100%(1)100% found this document useful (1 vote)

141 viewsSqueeze Casting

Squeeze Casting

Uploaded by

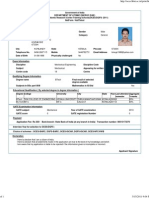

jishnusThis document discusses the fabrication of fiber reinforced metal matrix composites using squeeze casting technology and ultrasonic evaluation of the processing. Squeeze casting involves pouring molten metal into a die cavity and applying high pressure until solidification is complete. This allows for infiltration of the metal matrix into fiber preforms and results in composites with good bonding and mechanical properties. The document outlines the squeeze casting process parameters and advantages. It also describes using ultrasonic interrogation techniques like shear wave and longitudinal wave methods to non-destructively evaluate the consolidation of composites fabricated by squeeze casting and diffusion bonding. The ultrasonic evaluation is able to detect defects and differences in processing conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Squeeze Casting

Squeeze Casting

Uploaded by

jishnus100%(1)100% found this document useful (1 vote)

141 views38 pagesThis document discusses the fabrication of fiber reinforced metal matrix composites using squeeze casting technology and ultrasonic evaluation of the processing. Squeeze casting involves pouring molten metal into a die cavity and applying high pressure until solidification is complete. This allows for infiltration of the metal matrix into fiber preforms and results in composites with good bonding and mechanical properties. The document outlines the squeeze casting process parameters and advantages. It also describes using ultrasonic interrogation techniques like shear wave and longitudinal wave methods to non-destructively evaluate the consolidation of composites fabricated by squeeze casting and diffusion bonding. The ultrasonic evaluation is able to detect defects and differences in processing conditions.

Original Description:

squeeze casting

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document discusses the fabrication of fiber reinforced metal matrix composites using squeeze casting technology and ultrasonic evaluation of the processing. Squeeze casting involves pouring molten metal into a die cavity and applying high pressure until solidification is complete. This allows for infiltration of the metal matrix into fiber preforms and results in composites with good bonding and mechanical properties. The document outlines the squeeze casting process parameters and advantages. It also describes using ultrasonic interrogation techniques like shear wave and longitudinal wave methods to non-destructively evaluate the consolidation of composites fabricated by squeeze casting and diffusion bonding. The ultrasonic evaluation is able to detect defects and differences in processing conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

100%(1)100% found this document useful (1 vote)

141 views38 pagesSqueeze Casting

Squeeze Casting

Uploaded by

jishnusThis document discusses the fabrication of fiber reinforced metal matrix composites using squeeze casting technology and ultrasonic evaluation of the processing. Squeeze casting involves pouring molten metal into a die cavity and applying high pressure until solidification is complete. This allows for infiltration of the metal matrix into fiber preforms and results in composites with good bonding and mechanical properties. The document outlines the squeeze casting process parameters and advantages. It also describes using ultrasonic interrogation techniques like shear wave and longitudinal wave methods to non-destructively evaluate the consolidation of composites fabricated by squeeze casting and diffusion bonding. The ultrasonic evaluation is able to detect defects and differences in processing conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 38

At a glance

Powered by AI

The key takeaways are that squeeze casting is a process to fabricate metal matrix composites using high pressure, and ultrasonic evaluation can be used to study the consolidation of these composites.

The squeeze casting process involves pouring molten metal into a die cavity located on a hydraulic press. The press then closes and applies high pressure to the liquid metal until solidification is complete.

Some advantages of squeeze casting include fine grain structure, dimensional accuracy, improved mechanical properties, and no need for feeding systems.

FABRICATION OF FIBRE REINFORCED

METAL MATRIX COMPOSITES BY

SQUEEZE CASTING TECHNOLOGY &

ULTRASONIC EVALUATION OF THEIR

PROCESSING.

