0 ratings0% found this document useful (0 votes)

Milling-Model Answer

Milling-Model Answer

Uploaded by

ahmedelhussiny145Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

Milling-Model Answer

Milling-Model Answer

Uploaded by

ahmedelhussiny1450 ratings0% found this document useful (0 votes)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

Milling-Model Answer

Milling-Model Answer

Uploaded by

ahmedelhussiny145Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1/ 4

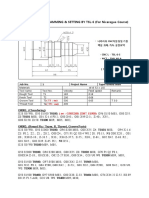

Write the part program for manufacturing the part below.

The material is a block 100 x 100 x 25

mm made of St 50. The feed used is 50 mm / min, the rotational speed is 300 rpm, the depth of

cut is not to exceed 30% of tool diameter and the step over is 80% of tool diameter. The work

offset is at 150 mm above the part top surface at the machine home zero. The tools available

are:

- 20 mm slot drill fitted in turret face no. 3 has T.L.O. of 40 mm

- 6 mm slot drill fitted in turret face no. 1 has T.L.O. of 35 mm

- 10 mm twist drill fitted in turret face no. 5 has T.L.O. of 60 mm

- Centre drill fitted in turret face no. 2 has T.L.O. of 20 mm

- 8 mm twist drill fitted in turret face no. 4 has T.L.O. of 45 mm

Note: The machine is equipped with fixed cycles, no finishing is required.

C3

C4 C2

C5

C1

% O002

N05 G90 G17 G21 G40 G49 G80 G15 G50;

N10 G54 S300 F50 M03; Work offset, speed 300 rpm, feed 50 mm/min,

Spindle on (CW).

N15 G28 Z0; Homing.

N20 T04 G43 H04 M06; Calling ø8 twist drill.

N25 G52 X50 Y50 Z-150; Shift the active coordinate system G54.

N30 G16 G00 X35 Y30; Polar system on, Approach to the center of hole C1.

N35 Z5 M08; Approach to the start plane, coolant on.

N40 G98 G82 Z-18 P500; Drilling the first hole.

N45 G91 Y30 L4; Drilling holes C2, C3, C4, and C5.

N50 G80 G90 G15 G49 G28 Z100; Cancel cycle and T.L.O, Polar system off,

homing.

N55 T03 G43 H03 D03 M06; Calling ø20 slot drill.

N60 G52 X0 Y0; Cancel shift the active coordinate system.

N65 G00 X25 Y25; Approach to the center of the circular pocket.

N70 Z5; Approach to the reference plane.

N75 G98 G88 I-10 D5 J20 B6 C16 V50; Milling the pocket.

N80 G80 G49 G28 Z100; Cancel cycle and T.L.O, homing.

N85 T01 G43 H01 D01 M06; Calling ø6 slot drill.

N90 G00 X75 Y25; Approach to the center of the rectangular pocket.

N95 Z5 Approach to the reference plane.

N100 G87 I-8 D5 A55 J20 K6 M0 B1.5 C4.8 V50; Milling the pocket.

N105 G80 G49 G28 Z100 M09; Cancel cycle and T.L.O, homing, coolant off.

N110 M05; Spindle off.

N115 M30; End of program.

Another solution

% O002

N05 G90 G17 G21 G40 G49 G80 G15 G50;

N10 G54 S300 F50 M03; Work offset, speed 300 rpm, feed 50 mm/min,

Spindle on (CW).

N15 G28 Z0; Homing.

N20 T04 G43 H04 M06; Calling ø8 twist drill.

N25 G52 X50 Y50 Z-150; Shift the active coordinate system G54.

N30 G16 G00 X35 Y30; Polar system on, Approach to the center of

hole C1.

N35 Z5 M08; Approach to the start plane, coolant on.

N40 G98 G82 Z-18 P500; Drilling the first hole.

N45 G91 Y30 L4; Drilling holes C2, C3, C4, and C5.

N50 G80 G90 G15 G49 G28 Z100; Cancel cycle and T.L.O, Polar system off,

homing.

N55 T03 G43 H03 D03 M06; Calling ø20 slot drill.

N60 G00 X-25 Y-25; Approach to the center of the circular pocket.

N65 Z5; Approach to the reference plane.

N70 G98 G88 I-10 D5 J20 B6 C16 V50; Milling the pocket.

N75 G80 G49 G28 Z100; Cancel cycle and T.L.O, homing.

N80 T01 G43 H01 D01 M06; Calling ø6 slot drill.

N85 G00 X25 Y-25; Approach to the center of the rectangular pocket.

N90 Z5; Approach to the reference plane.

N95 G87 I-8 D5 A55 J20 K6 M0 B1.5 C4.8 V50; Milling the pocket.

N100 G80 G49 G28 Z100 M09; Cancel cycle and T.L.O, homing, coolant off.

N105 M30; End of program.

You might also like

- g75 Fanuc Canned Cycle Grooving CNC ProgramNo ratings yetg75 Fanuc Canned Cycle Grooving CNC Program2 pages

- Subroutine (M98 - M99) Mirror (G51) Cycles (G81-G83-G84 - G85), Using Create Missing ToolNo ratings yetSubroutine (M98 - M99) Mirror (G51) Cycles (G81-G83-G84 - G85), Using Create Missing Tool6 pages

- Writing A Program For Tapping Cycle On CNC Milling MachineNo ratings yetWriting A Program For Tapping Cycle On CNC Milling Machine17 pages

- Manufacturing of Rock Lever Shaft and Cam Follower in CNC MachineNo ratings yetManufacturing of Rock Lever Shaft and Cam Follower in CNC Machine28 pages

