02-Kobetsu Kaizen

02-Kobetsu Kaizen

Uploaded by

Suresh BabuCopyright:

Available Formats

02-Kobetsu Kaizen

02-Kobetsu Kaizen

Uploaded by

Suresh BabuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

02-Kobetsu Kaizen

02-Kobetsu Kaizen

Uploaded by

Suresh BabuCopyright:

Available Formats

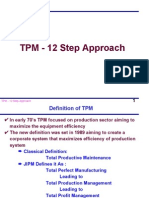

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Kobetsu Kaizen

or

Focussed Improvements

PILLAR

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Losses and why they occur

Loss is defined as wastage of material, money, time and

energy. Some of the reasons for the wastage can be

summarized as below:

Whenever an operation exceeds its standard timings

Whenever an operation is intercepted

Whenever a non -value adding operation is performed

Whenever a machine is idle when it should have given the

rated output

When a machine and or man do not give the rated out put.

Consuming additional time, money, energy than the

specified norms etc.

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KAIZEN

Kaizen Levels

Restoration

Betterment

Kaizen

Revolution

Renovation

Kaizen = Fill difference between present status and goal

- Aim at good condition in the past.

-Aim at achieving what the equipment

and the operation must be in the future.

Renovating Kaizen

Future Level

Difference

Present Level

Restorative

Difference

Past Level

Present Level

First, bring to a condition of the past,

another line or another company

Copying is also technology

Develop new ideas by changing conception

Importance is to train people who can maintain

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Kobetsu Kaizen Pillar

Target: 16 Major losses

1. Seven major losses that impede overall equipment

efficiency

2. Losses that impede equipment loading time

3. Five Major losses that impede workers efficiency

4. Three major losses that impede efficient use of

production subsidiary resources

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Definition of 16 Major losses 7.1 1-4

Losses due to defects & reworking

Failure losses

Losses due to failures. Types of failures include sporadic

function-stopping failures, and function-reduction failures in

which the function of the equipment drops below normal levels.

1

Setup and

adjustment losses

Stoppage losses that accompany setup changeovers

2

Cutting blade

change losses

Stoppage losses caused by changing the cutting blade due to

breakage, or caused by changing the cutting blade when the

service life of the grinding stone, cutter or bite has been

reached.

3

Start-up losses

When starting production, the losses that arise until equipment

start-up, running-in and production processing conditions

stabilize.

4

Minor stoppage

and idling losses

Losses that occur when the equipment temporarily stops or idles

due to sensor actuation or jamming of the work. The equipment

will operate normally through simple measures (removal of the

work and resetting).

5

Seven major losses that impede overall equipment efficiency

A

Speed losses

Losses due to actual operating speed falling below the designed

speed of the equipment.

6

Defect & rework loss 7

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Definition of 16 Major losses (Contd) 7.1 1-4

Losses that impede equipment loading time

B

Shutdown (SD)

losses

Losses that arise from planned equipment stoppages at the

production planning level in order to perform periodic inspection

and statutory inspection

8

Management

losses

Waiting losses that are caused by management, such as waiting

for materials, waiting for a dolly, waiting for tools, waiting for

instructions, waiting for repair of breakdowns, etc.

9

Motion losses

Mar-hour losses arising from differences in skills involved in

setup and adjustment work, cutting blade change work, etc.

10

Five Major losses that impede workers efficiency C

Line organization

losses

Idle time losses when waiting for multiple processes or multiple

platforms.

11

Distribution

losses

Distribution man-hour losses due to transport of materials,

products (processed products) and dollies.

12

Measurement and

adjustment losses

Work losses from frequent measurement and adjustment in

order to prevent the occurrence and outflow of quality defects.

13

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Definition of 16 Major losses (Contd) 7.1 1-4

Three major losses that impede efficient use of production

subsidiary resources

D

Energy losses

Losses due to ineffective utilization of input energy (electric, gas,

fuel oil, etc) in processing.

14

Die, jig and tool

losses

Financial losses (expenses incurred in production, regarding,

renitriding, etc.) which occur with production or repairs of dies,

jigs and tolls due to aging beyond services life or breakage.

15

Yield losses

Material losses due to differences in the weight of the input

materials and the weight of the quality products.

16

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

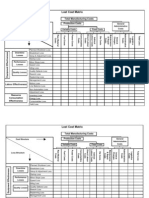

Loss Structure During Production Activities (16 Major Losses)

[Manpower

Efficiency]

[Equipment Efficiency]

5

M

a

j

o

r

L

o

s

s

e

s

P

r

e

v

e

n

t

i

n

g

E

f

f

i

c

i

e

n

c

y

o

f

M

a

n

p

o

w

e

r

Waiting

instruction loss

Waiting material

loss

Equipment

downtime loss

Equipment

performance

loss

Method/procedu

res loss

Skills and

morale loss

Line

organization

loss

Unautomated

system loss

9. Management

loss

12. Logistics loss

13. Measurement and

adjustment loss

Excluding man-

hour (Supported

by other

departments)

Production

Man-hour

loss

Line

organisa

-tion

man-

hour

loss

<Equipment>

Man-hour Elapsed time

<person>

8. Breakdown loss

1. Equipment

failure loss

2. Set-up loss

4. Start - up loss

Other downtime loss

5. Minor stoppage &

idling loss

6. Reduced speed

7. Defects and

rework loss

3. Cutting blade and

jig change loss

Operated man-hour

Duty hour

Loading man-hour Loading time

Net operational

Man-hour

Operating time

Effective

man-hour

Net Operating

time

Valued man-hour

(man-hour for

turnout)

Valued

operating time

Scheduled

downtime

Scheduled

downtime

Downti

me loss

Performa

nce loss

Defects

quality

loss

(Adjustment

of measurement)

Cleaning

checking

Waiting

instruction

Quality

confirmation

Waiting

personnel

distribution

Waiting

materials

Start-up loss

Overload loss

Radiation loss

15. Energy loss

Input energy

Loading time

Effective energy

No. of qualified

products

Weight of

qualified products

<Energy> <Materials>

Start-up loss

Cutting loss

Losses in weight

Losses in excesses

(increased commission)

14. Yield loss

Defects quality loss

[Efficiency of material and energy]

3 Major Losses Preventing Efficiency of Material and Energy.

16. Die and Tool loss

8

M

a

j

o

r

L

o

s

s

e

s

P

r

e

v

e

n

t

i

n

g

E

f

f

i

c

i

e

n

c

y

o

f

e

q

u

i

p

m

e

n

t

10. Operating

motions loss

Defects

in man-

hour

loss

11. Line organisation

loss

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Relationship between Six Major Losses on

Equipment and Overall Equipment Effectiveness

products quality of Rate

Performance

efficiency

Availability

equipment Overall

effectiveness

=

Loading

time

Operating

time

Net

operating

time

D

o

w

n

t

i

m

e

l

o

s

s

e

s

S

p

e

e

d

l

o

s

s

e

s

Valuable

operating

time

D

e

f

e

c

t

l

o

s

s

e

s

C Equipment

Failure

C Set up and

adjustment

CIdling and minor

stoppage

CReduced speed

C Defects in

process

Reduced yield

87% 100

460mins.