CONTENTS

INTRODUCTION

PROCESS OUTLINE

CLASSIFICATION

PROCESS PARAMETERS

ADVANTAGES

SC TECHNOLOGY IN MMC

FLOW CHART FOR PROCESSING

SQUEEZE INFILTRATION THEORY

PROCESS DETAILS

CASTING DEFECTS

MAJOR ENGINEERING COMPONENTS MANUFACTURED BY

SC TECHNIQUE

ULTRA SONIC EVALUATION

APPLICATIONS

EXPERIMENTAL APPROACH

SHEAR WAVE INTERROGATION

LONGITUDINAL WAVE INTERROGATION

RESULTS

DISCUSSION

CONCLUSION

REFERENCE

INTRODUCTION

Squeeze casting (SC) is a generic term to specify a fabrication

technique where solidification is promoted under high pressure

within a re-usable die.

The idea was initially suggested by Chernov in 1878 to apply

steam pressure to molten metal while being solidified.

In this process a die set is placed on a hydraulic press and

preheated, and the exact amount of molten alloy is poured into

the lower half of the open die set, the press closed so that the

alloy fills the cavity and the pressure maintained until complete

solidification occurs (31 - 108 MPa pressure).

PROCESS OUTLINE

A pre-specified amount of molten metal is poured into a

preheated die cavity, located on the bed of a hydraulic press.

The press is activated to close off the die cavity and to pressurise

the liquid metal.

The pressure is held on the metal until complete

solidification.

Finally the punch is withdrawn and the component is

ejected.

CLASSIFICATION

PROCESS PARAMETERS

Molten metal pouring temperature

Melt volume

Melt quality and quantity

Preform preheating temperature

Die temperature

Applied squeeze pressure

Pressurization rate

Pressure applied duration

Lubrication level

ADVANTAGES

Fine grained with excellent surface finish.

No porosity.

Variety of shapes and size.

Improvement in mechanical properties like Yield strength,

Fatigue strength, Elongation.

Dimensional accuracy

No feeding systems,runners,risers,gates

Superior weldability and heat treatability.

S C TECHNOLOGY IN MMC

Fiber reinforced metal matrix composites have fibers that

are discontinuous and they are typically circular and vary in

diameter from 0.1 cm to 0.1mm.

In order to obtain proper bonding, wetting of the fiber by

the matrix material is essential. So, squeeze casting is used

to apply very high pressures to increase the bonding

between the liquid metal and alloy with the fiber.

The most common method to apply the reinforcement in

the desired location has been with the use of fiber performs

A fiber perform is similar to a sponge made of the fibers

that will go into the composite.

The main challenge to the use of performs is the high

pressures currently used to infiltrate the metal. These high

pressures may break the preform.

FLOW CHART FOR PROCESSING

SQUEEZE INFILTRATION THEORY

Liquid metal is injected into the interstices of short fibers

usually called as a preform.

Performs are made up of aluminasilicate fibers with a known

volume fraction of fibers and voids.

Fibers do not act as preferential crystal nucleation sites during

melt solidification .

Prolonged fiber-melt contact often under higher hydrostatic

pressure and with solute enrichment tends to favour the

formation of a strong interfacial bonding.

PROCESS DETAILS

CASTING DEFECTS

Oxide inclusions

Porosity and voids

Blistering

Cold laps and cold shuts

Sticking of casting with the die surface

Major engineering components

manufactured by SC technique

Engineering components required by foundries and

automotive industries are produced by this technology.

Aluminum dome, ductile iron mortar shell, stainless steel

blades, super alloy discs, aluminium automotive wheels

and gear blanks of brass and bronze.

Applications include aluminum alloy pistons for engines,

disc brakes, brass and bronze bushings, gears, differential

pinion gears, steel missile components and cast iron parts.

ULTRASONIC EVALUATION

Non-destructive evaluation techniques using ultrasonic

shear wave and longitudinal wave interrogations.

To evaluate the consolidation behavior of a Ti-14Al-

21Nb/SiC model composite containing a single Sic fiber

andTi-6Al-4V/SiC single-ply composite.

