ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and Vents

ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and Vents

Uploaded by

uddinnadeemCopyright:

Available Formats

ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and Vents

ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and Vents

Uploaded by

uddinnadeemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and Vents

ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and Vents

Uploaded by

uddinnadeemCopyright:

Available Formats

SECTION 10200 LOUVERS AND VENTS PART 1 - GENERAL 1.1 SECTION INCLUDES A. 1.

2 Extruded aluminum louvers, louver screens and vents as shown on Drawings.

REFERENCES The publications listed below form a part of this specification to the extent referenced. The publications are referred to in the text by basic designation only. A. SAUDI ARABIAN STANDARDS ORGANIZATION (SASO) SASO 79 Aluminum and aluminum alloys products for architectural application Part 1: Sheets, strips, bars and structural Sections. Testing methods for aluminum and aluminum alloys products for building purposes Part 1: Sheets, strips, bars and structural Sections.

SASO 80

B.

AIR MOVEMENT AND CONTROL ASSOCIATION INTERNATIONAL, INC. (AMCA) AMCA 500-89 AMCA 501-93: (Revised 1994): Test Methods for Louvers, Dampers Application Manual for Air Louvers

C.

AMERICAN ARCHITECTURAL MANUFACTURERS ASSOCIATION (AAMA) AAMA 603.8-92 (Revised to Include 9/14/83 Addendum): Voluntary Performance Requirements and Test Procedures for Pigmented Organic Coatings on Extruded Aluminum

D.

AMERICAN STANDARD FOR TESTING AND MATERIALS (ASTM) ASTM B 209-95 ASTM B 209M-95 ASTM B 221-95a ASTM B 221M-95a Specification for Aluminum and Aluminum-Alloy Sheet and Plate Specification for Aluminum and Aluminum-Alloy Sheet and Plate [Metric] Specification for Aluminum-Alloy Extruded Bars, Rods, Wire, Shapes and Tubes Specification for Aluminum-Alloy Extruded Bars, Rods, Wire, Shapes and Tubes [Metric]

E.

AMERICAN WELDING SOCIETY (AWS)

10200-1 Louvers and Vents

ITCC in Riyadh Residential Complex J10-13300

AWS D1.2-90 F.

Structural Welding CodeAluminum

NATIONAL ASSOCIATION OF ARCHITECTURAL METAL MANUFACTURERS (NAAAMM) Metal Finishes Manual for Architectural and Metal Products, 1988

1.3

DEFINITIONS A. Louver Terminology: Definitions of terms for metal louvers contained in AMCA 501 apply to this Section, unless otherwise defined in this Section or in referenced standards. Drainable-Blade Louver: Louver designed to collect and drain water to exterior at sill by means of gutters in front edges of blades and channels in jambs and mullions.

B.

1.4

PERFORMANCE REQUIREMENTS A. Structural Performance: Provide exterior metal louvers capable of withstanding the effects of loads and stresses from wind and normal thermal movement without evidencing permanent deformation of louver components including blades, frames, and supports; noise or metal fatigue caused by louver blade rattle or flutter; or permanent damage to fasteners and anchors. 1. 2. Wind Load: Uniform pressure of 25 lbf/sq. ft. (1200 Pa), acting inward or outward Thermal Movements: Provide louvers that allow for thermal movements resulting from the following maximum change (range) in ambient and surface temperatures by preventing buckling, opening of joints, overstressing of components, and other detrimental effects: a. Temperature Change (Range): 120 deg F (67 deg C), ambient; 180 deg F (100 deg C), material surfaces.

1.5

SUBMITTALS A. B. Product Data: For each type of product specified. Shop Drawings: For louver units and accessories. Include plans; elevations; sections; and details showing profiles, angles, and spacing of louver blades. Show unit dimensions related to wall openings and construction; free area for each size indicated; profiles of frames at jambs, heads, and sills; and anchorage details and locations. Samples for Initial Selection: Manufacturer's color charts showing the full range of colors available for units with factory-applied color finishes.

C.

D.

