Specification Sheet Shell and Tube Exchanger (Si Units) Api 660

Specification Sheet Shell and Tube Exchanger (Si Units) Api 660

Uploaded by

Ivan PuentesCopyright:

Available Formats

Specification Sheet Shell and Tube Exchanger (Si Units) Api 660

Specification Sheet Shell and Tube Exchanger (Si Units) Api 660

Uploaded by

Ivan PuentesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Specification Sheet Shell and Tube Exchanger (Si Units) Api 660

Specification Sheet Shell and Tube Exchanger (Si Units) Api 660

Uploaded by

Ivan PuentesCopyright:

Available Formats

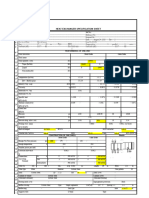

JOB NO. CE4160 ITEM NO.

104-E-135

PROJECT: KIRBY NORTH PHASE 1 DOC. NO. KNP-DS-M-104-E-135

P.O. NO. REV. NO. 0

SPECIFICATION SHEET INQUIRY NO. DATE: 1/31/2013

SHELL AND TUBE EXCHANGER

(SI UNITS) API 660 PAGE 1 OF 5

Rev.

1 Client CNRL Location CONKLIN, AB

2 Process Unit CPF UNIT 4 Fabricator Exchanger Industries

3

4 Service of Unit SALES OIL TANK HEATER No. of Units 1

5 Size 381 - 6096 TEMA Type BEU Connected in 1 Parallel 1 Series 1

6 Surface/Unit (gross) 36.9 m2 Shells/Unit 1 Surface/Shell (Eff.) 36.7 m2

7 PERFORMANCE OF ONE UNIT

8 Fluid Allocation (Inlet) SHELL SIDE (Outlet) (Inlet) TUBE SIDE (Outlet)

9 Fluid Name SALES OIL GLYCOL

10 Fluid Quantity, Total kg/h 56495 10527

11 Vapor (MW) kg/h

12 Liquid kg/h 56495 56495 10527 10527

13 Steam kg/h

14 Water kg/h

15 Noncondensable / MW kg/h / /

16 Temperature °C 30 40 90 60

17 Density (Vapor/Liquid) kg/m3 920 915 1038.6 1062

18 Viscosity (Vapor/Liquid) mPa.s 230 119 1.4113 2.743

19 Specific Heat (Vapor/Liquid) kJ/(kg.K) 1.822 1.863 3.4057 3.272

20 Thermal Conductivity (Vapor/Liquid) W/(m.K) 0.1425 0.1402 0.3364 0.3450

21 Latent Heat kJ/kg @ °C @ @

22 Inlet Pressure kPa (ga) 220 1171

23 Velocity m/s 0.58 0.62

24 Pressure Drop (Allowable/Calculated) kPa 70 65.49 70 18.819

25 Fouling Resistance m2.K/W 0.000528 0.000176

2. 588.73 1121.76

26 Avg. Film Coefficient W/(m K)

27 Heat Exchanged 292.47 kW MTD (Corrected) (Weighted) 37.9 °C

28 Transfer Rate (Required/Fouled/Clean) 210.13 274.77 346.69 W/(m2.K)

29 ρV2 [kg/(m.s2)]: Inlet Nozzle 4072.51 Bundle Entrance 39.5 Bundle Exit 102.93

30 CONSTRUCTION PER SHELL

31 Tube No. 102 U-legs OD 19.05 mm NOZZLES - No. Size & Rating

32 Thickness 2.108 mm (Min./Avg.) Min SHELL SIDE TUBE SIDE

33 Pitch 25.4 mm Tube Pattern 45 Inlet

34 Length 6.096 m Type Plain Outlet SEE PAGE 2 OF 5

35 Tube-Tubesheet Joint Rolled 2 RG Intermediate

36 Shell Diameter (ID/OD) 381 ID / mm Vent

37 Cross Baffle Type Single Segmental Drain

38 Spacing: c/c 206.375

mm No. of Crosspasses 25

39 % Cut 36.1 Design Press. kPa (ga) 3500 3500

40 Tube Support Type N/A Vacuum Press. kPa (abs) FV / 148 °C FV / 148 °C

41 Long Baffle Seal Type N/A Design Temp(Max/MDMT) °C 150 / -29 150 / -29