60mins. 460mins

ty Availabili

(e.g)

100

e loadingtim

downtime e loadingtim

ty Availabili

=

=

50% 100

400mins

400units x nit 0.5mins./u

e Performanc

efficiency

(e.g)

time Operating

amount processed x time cycle l theoretica

e Performanc

efficiency

= =

= 100

98% 100

units 400

units 8 - units 400

quality of Rate

products

(e.g)

100 100

amount processed

amount defect - amount processed

quality of Rate

products

= =

= =

42.6% 100 0.98 0.50 0.87 (e.g.) =

Equipment Six major losses

Calculation of overall equipment effectiveness

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Plant Total Efficiency = Availability x Performance x Rate of Quality pro ducts

efficiency

Plant Total Efficiency

Calendar hour (A)

Running hour (B)

Operation

hour(C)

L

o

s

s

b

y

s

u

s

p

e

n

s

i

o

n

L

o

s

s

b

y

s

t

o

p

p

a

g

e

Net

Operation

hour (D)

L

o

s

s

b

y

c

a

p

a

c

i

t

y

ty

(

hour

) -

ty =

% 100

(C)

(D)

e Performanc

efficiency

100%

(T/H) production Standard

(T/H) production average Actual

e Performanc

efficiency

=

=

% 100

(D)

(E)

quality of Rate

products

% 100

(T) Production

) ( - (T) Production

quality of Rate

products

=

=

C Planned maintenance

C Production control

C Equipment breakdown

C Process breakdown

C Regular Production

Irregular Production

; Process Deficiency

^ Reprocessing

Valued

operation

hour (E)

L

o

s

s

b

y

d

e

f

i

c

i

e

n

c

y

<Plant> <8 - major losses> <Calculation of the overall plant efficiency>

100%

ur Calenderho

100%

(A)

(C)

Availabili

Calender

Availabili

=

; ^ (T )

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Chronic loss Causes

Cause

Cause

Cause

Cause

Cause

Cause

Cause

Cause

Understanding

the cause

( Single cause) ( Several cause)

(Combination Several cause)

It is difficult to focus on and understand causes

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

BACKGROUND OF CHRONIC LOSSES

Chronic Losses Persistently Exist Data Cannot be gathered Do not know how to do it

Countermeasures cannot be taken

Scale of losses cannot be determined Measurement is not taken

Causes cannot be determined

Only temporary measures are taken

Countermeasures are not taken Did not know chronic losses

Characteristics of chronic

losses are not understood

Chronic losses cannot be reduced or eliminated

Did not know chronic losses occurred

All factors are not analysed

Too much concern with ratio

of influence which primarily

contributes to results

Countermeasures are taken,

but situation does not improve

All factors are

Not identified

Prejudiced by past experience

Lack of organisation-

Developed technology

Do not notice it

Chronic

Losses

Know chronic

Losses have

occurred

Do not know

Chronic losses

are occurring

Countermeasures are taken

Countermeasures cannnot be taken

Countermeasures are not taken

-Do not know what are chronic losses and have not perceived them.

Chronic losses occur mainly in minor stoppages, low speed, rework,

start-up loss, etc.

-Situation does not improve

-No sign of improvement

-Fundamental measures are not taken

Only temporary measures are taken

-Losses are not understood

quantitatively and

Scale of losses is not perceived.

- Occurrence of chronic losses itself is

underestimated

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Cannot be solved even if various actions are

taken. Renovating countermeasures are

needed.

Most cases can be solved on the spot.

Restorative measures will work.

Countermeasure

Causal sequence is not clear and cause

system is compounding. Past experience and

intuition do not work

Causal sequence is relatively monotonous.

Can be guessed by past experience and

intuition in many cases

Cause

Actualize as loss compared between

maximum value and technical level.

Recognized as loss compared with present

level

Actualization

Phenomenon always occurs within a certain

dispersion range.

- Repeated in short cycles

- Phenomenon always occurs with certain

quantitative dispersions

Entirely new phenomenon suddenly occurs.

Phenomenon suddenly occurs after

exceeding a certain dispersion range

Loss Mode

Chronic Loss Sporadic Loss Division

SPORADIC LOSS AND CHRONIC LOSS

JIPM, 1994

Chronic

Losses

Sporadic Losses

Pursuit of Maximum

(Reduction to Zero)

Loss

Rate

Time

Why - Why Analysis PM Analysis

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

CHRONIC LOSS SOLUTION APPROACH

Causes are unknown

Just address the cause

Theoretically trace root of cause

To be solved

Even if not solved, clue to the

solution is found

The approach to eliminate doubtful factors might take time, but it can be said from experience that the

method will be effective

Hypothetical verification method does not take time and is useful, but it does not work well when there are

many factors to be considered and the probability is small.

(1) Analyse the Phenomena

(2) Review the possible factors by Factor

system

(3) Point out all the defect factors

PM Analysis

Troubleshoot the defects

Study what the equipment must be

Think much on the slight defects

Prevent the defects

Restoration

JIPM, 1994

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Heinreich law

1

29

300

Major Defect

Medium Defect

Minor Defect

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

SLIGHT DEFECTS

JIPM, 1994

* Importance of Slight Defects

Major Defects

Major Failure will be caused if not troubleshot

Slight Defects

Further segmenting is difficult. Impacts on results are generally

considered to be slight. Rubbish, stains, play, rust, leaks,

scratches, wear, deformation, etc.

Medium Defects

Defects, minor stoppages and other troubles are caused

Slight Defects grow

Eliminate synergism caused by accumulation of slight defects

Synergism is action multiplied by actions of individual

factors when factors overlap

It is true that some causes work directly or indirectly in all

trouble phenomena. Sometimes, these phenomena cannot

be understood, even if human is gathered.

* Precautions for Identifying Slight Defects

1. Fundamental review starting

with principles and rules

2. Do not adhere to the ratio of

influence contributing to results

1. As a tendency, emphasis is placed on major and

medium defects, and slight defects are left neglected

2. In the initial stage, immediate effects can be obtained

and troubles can be reduced if major and medium defects

are attacked as a priority.

3. In many cases, chronic losses do not decrease.

4. It is no exaggeration to say that chronic losses are due

to negligence of slight defects.

Narrowing down of causes. Find clues to solution.

Law of Heinrich

Even if each factor has only

a very small probability

-Compounding causes

-Multiple causes.

- Compounding causes

For prevention

1. Other factors are included

2. Large impacts are caused if other

factors overlap.

3. Mutual chain reaction with other

factors

1. There are many causes that are

induced even though results are one.

2. Sometimes, results are caused by

compounding factors.

3. Combinations of factors change

each time

- Review phenomenon analysis from standpoint of principles and rules. Review correlation with equipment.

- Exercise care and openly examine if slight defects are overlooked or neglected, without looking at

phenomena only.

- Ratio of influence contributing to results should not be made an issue. (Efforts on slight defects will become

secondary)

- What is questionable and doubtful reasoning should be identified without sticking to ready-made ideas of the

past.

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

JIPM, 1994

WHY WHY ANALYSIS

Phenomenon

(Result)

Cause

Phenomenon

(Result)

Cause

Phenomenon

(Result)

Cause

Phenomenon

(Result)

Primary Secondary Tertiary . . .

Final cause is till mens

actions are expressed

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Why did you clean strainer Strainer was clogged

What is Your Final Action Replacing the o-ring

Repair error during maintenance work

Oil leaks from cylinder rod each time it operates

Question Answer

Why was hole made

Answer Question

Clean Strainer

Prevent Scattering of chips and cutting fluid

Why Strainer was Clogged Oil was Dirty Drain Oil and Clean

Why Oil was Dirty

ACTION WHY ANSWER

Standardise repairs

Example 2

Dirt entered the tank

upper plate of tank has hole and gap Plug hole and gap Why does dirt get in

WHY ANSWER ACTION

Yes After replacing the o-ring is it OK?

Why did you replace o-ring o-ring cut o-ring changed

Why o-ring out? rod has scratch scratch removed

chips were scattered and attached to rod

measures taken to prevent chips from

scattering

Why chips were attached on rod

Cylinder located within scattering range of

chips and rod cover is not plaed cyliners position changed and cover fixed

Why cylinder located within scatterign range

of chips and rod cover not replaced defective design and installation standard design and installation

Example 1

Cylinder Does Not Operate Smoothly

Cleaning Strainer

Yes

What is Your Final Action

After Cleaning Strainer, Is it OK

why rod has scratch

Why Why Analysis

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

PM ANALYSIS

These initials are taken for the work. PM analysis consists of the following steps:

Basic approaches to PM analysis

1) Seize phenomena by strictly following genba" and genbutsu" principles

2) Analyze mechanisms generating phenomena from the standpoint of physical

principles and rules

3) Understand functions and structures of machining principles, processes,

equipment and parts

4) Analyze minutely in relation to 4 M.