Samples for Verification: Of each type of metal finish required, prepared on Samples of same thickness and material indicated for final Work. Where

ITCC in Riyadh Residential Complex J10-13300

10200-2

Louvers and Vents

finishes involve normal color and texture variations, include Sample sets showing the full range of variations expected. E. Product Certificates: Signed by manufacturers of louvers certifying that the products furnished comply with requirements and are licensed to bear the AMCA seal based on tests made according to AMCA 500 and complying with AMCA's Certified Ratings Program.

1.6

QUALITY ASSURANCE A. Source Limitations: Obtain louvers and vents through one source from a single manufacturer where alike in one or more respects regarding type, design, or factory-applied color finish. Welding Standards: As follows: 1. 2. Comply with AWS D1.2, "Structural Welding Code--Aluminum." Certify that each welder has satisfactorily passed AWS qualification tests for welding processes involved and, if pertinent, has undergone recertification.

B.

C.

SMACNA Standard: Comply with SMACNA's "Architectural Sheet Metal Manual" recommendations for fabrication, construction details, and installation procedures.

1.7

PROJECT CONDITIONS A. Field Measurements: Verify louver openings by field measurements before fabrication and indicate measurements on Shop Drawings. Coordinate fabrication schedule with construction progress to avoid delaying the Work.

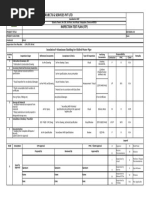

PART 2 - PRODUCTS 2.1 MATERIALS A. B. C. Aluminum Extrusions: ASTM B 221M, alloy 6063-T5 or T-52. Aluminum Sheet: ASTM B 209M, alloy 3003 or 5005 with temper as required for forming, or as otherwise recommended by metal producer for required finish. Fasteners: Of same basic metal and alloy as fastened metal or 300 series stainless steel, unless otherwise indicated. Do not use metals that are incompatible with joined materials. 1. 2. D. Use types and sizes to suit unit installation conditions. Use Phillips flat-head screws for exposed fasteners, unless otherwise indicated.

Anchors and Inserts: Of type, size, and material required for loading and installation indicated. Use nonferrous metal or hot-dip galvanized anchors and inserts for exterior installations and elsewhere as needed for corrosion

ITCC in Riyadh Residential Complex J10-13300

10200-3

Louvers and Vents

resistance. anchors. E.

Use toothed steel or expansion bolt devices for drilled-in-place

Bituminous Paint: Cold-applied asphalt mastic complying with SSPC-Paint 12 but containing no asbestos fibers, or cold-applied asphalt emulsion complying with ASTM D 1187.

2.2

FABRICATION, GENERAL A. Assemble louvers in factory to minimize field splicing and assembly. Disassemble units as necessary for shipping and handling limitations. Clearly mark units for reassembly and coordinated installation. Maintain equal louver blade spacing to produce uniform appearance. Fabricate frames, including integral sills, to fit in openings of sizes indicated, with allowances made for fabrication and installation tolerances, adjoining materials' tolerances, and perimeter sealant joints. Include supports, anchorages, and accessories required for complete assembly. Provide vertical mullions of type and at spacing indicated, but not more than recommended by manufacturer, or 1830 mm o.c., whichever is less. At horizontal joints between louver units, provide horizontal mullions, unless continuous vertical assemblies are indicated. Provide sill extensions and loose sills made of same material as louvers where indicated or required for drainage to exterior and to prevent water penetrating to interior. Join frame members to one another and to fixed louver blades with fillet welds, threaded fasteners, or both, as standard with louver manufacturer, concealed from view; unless otherwise indicated or size of louver assembly makes bolted connections between frame members necessary.

B. C.

D. E.

F.

G.

2.3

FIXED, EXTRUDED-ALUMINUM LOUVERS A. B. Louver Construction: Provide fixed-blade louvers with extruded-aluminum frames and blades. Horizontal Louvers: Either drainable- or non-drainable-blade type complying with the following: 1. 2. 3. 4. Louver Depth: Frame Thickness: Blade Thickness: Performance Requirements: 150 mm, unless otherwise indicated. 2.06 mm. 2.06 mm As indicated on shop drawings.