Partially and fully consolidated composite samples

prepared by diffusion bonding methods were examined by

these techniques.

APPLICATIONS

Characterizing the quality and mechanical behavior of

composite materials.

To screen for macroscopic defects such as ply

delaminations and non-uniform fiber spacing arising from

either missing fibers or displacement of fibers during

fabrication.

NDE is an equally valuable tool for detecting microscopic

defects arising during the fabrication of composites

EXPERIMENTAL APPROACH

FABRICATION

SINGLE FIBER COMPOSITES

Sic fiber in a Ti-14Al-21Nb matrix.

2mm thick

Diffusion bonding

PANEL A:Vacuum hot pressing at 925C under 5.5 MPa

pressure for 30 min followed by hot isostatic pressing

(HIPing) at 1010Cunder 1OOMPa pressure for 2 hr.

PANEL B:Vacuum hot pressing at 982C under a pressure of

9.2 MPa for 30 min .

SINGLE-PLY COMPOSITES

Sic fibers in a Ti-6Al-4V (wt%) alloy matrix

2 MM THICK

Vacuum hot pressing at 954C under a pressure of 9.2 MPa

for 2 hr.

SHEAR WAVE INTERROGATION

A 25 MHz focused transducer (6.3 mm diameter, 12.7 mm

focal length) was used in the pulse-echo mode.

The ultrasonic wave front was incident on the specimen

surface inclined to the vertical plane at an angle of either

18 or 24.

Vertically polarized shear waves propagated in the matrix

and were incident on the fiber /matrix interface.

The wavelength of the wave propagating in the matrix is

calculated by the simple expression, A = c

i

/f, where c

i

is the

velocity of the ultrasonic stress wave, f is the frequency.

Contd

In the case of the Ti-14Al-21Nb matrix alloy, the

velocity of the shear wave generated by the 25 MHz

transducer was measured to be c

s

= 3209m/s.

For Ti-6Al-4V matrix alloy were found to be c

s

= 3163

m/s.

LONGITUDINAL WAVE INTERROGATION

A 5O MHz focused transducer (6.3 mm diameter, 25.4 mm

focal length) was used in the pulse-echo mode.

The wave front was incident normal to the specimen surface .

A compressional wave propagates in the matrix and is reflected

from the fiber back to the transducer.

The velocity of the longitudinal wave propagating in the matrix

was measured to be c

L

= 6489 m/s, which is approximately twice

the shear wave velocity and for second one it is 6141 m/s.

RESULTS

DISCUSSION

Figure 3(a) corresponds to shearwave interrogation Of Ti-

14Al-21Nb/SiC and shows uniform reflection along the

fiber.

The matrix is completely consolidated around the fiber.

The maximum of the reflected signal occurs .

Fig 3 (b) : shows the image resulting from longitudinal

wave interrogation of this material.

Fig. 4 shows two ultrasonic images obtained by shear wave

interrogation of the composite sample which was

consolidatedby vacuum hot pressing alone.

The composite is poorly consolidated.

The reflector is defined by the envelope that includes both

the fiber and the void regions.

Fig 5 shows the longitudinal interrogation of panel B.

It shows non uniformity of panel.

An optical micrograph from cross section of panel A and panel B

is shown in fig 6 and fig 7 respectively.

It agrees with the result of ultrasonic evaluation.

Ultrasonic techniques are equally applicable for composites

containing high volume fraction of fibers.

Fig 8 shows shear wave interrogation of Ti-6Al-4V/SiC single-

ply composite specimen.

Left side fully consolidated and right side incomplete

consolidation.

CONCLUSION

The properties of the castings manufactured by normal liquid

metallurgy route are inferior and its durability is poor.

In order to improve its performance in the working conditions

,the old technological processing methods are obsolete and it

must be altered and modified.

Squeeze casting is adopted to produce superior quality

composite castings.

The composite castings produced by this method are

application-oriented products, which can be manufactured by

mass production.

