Hydraulic and pneumatic

- 1. College Of Engineering Roorkee SATYAM SAINI ME-4TH YEAR ROLL NO-27

- 3. Pneumatic- When the work is done operated by air or gas under pressure so its known as pneumatic. Pneumatics is a branch of engineering that makes use of gas or pressurized air.Pneumatic systems used in industry are commonly powered by compressed air or compressed inert gases. The device that converts energy from the pressurized gas into motion is called pneumatic actuator, “the machines with pneumatic loading are more efficient“

- 4. Pneumatic laws:- Charles law :- Charles's Law describes the directly proportional relationship between the volume and temperature (in Kelvin) of a fixed amount of gas, when the pressure is held constant This equation can be used to solve for initial or final value of volume or temperature under the given condition that pressure and the number of mole of the gas stay the same.

- 5. Boyles law:- Boyle’s Law describes the inverse proportional relationship between pressure and volume at a constant temperature and a fixed amount of gas. This law came from a manipulation of the Ideal Gas Law. This equation would be ideal when working with problem asking for the initial or final value of pressure or volume of a certain gas when one of the two factor is missing.

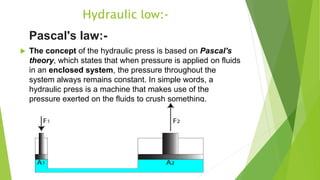

- 6. Hydraulic:- Hydraulics is a topic in applied science and engineering dealing with the mechanical properties of fluids. The hydraulic press depends on Pascal's principle-the pressure throughout a closed system is constant. Joseph Bramah invented the hydraulic press, hence it is also known as the Bramah Press. Use fluids as working media. On a very basic level Hydraulics is used for the generation, control, and transmission of fluids in order to produce some mechanical work or in general as a part of river engineering.

- 7. Hydraulic low:- Pascal's law:- The concept of the hydraulic press is based on Pascal's theory, which states that when pressure is applied on fluids in an enclosed system, the pressure throughout the system always remains constant. In simple words, a hydraulic press is a machine that makes use of the pressure exerted on the fluids to crush something.

- 8. Comparison between Hydraulic and Pneumatic Systems HYDRAULIC SYSTEM PNEUMATIC SYSTEM 1 Use fluids as working media 2 slow speed 3 Generally designed for closed systems 4 System get slowdown of leakage occurs 5 Valve operation are 6 Heavier in weight 7 Pumps are used to provide pressurized liquids Use the air as working media High speed Pneumatic systems are usually designed as open system Leakage does not affect the system much more difficult easy to operate the valves Light in weight Compressors are used to provide compressed gas

- 9. General application of pneumatic and hydraulic:- Clamping Shifting Positioning Diverting Feeding Packing

- 10. ADVANTAGES OF PNEUMATIC SYSTEM:- Low inertia effect of pneumatic components due to low density of air. Pneumatic Systems are light in weight. Operating elements are cheaper and easy to operate. Power losses are less due to low viscosity of air. High output to weight ratio. Pneumatic systems offers a safe power source in explosive environment. Leakage is less and does not influence the systems. Moreover, leakage is not harmful.

- 11. Advantage of hydraulic system:- 1. Easy and accuracy of control: By the using of simple levers and push buttons, the operator of a hydraulic system can easily start, stop, speed up and slow down. 2. Multiplication of force: A fluid power system (without using cumbersome gears, pulleys and levers) can multiply forces simply and efficiently from a fraction of a pound, to several hundred tons of output. 3. Constant force and torque: Only fluid power systems are capable of providing a constant torque or force regardless of speed changes. 4. Simple, safe and economical: In general, hydraulic systems use fewer moving parts in comparison with mechanical and electrical systems. Thus they become simpler and easier to maintain.

- 12. thanks