2.4

LOUVER SCREENS A. B. General: Provide louvers with screens at locations indicated. General: Provide each exterior louver with louver screens complying with the following requirements:

ITCC in Riyadh Residential Complex J10-13300

10200-4

Louvers and Vents

1. 2. C. D.

Screen Location for Fixed Louvers: Interior face. Screening Type: Bird screening, unless otherwise indicated.

Secure screens to louver frames with stainless-steel machine screws, spaced a maximum of 150 mm from each corner and at 300 mm o.c. Louver Screen Frames: Fabricate screen frames with mitered corners to louver sizes indicated and to comply with the following requirements: 1. Metal: Same kind and form of metal as indicated for louver to which screens are attached. Reinforce extruded-aluminum screen frames at corners with clips. Finish: Same finish as louver frames to which louver screens are attached. Type: Rewirable frames with a driven spline or insert for securing screen mesh.

2. 3. E.

Louver Screening for Aluminum Louvers: As follows: 1. Bird Screening: Aluminum, 12.7-mm square mesh, 1.6-mm wire.

2.5

FINISHES A. B. C. Comply with NAAMM's "Metal Finishes Manual for Architectural and Metal Products" for recommendations for applying and designating finishes. Finish louvers after assembly. Exposed aluminum surfaces shall have the manufacturer's standard powder-coated finish, 60 - 80 micron thick unless otherwise indicated on Drawings. 1. Color and Gloss: As selected by Engineer from manufacturer's full range of colors.

2.6

PREPARATION A Coordinate Setting Drawings, diagrams, templates, instructions, and directions for installation of anchorages that are to be embedded in concrete or masonry construction. Coordinate delivery of such items to Project site.

PART 3 - EXECUTION 3.2 INSTALLATION A. B. Locate and place louver units level, plumb, and at indicated alignment with adjacent work. Use concealed anchorages where possible. Provide brass or lead washers fitted to screws where required to protect metal surfaces and to make a weathertight connection.

ITCC in Riyadh Residential Complex J10-13300

10200-5

Louvers and Vents

C. D. E.

Form closely fitted joints with exposed connections accurately located and secured. Provide perimeter reveals and openings of uniform width for sealants and joint fillers, as indicated. Repair finishes damaged by cutting, welding, soldering, and grinding. Restore finishes so no evidence remains of corrective work. Return items that cannot be refinished in the field to the factory, make required alterations, and refinish entire unit or provide new units. Protect galvanized and nonferrous-metal surfaces from corrosion or galvanic action by applying a heavy coating of bituminous paint on surfaces that will be in contact with concrete, masonry, or dissimilar metals. Install concealed gaskets, flashings, joint fillers, and insulation, as louver installation progresses, where weathertight louver joints are required. Comply with Division 7 Section "Joint Sealants" for sealants applied during louver installation.

F.

G.

3.3

ADJUSTING, CLEANING, AND PROTECTING A. B. Test operation of adjustable louvers and adjust as needed to produce fully functioning units that comply with requirements. Periodically clean exposed surfaces of louvers and vents that are not protected by temporary covering to remove fingerprints and soil during construction period. Do not let soil accumulate until final cleaning. Before final inspection, clean exposed surfaces with water and a mild soap or detergent not harmful to finishes. Thoroughly rinse surfaces and dry. Protect louvers and vents from damage during construction. Use temporary protective coverings where needed and approved by louver manufacturer. Remove protective covering at the time of Substantial Completion. Restore louvers and vents damaged during installation and construction so no evidence remains of corrective work. If results of restoration are unsuccessful, as determined by the Engineer, remove damaged units and replace with new units. 1. Clean and touch up minor abrasions in finishes with air-dried coating that matches color and gloss of, and is compatible with, factory-applied finish coating. END OF SECTION

C. D.

E.

