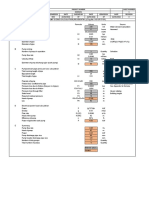

PS Design Calc

Uploaded by

m.reafat.eljammalPS Design Calc

Uploaded by

m.reafat.eljammalFAWAZIA ONLINE PS

Mechanical Calculation

Pumps Data:

Type Submerssible

Number of pumps (duty) n 1

Number ofr pumps (stand by) 1

Flow rate / Pump Q/pump 100 m3/h

Flow rate (all duty pumps) Q total 100 m3/h

0.028 m3/s

Calculating Sump Dimensions:

Assume inlet flow rate to the sump Qi = 0.9 Qp 0.025 m3/s

Assume number of starts / hour 10 starts/hr

Required cycle time 6 min

360 sec

Required volume V' = T/[(1/Qi) + (1/(Qp - Qi)] 1.0 m3

Assume liquid working depth (H) H 0.56 m

Area A' = V/H 1.7 m2

Assume sump width W 2.5 m

Calculated sump length L' 0.69 m

Selected sump length L 3 m For pumps accommodation,installation and maintenance

Actual working volume V=H*W*L 4.20 m3

Acctual cycle time T = (V/Qi) + [V/(Qp - Qi)] 1680 sec

28 min

Actual number of starts per hour 2.14 starts / hr

Sump Data:

Finished ground level FGL 2.7 m

Inlet pipe invert level ILinlet pipe -2.32 m

Inlet pipe diameter Dinlet pipe 0.25 m

Inlet pipe top level T.Linlet pipe -2.07 m

High water level H.W.L = I.L - 0.2 -2.52 m

Low water level L.W.L = H.W.L - H (depth) -3.08

Assume minimum liquid depth 0.8 m

(to be verified with the selected vendor)

Sump bottom level B.Lsump = L.W.L - Minimum water depth -3.88 m

Start level for duty pump Start levelduty pump = ILinlet pipe - 0.2 -2.52 m

Start level for standby pump Start levelSB pump = ILinlet pipe - 0.1 -2.42 m

Pump stop level Stop level = L.W.L -3.08 m To be verrified by vendor

Forcemain Data:

Assume flow velocity v 1.50 m/s

Reqired pipe corss section area A' = Qp / v 0.02 m2

Required pipe diameter D' = (A'*4/3.14)^0.5 0.154 m

Selected Diameter D 0.2 m According to network study

Actual flow velocity v=Q/A 0.88 m/s

Pipe length Lforcemain 1715 m According to network study

Highest point level H.P.L 3.92 m

Check Pump Head:

Static head HS = (Highest point) - (Pump stop level) 7.00 m

Friction Losses:

Main Losses HLmain = 10.6 L/d^4.87)(Q/C)^1.85 6.52 m Using Hazen Wiliam Formula

Secondary Losses HLsec = 0.25 (HLmain) 1.63 m

Total friction losses HLtotal = HLmain + HLsec 8.15 m

Static head + head losses HS + HLtotal 15.15 m

Assume residual head % Hres % 25%

Residual head Hres 3.79 m

Required head Htotal = HS + HLtotal + Hres 18.93 m

Selected head 19.0 m

Expected Motor Power:

Hydraulic power (Q)(H)(Ꝭ)(g) 5177.5 W

Assume pump effeicincy 55%

Assume motor effeicincy 76%

Expected motor input power Hydraulic power / (pump eff. X motor eff.) 12386 W

12.4

You might also like

- Tarea #3: Difusión en Estado Estacionario y Pseudoestacionario Sin Reacción QuímicaNo ratings yetTarea #3: Difusión en Estado Estacionario y Pseudoestacionario Sin Reacción Química8 pages

- Hazen William's Equation: by Eng. Ahmed Ghassan & Eng. Ahmed AmmarNo ratings yetHazen William's Equation: by Eng. Ahmed Ghassan & Eng. Ahmed Ammar13 pages

