Ductile Iron Casting Specfications and Details All Standards

Ductile Iron Casting Specfications and Details All Standards

Uploaded by

N.PalaniappanCopyright:

Available Formats

Ductile Iron Casting Specfications and Details All Standards

Ductile Iron Casting Specfications and Details All Standards

Uploaded by

N.PalaniappanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ductile Iron Casting Specfications and Details All Standards

Ductile Iron Casting Specfications and Details All Standards

Uploaded by

N.PalaniappanCopyright:

Available Formats

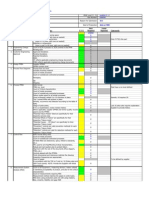

Ductile Iron Casting Specifications

IIntroduction The purpose of standard specifications for Ductile Iron castings is to provide a body of information which can be used with confidence by both designer and foundry to select, define and agree upon a set of specific properties which will ensure that the castings meet the intended use of the designer. The use of standard specifications simplifies the purchase of castings from multiple suppliers because it defines a standard casting whose properties meet the designer's needs, regardless of where, or how the castings were produced. Specifications should be chosen carefully and used sparingly to ensure that they adequately define the designer's needs without adding superfluous constraints which needlessly restrict the suppliers' options, complicate the casting process and increase the cost of the casting. It is the responsibility of both the designer and the foundry to be aware of the role and the limitations of specifications and to agree upon a specification that provides the optimum ratio of performance to cost. It is up to the designer to specify a set of properties mechanical, physical, chemical or dimensional - which best suit the casting to its purpose. Once the specification has been selected, the foundry must ensure that all castings delivered meet or exceed the specification. The raw materials and production methods used by the foundry to provide conforming castings are not normally restricted by the designer or the specification unless the specification includes such instructions, or the designer and foundry agree to append additional instructions to a specification. Such instructions should be used judiciously, because they almost invariably increase the casting cost and restrict the number of foundries which can provide competitive bids. North America The ASTM has five standards covering Ductile Iron castings. ASTM A 536 is the most frequently used, covering the general engineering grades of Ductile Iron. The other standards cover austenitic and special Ductile Iron applications. The ASTM has issued in 1990 a new specification defining the properties of Austempered Ductile Iron. The SAE standard J434 is commonly used for specifying automotive Ductile Iron castings. In an attempt to create a single, comprehensive system for designating metals and alloys the ASTM and SAE have jointly developed the Unified Numbering System (UNS). While not itself a specification, the UNS designation is gaining some degree of acceptance in North America as a useful means of simplifying and correlating the various existing specifications. The UNS designations for Ductile Irons, crossreferenced to the corresponding ASTM, AMS, SAE and MIL specifications, are shown below. UNS numbers and corresponding American specifications Standard UNS ASTM A395 ASTM A536 ASTM A476 ASTM A716 AMS SAE J434 MIL-I-24137 UNS ASTM A439 ASTM A536 SAE J434 100-70- 120-9003 02 D7003 DQ & T D4018 D4512 (A) F34800 F36200 F43000 F43001 F43002 F43003 D-2 D-2B D-2C C-3 F43004 C-3A ****** 5315 D5506 5316 60-4018 60-4018 65-4512 80-5506 80-60-03 Numbers/Grades F3000 F32800 F32900 F33100 F33101 F33800 F34100

UNS ASTM A439 ASTM A571 AMS MIL-I-24137 Other Standards

F43005 F43006 F43007 F43010 F43020 F43021 D-4 D-5 D-5B D-2M

F43030

5395 (B) (C)

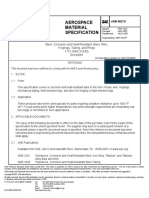

This section also summarizes the national standards for Ductile Iron for the other major industrialized countries and the international ISO standard. This standard, and its replacement, the EuroNorm standard EN will become increasingly important with the formation of the European Community. There are many additional standards for Ductile Iron, some national, and others valid only within a specific technical or commercial organization. While each specification may have its own distinguishing characteristics, there are also many similarities between specifications. Before using any specification, the designer should obtain a complete copy of the current issue from the specifying body to familiarize himself with both the properties specified and the conditions under which they are to be measured. Standard specifications for Ductile Iron are normally based on mechanical properties, except for those defining austenitic Ductile Iron, which are based on composition. Mechanical property values are given in the units normal to the particular specifying body. Conversions for SI, metric non-SI, and non-metric units are given at the end of this section to assist in comparing specifications. DUCTILE IRON SPECIFICATIONS ASTM A 395 - Ferritic Ductile Iron Pressure-Retaining Castings for Use at Elevated Temperatures This standard specifies chemical, physical, and hardness requirements. Chemical Requirements The castings shall conform to the following requirements for chemical composition (Note 3): Physical Requirements Tensile Properties - The Ductile Iron as represented by the test specimens shall conform to the following requiremenets for tensile properties: Tensile strength, min, psi (MPa) Yield strength, min, psi (MPa) Elongation in 2 in. or 50 mm min. Total carbon, min, % Silicon, max, % Phosphorus, max, % 3.00 2.50 0.08 60 000 (414) 40 000 (276) 18%

Hardness: - The hardness of the heat-treated Ductile Iron as represented by the test specimens and castings shall be within the following limits: HB, 3000-kgf load 143 to 187