ITCC in Riyadh Residential Complex J10-13300

10200-6

Louvers and Vents

You might also like

- Introduction To Materials Science For Engineers 8th Edition Shackelford Solutions Manual DownloadDocument14 pagesIntroduction To Materials Science For Engineers 8th Edition Shackelford Solutions Manual DownloadTresa Hogan100% (22)

- Structural Beam Design GuideDocument16 pagesStructural Beam Design GuideEric PoissonNo ratings yet

- Louvers CSI SpecificationDocument6 pagesLouvers CSI SpecificationRowdyRaheelNo ratings yet

- Steel Joists - MST PDFDocument7 pagesSteel Joists - MST PDFwafikmh4No ratings yet

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Generator MaintenanceDocument24 pagesGenerator MaintenancePablo Gaspar D'Agostini Amengual100% (11)

- High Risk Construction Work Safe Work Method Statement (SWMS) TemplateDocument2 pagesHigh Risk Construction Work Safe Work Method Statement (SWMS) Templatekittu2207No ratings yet

- V6JN5 3part CsiDocument3 pagesV6JN5 3part CsiWahyu Candra WardanaNo ratings yet

- Section 077100 - Roof SpecialtiesDocument6 pagesSection 077100 - Roof SpecialtiesWENDING HUNo ratings yet

- 053100 Steel DeckingDocument8 pages053100 Steel DeckingSteve LezamaNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 08120-1 Aluminum Doors and FramesDocument6 pagesITCC in Riyadh Residential Complex J10-13300 08120-1 Aluminum Doors and FramesuddinnadeemNo ratings yet

- Steel Joist FramingDocument5 pagesSteel Joist FramingSteve LezamaNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 05120-1 Structural SteelDocument6 pagesITCC in Riyadh Residential Complex J10-13300 05120-1 Structural SteeluddinnadeemNo ratings yet

- Division 5Document15 pagesDivision 5hari banggaNo ratings yet

- 08 63 00 PDFDocument11 pages08 63 00 PDFAnonymous hk1fhAkwyNo ratings yet

- COLD-FORMED METAL FRAMING Rev.1Document7 pagesCOLD-FORMED METAL FRAMING Rev.1mohdNo ratings yet

- GratingsDocument3 pagesGratingssaurabhsubhuNo ratings yet

- King Abdullah Bin Abdulaziz Project Mataf Extension - DesignDocument14 pagesKing Abdullah Bin Abdulaziz Project Mataf Extension - DesignshoebNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 08470-1 Revolving DoorsDocument16 pagesITCC in Riyadh Residential Complex J10-13300 08470-1 Revolving DoorsuddinnadeemNo ratings yet

- Structural Steel Spec. and ConstructionDocument12 pagesStructural Steel Spec. and ConstructionAshwani DograNo ratings yet

- Metal Doors and Frames - MSTDocument14 pagesMetal Doors and Frames - MSTwafikmh4No ratings yet

- 054000 Cold Formed Metal FramingDocument8 pages054000 Cold Formed Metal FramingSteve LezamaNo ratings yet

- Standing Seam Metal Roof Panels Fabral Stand N Seam 2Document9 pagesStanding Seam Metal Roof Panels Fabral Stand N Seam 2TomNo ratings yet

- CompositeJoistStandardSpecifications PDFDocument8 pagesCompositeJoistStandardSpecifications PDFcorrokokoNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 11490-1 Athletic EquipmentDocument5 pagesITCC in Riyadh Residential Complex J10-13300 11490-1 Athletic EquipmentuddinnadeemNo ratings yet

- Stationary Metal Wall LouversDocument3 pagesStationary Metal Wall Louversjack.simpson.changNo ratings yet

- Guide Specification - SDP 200: GeneralDocument10 pagesGuide Specification - SDP 200: GeneralhbookNo ratings yet

- 089000 Louvers and ventsDocument7 pages089000 Louvers and ventsSteve LezamaNo ratings yet

- Section 10200 Louvers and VentsDocument3 pagesSection 10200 Louvers and VentsMØhãmmed ØwięsNo ratings yet

