0 ratings0% found this document useful (0 votes)

7 views122ES

122ES

Uploaded by

Shubham RajputCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

122ES

122ES

Uploaded by

Shubham Rajput0 ratings0% found this document useful (0 votes)

7 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views3 pages122ES

122ES

Uploaded by

Shubham RajputCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

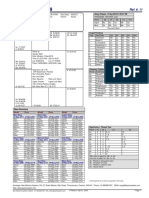

BVM ENGINEERING COLLEGE [AN AUTONOMOUS INSTITUTION]

122ES: BASICS OF PRODUCTION ENGINEERING

CREDITS- 4 (Lc , Tc , Pc : 3,0,1)

Course Objectives:

1. To introduce the fundamental concepts, principles, and manufacturing processes

(recent and traditional) in production engineering.

2. To provide an understanding of material properties and their importance in materials

selection to undertake design for manufacture.

3. To develop basic skills in using production engineering tools and techniques.

4. To emphasize the importance of manufacturing and quality management.

Teaching and Assessment Scheme:

Teaching Scheme

Credits Assessment Scheme Total

(Hours per week)

Marks

Theory Practical

L T P C

ESE CE ESE CE

3 0 2 4 60 40 20 30 150

Course Contents

Unit Topics Teaching

No. Hours

1 Introduction to Production Engineering: 03

Definition and scope of production engineering

Role and responsibility of production engineers in industry

Compare and Contrast: production engineering with mechanical

engineering.

2 Materials and Material Properties: 04

Classification of materials: metals, polymers, ceramics, composites

Mechanical, thermal and electrical properties of materials: strength,

hardness, ductility, toughness, creep, fatigue thermal conductivity,

thermal expansion, thermal resistance, electrical conductivity,

electrical resistance

Selection criteria for materials in manufacturing

Unit Topics Teaching

No. Hours

3 Manufacturing Processes 12*

Casting: types, processes, and applications

Forming: forging, rolling, extrusion, drawing, sheet metal forming

Welding: principles, methods, and equipment

Machining: turning, milling, drilling, grinding

Non-traditional machining processes: EDM, ECM, laser cutting

Additive manufacturing: 3D printing, rapid prototyping

4 Production Engineering Tools and Techniques 05

Introduction to conventional and CNC machines

Tool design and tool materials

Measurement and inspection tools

5 Safety and Sustainability 03

Occupational Safety: Safety in Industry, Safety Rules in

Industry/Workshop, Safety Signs and Charts

Environmental Impact: Minimizing Industrial Waste, Industrial

ways for governing water, air and land pollution.

6 Quality Control and Management 03

Principles of quality control

Statistical process control

Six Sigma

7 Manufacturing Management 08

Concepts of productivity enhancement tools

Production operation management

Optimization techniques in production

Production systems: flexible manufacturing systems, lean

manufacturing systems

Total Productive Maintenance (TPM)

Quality systems in production engineering

8 Manufacturing Peripherals 04

Air Compressors, Pumps, IC Engines, Prime Movers (Introduction,

types, applications)

Total 42

* To be covered in the practical classes

List of References:

1. S. K. Hajra Choudhari, A K Hajra Chaudhary and N. Roy, “Elements of Elements of

Workshop Technology, Vol 1| Manufacturing Processes”, Media Promoters and

Publishers Pvt. Ltd.

2. S. K. Hajra Choudhari, A K Hajra Chaudhary and N. Roy, “Elements of Elements of

Workshop Technology, Vol 2| Machine Tools”, Media Promoters and Publishers Pvt.

Ltd.

3. Serope Kalpakjian and Steven Schmid, "Manufacturing Engineering and Technology",

Pearson Education (India Edition)

4. "Fundamentals of Modern Manufacturing: Materials, Processes, and Systems" by

Mikell P. Groover

5. Dale H. Besterfield, "Quality Control" Pearson Education, 2012

6. R A Lindberg, “Processes and Materials for Manufacture”, Prentice Hall India.

7. Ian Gibson, David Rosen, and Brent Stucker "Additive Manufacturing Technologies:

3D Printing, Rapid Prototyping, and Direct Digital Manufacturing"

8. P. H. Joshi, “Production Engineering” 2010 McGraw-Hill Education (India) Private

Limited.