Finally, two different ultrasonic NDE techniques using

shear wave and longitudinal wave interrogations were

applied to study the consolidation characteristics of singly

fibre and single ply composites.

A good correlation was found between the ultrasonic

images and the extent of consolidation of the matrix alloy

around the fibers as determined by metallography.

The results demonstrate the usefulness of these ultrasonic

techniques in evaluating the processing behavior of metal

matrix composites.

REFERENCES

M.R.Ghomaschi,A.Vikhrov Squeeze casting:an overview,Journal

of Materials Processing Technology 101 (2000) 1-9

T.R Vijayaram,S.Sulaiman,A.M.S Hamouda,M.H.M Ahmad,

Fabrication of fibre reinforced metal matrix composites by

squeeze casting technology, Journal of Materials Processing

Technology 178 (2006) 34-38

S .Krishnamurthy,T.E Matikas,P.Karpur, Ultrasonic Evaluation

of processing of fibre reinforced metal matrix

composites,Composites Science and Technology 54 (1995)

161- 168

THANK YOU

You might also like

- Jet Cooling English Presentationv2Document21 pagesJet Cooling English Presentationv2susu22200050% (2)

- Web043 Safe Reliable Die ClampingDocument40 pagesWeb043 Safe Reliable Die Clampingsinr100% (1)

- Study of Flow and Heat Transfer in High Pressure Die Casting Cooling ChannelDocument10 pagesStudy of Flow and Heat Transfer in High Pressure Die Casting Cooling ChannelSüleymanŞentürkNo ratings yet

- 7 Mould Materials PDFDocument8 pages7 Mould Materials PDFBa BuNo ratings yet

- Countermeasure For DC Defective Products: DC School Text BookDocument13 pagesCountermeasure For DC Defective Products: DC School Text Bookmike100% (2)

- The Effect of Jet-Cooling Application On Microstructural Properties of The Overheating Areas in High Pressure Die Casting PartsDocument4 pagesThe Effect of Jet-Cooling Application On Microstructural Properties of The Overheating Areas in High Pressure Die Casting PartsSüleymanŞentürkNo ratings yet

- PQ TOS555 How To Check PQ Amplifier (During Pump Run)Document3 pagesPQ TOS555 How To Check PQ Amplifier (During Pump Run)mike100% (1)

- Die Cast Chill VentsDocument6 pagesDie Cast Chill VentsSunil SharmaNo ratings yet

- YSS Die Casting Die MaterialDocument14 pagesYSS Die Casting Die MaterialVishal BalkwadeNo ratings yet

- 001 Plunger PDFDocument4 pages001 Plunger PDFKmilo GiraldoNo ratings yet

- Effect of Melt Cleanliness On The Formation of Porosity Defects in Automotive Aluminium High Pressure Die Castings 2002 Journal of Materials ProcessinDocument12 pagesEffect of Melt Cleanliness On The Formation of Porosity Defects in Automotive Aluminium High Pressure Die Castings 2002 Journal of Materials ProcessinNwofor ChigoziNo ratings yet

- Casting Technology: DC School Text BookDocument22 pagesCasting Technology: DC School Text Bookhasan waqarNo ratings yet

- Toshiba Machine Co., Ltd. Die Cast Machine Engineering DivDocument25 pagesToshiba Machine Co., Ltd. Die Cast Machine Engineering DivmikeNo ratings yet

- Catalogo Die Cast DMEDocument24 pagesCatalogo Die Cast DMEkontacNo ratings yet

- Productivity Improvement High Pressure Die Casting: Presentation byDocument26 pagesProductivity Improvement High Pressure Die Casting: Presentation byNIMISHNo ratings yet

- ADSTEFAN Management Presentation - HPDCDocument21 pagesADSTEFAN Management Presentation - HPDCGeovanni Emmanuel Aguilar RangelNo ratings yet

- VacuumDocument6 pagesVacuum03sri03No ratings yet

- Die Casting ProcessDocument35 pagesDie Casting ProcessgarciarodrigoNo ratings yet