ASTM A439 AUSTENITIC DUCTILE IRON CASTINGS Chemical Requirements Type Element Total carbon, max Silicon D-2A D-2B D-2C D-3A D-3A D-4 D-5 D-5B D-5S

Composition, % 3.00 3.00 2.90 2.60 2.60 2.60 2.40 2.40 2.30

1.50-3.00 1.50-3.00 1.00-3.00 1.00-2.80 1.00-2.80 5.00-6.00 1.00-2.80 1.00-2.80 4.90-5.50

Manganese Phosphorus, max Nickel Chromium

A B

0.70-1.25 0.70-1.25 1.80-2.40 1.00 maxB 1.00 maxB 1.00 maxB 1.00 maxB 1.00 maxB 1.00 max 0.08 18.0022.00 0.08 18.0022.00 0.08 21.0024.00 0.50maxB 0.08 28.0032.00 0.08 28.0032.00 0.08 28.0032.00 0.08 34.0036.00 0.08 34.0036.00 0.08 34.0037.00

1.75-2.75 2.75-4.00

2.50-3.50 1.00-1.50 4.50-5.50 0.10 max 2.00-3.00 1.75-2.25

Additions of 0.7 to 1.0% of molybdenum will increase the mechanical properties above 800oF (425oC). Not intentionally added.

Mechanical Requirements Type Element Tensile strength, min, ksi (MPa) Yield strength (0.2 percent offset), min, ksi (MPa) Elongation 2 in. or 50mm, min, % Brinell hardness (300 kg) D-2 D-2B D-2C D-3 D-3A Properties 58 (400) 58 (400) 58 (400) 55 (379) 55 (379) 60 (414) 55 (379) 55 (379) 65 (449) 30 (207) 30 (207) 28 (193) 30 (207) 30 (207) 8.0 7.0 20.0 6.0 10.0 --30 (207) 30 (201) 30 (207) 20.0 6.0 10 D-4 D-5 D-5B D-5S

139-202 148-211 121-171 139-202 131-193 202-273 131-185 139-193 131-193

ASTM A 476

DUCTILE IRON CASTINGS FOR PAPER MILL DRYER ROLLS Tensile Requirements Test Coupon Section Thickness Tensile strength, min, ksi Yield strength, min, ksi Elongation in 2 in., min, % 1 in. 80 60 3.0 3 in. 80 60 1.0

Chemical Requirements The castings shall conform to the following chemical requirements: Total carbon, min, % Silicon, max, % Phoshorus, max, % Sulfur, max, % 3.0 3.0 0.08 0.05

The castings shall have a carbon equivalent of 3.8 to 4.5 inclusive. ASTM A 536 DUCTILE IRON CASTINGS Tensile Requirements Grade 60/40/18 Tensile strength, min, psi Tensile strength, min, MPa 60 000 414 Grade 65/45/12 65 000 448 Grade 80/55/06 80 000 552 Grade 100/70/03 100 000 689 Grade 120/90/02 120 000 827

Yield strength, min, psi Yield strength, min, MPa Elongation in 2 in. or 50 mm, min, %

40 000 276

45 000 310

55 000 379

70 000 483

90 000 621

18

12

6.0

3.0

2.0

Tensile Requirements for Special Applications Grade 60/42/10 Tensile strength, min, psi Tensile strength, min, MPa Yield strength, min, psi Yield strength, min, MPa Elongation in 2 in. or 50 mm, min, % 60 000 415 42 000 290 10 Grade 70/50/05 70 000 485 50 000 345 5 Grade 80/60/03 80 000 555 60 000 415 3

ASTM A 571 AUSTENITIC DUCTILE IRON CASTINGS FOR PRESSURECONTAINING PARTS SUITABLE FOR LOW-TEMPERATURE SERVICE This standard specifies that all castings shall be heat treated by annealing between 1600 and 1800oF for 1 hour per inch of casting section and furnace cooling. Chemical Requirements Element Total carbon Silicon Manganese Nickel Chromium Phosphorus

A

Mechanical Property RequirementsA Class 1 Tensile Strength, min, ksi Yield Strength 0.2% (offset), min, ksi Elongation, min, % Brinell Hardness, 3000 kg Charpy V-notch, ft-lbf min, average 3 tests min, individual test

A

Composition, % 2.2-2.7A 1.5-2.50 3.75-4.5 21.0-24.0 0.20 max 0.08 max

Class 2 60 25 25 111-171 20 15

65 30 30 121-171 15 12

For castings with sections under 1/4 in., it may be desirable to adjust the carbon upwards to a maximum of 2.90%. ASTM A 897

Heat-treated condition

AUSTEMPERED DUCTILE IRON Min. Tensile Str. Min. Yield Str. MPa Ksi 80 Elongation Percent 10

A897 M Impact Energy* Joules Ftlb 75 Hardness BHN** 269-321

Grade 125/80/10

MPa

Ksi 125

850/550/10 150/100/7 1050/700/7 175/125/4 1200/850/4 200/155/1 1400/1100/1 230/185/1600/1300/-