- 1st - T - Lect No.11 - CAM - Multiple Machining - SubprogramNo ratings yet1st - T - Lect No.11 - CAM - Multiple Machining - Subprogram24 pages

- Circular Interpolation Programming Example 123456100% (1)Circular Interpolation Programming Example 12345614 pages

- Debre Tabor University: Faculty of Technology Department of Electromechanical EngineeringNo ratings yetDebre Tabor University: Faculty of Technology Department of Electromechanical Engineering25 pages

- G12 Circular Pocket Milling CW G13 Circular Pocket Milling CCW Group 00No ratings yetG12 Circular Pocket Milling CW G13 Circular Pocket Milling CCW Group 003 pages

- Fanuc CNC Stock Removal Rough Turning Cycle g71 II Example 2No ratings yetFanuc CNC Stock Removal Rough Turning Cycle g71 II Example 23 pages

- Faculty Innovative Design and TechnologyNo ratings yetFaculty Innovative Design and Technology7 pages

- 8 Fixed Canned Cycles (CNC Course CD) PDFNo ratings yet8 Fixed Canned Cycles (CNC Course CD) PDF24 pages

- Project CNC Vertical Milling Machine: Manufactura Asistida Por Computadora UpaoNo ratings yetProject CNC Vertical Milling Machine: Manufactura Asistida Por Computadora Upao4 pages

- CNC Edge Programming - 3 Axis ProgrammingNo ratings yetCNC Edge Programming - 3 Axis Programming9 pages

- (123doc) - 5-Bai-Tap-Chuong-Trinh-Phay-Cho-May-Cnc-Co-Bai-Giai-Va-Xuat-GcodeNo ratings yet(123doc) - 5-Bai-Tap-Chuong-Trinh-Phay-Cho-May-Cnc-Co-Bai-Giai-Va-Xuat-Gcode8 pages

- Technical Update Heat Input and Interpass Temperature During Welding PDFNo ratings yetTechnical Update Heat Input and Interpass Temperature During Welding PDF6 pages

- IDBC-TS-NCCAL-C00008 Rev.B Calculation For Anchor BoltNo ratings yetIDBC-TS-NCCAL-C00008 Rev.B Calculation For Anchor Bolt17 pages

- Shaper Machine: Definition, Working, Types, Operations, Specification, Advantages, Disadvantages, and ApplicationNo ratings yetShaper Machine: Definition, Working, Types, Operations, Specification, Advantages, Disadvantages, and Application13 pages

- Laser CNC Machine How To Install 15w Laser Head) Type10% (1)Laser CNC Machine How To Install 15w Laser Head) Type12 pages

- Docsity Ingles Tecnico Mecanica de MantenimientoNo ratings yetDocsity Ingles Tecnico Mecanica de Mantenimiento11 pages

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQNo ratings yet177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQ4 pages

- Technical Information ASSET DOC LOC 3008312 PDFNo ratings yetTechnical Information ASSET DOC LOC 3008312 PDF15 pages

- Investment Castings: BDG Reference SheetNo ratings yetInvestment Castings: BDG Reference Sheet10 pages

- ASME B1.20.1 Pipe Threads, General Purpose (Inch)No ratings yetASME B1.20.1 Pipe Threads, General Purpose (Inch)40 pages

- Subroutine (M98 - M99) Mirror (G51) Cycles (G81-G83-G84 - G85), Using Create Missing ToolSubroutine (M98 - M99) Mirror (G51) Cycles (G81-G83-G84 - G85), Using Create Missing Tool

- Writing A Program For Tapping Cycle On CNC Milling MachineWriting A Program For Tapping Cycle On CNC Milling Machine

- Manufacturing of Rock Lever Shaft and Cam Follower in CNC MachineManufacturing of Rock Lever Shaft and Cam Follower in CNC Machine

- 1st - T - Lect No.11 - CAM - Multiple Machining - Subprogram1st - T - Lect No.11 - CAM - Multiple Machining - Subprogram

- Debre Tabor University: Faculty of Technology Department of Electromechanical EngineeringDebre Tabor University: Faculty of Technology Department of Electromechanical Engineering

- G12 Circular Pocket Milling CW G13 Circular Pocket Milling CCW Group 00G12 Circular Pocket Milling CW G13 Circular Pocket Milling CCW Group 00

- Fanuc CNC Stock Removal Rough Turning Cycle g71 II Example 2Fanuc CNC Stock Removal Rough Turning Cycle g71 II Example 2

- Project CNC Vertical Milling Machine: Manufactura Asistida Por Computadora UpaoProject CNC Vertical Milling Machine: Manufactura Asistida Por Computadora Upao

- (123doc) - 5-Bai-Tap-Chuong-Trinh-Phay-Cho-May-Cnc-Co-Bai-Giai-Va-Xuat-Gcode(123doc) - 5-Bai-Tap-Chuong-Trinh-Phay-Cho-May-Cnc-Co-Bai-Giai-Va-Xuat-Gcode

- Computer Numerical Control Programming Tool ReferenceFrom EverandComputer Numerical Control Programming Tool Reference

- Technical Update Heat Input and Interpass Temperature During Welding PDFTechnical Update Heat Input and Interpass Temperature During Welding PDF

- IDBC-TS-NCCAL-C00008 Rev.B Calculation For Anchor BoltIDBC-TS-NCCAL-C00008 Rev.B Calculation For Anchor Bolt

- Shaper Machine: Definition, Working, Types, Operations, Specification, Advantages, Disadvantages, and ApplicationShaper Machine: Definition, Working, Types, Operations, Specification, Advantages, Disadvantages, and Application

- Laser CNC Machine How To Install 15w Laser Head) Type1Laser CNC Machine How To Install 15w Laser Head) Type1