5) Abandon priority principle and ready-made ideas and thoroughly eliminate

ones which are dubious by reasoning.

What is PM Analysis?

The term PM analysis comes from the following origin,

Phenomena (non)

Physical

Mechanism

Relationship (Machine, Man, Material and method)

P

M

Analysis

JIPM, 1994

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Steps of PM Analysis

1. Clarify the phenomenon/problem Classify precisely the phenomenon /problem

2. Conduct physical analysis of the

phenomenon

List all contributing factors related to the phenomenon

4. Investigate relation to equipment,

man, materials and methods

5. Study what the normal conditions are

6. Plant the appropriate investigation

methods

7. Investigate malfunctions

8. Implement of improvements

List all contributing factors related to the phenomenon

Investigate the correlation between equipment, jigs and

tools under which failure conditions are generated and list

up the factors which might have cause and effect

relationship

Study the optimal conditions for each factor related to the

mechanism, actual equipment, drawings and various

standards

Study the methods to investigate the factors

List up the items which are deviating from the normal

conditions and items of incidental defects

Draw up and implement the improvement plan for the

malfunction points

3. List factors related to the

phenomenon

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

IDENTIFY CORRELATION WITH 4M

Identify all elements that can be considered by reasoning to compose individual contributing

conditions in order to establish these conditions.

Phenomenon View of Physics Contribution condition 4M (Primary) 4M (Secondary)

Factor

Brotherly

Relation

Brotherly

Relation

Brotherly

Relation

Relation of 1:1

Result

Parental

Relation

Factor,

Results

Parental

Relation

Factor,

Results

Parental

Relation

* Not necessarily confined to contributing factor and degree of impacts

* Correlation with equipment, jigs and tools

Go mechanisms and structures establishing contributing conditions upstream from tips

(machining points) of phenomena sequentially to the foundation which support them.

* List all items that can be thought of by reasoning about materials, methods and men also

* If a listed item occurs, read whether or not conditions will really become contributing conditions to

check a match

JIPM, 1994

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Practice : Physical Analysis

JIPM, 1994

3

2

1

(3) Into which state does

it get out of shape?

(2) What is the physical

quantity which

connects?

(1) Which conditions

contribute to the

phenomenon?

Phenomenon

Much leak within

valve at

specified

pressure and oil

temperature

Body

Spool

Shoe

Slips

Floor

Battery

Lamp

does

not light

up.

Lamp

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

PM ANALYSIS (AIR CYLINDER)

Air pressure is low

Air hose is ripped

Air hose is long

Air hose is bent

Excessive drainage is accumulated

Foreign matter clogged in joint

Air leak through joint

Piston packing blemish or wear

Needle gasket blemish or wear

Cushion packing blemish or wear

Rod packing blemish or wear

O ring blemish or wear

Cylinder gasket blemish or wear

Bushing blemish or wear

Rod cover blemish or crack

Cylinder tube blemish or rip

Piston packing mounted in reverse

Needle gasket mounted in reverse

Head cover packing mounted in reverse

Rod cover packing mounted in reverse

Piston rod deformation, blemish or rust

Rod cover deformation, blemish or rust

Misalignment between piston rod and rod

cover

Foreign matter inserted between piston rod

and rod cover

Insufficient lubrication

Defective 3-point set

Dust wiper deformation, blemish or rust

Needed air does not

reach needle

Air leaks inside cylinder

Resistance exists

between piston rod and

rod cover

Rod thrusting

force is small

Resistance

received by rod

is large.

Resistance received by rod is

larger than advancing force

of rod

Advancing in force of rod : f1

Resistance received by

rod : f2

f1 < f2

Piston rod

of air

cylinder

stops

halfway

Relation with 4M (Secondary)

Relation with

4M (Primary)

Contributing

Condition

Physically View

(Logical reasoning)

Pheno-

menon

42

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Rod packing deformation or deterioration

Cushion packing deformation or deterioration

Bushing deformation or rust

Piston deformation, blemish or rust

Misalignment between piston and rod

Cylinder tube deformation, blemish or rust

Foreign matter between piston and cylinder tube

Insufficient lubrication

Defective 3-point set

Piston packing deformation or deterioration

Misalignment between piston and cylinder tube

Head cover deformation, blemish or rust

Misalignment between piston and head cover

Defective solenoid valve

Clogged exhaust port

Spring trouble

Needle gasket deformation or clogging

Cushion packing deformation or deterioration

Resistance exist

between piston and

cylinder tube

Exhaust air remains

Relation with 4M (Secondary)

Relation with 4M

(Primary)

Contributing

Condition

Physically View

(Logical reasoning)

Pheno-

menon

43

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

How to advance Kobetsu Kaizen

Set model

equipment

Organize

the project

team

Sixteen

major

losses

Select theme

and plan

implementation

Individual

improvement

project

activities

Improvement of

reliability

inherent to the

equipment

I

m

p

r

o

v

e

m

e

n

t

o

f

e

q

u

i

p

m

e

n

t

e

f

f

i

c

i

e

n

c

y

Reliability in the

use Enhancement

Prevention :

Standard, Review

Line manager (Leader)

Production Engineering

Design

Maintenance men

Others

(1) Failure loss

(5) Minor stoppage and

idling loss

(6) Speed loss

(7) Defect & rework loss

(2) Setup and adjustment

loss

(10) Operation motionloss

(12) Logistics Loss

(3) Cutting blade & Jig

change loss

(8) Shut down (SD)loss

(13) Measurement &

Adjustment loss

(14) Yield loss

(9) Management loss)

(11) Line organisation loss

(4) Startup and yield

(15) Energy loss

(16) Die & jig loss

Sixteen

major

losses

Function

failure

Depression

of function

Reduction in

frequency

Failure analysis

technique

PM analysis

Horizontal

development

IE

QC

VE

Others

Bottleneck process

Large loss

More horizontal

development elements

For equipment and lines

Keep matching with the

autonomous maintenance

model

Criteria to give the priority on the theme chosen:

The one which has greater needs

The one which is expected to provide a greater

influence

The one which seems to be improved within

approximately three months

Challenge zero six major

losses through project

activities under each theme

Autonomous

maintenance system

Preventive

maintenance system

Hinshitsu Hozen

System

TPM in Office

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Systems of TPM Success Result Indexes

A

m

o

u

n

t

o

f

r

e

d

u

c

e

d

c

o

s

t

Improvement of

throughput per time

(Time, shift, day, month)

Reduction of input cost

Improvement of labor

productivity

Reduction of material

loss cost

Efficiency of equipment

Unmanned operation

Efficiency of man

Efficiency of base units

Equipment operation

factor

(Planned stoppage)

(Possible operation time)

General equipment

efficiency

(Stoppage loss)

(Loading time)

Time operation

factor

(Stoppage loss)

(Loading time)

Performance

operation factor

(Speed loss)

(Not operation time)

Good product

ratio

(Defective loss)

(Valuable operation time)

Minor stoppage

idling loss

Administration

loss

Reduced speed

loss

Process error

correction loss

Man-hour loss

Automation

replacement loss

Material yield

loss

Energy loss

Dies, jigs and

tools loss

(Sub material loss)

Planned stoppage

Shut down loss

SD stoppage

Minor stoppage cycles

Equipment idling time

Repairing time

Disposal defectives

Speed difference

Automation

Semi-automation

No man operation at night

No man operation in lunch time

Work group organization loss

Improvement of standard

time

Number of machines per

man

Planned waiting

Waiting in material distribution

Startup loss Startup time

Setup loss

Setup cycles

Setup times

Tool replacement

loss

Cutting tool replacing cycles

Cutting tool replacing time

Breakdown loss

Number of breakdowns

Time of breakdowns

Work efficiency

Labor saving

Efficiencies

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KAIZEN GOALS FOR 7 MAJOR LOSSES

Utilize PM analysis.