- Water Supply Hydraulics Calculation: Transmission PipelineNo ratings yetWater Supply Hydraulics Calculation: Transmission Pipeline3 pages

- Name of Project Sample 2. Location 2.1. RMC Sample 2.2. Ward No: 2,3 3. District Kaski 4. Total Demand 2345 5. Total Rvts 2No ratings yetName of Project Sample 2. Location 2.1. RMC Sample 2.2. Ward No: 2,3 3. District Kaski 4. Total Demand 2345 5. Total Rvts 215 pages

- FINAL - AE241Thermal Engg Lab ManualMODNo ratings yetFINAL - AE241Thermal Engg Lab ManualMOD60 pages

- Example of selection of pump for a small water supply projectNo ratings yetExample of selection of pump for a small water supply project22 pages

- Cold Water Pump Calculation Shhet Type of Water Pump Location of Pump Unit Reference ModelNo ratings yetCold Water Pump Calculation Shhet Type of Water Pump Location of Pump Unit Reference Model1 page

- TEC Fire Fighting AutoPneumatic Tank SizingNo ratings yetTEC Fire Fighting AutoPneumatic Tank Sizing22 pages

- Hidrolika Intake Kali Grang Ke IPA Kali Garang A. Perhitungan Head PompaNo ratings yetHidrolika Intake Kali Grang Ke IPA Kali Garang A. Perhitungan Head Pompa7 pages

- NEW - Perhitungan Intake, Pompa Prasedimentasi DSBNo ratings yetNEW - Perhitungan Intake, Pompa Prasedimentasi DSB16 pages

- Multi Stage Centrifugal Pump Experiment No. 5No ratings yetMulti Stage Centrifugal Pump Experiment No. 56 pages

- Water - Hammer Damper Tank Hydropack-ExampleNo ratings yetWater - Hammer Damper Tank Hydropack-Example30 pages

- Find Eq - Length (M) :: Manual Pressure Drop CalculationNo ratings yetFind Eq - Length (M) :: Manual Pressure Drop Calculation7 pages

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsFrom EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsNo ratings yet

- Hydraulic Profile_WWTP (Inlet PS Addition)-15.08.2024No ratings yetHydraulic Profile_WWTP (Inlet PS Addition)-15.08.20241 page

- Industrial Generator Set Accessories: Voltage RegulatorsNo ratings yetIndustrial Generator Set Accessories: Voltage Regulators10 pages

- A Proposed Spectral Form For Fully Developed Wind Seas Based On The Similarity Theory of S. A. KitaigorodskiiNo ratings yetA Proposed Spectral Form For Fully Developed Wind Seas Based On The Similarity Theory of S. A. Kitaigorodskii10 pages

- Presentation On Air Pollution and Its MeasurementNo ratings yetPresentation On Air Pollution and Its Measurement11 pages

- CHRYSIPPUS’ THEORY OF PNEUMA Paul HagerNo ratings yetCHRYSIPPUS’ THEORY OF PNEUMA Paul Hager12 pages

- Air Cylinder: Series A23, A24 Double Acting Cylinders (Square Type) Ø32 - 125 MMNo ratings yetAir Cylinder: Series A23, A24 Double Acting Cylinders (Square Type) Ø32 - 125 MM8 pages

- SC Dps - (PNCF) Phs-1&2 9th-Cbse Chem 568No ratings yetSC Dps - (PNCF) Phs-1&2 9th-Cbse Chem 5682 pages

- C.1 Simple Harmonic Motion Revision TeacherNo ratings yetC.1 Simple Harmonic Motion Revision Teacher42 pages

- POOL EQUIPMENT CATALOGUE Side Discharge - V.HEAT PUMPNo ratings yetPOOL EQUIPMENT CATALOGUE Side Discharge - V.HEAT PUMP13 pages

- Investigation Study of Solar Peltier Referigerator: Dept of Mechanical Engg, Nhce Banglore 1No ratings yetInvestigation Study of Solar Peltier Referigerator: Dept of Mechanical Engg, Nhce Banglore 131 pages