42 By-Pass Seal Type Seal Rod No. of Passes per Shell 1 4

43 Impingement Protection (Y/N) Y Corrosion Allowance

mm 3.2 3.2

44 MATERIALS OF CONSTRUCTION: SEE PAGE 2 OF 5 FOR MORE DETAILS

45 Shell SA-106-B Tubes SA-179 ANNEALED Gaskets:

46 Shell Cover SA-234-WPB Shell Side 316 SS core, flex graphite, Kammprofile

47 Channel or Bonnet SA-106-B Tube Side 316 SS core, flex graphite, Kammprofile

48 Channel Cover SA-234-WPB Floating Head N/A

49 Floating Head Cover/Bolts Spare Sets Req'd 1 set of spare gaskets, 10% of bolting

50 Tubesheet: Stat. SA-516-70N Floating Test Ring Req'd (Y/N) NO

51 Baffles: Cross SA-36 Long Insulation: Shell 64 mm mineral wool with aluminum jacket

52 Tube Support Material Channel Inlet/Exit 51 mm mineral wool with aluminum jacket

53 Expansion Joint Type N/A Expansion Joint Material N/A

54 Code Requirements ASME Sec. VIII, Div. 1 Stamp Y Calc. MAWP (Y/N) Y TEMA Class R

55 REMARKS : See notes on page 2

56

57

REVISION LOG

REV. DESCRIPTION DATE BY CHK'D APP'D

0 ISSUED FOR PURCHASE 1/31/2013 SS DA HB

¤ Revision 0 - ISSUED FOR PURCHASE - 2/4/2013 ¤

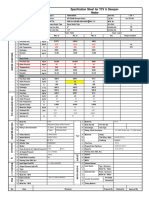

JOB NO. CE4160 ITEM NO. 104-E-135

PROJECT: KIRBY NORTH PHASE 1 DOC. NO. KNP-DS-M-104-E-135

P.O. NO. REV. NO. 0

SPECIFICATION SHEET INQUIRY NO. DATE: 1/31/2013

SHELL AND TUBE EXCHANGER

(SI UNITS) API 660 PAGE 2 OF 5

Rev.

1 CONNECTION SCHEDULE THERMAL EXPANSION DESIGN INFORMATION

2 No. Shell Mean Shell Tubesheet Tube Mean Tube

Mark Size Rating Facing Description

3 Req'd. (Optional) Metal Press. Mean Metal Metal Press.

4 S1 1 4 300# RFLWN SS INLET Temp. °C kPa (ga) Temp. °C Temp. °C kPa (ga)

5 S2 1 4 300# RFLWN SS OUTLET Design

6 Normal

7 Starting

8 T1 1 4 300# RFLWN TS INLET Shutdown

9 T2 1 4 300# RFLWN TS OUTLET Upset #1

10 Upset #2

11 Steam out

12 Expansion Joint Design Life Cycles

13

14

15 MATERIALS OF CONSTRUCTION Corr. Allow.

16 Shell: SA-106-B 3.2 mm

17 Head: SA-234-WPB 3.2 mm

18 Pipe/Stub Ends: SA-106-B 3.2 mm

19 Nozzle Necks: SA-106-B 3.2 mm

20 Nozzle Flanges: SA-105N 3.2 mm

21 Body Flanges: SA-105N 3.2 mm

22 Expansion Joint: mm

23 Supports: SA-516-70N & I.T mm

24 Bolting (internal): mm

25 Bolting (external): mm

26 Nozzle Reinforcement: mm

27 Tubes: SA-179 FULLY ANNEALED mm

28 Tubesheets: SA-516-70N 3.2 each side mm

29 Bonnet/Channel: SA-106-B 3.2 mm

30 Bonnet Head(s): SA-234-WPB 3.2 mm

31 Channel Cover(s): mm

32 Body Flanges: SA-105N 3.2 mm

33 Pipe/Stub Ends: SA-106-B 3.2 mm

34 Bolting (internal): mm

35 Bolting (external): SA-193-B7/SA-194-2H mm

36 Nozzle Reinforcement: mm

37 Nozzle Necks: SA-106-B 3.2 mm

38 Nozzle Flanges: SA-105N 3.2 mm

39 Baffles, Spacers, Tie Rods: CS mm

40 NOTES:

41 1. THIS DATA SHEET APPLIES TO UNITS 104-E-135 AND 104-E-136.