Clarify standards and review criteria.

Zero.

Reduce range to zero or to PPM

Defect and

Rework

Restudy cycle graphs.

Review machining conditions.

Study rigidity of equipment and jigs

Zero.

Reduce difference with design specifications to zero.

Pursue theoretical machining speed

Speed

Determine quantitatively.

Identify and eliminate minor defects.

Zero.

Zero with all equipment and facilities.

Minor Stoppage

Study impacts of thermal displacement.

Pursue fluctuation factors for various process conditions.

Minimize.

Reduce to zero or to PPM

Start-up

Pre-setting Zero.

Adjust to produce non-defectives right from the

beginning, without trial machining

Cutting Blade and

Jig Adjustment

Pursue machining theories. Minimize.

Reduce changes by extending cutting blade life.

Cutting Blade and

Jig Change

Analyze adjustment items by reasoning.

Improve precision and rigidity of equipment, parts and

jigs.

Zero.

Adjust to produce non-defectives right from the

beginning without trial machining.

Adjustment

Review and standardize work.

Common use of jigs and tools.

One-touch operation.

Minimize.

Shortest possible time.

Single-step setup.

Setup

Understand as ones own problems

Learn equipment and part mechanisms.

Learn how to pursue causes.

Study corrective maintenance and predictive maintenance

Zero.

Zero for all equipment and facilities.

Failure

Measures Goal Loss Category

JIPM, 1994

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 1

EQUIPMENT

FAILURE

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

GENERAL PROBLEMS WITH FAILURES

Low interest by production sector

- Production thinks failure should be handled by maintenance

Weak attitude toward failure analysis

- Phenomena are not observed in detail

- Broken locations and places nearby are not examined fully.

- Enough Genbutsu is not collected and analyzed.

- Causes are not pursued fully and only actions are taken

- Measures for preventing recurrence are not taken.

- Failures are not analyzed at on-sight.

Maintenance system and operation of it are weak.

- Check criteria are not defined, e.g., checking frequency, locations, methods and

criteria

- Maintenance calendar easily showing parts replacement and overhauling periods,

oiling and oil

change, and other items and operation system for it are weak.

- Failure history system

Attitude towards predictive maintenance (CBM) is weak.

- Measured values fluctuate greatly and are not reliable.

- Measured values do not change for a long time and lose confidence in audit results.

- Periodic measurement and trend control are not implemented

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KAIZEN PROGRAM FOR FAILURE LOSSES

- Identify failures which occur again based on

maintenance records

- Take permanent measures on failures on which

only temporary measures are taken (Causes are

known, but actions cannot be taken due to time,

technology or budget.)

- Understand and take actions on manufacturing

responsibilities, e.g., operational errors (Training, FP,etc.)

- Study failures which can be dealt with by Jishu Hozen

(Plan and prepare locations to be checked and skill

training)

Classify by line and equipment

Classify by failure location

Classify by failure mode

Classify by cause

Classify by type sporadic or repeated failure

Classify by ease ( If can be prevented by Jishu Hozen)

1. Classify and Rearrange Past Failures

- Thorough analysis and guidance

- Verify and take actions on repair errors (Skill

training)

- Analyze failures as our own problem

- Repeat WHY WHY Analysis

- Check similar equipment and locations and correct

Fuguai

Reanalyse failures that have occurred again

Through analysis of new failures

Steps for zero failures Production Roles Maintenance roles

2. Failure Analysis and General Checks

3. Eliminate Forced Deterioration and

Restore Deterioration Left Unattended

- Correct, train and guide Fuguai

- Consolidate and guide operating conditions

- Eliminate forced deterioration of invisible parts

- Find and restore Fuguai by cleaning

- Provide basic conditions

- Learn and observe operating conditions

4. Study and Improve Weaknesses

(Corrective Maintenance)

5. Prepare and Consolidate Standards

(Including Failures Involving Defects)

- Analyze and correct design weaknesses

- Study measures to lengthen life

- Improve mechanisms.

- Improve basic conditions so that they can be maintained

easily (Countermeasures on sources and places difficult

to check, clean and oil)

- Enforce visual control

- Make general checks of equipment.

6. Maintenance Efficiency

7. Explosion of Predictive Maintenance

JIPM, 1994

- Prepare periodical maintenance manual

- Determine lives of equipment and composite parts

- Determine deterioration pattern (DFR, CFR, IFR)

- Analyze relationship between equipment accuracy

and quality characteristics.

- Prepare Jishu Hozen manual

- Check by check list and restore deterioration

- Enhanced maintainability

- Maintenance (survey, preparations, work, etc.)

- Enhanced spare parts management

- Good housekeeping of drawings and other

documents

- Enhanced visual control

- Determine deterioration and predict life by

precision diagnostic equipment.

- Status monitoring and trend control by simple diagnostic

equipment.

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KAIZEN IDEA - SHEET

Scope & plan for Horizontal Deployment :

Sl. No. M/c No. Target Dt. Responsibility Status

1 16 m/cs Jan 2000 BK Jha Completed

Problem/present Status :

Frequent break-down of MG welding machine (1304)

(Average 4/month) due to failure of wire feeder

Kaizen Theme :

Reduction of Break-down in welding

Bench mark 4 brush set/month

Target 0

Kaizen start November 1999

Kaizen Finish November 1999

Team members :

1. B K Jha 4. R K Yadav

2. R B Yadav

3. R Dhaiya

Result: Analysis :

Why 1 : Feeder motor not working

Why 2 : No power supply to armature of motor

Why 3 : DC motors carbon contact brush found

worn out and carbon deposited on

commutator

Why 4 : Sparking at roating contact while

operating and specially while breaking

Why 5 : Brush is operating at high voltage and

reverse current is applied while breaking

Idea : To provide DC Motor in wire feeder with low operating voltage and to provide breaking

with permanent magnet

Bharat Seats Limited

Countermeasures :

System changed to low voltage supply and

breaking by permanent magnet has reduced

break down and brush consumption to zero for

3 years

Benefits

Equipment failure reduced from 4 / month to 0

Saving in time loss = 80 min./machine/month

Productivity increased = 133 component/

machine

Carbon brush saved per month = 50 sets

Saving = Rs 110 x 50

= Rs 5500 per month/machine

42 Volts

Breaking by

Permanent Magnet

Field Magnetism by

Permanent Magnet

110 volts

DC current

Breaking by Reverse

DC Current

Field Magnetism by

DC Current

0

1

2

3

4

5

6

Oct'99 Nov'99 Oct'99 Jan'00

0

1

2

3

4

5

6

Oct'99 Nov'99 Dec'99 Jan'00

Brush

Consumption Equipment Failure

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Example of Why-Why Analysis.

TPM

(For Equipment Failure)

BIRLA TYRES

THEME:- IDEA:-

B.M.:-

TARGET:-

BEFORE:-

AFTER:-

ANALYSIS:- RESULT:- EQUIPMENT FAILURE DOWN TIME /

MONTH.

BENEFIT (J#4 M/c) :-

DATE:-

MACHINE :-

PERIOD:-

HORIZONTAL PLAN:-

BENEFIT (ALL MACHINE):-

59 J#4 TYRE BUILDING MACHINE

TO ELIMINATE EQUIPMENT FAILURE DUE

TO ROTORY COUPLING PIN BREAKAGE.

65' / 4 NUMBERS PER MONTH ZERO

PHYSICAL PHENOMENA :-

ROTORY COUPLING PIN BROKEN

Why -1 : ROTORY PIN SHEARING.

Why -2 : LESS STRENGTH OF PIN.

Why -3 : POOR DESIGN OF COUPLING.