- Aluminum Die Casting Process FlowDocument13 pagesAluminum Die Casting Process FlowPrabish KumarNo ratings yet

- Numerical Simulation of Low Pressure Die-Casting Aluminum WheelDocument5 pagesNumerical Simulation of Low Pressure Die-Casting Aluminum WheelMostafaNo ratings yet

- Maintenance Checks of Your Bühler Die Casting Machine.: Ecoline SeriesDocument2 pagesMaintenance Checks of Your Bühler Die Casting Machine.: Ecoline SeriesMohamedNo ratings yet

- Web072 Die Casting Modeling CapabilitiesDocument33 pagesWeb072 Die Casting Modeling CapabilitiessinrNo ratings yet

- Mce451 - Lecture 2Document16 pagesMce451 - Lecture 2mohammedshahrukhbimNo ratings yet

- Introduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13Document13 pagesIntroduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13luisA1923No ratings yet

- Semi Solid & Squeeze CastingsDocument16 pagesSemi Solid & Squeeze Castingsvinny1978No ratings yet

- Die Casting GuidelinesDocument12 pagesDie Casting GuidelinesMichael Arvin GabineteNo ratings yet

- PQ2 RosmantDocument5 pagesPQ2 RosmantluisA1923No ratings yet

- Optimization of Cooling-Heating System in HPDC Tools: January 2016Document9 pagesOptimization of Cooling-Heating System in HPDC Tools: January 2016MostafaNo ratings yet

- Web073 Die Casting Modeling Capabilities2. Modeling DifferencesDocument27 pagesWeb073 Die Casting Modeling Capabilities2. Modeling DifferencessinrNo ratings yet

- Virtualization High Vacuum and High Performance HPDC Machine Top Quality Casting PDFDocument4 pagesVirtualization High Vacuum and High Performance HPDC Machine Top Quality Casting PDFAditheya Varthan MNo ratings yet

- 14 Chandan Deep SinghDocument8 pages14 Chandan Deep SinghVinod ChandranNo ratings yet

- Magnesium Die CastingDocument3 pagesMagnesium Die CastingReza ArdhyatamaNo ratings yet

- Die Cast Chill VentsDocument32 pagesDie Cast Chill Ventspurushothaman1234566No ratings yet

- Porosity Formation in AlSi9Cu3 Alloy Castings - The Influence of Iron, Strontium, Sodium, Antimony and BismuthDocument240 pagesPorosity Formation in AlSi9Cu3 Alloy Castings - The Influence of Iron, Strontium, Sodium, Antimony and BismuthSüleymanŞentürkNo ratings yet

- Casting DefectDocument5 pagesCasting DefectSaurabhNo ratings yet

- 15ae307j - Aees - Unit 3Document41 pages15ae307j - Aees - Unit 3Aahana KhannaNo ratings yet

- Casting SimulationDocument12 pagesCasting SimulationIshwar GuptaNo ratings yet

- MAGMA How To UseDocument113 pagesMAGMA How To Usepurushothaman1234566No ratings yet

- Mould HPDC RunnerDocument18 pagesMould HPDC RunnerSahri KarimNo ratings yet

- Prefil Footprinter FlyerDocument6 pagesPrefil Footprinter FlyerAmmarNo ratings yet

- Fondarex Vacuum System HIGHVAC Progress BrochureDocument22 pagesFondarex Vacuum System HIGHVAC Progress Brochurebertan dağıstanlı50% (2)

- Advantages of LPDCDocument2 pagesAdvantages of LPDCSuhas KrishnaNo ratings yet

- Toshiba Machine Co., Ltd. Die Cast Machine Engineering DivDocument23 pagesToshiba Machine Co., Ltd. Die Cast Machine Engineering DivmikeNo ratings yet

- MAG Design GuideDocument32 pagesMAG Design Guidekarthik_thanguduNo ratings yet

- Fast Flow Channel SimulationDocument4 pagesFast Flow Channel Simulationgrg_greNo ratings yet

