUWOYE NICOSIADocument13 pagesBiofuel: Hydrotreating of Vegetable Oil To Produce Renewable Diesel Fuel IBUKUN OLUWOYE NICOSIAIbukun OluwoyeNo ratings yet

- CH215 Industrial Organic Chemistry II 24-12-2021Document229 pagesCH215 Industrial Organic Chemistry II 24-12-2021Fortune VusheNo ratings yet

- green_chemistry (1).pptxDocument29 pagesgreen_chemistry (1).pptxpiyushchande28No ratings yet

- BABS 1202 Study NotesDocument82 pagesBABS 1202 Study NotesyishadabeeNo ratings yet

- Unlocking Green Energy : A Practical Look at Biogas Production Using Agricultural Biomass and Organic WasteFrom EverandUnlocking Green Energy : A Practical Look at Biogas Production Using Agricultural Biomass and Organic WasteNo ratings yet

- Advances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsFrom EverandAdvances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsLalit Kumar SinghNo ratings yet

- Osama DawoudDocument33 pagesOsama DawoudEyob AdNo ratings yet

- Escope An Energy Efficiency Simulator For Internet Data Centers 2023 MDPIDocument21 pagesEscope An Energy Efficiency Simulator For Internet Data Centers 2023 MDPIshashankatrey99No ratings yet

- Electric Hoist Manual-R10Document72 pagesElectric Hoist Manual-R10Dola EzzetNo ratings yet

- Datasheet - DC05CDNC1A - 50010100-A User ManualDocument30 pagesDatasheet - DC05CDNC1A - 50010100-A User ManualinibapaguaNo ratings yet

- Lapp Pro261425enDocument5 pagesLapp Pro261425engogugangNo ratings yet

- 35mm2 Wire SpecsDocument3 pages35mm2 Wire SpecsSohail QureshiNo ratings yet

- Bill of Quantity: CNG Sorong 2 MMCFD or 70000 m3 Description QtyDocument4 pagesBill of Quantity: CNG Sorong 2 MMCFD or 70000 m3 Description QtyAnggun RushNo ratings yet

- Parts ListDocument179 pagesParts ListWilson PalacioNo ratings yet

- ORIFICE AND FREE JET FLOW FME17 Group7Document11 pagesORIFICE AND FREE JET FLOW FME17 Group7Joven MukayNo ratings yet

- Activity 10: Teaching Internship Eportfolio ActivityDocument20 pagesActivity 10: Teaching Internship Eportfolio ActivityCellyia PerezNo ratings yet

- Manual HobartDocument39 pagesManual HobartВолодимир БроNo ratings yet

- ENS4152 Proposal and Risk Assessment ReportDocument11 pagesENS4152 Proposal and Risk Assessment ReportAhmed AliNo ratings yet

- 9 Two Stroke Petrol EnginesDocument7 pages9 Two Stroke Petrol EnginesA.Antony RozarioNo ratings yet

- APPENDIX 4 Statement On Telescopic Spout Operation Fraser Surrey Docks DTCF AmendmentDocument8 pagesAPPENDIX 4 Statement On Telescopic Spout Operation Fraser Surrey Docks DTCF AmendmentRestuNo ratings yet

- UNESCO Groundwater & Sustainable Development Goals Poster (J Bowleg, May-2022)Document1 pageUNESCO Groundwater & Sustainable Development Goals Poster (J Bowleg, May-2022)J BowlegNo ratings yet

- Products Truck hd170 Cargo SpecDocument6 pagesProducts Truck hd170 Cargo SpecJonathan Perfecto MedinaNo ratings yet

- 4 - Fundamentals of Welding (Chapter 25)Document61 pages4 - Fundamentals of Welding (Chapter 25)faisalNo ratings yet

- D1 - 1 - PRV - Codes & Standard - WriteupDocument33 pagesD1 - 1 - PRV - Codes & Standard - Writeupanurag kumarNo ratings yet

- Ahmad Muizzuddin Ahmad Sharainon, Aniq Harith Khairol Afandi, Danial Haqiemi Saifuddin, Muhammad Hanafi Asril Rajo MantariDocument7 pagesAhmad Muizzuddin Ahmad Sharainon, Aniq Harith Khairol Afandi, Danial Haqiemi Saifuddin, Muhammad Hanafi Asril Rajo MantariSunil Kumar P GNo ratings yet

- Dangerous and Prohibited Goods and Packaging Guide: January 2020Document49 pagesDangerous and Prohibited Goods and Packaging Guide: January 2020efhjewfhueiwuhfNo ratings yet

- Grundfos - NK 125 315 317 A2 F A E BAQEDocument14 pagesGrundfos - NK 125 315 317 A2 F A E BAQEMaryasa RobedNo ratings yet

- Science 2 Harshal Small FotntDocument3 pagesScience 2 Harshal Small Fotntytubeworld36No ratings yet

- Chapter 3 - Circular WallDocument13 pagesChapter 3 - Circular WallAdit andriiNo ratings yet

- IEEE Recommended Guide For Measuring Ground Resistance and Potential Gradients in The EarthDocument20 pagesIEEE Recommended Guide For Measuring Ground Resistance and Potential Gradients in The EarthSOURAVNo ratings yet

- Chint 2-7-2021Document8 pagesChint 2-7-2021cwepvskpNo ratings yet

- RobibsonDocument3 pagesRobibsonmailtojamil05No ratings yet

- Équivalences D'huiles - Fluides Hydrauliques Des Différentes MarquesDocument8 pagesÉquivalences D'huiles - Fluides Hydrauliques Des Différentes Marquesyassineguenfoud412No ratings yet

- Electric Field Distribution in Glass and Porcelain Pin InsulatorsDocument5 pagesElectric Field Distribution in Glass and Porcelain Pin Insulatorsdemy antonyNo ratings yet

- M/T Saracena: 20.500 DWT - Twin Screw Diesel Driven Oil Chemical Tanker Ice Class 1A - Rina ClassDocument2 pagesM/T Saracena: 20.500 DWT - Twin Screw Diesel Driven Oil Chemical Tanker Ice Class 1A - Rina ClasshalimNo ratings yet