TO PROVIDE CHAIN COUPLING TO AVOID PIN

BREAKAGE WITH HEIGHER FACTOR OF

SAFETY.

15/10/99

TO

15/03/00

31/07/2001

KAIZEN THEME IMPLEMENTATION SHEET

65

0

BEFORE AFTER

0

10

20

30

40

50

60

70

T

I

M

E

I

N

M

I

N

U

T

E

S

.

PIN TYPE COUPLING

MAX. TORQUE RATING = 2.8 NM.

CHAIN COUPLING

MAX. TORQUE RATING = 5 NM.

0

6

BEFORE AFTER

0

1

2

3

4

5

6

7

NUMBER OF TYRES PER MONTH

0

66

BEFORE AFTER

0

10

20

30

40

50

60

70

NUMBER OF TYRES PER MONTH

MACHINE PLAN COMPLETED

J# 4,9,1,2, OCT'99 OCT'99

J# 3,5,6 DEC'99 DEC'99

J# 7,8,10,11 FEB'00 FEB'00

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 2

SETUP &

ADJUSTMENT LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Sona

Sona Koyo Steering Systems Ltd. KAIZEN IDEA - SHEET

Kaizen Theme : TO REDUCE HIGH CHANGE- Idea : PUT A TROLLEY UNDER CHIP AND COOLANT TRAY SO THAT

OVER TIME ON RACK TEETH BROACHING

REMOVAL OF TRAY SHOULD BE EASY

Problem / present Status Counter measure : Bench mark 310 Secs.

Target 140 Secs.

Start 15/5/2001

Kaizen Finish 19/5/2001

Team members :

A.K. DASGUPTA

MANOJ SHARMA

R. BAJAJ

Benefits :

TROLLEY REMOVAL AND

Analysis : Result : FIXING TIME REDUCED

WHY : CHANGE OVER ON BROACHING M/C TO BE BY 170 Secs.

REDUCED

: DUE TO HIGH CHANGEOVER TIME ON M/C

: OPERATOR HAS TO USE CHAIN PULLEY FOR

REMOVAL OF TRAY

Scope & plan for Horizontal Deployment :

Sr.No. M/c No. Target Dt. Responsibility Status

310

140

0

100

200

300

400

BEFORE AFTER

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

TPM Plant : TSK Plant I SUNDARAM BRAKE LININGS LIMITED

Notching

Kaizen Theme : Idea :

To reduce setup time loss reduction in To provide setting stopper.

Notching machine

Problem / Present status Current status 480 seconds

Target 70 seconds

Setting stopper provided for easy alignment. Kaizen started on 05.04.2001

Notching setting time is more Kaizen finished on 07.04.2001

BEFORE AFTER Team Members

B.Vivekanandan G.Arunachalam

480 seconds

B.Munishkumar M.Santhakumar

Benefits :

Setting can be done by any producer.

No stopper Stopper

Analysis Results Scope & Plan for Horizontal Deployment

Setting time reduced by 80 seconds

Why 1 : S.No Machine Target Resp Status

Due to drill head alignment difficult. 1 Padi Plant

Why 2: 2

No setting stopper for drill head

alignment. 3

4

5

Counter Measure

KAIZEN IDEA - SHEET

480

100

0

100

200

300

400

500

600

BEFORE AFTER

I

n

s

e

c

o

n

d

s

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

PU: Foundry. REF NO:-

CELL: Core Room

LOSS : Set up

Kaizen Theme :

To reduce set up time for ejector plate

from 60 mins to 10 mins per occurance

Problem / present Status:

Team Members :

1. 4. Pramod Bhagat

2. 5.

3. 6.

1 Increase in output by 3 nos. per day

2 Reduction in consumption of washers

Analysis : 3 Reduction on cost of long studs

Set up time is more 90

80

70

Removal, fixing and adjustment 60

time more 50

40

Dismentling and assembly time more 30

as number of parts are more 20

Ejector plate gets warped due to heat 10

J F M A M J J A S

Faulty design Months

T

i

m

e

i

n

M

i

n

u

t

e

s

1. Std size spacers are welded to ejector plate. 2. Reinforcement to

ejector plate to avoid warpage elliminating use of washers. 3. Use of

small bolts in stead of long studs.

Result :

Counter Measure:

KAIZEN SHEET

Idea :

Re design upper ejector plate

Murdeshwar

60 minutes

Spacers and studs - 4 nos each and various

washers required for ejector plate set up

10 minutes

Jan-00

Bench Mark

Target

Start

Amar Patil

Lalit Sedani

Benefits:(Mention in PQCDSM as applicable)

HORIZONTAL DEPLOYMENT

M/C NO. PU

Mar-00

Kaizen Finish

Satish Sohoni

Foundry

22/2

22/3

M/C NO.

Foundry 22/1

PU

Foundry

Example of Set Up time reduction

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Sona

Sona Koyo Steering Systems Ltd. KAIZEN IDEA - SHEET

Kaizen Theme : TO REDUCE SET UP TIME

ON C-67 INJECTION MOULDING M/C

Problem / present Status Counter measure : Bench mark 1480 Secs.

Target 415 Secs.

Start 9/10/00

Kaizen Finish 10/03/00

Team members :

RAKESH GARG

G.R. YADAV

MANOJ SHARMA

S.K.GUPTA

CHINTESH

MOULD WAS REPLACED FOR SET UP ONLY REST BLOCKS ARE CHANGED FOR SET UP

Benefits :

Analysis : Result :

SET UP TIME REDUCED

BY 1065 Secs.

WHY:

Scope & Plan for Horizontal Deployment

BECAUSE DIFFERENT MOULDS ARE USED FOR Sr.No. M/c No. Target Dt. Responsibility Status

DIFFERENT MODELS

SET UP TIME IS MORE

Idea : COMMON MOULD TO BE USED BY REPLACING PARTS ONLY

OPERATOR'S FATIGUE

REDUCED

0

5

10

15

20

25

30

Before After

1480

415

0

500

1000

1500

2000

BEFORE AFTER

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 3

TOOL & JIG CHANGE

LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Sona

Sona Koyo Steering Systems Ltd. KAIZEN IDEA - SHEET

Kaizen Theme : QUICK FITMENT OF RUNNERIdea : MODIFICATION OF RUNNER PLATE BY PROVIDING CHAMFER

PLATE

Problem / present Status Counter measure : Bench mark 20 Secs.

Target 10 Secs.

Start 19/12/2000

Kaizen Finish 19/12/2000

Team members :

CHINTESH

PARMOD JAIN

JITENDER

RAKESH GARG

Benefits :

Analysis : Result :

WHY TAKE MORE TIME TO PUT RUNNER PLATE 10 SEC TIME REDUCED FOR

ON CAVITY CHANGEOVER

NO CHAMFER ON RUNNER PLATE & ACTIVITY

Scope & plan for Horizontal Deployment :

Sr.No. M/c No. Target Dt. Responsibility Status

20

10

0

5

10

15

20

25

BEFORE AFTER

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 4

START UP LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 5

MINOR STOPPAGE &

IDLING LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

GENERAL PROBLEMS ON MINOR STOPPAGES

Efforts to actualize as losses are not sufficient.

Actions taken are poor .

- Only emergency measures are taken as temporary measures.

Phenomena are not discerned fully.

Obstruction to unattendance operation.

- Operators are used for restoration.

- Minor stoppages keep operators from operating multiple stations or

machines.

- One minor stoppage will ruin the effects of unattendance operation

during breaks.