42 2. ABSA REGISTRATION IS REQUIRED.

43 3. THE DESIGN OF CONNECTIONS SHALL BE SUITABLE TO WITH STAND THE LOADS AND MOMENTS REQUIREMENTS.

44 4. FLANGES WITH STUDS 1 1/2" DIAMETER AND GREATER SHALL BE DESIGNED FOR THE USE OF HYDRAULIC BOLT TENSIONERS.

45 5. THE TUBE TO TUBESHEET JOINT SHALL BE EXPANDED IN TWO GROOVES.

46 6. VENDOR SHALL PROVIDE PAINTING PER THE PAINTING SPECIFICATION.

47 7. VENDOR SHALL PROVIDE INSULATION AND ITS SUPPORTS AS REQUIRED.

48 8. MAIN APPLICABLE SPECIFICATIONS:

49 KBP-SPEC-ME-103: TUBULAR HEAT EXCHANGERS

50 KBP-SPEC-ME-106: PRESSURE VESSELS

51 KBP-SPEC-PL-101: EXTERNAL PAINTING AND COATINGS

52 KBP-SPEC-WM-100: WELDING OF PRESSURE COMPONENTS

53 KBP-SPEC-EL-218: ELECTRICAL HEAT TRACING

54

55 NOTES CONTINUED ON PAGE 3 OF 5.

56

57

58 GASKETS MECHANICAL DATA

59 Shell Side: * Thickness: 3.2 mm MAWP (hot and corroded): * kPa (ga)

60 y= 52400000 Pa m= 3.75 MAP (new and cold): * kPa (ga)

61 Tube Side: Thickness: 3.2 mm Hydrotest Pressure:

62 y= 52400000 Pa m= 3.75 Field: * kPa (ga) Shop: * kPa (ga)

63 Floating Head: Thickness: N/A mm Weights: Empty: 1683 kg Bundle: 682 kg

64 y= N/A Pa m= N/A Full of Water: 2402 kg

¤ Revision 0 - ISSUED FOR PURCHASE - 2/4/2013 ¤

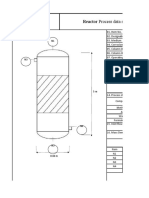

JOB NO. CE4160 ITEM NO. 104-E-135

PROJECT: KIRBY NORTH PHASE 1 DOC. NO. KNP-DS-M-104-E-135

P.O. NO. REV. NO. 0

SPECIFICATION SHEET INQUIRY NO. DATE: 1/31/2013

SHELL AND TUBE EXCHANGER

(SI UNITS) API 660 PAGE 3 OF 5

Rev.

1 ADDITIONAL REMARKS, SKETCHES, ETC. (Optional)

2

3 NOTES CONTINUED FROM PAGE 2 OF 5.

4 9. MINIMUM SPOT RT IS REQUIRED. 100% MT FOR WELDS OF LIFTING LUGS IS REQUIRED.

5 10. TWO GROUNDING LUGS ARE REQUIRED.

6 11. ELECTRICAL HEAT TRACING (EHT) IS REQUIRED FOR THE SHELL SIDE (SALES OIL) TO MAINTAIN A PROCESS TEMPERATURE OF 30 DEG C.

7 12. "*" DENOTES THAT VENDOR SHALL CONFIRM, MODIFY, OR PROVIDE THE INFORMATION.

8 13. LIFTING LUGS SHALL BE DESIGNED FOR A MINIMUM DESIGN METAL TEMPERATURE OF -45 DEG C.

9 14. VENDOR TO PROVIDE MECHANICAL DATA SPECIFIED IN SHEET 2 OF 5.

10 15. THE EXCHANGER SIZE, DUTY, AND DESIGN SHALL PREFERABLY BE IDENTICAL TO KIRBY SOUTH DESIGN AS SPECIFIED IN THIS DATA SHEET.