- Section 02820 Ornamental Metal Fences and GatesDocument14 pagesSection 02820 Ornamental Metal Fences and GatesMØhãmmed ØwięsNo ratings yet

- SECTION 08 90 00 Louvers and VentsDocument10 pagesSECTION 08 90 00 Louvers and VentsJuanPaoloYbañezNo ratings yet

- Steel Floor Deck Guide SpecificationsDocument5 pagesSteel Floor Deck Guide SpecificationsRafaArdiSyahrezaNo ratings yet

- Structural Steel FramingDocument5 pagesStructural Steel FramingSteve LezamaNo ratings yet

- SECTION 05 12 00 Structural Steel FramingDocument6 pagesSECTION 05 12 00 Structural Steel FramingmiteshsuneriyaNo ratings yet

- Section 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesDocument23 pagesSection 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesMohammed HarrisNo ratings yet

- Handrail & PlatformDocument58 pagesHandrail & Platformvhung TranNo ratings yet

- Spec. Structural SteelDocument6 pagesSpec. Structural Steeldharwin apNo ratings yet

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocument3 pagesEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiNo ratings yet

- HVAC Ducts and CasingsDocument10 pagesHVAC Ducts and CasingsmanikantanNo ratings yet

- Specification of ColdFormedTrusses 2-13-2023Document6 pagesSpecification of ColdFormedTrusses 2-13-2023perfectdesigns642No ratings yet

- 05 41 00 Structural Metal Stud FramingDocument10 pages05 41 00 Structural Metal Stud Framingjcunha4740No ratings yet

- 05210-1 TCC in Riyadh Residential Complex J10-13300 Steel JoistsDocument7 pages05210-1 TCC in Riyadh Residential Complex J10-13300 Steel JoistsuddinnadeemNo ratings yet

- 31 63 29 Drilled Concrete PiersDocument13 pages31 63 29 Drilled Concrete PierssbunNo ratings yet

- Guide Specifications For NUTRUSS Cold-Formed Steel FramingDocument6 pagesGuide Specifications For NUTRUSS Cold-Formed Steel FramingKeysha ApriliaNo ratings yet

- Section - 05 50 00 Metal FabricationsDocument9 pagesSection - 05 50 00 Metal FabricationsEliseo LagmanNo ratings yet

- SECTION 05 21 00 Steel Joist FramingDocument5 pagesSECTION 05 21 00 Steel Joist FramingJuanPaoloYbañezNo ratings yet

- Angle Frame Bleachers: 3 Part SpecificationsDocument4 pagesAngle Frame Bleachers: 3 Part SpecificationsAnn BonifacioNo ratings yet

- FL - Ta1056Document7 pagesFL - Ta1056ery achjariNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09250-1 Gypsum BoardDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09250-1 Gypsum BoarduddinnadeemNo ratings yet

- SharonStairsSpecs PDFDocument7 pagesSharonStairsSpecs PDFJohn TreffNo ratings yet

- SECTION 05 36 00 Composite Metal DeckingDocument9 pagesSECTION 05 36 00 Composite Metal DeckingJuanPaoloYbañezNo ratings yet

- 09 22 16.13mbaDocument11 pages09 22 16.13mbaHanamanthNo ratings yet

- Section051200 StructuralsteelDocument5 pagesSection051200 StructuralsteelZeljko VasicNo ratings yet

- Duct Accessories - RevDocument5 pagesDuct Accessories - RevLuis Gabriel BautistaNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 12485-1 Foot GrillesDocument2 pagesITCC in Riyadh Residential Complex J10-13300 12485-1 Foot GrillesuddinnadeemNo ratings yet

- 09 22 16ssbDocument7 pages09 22 16ssbHanamanthNo ratings yet

- ACS Specs GFRC1Document10 pagesACS Specs GFRC1Chrill DsilvaNo ratings yet

- Metal StairsDocument5 pagesMetal Stairsshivayogi asundiNo ratings yet

- SECTION 05 50 00 Metal Fabrications Spec Writer NoteDocument35 pagesSECTION 05 50 00 Metal Fabrications Spec Writer NoteJuanPaoloYbañezNo ratings yet