JIPM, 1994

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KAIZEN PROGRAM TO IMPROVE MINOR STOPPAGE LOSS

Where they occur, how many, how frequently, with what product,

when, and in what condition (including condition by program)

* Survey the actual condition of phenomena

1. Understand present status

JIPM, 1994

* Stratify phenomena

* PM analysis

* List all Fuguai that can be considered

2. Analyze Phenomena

Attach Efu in place for each slight defect or Fuguai

Check during Jishu-Hozen activities

* Keep equipment and machines clean

* Attaching and removing Efu

3. Identify, Restore and Improve slight defect and Fuguai

* Verify effects

* Reflect in Jishu-Hozen criteria

* Select problems for zero minor stoppages

4. Verify Results

Timing, Installation angle, vacuum pressure, vibration

Acceleration and deceleration timing, sensor suitability, sensor

mounting conditions, chute shape, coolant condition, air blow

condition, positioning mechanism, clearance, accuracy of each

part, fitting accuracy, condition and method of disposing chips.

* Compare with design conditions

* Improve design weaknesses

5. Study optimal conditions

* Improve parts and members with short life

* Improve dirty locations. (Ideas to eliminate needs for cleaning)

6. Longer MTBF

Fixation of fluctuation factors, prediction of changes, and

automatic restoration of variations

* Zero minor stoppages

7. Challenge to Unattendance Operation (In Zero Minor Stoppages)

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Example of Minor Stoppage and Idling Loss

TPM Plant : TSK Plant I SUNDARAM BRAKE LININGS LIMITED

IDG 2

Kaizen Theme : Idea :

To eliminate Minor stoppage and idling loss in To increase end stopper height

ID Grinding machine.

Problem / Present status Current status 6 occurrences

Target 0

End stopper height increased Kaizen started on 10.07.2001

Product getting overlapped in rear end Kaizen finished on 11.07.2001

stopper after grinding. BEFORE Team Members

B.Vivekanandan G.Arunachalam

B.Munishkumar M.Santhakumar

Benefits :

AFTER

Product over lapping eliminated.

Analysis Results Scope & Plan for Horizontal Deployment

Minor stoppage Trend

Why 1 : S.No Machine Target Resp Status

Product slipped from its position 1 TSKP 2 25.07.2001 KK Comp

IDG

2

Why 2 :

End stopper height is less. 3

4

5

KAIZEN IDEA - SHEET

Counter Measure

6

0

0

1

2

3

4

5

6

7

BEFORE AFTER

O

c

c

u

r

e

n

c

e

s

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Believe in the Best

Kaiun Theme :

Problem / Present Status : Counter Measure :

Analysis : Result :

Benefits :

Sl.

No.

M/c. No.

Responsibilit

y

Status

Not applicable.

Scope & Plan for Horizontal Deployment

1. Minor stoppage reduced to zero .

2. Production Increased by 23400 nos per

month.

Target Dt.

3. Rejection reduced from 2075 Nos. to Zero per

month.

Kaizen Finish Date 02.07.00

Team Members :

Mahesh, Deepak, Jayaraj, Chandrashekar,

Nagaraju.

Kaizen Regn. No. R6/178/00

Kaizen Start Date 20.12.99

Department R6

Can getting stuck between star wheel &

hopper guide leading to stop the flow of cans

to tamping m/c.

Increased no of slots from 37 to 48 by

increasing the diameter of starwheel, there by

reduce the RPM of starwheel.

Location Tamping

Bench Mark 78min, /499 Occ/Month.

Target Zero

Idea :

To increase no of slots available for can locating.

To reduce the minor stoppage of Tamping.

Soft Energy Business Group

KAIZEN IDEA SHEET

DRY CELL DIVISION.

MADDUR.

1. Can not located in the star wheel slot.

2. No. of slots available for locating the can is

less.

3. RPM of the star wheel is more.

4. Machine designed that way.

BPL

0

10

20

30

40

50

60

70

80

90

May-00 Jun-00 Jul-00 Aug-00

Kaizen

Done

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 6

REDUCED SPEED

LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Example of Eliminating Operating Motion Loss

Time.

TPM

(Idling Loss)

BIRLA TYRES

THEME:- IDEA:-

B.M.:-

TARGET:-

BEFORE:-

AFTER:-

ANALYSIS:- RESULT:-

BENEFIT :-

DATE:-

MACHINE / PROCESS:-

PERIOD:-

HORIZONTAL PLAN:-

BENEFIT (ALL MACHINE):-

P#5 BAND BUILDING

TO REDUCE THE SPEED LOSS AT BAND

BUILDING MACHINE.

3.36 MINUTES PER CYCLE

CYCLE TIME OF P#5 BAND BUILDING M/C IS MORE.

Why -1 :PLY FEEDING TIME MORE.

Why -2 : MANUAL METHOD OF PLY FEEDING.

Why -3 : NO ARRANGEMENT FOR PLY FEEDING.

THE MANUAL PLY FEEDING SYSTEM TO

REPLACED BY MOTERISED SYSTEM.

APR.' -

MAY'2001

31/07/2001

3.36

2.83

BEFORE AFTER

0

1

2

3

4

C

Y

C

L

E

T

IM

E

IN

M

IN

U

T

E

S

.

KAIZEN THEME IMPLEMENTATION SHEET

N.A.-

2.83 MINUTES PER CYCLE

125

148

BEFORE AFTER

0

50

100

150

200

NO. OF BAND PRODUCTION PER SHIFT.

N.A.-

MANUAL PLY FEEDING

MOTERISED PLY FEEDING

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Example of Speed loss

Moving Bolster

Moulds

Manufacturer

recommended speed

85 mm/sec

But actual speed is

35 mm/sec

Before

Main Ram

Tie Rod

After

Machine restored as

per Manufacturer

recommended speed

of 85 mm/sec

Machine : Vertical Curing Press

Operation : Press Curing

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 7

DEFECT & REWORK

LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

JIPM, 1994

GENERAL PROBLEMS ON DEFECTS

Defects tend to be left as they are because the situation does not improve

even if countermeasures are taken

- Approaching method is wrong

Sporadic and chronic losses are not understood

- Errors by engineers who think only in the realm of organisation

developed

technologies

Actual conditions of on-site is not understood. ( Work, setup,

equipment, etc.)

Methods of seizing and exploring factors are poor

- Defects are not taken up as defects

- Defects are not considered to affect phenomena

Rework is not considered as losses

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KAIZEN PROGRAM FOR DEFECT LOSSES

* Process and location where defect is generated

* Relations between equipment accuracy, method and conditions and quality.

* Comparative study (non-defectives, defectives and other machines)

* Study of mechanism

Mechanism, jigs, tools, setup and

machining conditions

1. Stratification of Defect Phenomena

JIPM, 1994

* List factors by cause and effect diagrams and 4M analytic charts

* List important factors and draft Kaizen Countermeasures

3. 4 M Analysis and Countermeasure Drafting

* Prepare a plan for Kaizen Implementation

* Implement Kaizen and set conditions

* Verify results

* Stratification of remaining defect phenomena

* Physical analysis of Phenomena

* Contributing conditions

* Analyze correlations with 4M

* Study of what the human resources and equipment condition must be

* Study machining conditions

4. Countermeasure Implementation and Result Verification

5. Implement PM Analysis

* Study of measuring method

* Survey accuracy

* Restore and improve Fuguai

6. Identification of Defects and Implementation of Countermeasures

* Verify results

* Study accuracy to be maintained

* Set and execute control criteria

7. Verifications of Results and Prevention of Recurrence

* Clarify quality standard and quality characteristic values

* Through stratification of defect modes

ABC analysis, time series data, Cp value,

unadjusted time series data

2. Survey of Defect Process and Location

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Example of Why-Why Analysis.

TPM

(For Quality Defect)

BIRLA TYRES

THEME:- IDEA:-

PHYSICAL PHENOMENON.:-

TARGET:-

BEFORE:-

AFTER:-

ANALYSIS:- RESULT:-

DATE:-

MACHINE / PROCESS:-

PERIOD:-

BENEFIT :-

TYRE CURING

ELIMINATION OF TRUCK TYRE

SCRAP DUE TO TREAD BLOW.

ZERO

Why -1 : AIR INBETWEEN TYRE CARCUS

AND BLADDER.