11 16. DESIGN OF ANCHOR BOLT DIAMETER SHALL BE BASED ON ASTM A325 BOLTS.

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

¤ Revision 0 - ISSUED FOR PURCHASE - 2/4/2013 ¤

JOB NO. CE4160 ITEM NO. 104-E-135

PROJECT: KIRBY NORTH PHASE 1 DOC. NO. KNP-DS-M-104-E-135

P.O. NO. REV. NO. 0

SPECIFICATION SHEET INQUIRY NO. DATE: 1/31/2013

SHELL AND TUBE EXCHANGER

(SI UNITS) API 660 PAGE 4 OF 5

Rev.

1

2 Sales Oil Heat Curve Heat Release Curve

3 -2700.0 1.2

4 Fluid Name: GLYCOL Ref. Pressure 1: 12.64 bar (abs)

1

5 Pressure Temp. Enthalpy Mass Vapor

Mass Vapor Fraction

o

Enthalpy (kJ/kg)

6 bar (abs) C kJ/kg Fraction

-2800.0 0.8

7

8 0.6

9

10 -2900.0 0.4

11

0.2

12

13 -3000.0 0

14 Temperature (oC)

15

Enthalpy Mass Vapor Frac

16

17

18

19 Density Density Viscosity Viscosity Thermal Thermal Sp. Heat Sp. Heat Surface Liquid Liq. Crit.

20 Vapor Liquid Vapor Liquid Cond., Vap Cond., Liq Vapor Liquid Tension Critical Press. Temp.

21 kg/m3 kg/m3 mPa.s mPa.s W/m.K W/m.K kJ/(kg.K) kJ/(kg.K) N/m bar (abs) o

C

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Heat Release Curve

37 Fluid Name: GLYCOL Ref. Pressure 2: 10.64 bar (abs) -2700 1.2

38 Pressure Temp. Enthalpy Mass Vapor

39 bar (abs) o

C kJ/kg Fraction 1

Enthalpy (kJ/kg)

40

0.8

Mass Vapor

41

Fraction

42 0.6

43

0.4

44

45 0.2

46

47 -2800 0

Temperature (oC)

48

Enthalpy Mass Vapor Frac

49

50

51

52 Density Density Viscosity Viscosity Thermal Thermal Sp. Heat Sp. Heat Surface Liquid Liq. Crit.

53 Vapor Liquid Vapor Liquid Cond., Vap Cond., Liq Vapor Liquid Tension Critical Press. Temp.

54 kg/m3 kg/m

3 .

mPa s

.

mPa s W/m K

.

W/m K

. .

kJ/(kg K)

.

kJ/(kg K) N/m bar (abs) o

C

55

56

57

58

59

60

61

62

63

64

¤ Revision 0 - ISSUED FOR PURCHASE - 2/4/2013 ¤

JOB NO. CE4160 ITEM NO. 104-E-135

PROJECT: KIRBY NORTH PHASE 1 DOC. NO. KNP-DS-M-104-E-135

P.O. NO. REV. NO. 0

SPECIFICATION SHEET INQUIRY NO. DATE: 1/31/2013

SHELL AND TUBE EXCHANGER

(SI UNITS) API 660 PAGE 5 OF 5

Rev.

DESIGN CONDITIONS FOR EXPANSION JOINT (Optional)

1 SHELL SIDE TUBE SIDE

2 d

Mean Metal d

Mean Metal

Fluid Temperature Pressure e Fluid Temperature Pressure

3 Case a Flow Temp. Flow Temp. e

4 Condition b Inlet Outlet

c Condition b Inlet Outlet

c

o o o o o o

5 C C kPa (ga) C C C kPa (ga) C

6

7

8

9

10

11

12

13

14

15

16

17 Determine the mean shell and tube metal temperatures at the following operating conditions. Evaluate the need for an expansion joint based on the metal

18 temperatures at these conditions with either or both sides clean or with specific fouling.

19

20 Unless otherwise specified, operation in accordance with the recommendations of the TEMA Standards, paragraph E3.2, "Operating Procedures", is assumed.