850 150 1050 175 1200 200 1400 230 1600

550 100 700 125 850 155 1100 185 1300

10 7 7 4 4 1 1 *** ***

100 60 80 45 60 25 35 *** ***

269-321 302-363 302-363 341-444 341-444 388-477 388-477 444-555 444-555

* Values obtained using unnotched Charpy bars tested at 72 deg. F (20 deg. C). The values in the table are the average of the three highest of four tested samples. ** Hardness is not a mandatory specification and is shown for information only. *** Elongation and impact specifications are not required. Complete specifications may be obtained from: American Society for Testing Materials. 1916 Race Street, Philadelphia, PA 19103. Society of Automotive Engineers Inc., 485 Lexington Ave., New York , NY 10017. American Society of Mechanical Engineers, 345 East 47th Street. New York, NY 10017. NOTE: SAE specification for Ductile Iron casting and austempered Ductile Iron casting are currently being revised so they were not available as of the time of this printing. SAE J434 FEB2004 AUTOMOTIVE DUCTILE IRON CASTINGS Yield strength, Proof stress, Rpo.2 min. N/mm2 275

ksi

Tensile strength, Rm1 min. Grade N/mm2 400

ksi

Charpy Impact Relative Energy Typical Elongation Hardness Impact Values Wall Thickness Structure Joules ft.-lb. % HBW (Mpa) <=20mm 120 90 18 143-170 (14021667) 156-217 (15302128) 187-229 (18342246) 217-269 (21282638) 241-302 (23632961) 255-311 (25013050) Ferrite

D400 (D4018) D450 (D4512) D500 (D5506) D550 (D5504) D700 (D7003) D800 DQ&T

58

40

450

65

310

45

<=20mm

80

60

12

Ferrite-Pearlite

500

73

345

50

<=20mm

54

40

Ferrite-Pearlite

550

80

380

55

<=20mm

40

30

Pearlite-Ferrite

700

102

450

65

<=20mm

27

20

Pearlite Pearlite or Tempered Martensite

800

116

480

70

A wide variety of properties are possible. Minimum properties are specified by Range Tempered Martensite agreement between manufacturer and purchaser. specified by

agreement * These irons are primarily specified on hardness and structure. The mechanical properties are given for information only. **Quenched and tempered grade; hardness to be agreed between supplier and purchaser.

JAPAN Jis G5503-1995

Austempered Spheroidal Graphite Iron Castings Mechanical properties of separately cast test sample

Symbol of grade FCAD 900-4 FCAD 900-8 FCAD 1000-5 FCAD 1200-2 FCAD 1400-1

Tensile strength N/mm2 900 min. 900 min. 1000 min. 1200 min. 1400 min.

Yield strength N/mm2 600 min. 600 min. 700 min. 900 min. 1100 min.

Elongation % 4 min. 8 min. 5 min. 2 min. 1 min.

Hardness HB 341 min. 401 min.

JAPAN Jis G 5502-1995

SPHEROIDAL GRAPHITE IRON CASTINGS Mechanical properties of separately cast test sample

Symbol of grade

Tensile strength N/mm2

Yield strength N/mm2

Elongation %

Charpy absorption energy Mean Test value of Individual Temp. 3 value J o C pieces J

(Information reference)

Hardness HB

Matrix structure

FCD 35022 FCD 35022L FCD 40018 FCD 40018L FCD 40015 FCD 45010 FCD 5007 FCD 6003

350 min.

220 min.

22 min.

23 5 -40 2

17 min. 12 min. 14 min. 12 min. -

14 min. 9 min. 11 min. 9 min. -

150 max.

Ferrite

400 min.

250 min.

18 min.

23 5 -20 2

130 to 180

15 min. 450 min. 500 min. 600 min. 280 min. 320 min. 370 min. 10 min. 7 min. 3 min.

140 to 210 150 to 230 170 to 270 Ferrite + pearlite Pearlite + ferrite

FCD 7002 FCD 8002

700 min. 800 min.

420 min. 480 min.

2 min.

180 to 300 200 to 330

Pearlite Pearlite or tempered structure

Mechanical properties of cast-on test sample

Chief

Symbol of grade

thickness of iron casting mm

Tensile strength N/mm2

Yield strength N/mm2

Elongation %

Charpy absorption energy Mean value of 3 pieces J 14 min.

(Information reference)

Test Temp. o C FCD 40018A Over 30, up to and incl. 60 Over 60, up to and incl. 200 FCD 40018AL Over 30, up to and incl. 60 Over 60, up to and incl. 200 FCD 40015A Over 30, up to and incl. 60 Over 60, up to and incl. 200 FCD 5007A Over 30, up to and incl. 60 Over 60, up to and incl. 390 min. 250 min. 15 min. 23 5

Individual value J 11 min.

Hardness HB 120 to 180

Matrix structure Ferrite

370 min.

240 min.

12 min.

12 min.

9 min.

390 min.

250 min.

15 min.

-20 2

370 min.

240 min.

12 in.

10 min.

7 min.

390 min.

250 min.

15 min.

370 min.

240 min.

12 min.

450 min.

300 min.

7 min.

130 to 230

Ferrite + pearlite

420 min.

290 min.

5 min.