Why -2 : BLADDER NOT TOUCHING THE

TYRE CARCUS.

Why -3 : HEIGHER STRECH IN BLADDER

Why -4 : BLADDER SIZE LESS.

BLADDER HAVING LOWER STRECH (WITH RESPECT

TO TYRE) TO BE USED IN ORDER TO GET BETTER

CONTACT BETWEEN BLADDER AND TYRE AS WELL

AS TO AVOID TRED BLOW AFFECTED TYRES BY

INCREASING BLADDER SIZE.

15/10/99

TO

15/03/00

31/07/2001

30 27

0 0 0

9

8

-

9

9

9

9

-

0

0

0

0

-

0

1

A

P

R

'-

J

U

N

'0

1

J

U

L

'0

1

PERIOD

0

10

20

30

N

U

M

B

E

R

S

KAIZEN THEME IMPLEMENTATION SHEET

9

8

-

9

9

9

9

-

0

0

0

0

-

0

1

A

P

R

'-

J

U

N

'0

1

J

U

L

'0

1

PERIOD

0

20

40

60

80

100

120

T

h

o

u

s

a

n

d

s

R

U

P

E

E

S

550 SIZE

BLADDER

AIR BETWEEN BLADDER

AND TYRE

NO AIR BETWEEN BLADDER

AND TYRE

590 SIZE

BLADDER

TYRE

TYRE

B.M.:- 30 TYRES SCRAP PER MONTH

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 8

SHUT DOWN LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

BPL Limited B:ABZ:F: 0001

Alkaline Battery Division Eff.Date: 01/06/2001

EXCELL T P M Issue No: 2

Dept: CONSOLIDATED CAN

Name: Nataraj & S.M.Shrikanth Kaizen No: ABK / 674 / 2000

Pillar: PM Start Date: 20/01/01

Theme: TO Reduce Schedule Down Time *A - Adjustment / Parts change End Date: 25/01/01

Loss (8)

*B - No action *C - Setup / Trial

Machine / Line: Pellet Insertor / LR 6 - 1

Problem Description: Sensor Position Shifts During Maintenance Activity.

70 Mins / Month ' Zero '

WHY ? 1 : Sensor Position Changes During Sensor

Cleaning Process.

WHY ? 2 : Sensor Fixture Is Madeup Of 5 Pieces

And Tightened With 6 Screws.

Idea: Counter Measure :

1. Minimise The Number Of Screws In The Existing 1. 5 Piece Fixture Is Replaced With A Single Piece

Fixture. Fixture.

Action: Action:

How to Maintain? 1. Match Marking.

2. Checking Of Screw Tightness

Once / 15 Days.

Horizontal 1. LR 6 - 2 Apr - 2001

Deployment in :

Benefits: Production / Hr Increased To

8790 Pcs.

V. MANOJ

Page: 1 of 1

RESULTS GRAPH

IMPLEMENTATION

Type of Problem*

A / B / C

FOLLOW - UP

ANALYSIS

(Dept.Head) (Sub-Committee)

Bench Mark: Target:

Prepared By: Checked By : Approved By:

AFTER KAIZEN BEFORE KAIZEN

(Name)

K A I Z E N

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 10

MOTION LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Example of Operating Motion loss

Mix pockets kept away from the

workstation and operator need to

walk to take the mix pocket.

(Walking distance upto 1 meter)

3 secs per cycle

1 sec per cycle

Mix pockets kept near the the

workstation to reduce the

walking and easy collection of

mix pockets. (No walking)

Machine : Gang press-3

Operation : Curing

Before After

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 11

LINE ORGANISATION

LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Example of Organisation Loss Reduction

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 13

MEASUREMENT &

ADJUSTMENT LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Example of Adjustment Downtime Loss Reduction

TPM Plant : TSK Plant I SUNDARAM BRAKE LININGS LIMITED

PGrinder

Kaizen Theme : Idea :

To Reduce adjustment loss in Plunge To modify the design.

grinder 2

Problem / Present status Current status 60 secs

Target 30 secs

More time for arc length adjustment . Arc length adjustment handle length increased and handle Kaizen started on 16.02.2001

kept outside the machine guard for easy access & adjustment Kaizen finished on 28.02.2001

60 seconds BEFORE AFTER Team Members

B.Vivekanandan G.Arunachalam

Handle B.Munishkumar M.Santhakumar

Benefits :

Adjustment time reduced from 60

secs to 30 secs.

Difficult to adjust Easy to adjust

Analysis Results Scope & Plan for Horizontal Deployment

Adjustment time reduced

Why 1 : S.No Machine Target Resp Status

Difficult to adjust. 1 TSKP 2 10.03.2001 KK Comp

Why 2 : 2

Adjustment knob kept at inaccessible

position. 3

Why 3 : 4

Design Error.

5

KAIZEN IDEA - SHEET

Counter Measure

60

30

0

10

20

30

40

50

60

70

BEFORE AFTER

I

n

s

e

c

s

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 14

ENERGY LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Kaizen Theme :

TO REDUCE POWER CONSUMPTION

Problem / present Status: Counter Measure:

Team Members :

1.

2.

3.

Analysis : Result : = 31536 UINITS / YEARS ( 365 DAYS)

= Rs.133081 ( Rs.4.22 / KWH )

M/c. No Responsibility Status

Idea : TO CONVERT WATER COOLED PACKAGE A/C INTO USER FRIENDLY

AIR COOLED PACKAGE A/C.

Bench Mark 4.5 KW

PUMP & COOLER TOWER ELEIMINATED. Target

Kaizen Finish

M.V.AGASHE

KW OF WATER PUMP & COOLING TOWER FAN= 4.5 KW

= 4.5 KW X 0.80 ( LOAD FACTOR ) 24 HRS.

= 86.4 UNITS / DAY

Zero

Start

01-Mar-01

15-Apr-01

S.S.DIGHE

U.S.JOSHI

Benefits:

AS A SYSTEM IS WATER COOLED, IT IS

REQUIRED WATER PUMP, COOLING

TOWER AND WATER. ALSO SYSTEM IS

VERY OLD (15 YESRS) HENCE NOT VERY

EFFICIENT.

ELIMINATED 5 HP CONDENSOR WATER

PUMP AND 1 HP COOLING TOWER FAN

AND SAVEED IN ELECTRICAL POWER

CONSUMPTION.

Scope & Plan for Horizontal deployment :

Sr.No Target dt

1ST FL. AD. EDP DPET.WATER COOLED

A/C SYSTEM.USED.

WATER PUMP

COOLING

TOWER

CONDENSOR

A/C UNIT

A/C UNIT

CONDENSOR

WATER COOLED A/C SYSTEM AIR COOLED A/C SYSTEM

ELIMINATED 3000 LITERS/DAY WATER

AND SAVED MUNICIPAL COST

WATER.

COST OF INSTALLATION @ Rs. 85000

USER FRIENDLY OPERATION

PAY BACK WITHIN ONE YEAR

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KKP2-U3-4

TPM Plant : TSK Plant II SUNDARAM BRAKE LININGS LIMITED

Kaizen Theme : Idea :

To reduce power consumption in U Line -III To modify the grinding wheel design to perform two operation at a time.

Problem / Present status Current Status 10 Secs

Target 0

The grooving operation and skimming Stepped grinding wheel provided to perform both grooving & Kaizen started on 20.05.01

operation were done separately with skimming operation in one machine. Kaizen finished on 25.05.01

two machines. Team Members

S.Rengarajan

S.Chandramohan

R.Raja ambikeswaran

V.Mohandass

K.Chellamuthu.

Benefits :

One operation eliminated

Power cost Savings - Rs.1603 per month.

