Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser.

Power optimization and static performance investigation of an island-mode doubly-fed induction generator (DFIG)

Power optimization and static performance investigation of an island-mode doubly-fed induction generator (DFIG)

2011, 2011 IEEE International Conference on Control System, Computing and Engineering, ICCSCE 2011

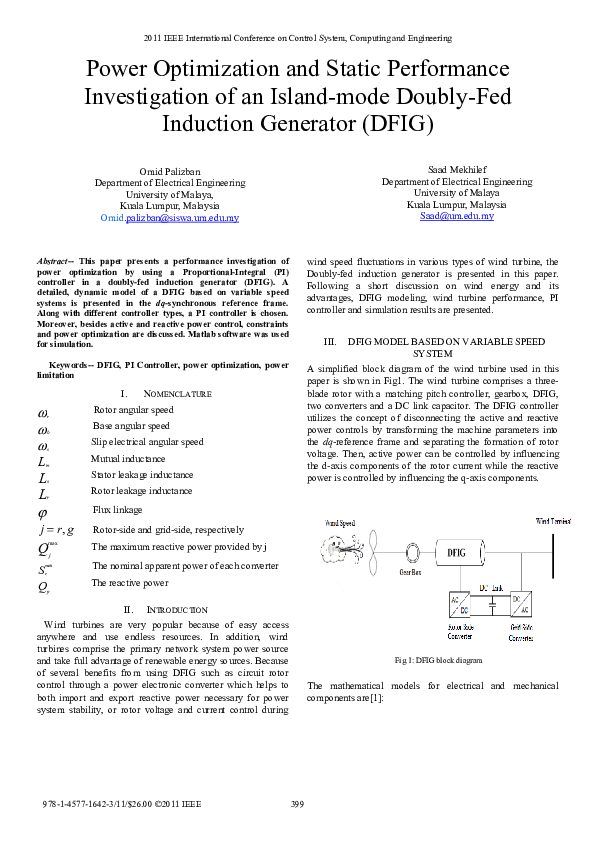

This paper presents a performance investigation of power optimization by using a Proportional-Integral (PI) controller in a doubly-fed induction generator (DFIG). A detailed, dynamic model of a DFIG based on variable speed systems is presented in the dq-synchronous reference frame. Along with different controller types, a PI controller is chosen. Moreover, besides active and reactive power control, constraints and power optimization are discussed. Matlab software was used for simulation. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=6190559

Related Papers

Inventions

Power Optimization Control Scheme for Doubly Fed Induction Generator Used in Wind Turbine GeneratorsScientists and researchers are exploring different methods of generating and delivering electrical energy in an economical and reliable way, enabling them to generate electricity focusing on renewable energy resources. All of these possess the natural property of self-changing behavior, so the connection of these separate independent controllable units to the grid leads to uncertainties. This creates an imbalance in active power and reactive power. In order to control the active and reactive power in wind turbine generators with adjustable speed, various control strategies are used to allay voltage and current variations. This research work is focused on the design and implementation of effective control strategies for doubly fed induction generator (DFIG) to control its active and reactive power. A DFIG system with its control strategies is simulated on MATLAB software. To augment the transient stability of DFIG, the simulation results for the active and reactive power of conventio...

2015 •

An intelligent control of Doubly Fed Induction Generator (DFIG) system using Proportional-Integral (PI)controller tuned by optimization techniques is proposed in this paper.System identification technique was presented in this work to estimate the transfer function of the reactive power loop and speed loop of the proposed system.An implemented laboratory prototype consists of 0.37kW, 220 V, 50Hz Brushless DC Motor (BLDC) and its drive circuit controlled by voltage source inverter for various wind speed.A 0.27 kW wound rotor induction machine, working as the DFIG, coupled with turbine machine by a coupler and driven through a back-to-back converter. This system can be applied as a stand-alone power supply system or as the emergency power system when the electricity grid fails. The rotor side converter is controlled using the field-oriented control to control the reactive power at different rotor speeds.Grey Wolf Optimizer (GWO) proposed in this study to tune the (PI) controller. More...

9th International Conference on Electrical Engineering ICEENG 2014

Modeling, Analysis and Control of Doubly Fed Induction Generators for Wind Turbines2014 •

This paper presents modeling, analysis and control of a grid connected Doubly Fed Induction Generator (DFIG) wind turbine, during steady-state and transient operations. A mathematical model for different parts of the wind energy conversion system using DFIG has been examined using MATLAB/SIMULINK. A control structure using standard Proportional Integral (PI) controller and a voltage-oriented control strategy based on a rotating reference frame has been used. The machine model considers operating conditions below and above synchronous speed. The Maximum Power Point Tracking (MPPT) method has been presented also to improve efficiency and energy extraction in wind turbine systems. Characteristic power curve method has been used as one of the popular MPPT methods. In this paper, simulation results of the DFIG model have been presented. Then, DFIG model has been connected to the grid model and examined using PI controller under different conditions. The Internal Model Control (IMC) method has been used for tuning the PI controller. The proposed PI controller shows stable operation at different conditions.