Course Outcomes:

Upon successful completion of the course, students will be able to:

1. Understand the fundamental concepts of production engineering. (Cognitive Outcome)

2. Identify and understand various manufacturing processes and manufacturing

management tools.(Cognitive Outcome)

3. Understand material properties and their selection for different manufacturing

processes (Cognitive Outcome)

4. Apply manufacturing methods to make simple and elementary components

(Behavioural Outcome)

5. Appreciate the importance of production engineering and manufacturing management

tools, and techniques in the engineering situations. (Affective Outcome)

You might also like

- Chemical Plant Design (Complete Lectures) PDFDocument224 pagesChemical Plant Design (Complete Lectures) PDFMoiz Ehsan86% (7)

- MPN Document PDFDocument15 pagesMPN Document PDFAmit Dahiya100% (1)

- CA2 Y9772 enDocument34 pagesCA2 Y9772 enjfdezmtnezNo ratings yet

- Management Information SystemsDocument2 pagesManagement Information SystemsDhruv DarjiNo ratings yet

- 2nd Sem PDM SyllabusDocument11 pages2nd Sem PDM SyllabusVinay AlagundiNo ratings yet

- FALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 14-Jul-2020 SyllabusDocument3 pagesFALLSEM2020-21 MEE3501 ETH VL2020210100431 Reference Material I 14-Jul-2020 SyllabusJawa freakNo ratings yet

- M.Tech, PDM - Syllabus 2020-21Document52 pagesM.Tech, PDM - Syllabus 2020-21nadhavanpouniahNo ratings yet

- 4ME506 Full Nutcracker 18-19Document26 pages4ME506 Full Nutcracker 18-19Gabriel NohraNo ratings yet

- Manufacturing Process 4 PDFDocument2 pagesManufacturing Process 4 PDFVijayalaxmi MudhigondaNo ratings yet

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3jpbhimaniNo ratings yet

- Plant Maintenance and Safety EngineeringDocument3 pagesPlant Maintenance and Safety EngineeringBhushan Shankar KambleNo ratings yet

- L0 MEC205 Zero Lecture UpdatedDocument42 pagesL0 MEC205 Zero Lecture UpdatedJames PrakashNo ratings yet

- CIM Course PlanDocument8 pagesCIM Course PlanKamal Vijay Ram R SNo ratings yet

- Course Outline MFG IIDocument2 pagesCourse Outline MFG IIAbrham ChanieNo ratings yet

- 3CP08Document1 page3CP08Rakshit VajaNo ratings yet

- 6th Sem SyllabusDocument16 pages6th Sem SyllabusSOUMIK DASNo ratings yet

- Me Sem678Document122 pagesMe Sem678Gaurab SarkarNo ratings yet

- SyllabusDocument3 pagesSyllabusDishank UpadhyayNo ratings yet

- Gujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807Document2 pagesGujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807ganeshNo ratings yet

- Subject Production Techology SyllabusDocument3 pagesSubject Production Techology SyllabusbmdbmdbmdNo ratings yet

- Iom 1508Document5 pagesIom 1508zahin_13200No ratings yet

- Honours Minor Degree Program Syllabus - 6Document25 pagesHonours Minor Degree Program Syllabus - 6Tarini DeshpandeNo ratings yet

- Department: Production Engineering LaboratoryDocument70 pagesDepartment: Production Engineering LaboratorySourabh PradhanNo ratings yet

- 19ME307 Rapid Product DevelopmentDocument2 pages19ME307 Rapid Product DevelopmentsahilNo ratings yet

- Mee3502 - Design-Process-Planning-And-Management - Eth - 1.0 - 62 - Mee3502 - 58 AcpDocument3 pagesMee3502 - Design-Process-Planning-And-Management - Eth - 1.0 - 62 - Mee3502 - 58 AcpwewewewNo ratings yet

- Course Outlines For Different SubjectsDocument7 pagesCourse Outlines For Different SubjectsjosephNo ratings yet

- 5 6052945999217820047 PDFDocument93 pages5 6052945999217820047 PDFFifa HDNo ratings yet

- Course Curriculum: Uttar PradeshDocument3 pagesCourse Curriculum: Uttar PradeshHtat Myat AungNo ratings yet

- Workshop Laboratory Manual PDFDocument95 pagesWorkshop Laboratory Manual PDFPradipta PaulNo ratings yet

- Product Design and Value EngineeringDocument3 pagesProduct Design and Value EngineeringsachinsachinNo ratings yet

- Manufacturing ProcessDocument3 pagesManufacturing ProcessReham EltuhamyNo ratings yet