200 FCD 6003A Over 30, up to and incl. 60 Over 60, up to and incl. 200 600 min. 360 min. 2 min. 160 to 270 Pearlite + ferrite

550 min.

340 min.

1 min.

EUROPEAN STANDARD

SPHEROIDAL GRAPHITE CAST IRONS EN 1563 : 1997

Mechanical properties measured on test pieces machined from separately cast samples Material designation Symbol EN-GJS-350-22-LT1) EN-GJS-350-22-LT2) EN-GJS-350-22-LT EN-GJS-400-18-LT1) EN-GJS-400-18-LT2) EN-GJS-400-18-LT EN-GJS-450-15 EN-GJS-450-10 EN-GJS-500-7 EN-GJS-600-3 EN-GJS-700-2 EN-GJS-800-2 EN-GJS-900-2

1)

Number EN-JS1015 EN-JS1014 EN-JS1010 EN-JS1025 EN-JS1024 EN-JS1020 EN-JS1030 EN-JS1040 EN-JS1050 EN-JS1060 EN-JS1070 EN-JS1080 EN-JS1090

Tensile strength 0.2% proof stress Rm Rp0.2 N/mm2 min. N/mm2 min. 350 350 350 400 400 400 400 450 500 600 700 800 900

2)

Elongation A % min. 22 22 22 18 18 18 15 10 7 3 2 2 2

220 220 220 240 250 250 250 310 320 370 420 480 600

LT for low temperature.

RT for room temperature.

NOTE 1. The values for these maerials apply to castings cast in sand moulds of comparable thermal diffusivity. Subject to amendments to be agreed upon in the order, they can apply to castings obtained by alternative methods. NOTE 2. Whatever the method used for obtaining the castings, the grades are based on the mechanical properties measured on test pieces taken from samples separately cast in a sand mould or a mould of comparable thermal diffusivity. NOTE 3. 1N/mm2 is equivalent to 1 MPa. NOTE 4. the material designation is in accordance with EN 1560. Minimum impact resistance values measured on V-notch test pieces machines from separately cast samples Material designation Minimum impact resistance values (in J) At room temp. At (-20 2) oC At (-40 2) oC

(23 5) oC Symbol Number Mean value from 3 tests Individual value Mean Individual value from value 3 tests Mean value from 3 tests Individual value

EN-GJS350-22Lt1) EN-GJS350-22Rt2) EN-GJS400-18Lt1) EN-GJS400-18Lt2)

1) 2)

ENJS1015 ENJS1014 ENJS1025 ENJS1024

12

17

14

12

14

11

Lt for low temperature. Rt for room temperature.

NOTE 1. the values for these maerials apply to castings cast in sand moulds of comparable thermal diffusivity. Subject to amendments to be agreed upon in the order, they can apply to castings obtained by alternative methods. NOTE 2. Whatever the method used for obtaining the castings, the grades are based on the mechanical properties measured on test pieces taken from samples separately cast in a sand mould or a mould of comparable thermal diffusivity. NOTE 3. the material designation is in accordance with EN 1560.

EUROPEAN STANDARD

EN 1563 : 1997 (continued)

Mechanical properties measured on test pieces machined from separately cast samples Material designation Relevant wall thickness t mm tensile strength Rm N/mm2 min. t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 350 330 320 350 330 320 350 330 320 400 390 370 0.2% proof stress Rp0.2 N/mm2 min. 220 210 200 220 210 200 220 210 200 240 230 220 Elongation A % min. 22 18 15 22 18 15 22 18 15 18 15 12

Symbol Number EN-GJS-350-22U-Lt

1)

EN-JS1019

EN-GJS-350-22U-Rt2)

EN-JS1029

EN-GJS-350-22U

EN-JS1032

EN-GJS-400-18U-LT1)

EN-JS1049

EN-GJS-400-18U-RT2)

EN-JS1059

t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200 t<30 30<t<60 60<t<200

400 390 370 400 390 370 400 390 370

250 250 240 250 250 240 250 250 240

18 15 12 18 15 12 15 14 11

EN-GJS-400-18U

EN-JS1062

EN-GJS-400-15U

EN-JS1072

EN-GJS-450-10U

EN-JS1132

450 310 10 } To be agreed between the manufacturer and the purchaser. 500 450 420 600 600 550 700 700 660 320 300 290 370 360 340 420 400 380 7 7 5 3 2 1 2 2 1

EN-GJS-500-7U

EN-JS1082

EN-GJS-600-3U

EN-JS1092

EN-GJS-700-2U

EN-JS1102

EN-GJS-800-2U

EN-JS1112

800 480 2 } To be agreed between the manufacturer and the purchaser. 900 480 2 } To be agreed between the manufacturer and the purchaser.

EN-GJS-900-2U

EN-JS1122

1) 2)

LT for low temperature. RT for room temperature.