21

22

23

a

24 Case = e.g. steam out, upset, etc., which may affect design.

25

b

26 F = Flowing (specify flow rate), S = Stagnant, E = Empty.

27

c

28 Outlet temperature = (if known), thermal designer determines for other conditions.

29

d

30 Pressure = Specify design pressure for operating conditions. Use maximum actual pressure at other conditions.

31

e

32 Mean metal temperature = To be provided by the thermal designer.

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

¤ Revision 0 - ISSUED FOR PURCHASE - 2/4/2013 ¤

You might also like

- Solutions 11th Ed. Adkins Physical ChemistryDocument675 pagesSolutions 11th Ed. Adkins Physical ChemistryPreston Wigfall91% (33)

- Iso 4787 2021en 4787Document28 pagesIso 4787 2021en 4787Abram aNo ratings yet

- Chris Mills 2020Document17 pagesChris Mills 2020Amin100% (1)

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- ОЛ №3 от 12062020 PDFDocument3 pagesОЛ №3 от 12062020 PDFВалентин СелищевNo ratings yet

- Steam Heater E-002Document2 pagesSteam Heater E-002vidyaNo ratings yet

- Output Steam HeaterDocument2 pagesOutput Steam HeatervidyaNo ratings yet

- CCT ShellAndTubeReportDocument2 pagesCCT ShellAndTubeReportLuthfi LegooNo ratings yet

- E 101Document21 pagesE 101EberVelazquezChantacaNo ratings yet

- A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0Document2 pagesA44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0m.shehreyar.khanNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Lvgo Water Cooler Data Sheet E-0107Document6 pagesLvgo Water Cooler Data Sheet E-0107mohsen ranjbarNo ratings yet

- Hoja de Especificaciones Intercambiador de Calor 3Document7 pagesHoja de Especificaciones Intercambiador de Calor 3Gómez López Ángel DamiánNo ratings yet

- 07-3116 333 EC-33301 Iss - 0Document5 pages07-3116 333 EC-33301 Iss - 0rajuNo ratings yet

- Steam Heater: Printed: 4/13/2019 at 2:44:46 PM TEMA SheetDocument2 pagesSteam Heater: Printed: 4/13/2019 at 2:44:46 PM TEMA SheetvidyaNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- I-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Document5 pagesI-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Martin DanzeNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Output PDFDocument1 pageOutput PDFAlex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Desuper-heater Specification Sheet فناورانDocument1 pageDesuper-heater Specification Sheet فناورانMAHDINo ratings yet

- Data Sheet E41001Document6 pagesData Sheet E41001BFEVietnamNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocument7 pagesAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũNo ratings yet

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- Steam Table IAPWS-If97 v2010.0Document8 pagesSteam Table IAPWS-If97 v2010.0cemal gümrükçüoğluNo ratings yet

- Case 3Document1 pageCase 3nirajkulkarni09No ratings yet

- File: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Document14 pagesFile: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Camila Florencia ScarlatoNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- Shell & Tube Heat ExchangerDocument3 pagesShell & Tube Heat ExchangerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Case 4Document1 pageCase 4nirajkulkarni09No ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Hojas de DatosDocument8 pagesHojas de DatosEdson MoraNo ratings yet

- E-313 DesignDocument1 pageE-313 DesignAamir SultanNo ratings yet

- Heat Exchanger Datasheet Secondary Air Cooler E 102: Nitric Acid FacilitiesDocument2 pagesHeat Exchanger Datasheet Secondary Air Cooler E 102: Nitric Acid FacilitiesMohammad Mehdi JafariNo ratings yet

- 1Document1 page1kkkprotNo ratings yet

- Consub TemaDocument1 pageConsub TemaMAYANK AGRAWALNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- WPS 7018+70S2Document5 pagesWPS 7018+70S2rajuNo ratings yet

- Ea 102Document2 pagesEa 102Najmul SaqibNo ratings yet

- BTÑ HTDS - H 10Document1 pageBTÑ HTDS - H 10Juan Pablo Sanchez MelgarejoNo ratings yet

- Aspen Exchanger Design and Rating Plate V9Document4 pagesAspen Exchanger Design and Rating Plate V9samara navasNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- TEMA Sheed L-R ExchangerDocument1 pageTEMA Sheed L-R ExchangerAlejandra BuenoNo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Case 2Document1 pageCase 2nirajkulkarni09No ratings yet