- Course Outline DP 1Document5 pagesCourse Outline DP 1Abi FafNo ratings yet

- Industrial Engineering PDFDocument3 pagesIndustrial Engineering PDFviswabali1596No ratings yet

- Industrial Engineering Mod 1Document27 pagesIndustrial Engineering Mod 1will billNo ratings yet

- Course 12 Additive Manufacturing For Industry 4Document8 pagesCourse 12 Additive Manufacturing For Industry 4Ioan IonescuNo ratings yet

- DesignDocument45 pagesDesignedris farahNo ratings yet

- (E) MDM in Mechanical Engineering 2023 NEP Aug 3 2023Document13 pages(E) MDM in Mechanical Engineering 2023 NEP Aug 3 2023Sohar MarathiNo ratings yet

- Plant Design and EconomicsDocument311 pagesPlant Design and Economics76 NISHANT RANA100% (1)

- meetreport 3Document7 pagesmeetreport 32024uch1144No ratings yet

- Pec IvDocument6 pagesPec Iv3111hruthvikNo ratings yet

- Met305 Ise Study MaterialDocument76 pagesMet305 Ise Study MaterialSURYA R SURESHNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- What Is Chemical Engineeringv3Document16 pagesWhat Is Chemical Engineeringv3TrifosaAjengRiswantiWulandariNo ratings yet

- Product Design and Manufacturing: R.V. College of EngineeringDocument35 pagesProduct Design and Manufacturing: R.V. College of EngineeringSai SrinivasNo ratings yet

- ES111Document1 pageES111yash shahNo ratings yet

- M.Tech CM - ACM Sem-I To IV 2020-21Document75 pagesM.Tech CM - ACM Sem-I To IV 2020-21Max WatsonNo ratings yet

- Plant Design and EconomicsDocument311 pagesPlant Design and Economics56 JAY PATEL100% (1)

- Final M.E. Production EnggDocument18 pagesFinal M.E. Production EnggsatishNo ratings yet

- Policies and Standards - BSIE 1 / 17Document17 pagesPolicies and Standards - BSIE 1 / 17Ice JENo ratings yet

- Course Outine (Production Engineering I)Document2 pagesCourse Outine (Production Engineering I)GetahunNo ratings yet

- Sulinjo Part 2Document15 pagesSulinjo Part 2Rochart RaswinNo ratings yet

- CpE Laws - Professional Practice - Module 01Document29 pagesCpE Laws - Professional Practice - Module 01Joel Manacmul100% (1)

- PDE Teaching PlanDocument6 pagesPDE Teaching PlansrujankalaNo ratings yet

- BTech Mechanical - 2020-24 ADMDocument4 pagesBTech Mechanical - 2020-24 ADMKanu SharmaNo ratings yet

- B.E. (Production Engineering) Subject 1: In-Plant Training: Semester: VIIDocument10 pagesB.E. (Production Engineering) Subject 1: In-Plant Training: Semester: VIIGokul MuniNo ratings yet

- Program Specs - Industrial EngineeringDocument108 pagesProgram Specs - Industrial EngineeringRabab ElkomyNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityPriyank ChhatriwalaNo ratings yet

- TA202A: Introduction To Manufacturing Processes Manufacturing ProcessesDocument51 pagesTA202A: Introduction To Manufacturing Processes Manufacturing ProcessesLalla DasNo ratings yet

- B.Tech ME - 24092020Document104 pagesB.Tech ME - 24092020Vansh Pratap SinghNo ratings yet

- Lecture 1 - IntroductionCH1001_New_compressedDocument40 pagesLecture 1 - IntroductionCH1001_New_compressedkhueanhmaiducNo ratings yet

- Wachemo University College of Engineering and Technology School: Electrical and Mechanical Engineering Department of Mechanical EngineeringDocument2 pagesWachemo University College of Engineering and Technology School: Electrical and Mechanical Engineering Department of Mechanical EngineeringYonael MezmureNo ratings yet

- Mechanical Production Engineer Success: Careers, Interview Q&A, and TerminologyFrom EverandMechanical Production Engineer Success: Careers, Interview Q&A, and TerminologyNo ratings yet

- Unit 4Document12 pagesUnit 4Shubham RajputNo ratings yet

- Press OSER GeneralDocument1 pagePress OSER GeneralShubham RajputNo ratings yet

- PDFDocument4 pagesPDFShubham RajputNo ratings yet

- PDFDocument2 pagesPDFShubham RajputNo ratings yet

- PDFDocument6 pagesPDFShubham RajputNo ratings yet

- Chemistry: NotesDocument17 pagesChemistry: NotesShubham Rajput75% (4)