NOTE 1. The properties of a cast-on test piece cannot exactly the properties of the casting itself, but can be a better approximation than those obtained on a separtely cast sample. Further values are given in annex D for guidance. NOTE 2. N/mm2 is equivalent to 1 MPa. NOTE 3. The material designation is in accordance with EN 1560. EUROPEAN STANDARD EN 1563 : 1997 (continued) Material designation Symbol EN-GJS-HB130 EN-GJS-HB150 EN-GJS-HB155 EN-GJS-HB185 EN-GJS-HB200 Number EN-JS2010 EN-JS2020 EN-JS2030 EN-JS2040 EN-JS2050 Less than 160 130 to 175 135 to 180 160 to 210 170 to 230 Brinell hardness range HB Other properties (for information only) Rm N/mm2 350 400 400 450 500 Rp0.2 N/mm2 220 250 250 310 320

EN-GJS-HB230 EN-GJS-HB265 EN-GJS-HB3001) EN-GJS-HB330

1) 1)

EN-JS2060 EN-JS2070 EN-JS20801) EN-JS2090

1)

190 to 270 225 to 350 245 to 335 270 to 360

600 700 800 900

370 420 480 600

EN-GJS-HB300 (EN-JS2080) and EN-GJS2090) are not recommended for thick section castings. NOTE 1. 1 N/mm2 is equivalent to 1 MPa. Minimum impact resistance values measured on V-notched test pieces machined from cast-on samples Material designation Minimum impact resistance values (in J) At room temperature (23+5) oC Relevant wall thickness t mm t<60 60<t<200 t<60 60<t<200 30<t<60 60<t<200 30<t<60 60<t<200 Mean value from 3 tests Individual value At (-20+2) oC Mean value from 3 tests Individual value At (-40+2) oC Mean value from 3 tests 12 10 Individual value

Symbol EN-GJS350-22ULT1) EN-GJS350-22URT2) EN-GJS400-18ULT1) EN-GJS400-18URT2)

1) 2)

Number ENJS1019 ENJS1029 ENJS1049 ENJS1059

9 7 -

17 15 -

14 12 -

12 10 -

9 7 -

14 12

11 9

LT for low temperature. RT for room temperature.

NOTE 1. The values for the materials normally apply to castings with thicknesses between 30 mm and 200 mm and with a mass greater than 2000 kg or when the relevant wall thickness may vary between 30 mm and 200 mm. NOTE 2. The properties of a cast-on test piece cannot reflect exactly the properties of the casting itself, but can be a better approximation than those obtained on a separately cast sample. Further values are given in annex D for guidance. NOTE 3. 1 N/mm2 is equivalent to 1 MPa. NOTE 4. The material designation is in accordance with EN 1560. EUROPEAN STANDARD AUSTEMPERED DUCTILE CAST IRONS EN 1564 : 1997

Mechanical properties measured on test pieces machined from separately cast samples. Material designation Tensile strength 0.2% proof Elongation

Symbol

Number

Rm N/mm2 min. 800 1000 1200 1400

stress Rp0.2 N/mm2 min. 500 700 850 1100

A % min. 8 5 2 1

EN-GJS-800-8 EN-GJS-1000-5 EN-GJS-1200-2 EN-GJS-1400-1

EN-JS1100 EN-JS1110 EN-JS1120 EN-JS1130

NOTE 1. The values for the materials apply to castings cast in sand moulds of comparable thermal diffusivity. Subject to amendments to be agreed upon in the order, they can apply to castings obtained by alternative methods. NOTE 2. Whatever the method used for obtaining the castings, the grades are based on the mechanical properties measured on test pieces taken from samples separately cast in a sand mould or a mould of comparable thermal diffusivity. NOTE 3. 1 N/mm2 is equivalent to 1 MPa. NOTE 4. The material designation is in accordance with EN 1560. Hardness range Material designation Symbol EN-GJS-800-8 EN-GJS-1000-5 EN-GJS-1200-2 EN-GJS-1400-1 Number EN-JS1100 EN-JS1110 EN-JS1120 EN-JS1130 Brinell hardness range HB 260 to 320 300 to 360 340 to 440 380 to 480

NOTE: The material designation is in accordance with EN 1560. SOUTH AFRICA SPHEROIDAL GRAPHITE IRON CASTINGS SABS 936/937 Tensile strength Rm min. Proof stress Rp0.2 min. Elongation Hardness A min. % 17 12 7 4 3 2 HB <180 <200 170 240 210 250 230 300 260 330 Structure Ferrite Ferrite Ferrite & pearlite Pearlite Pearlite Pearlite or temper structure

Grade N/mm2 kgf/m2 ton/in2 N/mm2 kgf/m2 ton/in2 SG38 SG42 SG50 SG60 SG70 SG80 375 410 490 590 685 785 38.0 42.0 50.0 60.0 70.0 80.0 24.2 2.5 31.7 38.1 44.4 50.8 245 275 345 390 440 490 25.0 28.1 35.2 39.8 44.9 50.0 16.0 17.7 22.3 25.2 28.5 31.7

For information only. SOUTH AFRICA Grade AUSTEMPERED DUCTILE IRON CASTINGS SABS 1656 : 1995 Minimum tensile strength Rm MPa 850 1050 1200 1400 1600 Minimum proof stress Rp0.2 MPa 550 700 850 1100 1300 Minimum elongation % Impact strength (energy loss) J 100 80 60 35 Hardness 1)

ADI 850 ADI 1050 ADI 1200 ADI 1400 ADI 1600

1)