- Process Data Sheet For Fired HeaterDocument8 pagesProcess Data Sheet For Fired HeaterKarla SánchezNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar Perdawood100% (1)

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- C-386 (Set-A)Document32 pagesC-386 (Set-A)MANUPRIYA MANUPRIYANo ratings yet

- Bilangan Tak BerdimensiDocument16 pagesBilangan Tak BerdimensilutfiarifrchNo ratings yet

- Pressure Loss CalculationsDocument29 pagesPressure Loss CalculationssanketNo ratings yet

- Physics Notes .ImprovedDocument72 pagesPhysics Notes .Improvedogenrwot albertNo ratings yet

- Answers To Density Problems Density MassDocument3 pagesAnswers To Density Problems Density MassAlexandra-Sandy Tanseco Sarmiento0% (2)

- Ship CalculationDocument8 pagesShip Calculationrajishrrr100% (1)

- Hydraulic Basic LevelDocument286 pagesHydraulic Basic LevelMariaJose Hwa Ha HanNo ratings yet

- TM4 SUMO LD - Dana TM4 - WebDocument2 pagesTM4 SUMO LD - Dana TM4 - WebRoger ParsNo ratings yet

- Engeneering Properties of Food and Agricultural MatterialDocument112 pagesEngeneering Properties of Food and Agricultural MatterialMohamad Nadzri YahayaNo ratings yet

- 244LD Intelligent Buoyancy Transmitter With Torque Tube For Liquid Level, Interface and DensityDocument12 pages244LD Intelligent Buoyancy Transmitter With Torque Tube For Liquid Level, Interface and DensityTreeNo ratings yet

- 33 McKennaDocument15 pages33 McKennaGUNTHERVEGANo ratings yet

- Grade 8 Revision SheetDocument11 pagesGrade 8 Revision SheetRehamsalahNo ratings yet

- How To Calculate Quantities of Cement, Sand, Granite For Concrete Foundation From Building PlanDocument5 pagesHow To Calculate Quantities of Cement, Sand, Granite For Concrete Foundation From Building Planjmarkunongo_69397286No ratings yet

- Chap 4 ThermodynamicsDocument37 pagesChap 4 Thermodynamicsolivirus1007No ratings yet

- Physical Quantities and Measurement TechniquesDocument19 pagesPhysical Quantities and Measurement TechniqueslavanyagolebuissnessNo ratings yet

- HMB For Preheat TrainDocument8 pagesHMB For Preheat TrainHassaanNo ratings yet

- Sand replacement data sheetDocument2 pagesSand replacement data sheetsurenbhuniaNo ratings yet

- JMF Urugan PilhanDocument44 pagesJMF Urugan PilhanFAUZI ROHMAN80% (5)

- MEEN208 - 2018 Tutorials - 2019Document65 pagesMEEN208 - 2018 Tutorials - 2019Abdulmujeeb simpaNo ratings yet

- Science Capsule For ICAR Technician 2022 ExamDocument69 pagesScience Capsule For ICAR Technician 2022 ExamAbhijit NathNo ratings yet

- NLZ SeriesDocument12 pagesNLZ SeriesDinesh RajNo ratings yet

- NPTEL Concrete Engg and Tech Problem and Solved AnswersDocument5 pagesNPTEL Concrete Engg and Tech Problem and Solved AnswerssuranjanacNo ratings yet

- Floating Bodies PDFDocument8 pagesFloating Bodies PDFQSQFNo ratings yet

- Section 407 - Hot Mix Asphalt: 407.01 GENERALDocument25 pagesSection 407 - Hot Mix Asphalt: 407.01 GENERALDaiNo ratings yet

- Section 132 Airfield PavementDocument243 pagesSection 132 Airfield PavementKwan Chun Sing100% (2)

- TRB Test SeriesDocument12 pagesTRB Test SeriesGokul ParthibanNo ratings yet

- Calibration of Volumetric GlasswareDocument4 pagesCalibration of Volumetric GlasswareRajan Chugh100% (2)