- Biscuit Thickness Validation (HPDC)Document8 pagesBiscuit Thickness Validation (HPDC)IJRASETPublications100% (1)

- 2013-01 EM315 - EM311 CH02 Casting ProcessesDocument133 pages2013-01 EM315 - EM311 CH02 Casting ProcessesPrabu ÑÖnïtzNo ratings yet

- Dievar D20140715Document16 pagesDievar D20140715Keattikhun ChaichanaNo ratings yet

- Web003 Operator Training Class 3 - Die Casting Machine & Cell Area EquipmentDocument44 pagesWeb003 Operator Training Class 3 - Die Casting Machine & Cell Area EquipmentsinrNo ratings yet

- Aluminum Die Casting GuideDocument2 pagesAluminum Die Casting GuideAndrei Todea0% (1)

- TOS555 How To Adjust PQ AmplifierDocument4 pagesTOS555 How To Adjust PQ AmplifiermikeNo ratings yet

- LPDC Flow SimulationDocument5 pagesLPDC Flow SimulationDavid JendraNo ratings yet

- Study of Process Parameters in High Pressure Die CastingDocument9 pagesStudy of Process Parameters in High Pressure Die Castingruben6286No ratings yet

- Xii Sci It-Practicals Exp1 To 13Document24 pagesXii Sci It-Practicals Exp1 To 13kartiksormare2006No ratings yet

- Effect of Surface Nanostructure On Tensile and Low Cycle Fatigue Behavior of Al 2014 AlloyDocument17 pagesEffect of Surface Nanostructure On Tensile and Low Cycle Fatigue Behavior of Al 2014 AlloychamalNo ratings yet

- EDM With ECM PDFDocument8 pagesEDM With ECM PDFlogeshboy007No ratings yet

- Usw Review PaperDocument23 pagesUsw Review PaperRahul KumarNo ratings yet

- Microelectronic Engineering: Alexander Vladimirov GrigorovDocument9 pagesMicroelectronic Engineering: Alexander Vladimirov Grigorov135713571357No ratings yet

- AC4CDocument6 pagesAC4CTay Chu YenNo ratings yet

- Magnetic-Assisted Ultrasonic Nanocrystal Surface Modification InducedDocument13 pagesMagnetic-Assisted Ultrasonic Nanocrystal Surface Modification InducedfigueeroaaabelNo ratings yet

- Third Semester B.Tech Degree - Second Series Examination, JulyDocument2 pagesThird Semester B.Tech Degree - Second Series Examination, JulyjishnusNo ratings yet

- Nitrogen Stainless SteelsDocument7 pagesNitrogen Stainless SteelsjishnusNo ratings yet

- Nitrogen Stainless SteelsDocument7 pagesNitrogen Stainless SteelsjishnusNo ratings yet

- Annealing of 0.35% C Steel, Heating To Above UCT and Cooled in FurnaceDocument7 pagesAnnealing of 0.35% C Steel, Heating To Above UCT and Cooled in FurnacejishnusNo ratings yet

- National Institute of Technology Tiruchirappalli - 620 015, TAMIL NADUDocument5 pagesNational Institute of Technology Tiruchirappalli - 620 015, TAMIL NADUjishnusNo ratings yet

- A Novel Computational Method For Loop Gain and Phase Margins of TITO SystemsDocument18 pagesA Novel Computational Method For Loop Gain and Phase Margins of TITO SystemsjishnusNo ratings yet

- Barc Application FormDocument1 pageBarc Application FormjishnusNo ratings yet

- Casting notes-EME-1Document23 pagesCasting notes-EME-1AndrewNo ratings yet

- Machine Made Candles Processes and ManufacturingDocument10 pagesMachine Made Candles Processes and ManufacturingEldad AfeworkNo ratings yet

- Copper Alloy C95200Document11 pagesCopper Alloy C95200Lin DouaiNo ratings yet

- Basic Gating and Runner DesignDocument66 pagesBasic Gating and Runner DesignRockfort HarshaNo ratings yet