10 7 4 1 -

269 - 321 302 - 363 341 - 444 388 - 477 444 - 555

For information only. AUSTENITIC SPHEROIDAL GRAPHITE IRON CASTINGS Tensile strength Rm min. Proof stress Rp0.2 min. N/mm2 205 205 195 205 205 205 kgf/m2 21.0 21.0 20.0 21.0 21.0 21.0 ton/in2 13.3 13.3 12.5 13.3 13.3 13.3 Elongation A min. % 8 6 20 10 7 25 Hardness max. HB 200 255 170 230 200 170

SOUTH AFRICA

Grade ASG-2A ASG-2B ASG-3A ASG-4A ASG-5A ASG-6A

N/mm2 375 375 375 375 375 410

kgf/m2 38.0 38.0 38.0 38.0 38.0 42.0

ton/in2 24.2 24.2 24.2 24.2 24.2 26.5

PHYSICAL PROPERTIES OF SOME ELEMENTS Atomic Weight 26.97 121.76 137.36 9.02 209.00 10.82 112.41 40.08 12.00 140.13 52.01 Melting Point

o

Element Aluminum Antimony Barium Beryllium Bismuth Boron Cadmium Calcium Carbon Cerium Chromium

Symbol Al Sb Ba Be Bi B Cd Ca C Ce Cr

Boiling Point oF 3272 2516 2084 2732 2642 4622 1408 2522 6512 2552 3992

Density grs/cc 2.70 6.62 3.50 1.82 9.8 2.30 8.65 1.55 2.22 6.79 7.14

1220 1167 1562 2462 520 4172 610 1564 1427 3326

660 630 850 1350 271 2282 321 851 640 1812

Cobalt Columbium Copper Gold Iron Lead Lithium Magnesium Manganese Mercury Molybdenum Mickel Palladium Phosphorous Platinum Potassium Rhodium Selenium Silicon Silver Sodium Strontium Sulfur Tantalum Tellurium Thallium Thorium Tin Titanium Tungsten Uranium Vanadium Zinc Zirconium

Co Nb Cu Au Fe Pb Li Mg Mn Hg Mo Ni Pd P Pt K Rh Se Si Ag Na Sr S Ta Te Ti Th Sn Ti W U V Zn Zr

58.94 92.91 63.57 197.20 55.84 207.22 6.94 24.32 54.94 200.61 96.00 58.69 106.70 31.02 195.23 39.09 102.91 78.96 28.06 107.88 22.99 87.63 32.06 180.88 127.61 204.39 232.12 118.70 47.90 184.00 238.14 50.95 65.38 91.22

2696 3542 1982 1945 2795 621 367 1204 2273 -38 4748 2645 2831 111 3224 144 3551 428 2588 1761 207 1472 235 5162 846 578 3353 450 3272 6098 3074 3110 787 3092

1480 1932 1082 1062 1535 327 186 652 1245 2602 1452 1555 42 1755 62 1882 220 1420 961 97 800 112 2832 451 302 1827 232 1782 3334 1672 1692 419 1682

5252 5972 4259 4712 5430 2948 2437 2007 3452 676 6692 5252 3992 536 7772 1400 4532 1270 4712 3542 1616 2102 832 7412 2534 3002 5432 4100 5432 10526 6332 5432 1661 5252

8.90 8.57 8.94 1930 7.87 11.35 0.53 1.74 7.20 13.55 10.20 8.85 12.00 1.82 21.45 0.86 12.50 4.81 2.40 10.50 0.97 2.60 2.07 16.60 6.24 11.85 11.50 7.30 4.50 19.30 18.70 5.68 7.14 6.40

CONVERSIONS: English, SI units, and non-SI metric units 1 lbf/in2 = 1 psi = 1000 psi = 6.895 N/m2 = 6.895 MPa = 0.7031 kgf/mm2 =0.4464 tonf/in2 = 1 MN/m2 = 1 MPa

1 ksi

1 N/mm2

= 0.06475 tonf/in2 = 145.04 lbf/in2 = 0.10197 kgf/mm2 1 kgf/mm

2

= 9.8067 N/mm2 = 0.63497 tonf/in2 = 1422.4 lbf/in2 = 15.444 N/mm2 = 1.5749 kgf/mm2 = 2240 lbf/in2 = 1.3558 J = 0.1369 kgf-m = 0.73757 ft-lbf = 0.10197 kgf-m = 9.8067J = 7.3068 ft lbf Units English Multiplication Factor 6.45 .093 2.54 .305 .454 .556 SI Units cm2 m2 cm m kg

o

1 tonf/in 1 ft-lbf 1J 1kgf-m

Area Area Length Length Mass Temp

in2 ft2 in ft lb. (oF - 32)

You might also like

- ASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1No ratings yetASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials15 pages

- ASM Specialty Handbook Carbon and Alloy Steels33% (6)ASM Specialty Handbook Carbon and Alloy Steels2 pages

- Metal Injection Molded (MIM) Materials: Standard Specification ForNo ratings yetMetal Injection Molded (MIM) Materials: Standard Specification For7 pages

- Steel Rivets and Bars For Rivets, Pressure VesselsNo ratings yetSteel Rivets and Bars For Rivets, Pressure Vessels4 pages

- Measuring Flatness Characteristics of Steel Sheet Products: Standard Practice For100% (1)Measuring Flatness Characteristics of Steel Sheet Products: Standard Practice For9 pages