- 03 49 00 Glass Fiber Reinforced Concrete PanelsDocument15 pages03 49 00 Glass Fiber Reinforced Concrete PanelsSourav BasakNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Electrical Engineer CV (M Bilal M)Document4 pagesElectrical Engineer CV (M Bilal M)uddinnadeemNo ratings yet

- Panel Board ShortCircuit RatingsDocument2 pagesPanel Board ShortCircuit RatingsuddinnadeemNo ratings yet

- Panel Board ShortCircuit RatingsDocument2 pagesPanel Board ShortCircuit RatingsuddinnadeemNo ratings yet

- XXXXXX: Voltage Drop& Cable Sizing CalculationsDocument5 pagesXXXXXX: Voltage Drop& Cable Sizing CalculationsPradeesh Vijayan (v.prathi)No ratings yet

- Green Grounding ManualDocument23 pagesGreen Grounding Manualuddinnadeem100% (1)

- SECTION 01300 Submittals 1.01 General: Vocational Training CenterDocument11 pagesSECTION 01300 Submittals 1.01 General: Vocational Training CenterulyjohnignacioNo ratings yet

- 15400Document27 pages15400uddinnadeemNo ratings yet

- Where Indicated Supply and Apply On Concrete Screed A Multi Component Hard Wearing, Smooth, Matt or Satin Finish Polyurethane Based Flooring System at A Thickness of 2.5 MM UtilisingDocument1 pageWhere Indicated Supply and Apply On Concrete Screed A Multi Component Hard Wearing, Smooth, Matt or Satin Finish Polyurethane Based Flooring System at A Thickness of 2.5 MM UtilisinguddinnadeemNo ratings yet

- Submittal ReviewDocument22 pagesSubmittal ReviewuddinnadeemNo ratings yet

- 16716-Voice & Data SystemDocument13 pages16716-Voice & Data SystemuddinnadeemNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 pagesITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemNo ratings yet

- Nicet AlarmsDocument23 pagesNicet AlarmsWERMERMNo ratings yet

- 16453-Grounding & Bonding Telecommunication SystemDocument6 pages16453-Grounding & Bonding Telecommunication SystemuddinnadeemNo ratings yet

- 16715-Voice & Data CablingDocument16 pages16715-Voice & Data Cablinguddinnadeem100% (1)

- 16721-Fa SystemDocument17 pages16721-Fa SystemuddinnadeemNo ratings yet

- 16342-Metal Clad MV SWGRDocument14 pages16342-Metal Clad MV SWGRuddinnadeemNo ratings yet

- Lightning ProtectionDocument3 pagesLightning ProtectionuddinnadeemNo ratings yet

- 16504-Home Automation SystemDocument23 pages16504-Home Automation SystemuddinnadeemNo ratings yet

- 16410-Swiches & CBDocument15 pages16410-Swiches & CBuddinnadeemNo ratings yet

- LightingDocument13 pagesLightinguddinnadeemNo ratings yet

- GroundingDocument6 pagesGroundinguddinnadeemNo ratings yet

- 16461-Dry Type TransformerDocument8 pages16461-Dry Type TransformeruddinnadeemNo ratings yet

- Panel BoardDocument7 pagesPanel BoarduddinnadeemNo ratings yet

- Package SubstationDocument9 pagesPackage SubstationuddinnadeemNo ratings yet

- BuswayDocument5 pagesBuswayuddinnadeemNo ratings yet

- GeneratorDocument19 pagesGeneratoruddinnadeemNo ratings yet

- Innowell Engineering International PVT LTD.: Knowledge Transfer SessionDocument7 pagesInnowell Engineering International PVT LTD.: Knowledge Transfer SessionNiranjan MechNo ratings yet