- Primary Aluminium Casting Alloys 2010 - Rheinfelden Alloys - ENDocument117 pagesPrimary Aluminium Casting Alloys 2010 - Rheinfelden Alloys - ENtahera aqeelNo ratings yet

- 677 Aluminium Products Brochure E4Document2 pages677 Aluminium Products Brochure E4MeteusNo ratings yet

- INVESTING AND CASTING-handoutDocument13 pagesINVESTING AND CASTING-handoutSara M AminNo ratings yet

- Data Sheet Tolerance For Concrete SurfacesDocument10 pagesData Sheet Tolerance For Concrete SurfacesPedro RYNo ratings yet

- Vertical and Flaskless MoldingDocument1 pageVertical and Flaskless MoldingcoorgtigerNo ratings yet

- Ceramics - Fundamentals of Material Science and EngineeringDocument6 pagesCeramics - Fundamentals of Material Science and Engineeringjohn rhen uyNo ratings yet

- Casting PlatinumDocument8 pagesCasting PlatinumCarlos Mario Agudelo CastrillonNo ratings yet

- Train SLK r171 IntroDocument98 pagesTrain SLK r171 IntroIvo Almeida100% (1)

- Weld Cracking PDFDocument5 pagesWeld Cracking PDFjuanNo ratings yet

- Recent Advances in Materials For All-Ceramic RestorationsDocument19 pagesRecent Advances in Materials For All-Ceramic RestorationsManishak YessayanNo ratings yet

- Unit Two: Injection Molding Text: Richardson and Lokensgard Pages 143 - 151Document32 pagesUnit Two: Injection Molding Text: Richardson and Lokensgard Pages 143 - 151Anonymous q9eCZHMuSNo ratings yet

- Properties of Foundry SandDocument6 pagesProperties of Foundry Sandtouseefamin124100% (1)

- Effect of Chills On Tribological Behavior of Aluminum-Garnet-Carbon Hybrid CompositesDocument8 pagesEffect of Chills On Tribological Behavior of Aluminum-Garnet-Carbon Hybrid CompositesTJPRC PublicationsNo ratings yet

- NX Mold Training Material v181Document670 pagesNX Mold Training Material v181Anupam Kumar100% (1)

- Weber 2016Document6 pagesWeber 2016charon lastNo ratings yet

- (George C. Phillips (Auth.) ) A Concise IntroductionDocument164 pages(George C. Phillips (Auth.) ) A Concise IntroductionAvinash KumarNo ratings yet

- Twagirimana Evaluation 2014Document189 pagesTwagirimana Evaluation 2014osval2ioccNo ratings yet

- Determining Your Binder WorktimeDocument3 pagesDetermining Your Binder Worktimeagbajelola idrisNo ratings yet

- Listagem ASTM Volume 01 02 Ferrous Castings FerroalloysDocument6 pagesListagem ASTM Volume 01 02 Ferrous Castings FerroalloysCamilla BragançaNo ratings yet

- Sect 26 Transfer Troubleshooting GuideDocument10 pagesSect 26 Transfer Troubleshooting Guidearmando.bastosNo ratings yet

- Lecture 7-8 (ME664)Document26 pagesLecture 7-8 (ME664)Moloy SarkarNo ratings yet

- 101 Special Materials & Power ComponentsDocument31 pages101 Special Materials & Power ComponentsParakee100% (2)

- Steel Manufacturing ProcessDocument28 pagesSteel Manufacturing ProcesstranngNo ratings yet

- Casting SimulationDocument12 pagesCasting SimulationIshwar GuptaNo ratings yet

- Mil B 24480a (SH)Document8 pagesMil B 24480a (SH)Jeff95TANo ratings yet

- Moldflow: A Tool To Predict Post-Molding ProblemsDocument47 pagesMoldflow: A Tool To Predict Post-Molding ProblemspraveenmanturNo ratings yet