- John Deere Standard: Approved For Supplier DistributionNo ratings yetJohn Deere Standard: Approved For Supplier Distribution48 pages

- Steel Castings, Welding, Qualifications of Procedures and PersonnelNo ratings yetSteel Castings, Welding, Qualifications of Procedures and Personnel19 pages

- Oxygen-Free Copper in Wrought Forms For Electron Devices100% (1)Oxygen-Free Copper in Wrought Forms For Electron Devices6 pages

- Internship Report: Rayalaseema Thermal Power Project100% (3)Internship Report: Rayalaseema Thermal Power Project34 pages

- STD-INSP-0123 IGC Practice - A - (ASTM G28)No ratings yetSTD-INSP-0123 IGC Practice - A - (ASTM G28)7 pages

- Chemical Analysis of Steel Products: Standard Test Methods, Practices, and Terminology ForNo ratings yetChemical Analysis of Steel Products: Standard Test Methods, Practices, and Terminology For6 pages

- Why Intensity Isn't Dependent On Exposure Time: Lessons in Intensity and Coverage100% (1)Why Intensity Isn't Dependent On Exposure Time: Lessons in Intensity and Coverage1 page

- Asme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure VesselsNo ratings yetAsme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure Vessels3 pages

- Material Specification Metals Gmw4: Impressão Não ControladaNo ratings yetMaterial Specification Metals Gmw4: Impressão Não Controlada17 pages

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForNo ratings yetEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method For13 pages

- Astm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers India100% (1)Astm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers India6 pages

- SAE J827 - OCT2019 High-Carbon Cast-Steel ShotNo ratings yetSAE J827 - OCT2019 High-Carbon Cast-Steel Shot5 pages

- Astm A 623 - 08 Tin Mill Products-General RequirementsNo ratings yetAstm A 623 - 08 Tin Mill Products-General Requirements38 pages

- TM-2011 Rev 08 Steel, Rolled Product - Sheet and StripNo ratings yetTM-2011 Rev 08 Steel, Rolled Product - Sheet and Strip22 pages

- Bharat Heavy Electricals Limited: DEPT.235 - TIRUCHIRAPALLI - 620 014 Non-Destructive Testing100% (1)Bharat Heavy Electricals Limited: DEPT.235 - TIRUCHIRAPALLI - 620 014 Non-Destructive Testing13 pages

- Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and StripNo ratings yetPrecipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip6 pages

- Steel, Stainless Steel, Alloys, and Ferroalloysl: To RelatedNo ratings yetSteel, Stainless Steel, Alloys, and Ferroalloysl: To Related8 pages

- General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripNo ratings yetGeneral Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip26 pages

- Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing For General ServiceNo ratings yetSeamless and Welded Ferritic and Martensitic Stainless Steel Tubing For General Service7 pages

- Aluminum and Aluminum-Alloy Sheet and Plate (Metric) : Standard Specification ForNo ratings yetAluminum and Aluminum-Alloy Sheet and Plate (Metric) : Standard Specification For26 pages

- General Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel TubesNo ratings yetGeneral Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes12 pages

- Steel, Stainless Steel, Related Alloys, and Ferroalloys: Standard Terminology Relating ToNo ratings yetSteel, Stainless Steel, Related Alloys, and Ferroalloys: Standard Terminology Relating To9 pages

- Wear: Materials, Mechanisms and PracticeFrom EverandWear: Materials, Mechanisms and PracticeGwidon W. StachowiakNo ratings yet

- Ductile Iron Casting Specfications and Details All Standards PDFNo ratings yetDuctile Iron Casting Specfications and Details All Standards PDF15 pages

- Fabory - Fasteners - Technical Information100% (1)Fabory - Fasteners - Technical Information77 pages

- Bank of Chettinad in Ceylon in 1929 Nagarathar PerumaiNo ratings yetBank of Chettinad in Ceylon in 1929 Nagarathar Perumai2 pages

- Select The Country Select The Corresponding Country, You Desire To Watch The TimeNo ratings yetSelect The Country Select The Corresponding Country, You Desire To Watch The Time2 pages

- What Is A PPAP?: Frequently Asked Questions RegardingNo ratings yetWhat Is A PPAP?: Frequently Asked Questions Regarding4 pages

- The Current State of Worldwide Standards of Ductile IronNo ratings yetThe Current State of Worldwide Standards of Ductile Iron8 pages

- Mechanics of Composite Materials and Laminated100% (1)Mechanics of Composite Materials and Laminated139 pages

- Steelstrong: Always Strong in Valve WorldNo ratings yetSteelstrong: Always Strong in Valve World32 pages

- A1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryNo ratings yetA1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld Summary1 page

- Efficiency of Fabric Dust Filter (Bag Filter) in Reducing Suspended Particulate Matter LevelNo ratings yetEfficiency of Fabric Dust Filter (Bag Filter) in Reducing Suspended Particulate Matter Level22 pages

- Unit 5 - Overcoming Supply Chain ChallengesNo ratings yetUnit 5 - Overcoming Supply Chain Challenges20 pages