- Chemistry: ConceptDocument11 pagesChemistry: ConceptShubham Rajput100% (1)

- Chapter Wise: 10 YearsDocument7 pagesChapter Wise: 10 YearsShubham RajputNo ratings yet

- UNIT 5 Mechanics (2) - PDFDocument7 pagesUNIT 5 Mechanics (2) - PDFShubham RajputNo ratings yet

- Book Review: "Overlapping Intellectual Property Rights" by Neil Wilkof and Shamnad BASHEER (Eds.)Document6 pagesBook Review: "Overlapping Intellectual Property Rights" by Neil Wilkof and Shamnad BASHEER (Eds.)Jayaram ParlikadNo ratings yet

- TOPS 0-05 Product StewardshipDocument2 pagesTOPS 0-05 Product Stewardshipengpierre1403No ratings yet

- Andrew N Wilkins Resume (Final)Document2 pagesAndrew N Wilkins Resume (Final)api-283780895No ratings yet

- Aruna OBDocument35 pagesAruna OBsujeewaNo ratings yet

- 529 Gbd0908a Asm2Document33 pages529 Gbd0908a Asm2Phạm Trần Thu TràNo ratings yet

- Del NetDocument27 pagesDel NetHirak GhoshNo ratings yet

- Teaching Strategies and Methodologies For Teaching & LearningDocument89 pagesTeaching Strategies and Methodologies For Teaching & LearningMabelle Blancada Consulta100% (5)

- Advanced Circuit Theory Passive Synthesis: Giancarlo Storti GajaniDocument33 pagesAdvanced Circuit Theory Passive Synthesis: Giancarlo Storti GajaniPeter VinciguerraNo ratings yet

- 85 Movie Scenes Which Highlight Great LeadershipDocument112 pages85 Movie Scenes Which Highlight Great LeadershipRajgopal IyerNo ratings yet

- WM SAP Course SlidesDocument155 pagesWM SAP Course SlidesAdrian MarchisNo ratings yet

- Adlaw (G7 Factual & Personal)Document3 pagesAdlaw (G7 Factual & Personal)Catherine Rose Cagampang AdlawNo ratings yet

- Calculation Sheet: Perunding Nusajasa SDN BHDDocument7 pagesCalculation Sheet: Perunding Nusajasa SDN BHDSarahLukakuNo ratings yet

- MBTI TalkDocument2 pagesMBTI TalkShiv KeskarNo ratings yet

- 07th Framework Programme 2007-2013 Volume 1 Project Synopses, Calls 2007 & 2008 PDFDocument332 pages07th Framework Programme 2007-2013 Volume 1 Project Synopses, Calls 2007 & 2008 PDFCarlos PanaoNo ratings yet

- Awwa C210-15Document28 pagesAwwa C210-15PeymanMajidi83% (18)

- Unit 1 Operating System For Parallel Computer: Structure NosDocument39 pagesUnit 1 Operating System For Parallel Computer: Structure Nosgk_gbuNo ratings yet

- Ice AgeDocument188 pagesIce Ageapi-245005557100% (1)

- Komatsu PC800LC - 8Document1,327 pagesKomatsu PC800LC - 8blaktion100% (12)

- Synthetic Paraffinic Kerosene From Jatropha CurcasDocument4 pagesSynthetic Paraffinic Kerosene From Jatropha Curcasdijayof87No ratings yet

- Consistency of SoilDocument3 pagesConsistency of Soiladrie aleaNo ratings yet

- The Rise of Social BotsDocument11 pagesThe Rise of Social BotsarmsarivuNo ratings yet

- PMI Knowledge Areas: Stakeholder ManagementDocument16 pagesPMI Knowledge Areas: Stakeholder ManagementaangelbrightNo ratings yet

- Revised Alice in Borderland: Season 1 - EP 5, 6, 7 & 8 RecapDocument14 pagesRevised Alice in Borderland: Season 1 - EP 5, 6, 7 & 8 RecapChriston Taylor CaldwellNo ratings yet

- Investment PDFDocument1 pageInvestment PDFGautam RampalNo ratings yet

- Kindergarten DLL MELC Q1 Week 1.2Document11 pagesKindergarten DLL MELC Q1 Week 1.2Marian Grace De La TorreNo ratings yet

- Java 1. Factory MethodDocument9 pagesJava 1. Factory MethodkasimNo ratings yet