Analysis: Results: Scope & Plan for Horizontal Deployment

Why 1: Grooving & skimming operation S.No Machine Target Resp Status

done in two m/cs

Why 2 : Due to grinding wheel design NA

KAIZEN IDEA - SHEET

Counter Measure

0

10

0

2

4

6

8

10

12

BEFORE AFTER

T

i

m

e

i

n

S

e

c

s

Flat grinding

wheel

Stepped grinding

wheel

Product

Product

Example of Power consumption reduction

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Carton Box for Sealing

Motor for driving the Belt

Limit Switch for starting the motor

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LIGHTING LOAD REDUCTION ,REPLACING INCADECENT LAMPS WITH

MV / SODIUM VAPOUR LAMPS

Energy cost more and frequent

failures of filament lamps

Filament lamps

500 W x 50 Nos 25 kW

200 W x 100 Nos 20 kW

100 W x 50 Nos 5 kW

60 W x 40 Nos 2.4 kW

Fluorecent lamps

40 W x 2000 - 80 kW

M/c. lamps 60 W x 70 4.20 kW

M.V lamps 250 W x 45 11.25 kW

Total 147.88 kW

Filament lamps are high wattage and

frequent failure due to voltage fluctuation.

300 W Filament x 30 Nos 9.00 kW

200 W Filament x 50 Nos 10.00 kW

250 W MV lamp x 110 Nos 27.50 kW

36 W Flurocent x 1500 Nos 54.00 kW

11 W CFL lamp x 40 Nos 0.55 kW

60 W M/c. lamp x 50 Nos 1.20 kW

250 W Sodium x 20 Nos 5.00 kW

Total 107.25 kw

Contd.,

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Energy cost more and frequent

failures of filament lamps

Consumption / yr = 147.88 kw x 15

hrs x 250 days = 5,54,550 units

Energy cost / yr = Rs. 27.72 lakhs

Filament lamps are high wattage and

frequent failure due to voltage fluctuation.

Consumption / yr = 107.25 kw x 15

days x 250 days = 4,02,188 units

Energy cost / yr = Rs. 20.10 lakhs

Investment :- Rs. 5.5 lakhs

Annual Saving :- Rs. 7.62 lakhs

Pay back period :- 9 months

LIGHTING LOAD REDUCTION ,REPLACING INCADECENT LAMPS WITH

MV / SODIUM VAPOUR LAMPS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LED INDICATOR IN PLACE OF FILAMENT TYPE LAMPS

IN CONTROL PANELS

Energy and replacement cost

high.

Filament indication lamps

12 W x 180 Nos 2.16 kW

Consumption / Yr = 2.16 x 15 x 250

= 8100 Units

Energy Cost / Yr = Rs. 40,500

Filament lamps are high wattage and

prone frequent failure.

LED Indication lamps used

0.5 W x 180 Nos 0.09 kW

Consumption / Yr = 0.09 x 15 x 250

= 338 Units

Energy Cost / Yr = Rs. 1,690

Investment :- Rs. 0.18 lakhs

Annual Saving :- Rs. 0.39 lakhs

Pay back period :- 6 months Contd.,

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Energy cost and replacement

cost high.

Filament lamps are high wattage

and frequent failure due to voltage

fluctuation.

LED INDICATOR IN PLACE OF

FILAMENT TYPE LAMPS IN CONTROL PANELS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 15

DIE, JIG & TOOL

LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

CUTTING TOOL LIFE IMPROVEMENT

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Plant : TSK Plant I SUNDARAM BRAKE LININGS LIMITED

Kaizen Theme : Idea :

To reduce consumption of the Notching cutter. To reduce the notch cutter height.

Problem / Present status Current Status

Target

Notch cutter height reduced Kaizen started on 02.04.2001

Notch cutter consumption is more. kaizen finished on 09.04.2001

Team Members

B.Vivekanandan

S.Nagarajan

P.Manoharan

Benefits :

95 mm

Savings cost per drill Rs.1060

25 mm

Cost savings Rs 4240 / month

Analysis : Results

KAIZEN IDEA - SHEET

Counter Measure

6

2

0

2

4

6

8

10

Before After

Q

t

y

i

n

N

o

s

/

M

o

n

t

h

Why 1: Cutting load is more.

Why 2: Tool contact area less.

Why 3: Design error

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KAIZEN IDEA - SHEET

Scope & plan for Horizontal Deployment :

Sl. No. M/c No. Target Dt. Responsibility Status

1 SACMA 10/07/99 K Rajaram Completed

2 5LA 06/07/99 S Jayaraman Completed

3 19B4SL 15/07/99 P Velmuthu Completed

Problem/present Status :

The tool cost of heading insert is more

Kaizen Theme :

To reduce tool cost of heading

Insert : M10

Bench mark Rs. 50,000 (250 H.insert/YR)

Target Rs. 20,000(40H.Insert/Yr)

Kaizen start 10

th

December 1998

Kaizen Finish 15

th

February 1999

Benefits :

Consumption of heading insert/Annum

Before 250 Nos.

After 40 Nos.

Cost Savings/Annum - Rs. 30,000

(For M10)

Total cost Savings/Annum - Rs. 6,00,000

(For all sizes)

Team members :

1. K Rajaram 4. S Jayaraman

2. P Velmuthu

3. S Nagasubramanian

Counter measure :

Result: Analysis :

Why 1 : More heading inserts are

consumed

Why 2 : Each heading inserts gives

one lakh pieces

Why 3 : Only one side in the tool can

be used

Change tool design to use multi sides

Tool Consumption

Idea : To change design of heading insert to use six sides of the tool

Sundram Fasteners

Limited

TVS

8.8

TVS

8.8

TVS

8.8

TVS

8.8

Before After

Only one side can be used Six sides are used

Total qty. forged per Total qty. forged per

H.insert 1,00,000 pcs H.insert 6,00,000

pcs

0

50

100

150

200

250

300

250

Before

40

After

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

LOSS - 16

YIELD LOSS

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

Kaizen Idea Sheet

DGP Hinoday Ind . Ltd.

Bhosari, Pune

Ferrite Core Group Bhosari - KK Pillar

Kaizen Theme : Reduce loss of

Material at grinding of EC 40

Problem / Present Status :

1.Grinding Allowance - 1.5 mm

2. Material Loss- 2.4%

Problem Analysis:

Why grinding allowance 1.5 mm?

To grind chamfer & adjust variation in sintered

height

Why variation in Sint. Ht?

Variation in Green Density

Why variation in green density?

Variation in bulk density of Powder

Why variation in Bulk density?

Spray dryer process capability

Idea : Green density to be controlled within 2.93 +

or - 0.02 gm / cc

Counter measure :

Adjust compression ratio of Press according

to B D to achieve green density.

Before After

Data

Team Members :

Benefits :

Scope for Horizontal Deployment:

Benchmark

Target

Kaizen Start Date

Kaizen Finish Date

Results:

1.5

0.75

18.10.01

05.11.01

PRR / MDK / MAB

Saving of material loss

100 kg per month for

plan of EC 40 50 Core

Deployment for 40

Nos EC Core and 27

Nos, U Cores

2.4 -

2.8

0.5

As Sintered

24.2 +

or - 0.3

After Grinding

Grinding Allowance

1.5 mm 0.75 mm

Green Density gm/cc

2.93 + or - 0.05 2.93 + or - 0.02

Compression Ratio

2.2 fixed 2.2 + or - 0.1

Variable

Grinding Swarf reduction by 1

gm / core of 82 gm.

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

TPM Club India

Focussed Improvement Pillar

Confederation of Indian Industry

KAIZEN IDEA - SHEET

Problem/present Status :

Unable to meet the production demand in the CNC

turning operation of the gear primary Driven blanks

Kaizen Theme :

Increase productivity in blank turning operation

Bench mark Output per Hr - 50

Target Output per Hr - 58

Kaizen start November 1999

Kaizen Finish February 2000

Team members :

1. R Marisamy 4. N S Rajagopal

2. T Viswalingam

3. K Jayshanker

Result: Analysis :

Why 1 : The cutting time is more

Excess material is removed during

turning operation

Excess stock is available for turning

operation