- CREMER CARE Soap - Noodles - Cremer - Care PDFNo ratings yetCREMER CARE Soap - Noodles - Cremer - Care PDF9 pages

- DIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsNo ratings yetDIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic Molds4 pages

- Legend: Cbsc8 Earth Pit: Pig Signaller PTNo ratings yetLegend: Cbsc8 Earth Pit: Pig Signaller PT1 page

- Manufacturing & Marketing Process of Cane Based Products in SylhetNo ratings yetManufacturing & Marketing Process of Cane Based Products in Sylhet43 pages

- Calculation Methodologies For One Dimensional Process Piping Systems100% (1)Calculation Methodologies For One Dimensional Process Piping Systems4 pages

- Technologies For Direct Production of Flexible H2 - CO PDFNo ratings yetTechnologies For Direct Production of Flexible H2 - CO PDF10 pages

- ASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1ASTM B883Standard Specification For Metal Injection Molding (MIM) Ferrous Materials1

- Metal Injection Molded (MIM) Materials: Standard Specification ForMetal Injection Molded (MIM) Materials: Standard Specification For

- Steel Rivets and Bars For Rivets, Pressure VesselsSteel Rivets and Bars For Rivets, Pressure Vessels

- Measuring Flatness Characteristics of Steel Sheet Products: Standard Practice ForMeasuring Flatness Characteristics of Steel Sheet Products: Standard Practice For

- John Deere Standard: Approved For Supplier DistributionJohn Deere Standard: Approved For Supplier Distribution

- Steel Castings, Welding, Qualifications of Procedures and PersonnelSteel Castings, Welding, Qualifications of Procedures and Personnel

- Oxygen-Free Copper in Wrought Forms For Electron DevicesOxygen-Free Copper in Wrought Forms For Electron Devices

- Internship Report: Rayalaseema Thermal Power ProjectInternship Report: Rayalaseema Thermal Power Project

- Chemical Analysis of Steel Products: Standard Test Methods, Practices, and Terminology ForChemical Analysis of Steel Products: Standard Test Methods, Practices, and Terminology For

- Why Intensity Isn't Dependent On Exposure Time: Lessons in Intensity and CoverageWhy Intensity Isn't Dependent On Exposure Time: Lessons in Intensity and Coverage

- Asme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure VesselsAsme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure Vessels

- Material Specification Metals Gmw4: Impressão Não ControladaMaterial Specification Metals Gmw4: Impressão Não Controlada

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method For

- Astm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers IndiaAstm A582 Round Bar, Flat Bar & Astm A582 Material Suppliers India

- Astm A 623 - 08 Tin Mill Products-General RequirementsAstm A 623 - 08 Tin Mill Products-General Requirements

- TM-2011 Rev 08 Steel, Rolled Product - Sheet and StripTM-2011 Rev 08 Steel, Rolled Product - Sheet and Strip

- Bharat Heavy Electricals Limited: DEPT.235 - TIRUCHIRAPALLI - 620 014 Non-Destructive TestingBharat Heavy Electricals Limited: DEPT.235 - TIRUCHIRAPALLI - 620 014 Non-Destructive Testing

- Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and StripPrecipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and Strip

- Steel, Stainless Steel, Alloys, and Ferroalloysl: To RelatedSteel, Stainless Steel, Alloys, and Ferroalloysl: To Related

- General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripGeneral Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip

- Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing For General ServiceSeamless and Welded Ferritic and Martensitic Stainless Steel Tubing For General Service

- Aluminum and Aluminum-Alloy Sheet and Plate (Metric) : Standard Specification ForAluminum and Aluminum-Alloy Sheet and Plate (Metric) : Standard Specification For

- General Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel TubesGeneral Requirements For Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

- Steel, Stainless Steel, Related Alloys, and Ferroalloys: Standard Terminology Relating ToSteel, Stainless Steel, Related Alloys, and Ferroalloys: Standard Terminology Relating To

- Ductile Iron Casting Specfications and Details All Standards PDFDuctile Iron Casting Specfications and Details All Standards PDF

- Bank of Chettinad in Ceylon in 1929 Nagarathar PerumaiBank of Chettinad in Ceylon in 1929 Nagarathar Perumai

- Select The Country Select The Corresponding Country, You Desire To Watch The TimeSelect The Country Select The Corresponding Country, You Desire To Watch The Time

- What Is A PPAP?: Frequently Asked Questions RegardingWhat Is A PPAP?: Frequently Asked Questions Regarding

- The Current State of Worldwide Standards of Ductile IronThe Current State of Worldwide Standards of Ductile Iron

- A1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryA1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld Summary

- Efficiency of Fabric Dust Filter (Bag Filter) in Reducing Suspended Particulate Matter LevelEfficiency of Fabric Dust Filter (Bag Filter) in Reducing Suspended Particulate Matter Level

- DIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic Molds

- Manufacturing & Marketing Process of Cane Based Products in SylhetManufacturing & Marketing Process of Cane Based Products in Sylhet

- Calculation Methodologies For One Dimensional Process Piping SystemsCalculation Methodologies For One Dimensional Process Piping Systems

- Technologies For Direct Production of Flexible H2 - CO PDFTechnologies For Direct Production of Flexible H2 - CO PDF