- Katup (Valve)Document41 pagesKatup (Valve)Raka BarcelonistaNo ratings yet

- ACPML-101-HAR-RPT-008006 Spec Fire Fighting SystemDocument14 pagesACPML-101-HAR-RPT-008006 Spec Fire Fighting SystemoaklamNo ratings yet

- 2-Storey Residence 14th St. Sto. NiñoDocument4 pages2-Storey Residence 14th St. Sto. NiñoIsmael De Leon100% (1)

- John Ray D. Cuevas ACTIVITY 12/3/18 CE42-B06 1. What Is The Purpose of Estimating?Document12 pagesJohn Ray D. Cuevas ACTIVITY 12/3/18 CE42-B06 1. What Is The Purpose of Estimating?John Ray CuevasNo ratings yet

- Effect of Angle Ply Orientation On Tensile Properties of Bi Directional Woven Fabric Glass Epoxy Composite LaminateDocument7 pagesEffect of Angle Ply Orientation On Tensile Properties of Bi Directional Woven Fabric Glass Epoxy Composite LaminatePavan KishoreNo ratings yet

- D900 Drip Line: Maximize Your FarmDocument4 pagesD900 Drip Line: Maximize Your FarmJose Gabriel PintoNo ratings yet

- Q&A - CementDocument10 pagesQ&A - CementAnonymous cQ13WWeNo ratings yet

- Municipality/City Disposal Facility DF Location DF Status DF RehabilitationDocument5 pagesMunicipality/City Disposal Facility DF Location DF Status DF RehabilitationsorbisorbiNo ratings yet

- 6.trans - Presentation 500kV Shibo 3Document9 pages6.trans - Presentation 500kV Shibo 3Pavan KumarNo ratings yet

- PressureDocument5 pagesPressureSMBEAUTYNo ratings yet

- Catalogo Afa Cummins Qsk19 SeriesDocument81 pagesCatalogo Afa Cummins Qsk19 SeriesAlexis Sanchez100% (2)

- Manuals Series HSJ Safety Valves Crosby en en 5193124Document12 pagesManuals Series HSJ Safety Valves Crosby en en 5193124Ravi pathakNo ratings yet

- ITP Installation & Insulation & Cladding of Chilled Water Pipe SystemDocument1 pageITP Installation & Insulation & Cladding of Chilled Water Pipe SystemDineshNo ratings yet

- Installation of AHUDocument4 pagesInstallation of AHUamg007No ratings yet

- Introduction on Pomi AssignmentDocument4 pagesIntroduction on Pomi AssignmentPraveen PraakruthikNo ratings yet

- Labor Laws On Safety and Health - 39 PagesDocument39 pagesLabor Laws On Safety and Health - 39 PagesWilliamNo ratings yet

- Peran TCW ENGDocument2 pagesPeran TCW ENGbassem kooliNo ratings yet

- Eurocode 3 PDFDocument2 pagesEurocode 3 PDFKing50% (2)

- Construction Technology PDFDocument4 pagesConstruction Technology PDFkrunal suthar100% (1)

- ASTM International - BOS Volume 08.02 - 2017 ContentsDocument6 pagesASTM International - BOS Volume 08.02 - 2017 Contentspedro serranoNo ratings yet

- Daniel Tian Li: Drag / Collector Force Diagram GeneratorDocument1 pageDaniel Tian Li: Drag / Collector Force Diagram GeneratorMarianne Aravilla Dela CruzNo ratings yet

- PX45 SeriesDocument2 pagesPX45 SeriesrohandiNo ratings yet

- Superstructure of Ships-Module4Document9 pagesSuperstructure of Ships-Module4Pramod Kumar MallyaNo ratings yet

- Gursum Ipc 05 FinalDocument64 pagesGursum Ipc 05 FinalGurraacha AbbayyaaNo ratings yet

- PT-104 Pumping Trap Installation and MaintenanceDocument12 pagesPT-104 Pumping Trap Installation and MaintenancevkumaranNo ratings yet

- Smavit Shower TrayDocument12 pagesSmavit Shower TrayDani DaniNo ratings yet