IEEE Transactions on Industry Applications

Determination of Steady-State and Dynamic Control Laws of Doubly Fed Induction Generator Using Natural and Power Variables2013 •

IAEME PUBLICATION

PERFORMANCE ANALYSIS OF DOUBLY-FED INDUCTION GENERATOR USING PID CONTROLLER OPTIMIZED BY AQUILA OPTIMIZATION ALGORITHM2018 •

This research paper delves into the optimization of a Doubly Fed Induction Generator (DFIG) controller using the Aquila Optimization Algorithm (AOA). The proposed DFIG controller is rigorously analyzed and assessed through simulation. Several key performance metrics, including rise time, settling time, overshoot, and undershoot, are evaluated in a comparative analysis with a conventional PID controller. The results showcase a significant enhancement in the performance of the DFIG system when optimized by the AOA-driven PID controller. Notable improvements are observed in parameters such as reduced rise time, quicker settling time, and substantially decreased overshoot. Moreover, the introduction of AOA results in a more precise and responsive control system, offering promising prospects for the efficient utilization of DFIGs in high-power systems.

in recent years, wind energy has become one of the most important and promising sources of renewable energy, which demands additional transmission capacity and better means of maintaining system reliability. The wind energy conversion systems are connected to the grid through Voltage Source Converters (VSC) to make variable speed operation possible. The studied system here is a variable speed wind generation system based on DFIG using MATLAB Simulation. DFIG is the hybrid version of the Induction Generator. In the DFIG no extra auxiliary equipment is required to compensate the reactive power because the design of DFIG is such a way that reactive power is compensate by the Rotor Side or Grid Side Converter. The rotor side converter (RSC) usually provides active and reactive power control of the machine while the grid-side converter (GSC) keeps the voltage of the DC-link constant. Results show that the DFIG can work at variable speed; it gives the optimum output at respective speed. But induction generator only works at fixed speed. The power output is more reliable in DFIG. In induction generator capacitor bank or STATECOM is used for compensate the reactive power. In DFIG there is no need of such equipment’s for compensating the reactive power. DFIG is more stable at Transient Fault Condition than IG.

2019 26th International Workshop on Electric Drives: Improvement in Efficiency of Electric Drives (IWED)

Modeling, Algorithm Control And Simulation Of Variable-Speed Doubly-Fed Induction Generator In Grid Connected Operation2019 •

The paper presents the modeling, computer simulation’s results of a grid connected to a doubly fed induction generator (DFIG) at variable speed (higher, lower and synchronous speed) and give to the grid only active power. The stator windings machine is directly connected to the grid, the rotor winding machine is connected to the grid via slip-rings to a three-phase converter and made in the form of two back-to-back inverter and DC-link. The problems of synthesis of control systems that implement the principle of vector control are considered. A model of these control systems in the program MATLAB/Simulink is created. The models developed and results obtained provide information and method control for the development of DFIG generating systems.

Wind Energy Management

Modeling and Designing a Deadbeat Power Control for Doubly-Fed Induction Generator2011 •

− The doubly fed induction generator (DFIG) is a variable speed induction machine that is utilized in modern wind turbine generators. In this paper steady state characteristic of DFIG is studied. From mathematical model it is found that on increase of rotor injection voltage and resistance, the torque speed response is shifted from over synchronous to sub synchronous range. The stability of DFIG operation is entirely dependent on torque. The functional relationship of generator further validated using MATLAB and experimental model. DFIG find application mainly in wind energy conversion system.

Imperial Historiography and the Creation of Persian Scholarship on India: The Ā’īn-i Akbarī of Abū al-Fażl (d. 1602)

Introduction: Abū al-Fażl and Persian Historical Writingin the Multi-cultural Society of Mughal India2024 •

RELATED PAPERS

2024 •

Studia Gilsoniana

Mgr Lefebvre et la contre révolutionplafond3d.hypotheses.org

The concept of emergence as a methodological tool for understanding ceiling paintings?2023 •

Archives of Medical Sciences

Concomitant laparoscopic sleeve gastrectomy and laparoscopic cholecystectomy in a morbidly obese patient with situs inversus totalis2021 •

Folia Linguistica

Third-person singular zero in Norfolk English: An addendum2016 •

Indonesian Journal of Electrical Engineering and Computer Science

Test-framework: performance profiling and testing web search engine on non factoid queriesEvidence-Based Complementary and Alternative Medicine

Scolymus hispanicus (Golden Thistle) Ameliorates Hepatic Steatosis and Metabolic Syndrome by Reducing Lipid Accumulation, Oxidative Stress, and Inflammation in Rats under Hyperfatty Diet2021 •

Systems biology in reproductive medicine

Metabolomics analysis of follicular fluid in women with ovarian endometriosis undergoing in vitro fertilization2018 •

Journal of Hand Therapy

Does mental practice or mirror therapy help prevent functional loss after distal radius fracture? A randomized controlled trial2022 •

Prof. Dr. Saad Mekhilef

Prof. Dr. Saad Mekhilef